Page 1

User’s Guide

RCX C-Link Series:

Remote Camera Link Extenders

for use with Camera Link cameras

Doc. 008-02368-03d

Rev. 2011 June 29

Page 2

Engineering Design Team (EDT), Inc.

1400 NW Compton Drive, Suite 315

Beaverton, OR 97006

p 503-690-1234 / 800-435-4320

f 503-690-1243

www.edt.com

TM

EDT

and Engineering Design TeamTM are trademarks of Engineering Design Team, Inc. All other trademarks, service marks,

and copyrights are the property of their respective owners

†

.

© 1997-2011 Engineering Design Team, Inc. All rights reserved.

EDT, Inc. ii

Page 3

Terms of Use Agreement

Definitions. This agreement, between Engineering Design Team, Inc. (“Seller”) and the user or distributor (“Buyer”), covers the

use and distribution of the following items provided by Seller: a) the binary and all provided source code fo r any and all device

drivers, software libraries, utilities, and example applications (collectively, “Software”); b) the binary and all provided source code

for any and all configurable or programmable devices (collectively, “Firmware”); and c) the computer boards and all other physical

components (collectively, “Hardware”). Software, Firmware, and Hardware are collectively referred to as “Products.” This

agreement also covers Seller’s published Limited Warranty (“Warranty”) and all other published manuals and product information

in physical, electronic, or any other form (“Documentation”).

License. Seller grants Buyer the right to use or distribute Seller’s Software and Firmware Products solely to enable Seller’s

Hardware Products. Seller’s Software and Firmware must be used on the same computer as Seller’s Hardware. Seller’s Products

and Documentation are furnished under, and may be used only in accordance with, the terms of this agreement. By using or

distributing Seller’s Products and Documentation, Buyer agrees to the terms of this agreement, as well as any additional

agreements (such as a nondisclosure agreement) between Buyer and Seller.

Export Restrictions. Buyer will not permit Seller’s Software, Firmware, or Hardware to be sent to, or used in, any other country

except in compliance with applicable U.S. laws and regulations. For clarification or advice on such laws and regulations, Buyer

should contact: U.S. Department of Commerce, Export Division, Washington, D.C., 20230, U.S.A.

Limitation of Rights. Seller grants Buyer a royalty-free right to modify, reproduce, and distribute executable files using the

Seller’s Software and Firmware, provided that: a) the source code and executable files will be used only with Seller’s Hardware;

b) Buyer agrees to indemnify, hold harmless, and defend Seller from and against any claims or lawsuits, including attorneys’ fees,

that arise or result from the use or distribution of Buyer’s products containing Seller’s Products. Seller’s Hardware may not be

copied or recreated in any form or by any means without Seller’s express written consent.

No Liability for Consequential Damages. In no event will Seller, its directors, officers, employees, or agents be liable to Buyer

for any consequential, incidental, or indirect damages (including damages for business interruptions, loss of business profits or

information, and the like) arising out of the use or inability to use the Products, even if Seller has been advised of the possibility

of such damages. Because some jurisdictions do not allow the exclusion or limitation of liability for consequential or incidental

damages, the above limitations may not apply to Buyer. Seller’s liability to Buyer for actual damages for any cause whatsoever,

and regardless of the form of the action (whether in contract, product liability, tort including negligence, or otherwise) will be

limited to fifty U.S. dollars ($50.00).

Limited Hardware Warranty. Seller warrants that the Hardware it manufactures and sells shall be free of defects in materials

and workmanship for a period of 12 months from date of shipment to initial Buyer. This warranty does not apply to any product

that is misused, abused, repaired, or otherwise modified by Buyer or others. Seller’s sole obligation for breach of this warranty

shall be to repair or replace (F.O.B. Seller’s plant, Beaverton, Oregon, USA) any goods that are found to be non-conforming or

defective as specified by Buyer within 30 days of discovery of any defect. Buyer shall bear all installation and transportation

expenses, and all other incidental expenses and damages.

Limitation of Liability.

In no event shall Seller be liable for any type of special consequential, incidental, or penal damages,

whether such damages arise from, or are a result of, breach of contract, warranty, tort (including negligence), strict liability, or

otherwise. All references to damages herein shall include, but not be limited to: loss of profit or revenue; loss of use of the goods

or associated equipment; costs of substitute goods, equipment, or facilities; downtime costs; or claims for damages. Seller shall

not be liable for any loss, claim, expense, or damage caused by, contributed to, or arising out of the acts or omissions of Buyer,

whether negligent or otherwise.

No Other Warranties. Seller makes no other warranties, express or implied, including without limitation the implied warranties

of merchantability and fitness for a particular purpose, regard ing Seller’s Products or Documentation. Seller does not warrant,

guarantee, or make any representations regarding the use or the results of the use of the Products or Documentation or their

correctness, accuracy, reliability, currentness, or otherwise. All risk related to the results and performance of the Products and

Documentation is assumed by Buyer. The exclusion of implied warranties is not permitted by some jurisdictions. The above

exclusion may not apply to Buyer.

Disclaimer. Seller’s Products and Documentation, including this document, are subject to change without notice. Documentation

does not represent a commitment from Seller.

EDT, Inc. iii

Page 4

Contents

RCX C-Link Series: Remote Camera Link Extenders

Overview...................................................................................................................................................... 1

Care and Cautions.......................................................................................................................... 1

Related Resources.......................................................................................................................... 2

Connecting the Extender Assembly........ ... ... ... ... .... ... ... ... .... ... ... ... .......................................... ... .... .............. 3

Mounting the Extender.................................................................................................................... 4

Base Mode... .... ... ... ... .... ... ... ... ....................................... ... .... ... ... ... ... .... ... ... ... .................................. 4

With a standard framegrabber ........................................................................................... 4

With a FOX framegrabber.................................................................................................. 5

Medium or Full Mode ....... ... ... .... ... ... ... ... .... ... .......................................... ... ..................................... 5

With a standard framegrabber ........................................................................................... 6

With a FOX framegrabber.................................................................................................. 7

Eighty-bit packing............................................................................................................... 7

The LED....................................................................................................................................................... 7

Configuration and LED Configuration Codes............................................................................................... 7

Base Mode... .... ... ... ... .... ... ... ... ....................................... ... .... ... ... ... ... .... ... ... ... .................................. 8

Medium or Full Mode ....... ... ... .... ... ... ... ... .... ... .......................................... ... ..................................... 9

Resetting or Changing the Operating Mode.................................................................................... 9

Backward Compatibility................................................................................................................. 10

Status and LED Status Codes ................................................................................................................... 11

Firmware.................................................................................................................................................... 12

Versions........................................................................................................................................ 12

Querying, Verifying, and Updating................................................................................................ 12

Transceivers............................................................................................................................................... 14

Coaxial Cable ... ....................................... ... ... ... ... .... ... ....................................... ... ... ... .... ............................ 14

Pinouts....................................................................................................................................................... 15

Camera Link.................................. ... ... ... .... ... ... ... .... ... ....................................... ... ... ... ... ................ 15

Power............................................................................................................................................ 16

Cable assembly – Lemo to loose wire ............................................................................. 16

Cable assembly – Lemo to male DB9.............................................................................. 16

Cable assembly – Lemo to female DB9 RS232............................................................... 17

Cable assembly – Lemo resync....................................................................................... 18

Power Supply............................................................................................................................................. 18

Dimensions ................................................................................................................................................ 20

Appendix................................................................................................................................................................. 21

Alternative Mounting and Connecting Methods ......... ... ... ....................................... ... .... ... ... ... ................... 21

Mounting Holes............................................................................................................................. 21

Adapter Cabling ........ .... ... ... .......................................................................................................... 21

Revision Log ................. ... ... ... .... ... ... ....................................... ... ... .... ... ... ... ............................................................. 22

EDT, Inc. iv

Page 5

RCX C-Link Series: Remote Camera Link

Extenders

Overview

EDT’s RCX-series remote Camera Link extenders are compact modules that can be used to extend Camera

Link data over fiberoptic or coaxial cabling. All components work just as they do with Camera Link cabling.

This guide covers the following extenders: the RCX C-Link, which works with fiberoptic cable; and the RCX

C-Link Coax2, which works with coaxial cable. Thus, for simplicity, this guide will refer to them as follows:

• RCX C-Link Fiber extender

• RCX C-Link Coax2 Coax extender

Two extenders can link a camera to a standard framegrabber via fiber or coaxia l cable; or one extender can

connect a camera to an EDT FOX framegrabber, which has fiberoptic transceivers built in.

Specially configured pairs are available for medium or full mode operation (fiber version only).

NOTE All EDT extenders and framegrabbers mentioned in this guide are for Camera Link. For details on our

legacy AIA product, RCX LVDS / RS422, see its product page at www.edt.com.

Care and Cautions

Your EDT extender is built to withstand a variety of extreme conditions, as listed in the specifications on its

datasheet (see Related Resources on page 2). However, it is nonetheless a high-performan ce component

which, for optimal results, should be treated with care, as detailed below.

• The extender must be protected from even momentary power spikes over 18 volts.

• The connectors – especially the fiberoptic transceivers – must be kept clean and dry. If you su spect the

presence of moisture or debris in the connectors, you should blast a burst of compressed air:

— directly into the ports to dislodge any debris that has collected there; and

— away from the electronic components to blow out any moisture that has collected in the air nozzle.

CAUTION To avoid damaging your eyesight, never look directly into any transceiver.

EDT, Inc. 1

Page 6

RCX C-Link Series Overview

Related Resources

The resources below may be helpful or necessary for your applications.

• To find complete EDT information on any EDT product, go to www.edt.com and find the appropriate

product page. That page will provide links to the product’s datasheet specifications and user’s guide.

• To find EDT information that is not related to a specific EDT product (for example, installation packages

or cable pinouts for multiple products), go to www.edt.com and look in Product Documentation.

EDT Resource Detail Web link

• Application programming interface HTML and PDF versions www.edt.com/manuals.html

• Installation packages Software / firmware www.edt.com/software.html

• Specifications for EDT products Datasheets www.edt.com (find by product name)

• Documentation for EDT products User’s guides " (Product Documentation page)

• Cabling and pinout documentation Details on cabling and pinouts " (Product Documentation page)

Standard / Specification For From Web link

• PCI / PCIe PCI / PCIe bus PCI Special Interest Group

(PCI SIG)

• Camera Link Camera Link Machine Vision Online (MVO) www.machinevisiononline.org

• IRIG-B IRIG-B timestamping Inter Range Instrumentation

Group mod B

www.pcisig.com

irigb.com

EDT, Inc. 2011 June 29 2

Page 7

RCX C-Link Series Connecting the Extender Assembly

MDR26

power supply connector

thumbscrews

LC duplex fiberoptic

connector:

transmit

receive

LED

SMA coaxial

connectors:

transmit

receive

power supply connector

LED

Connecting the Extender Assembly

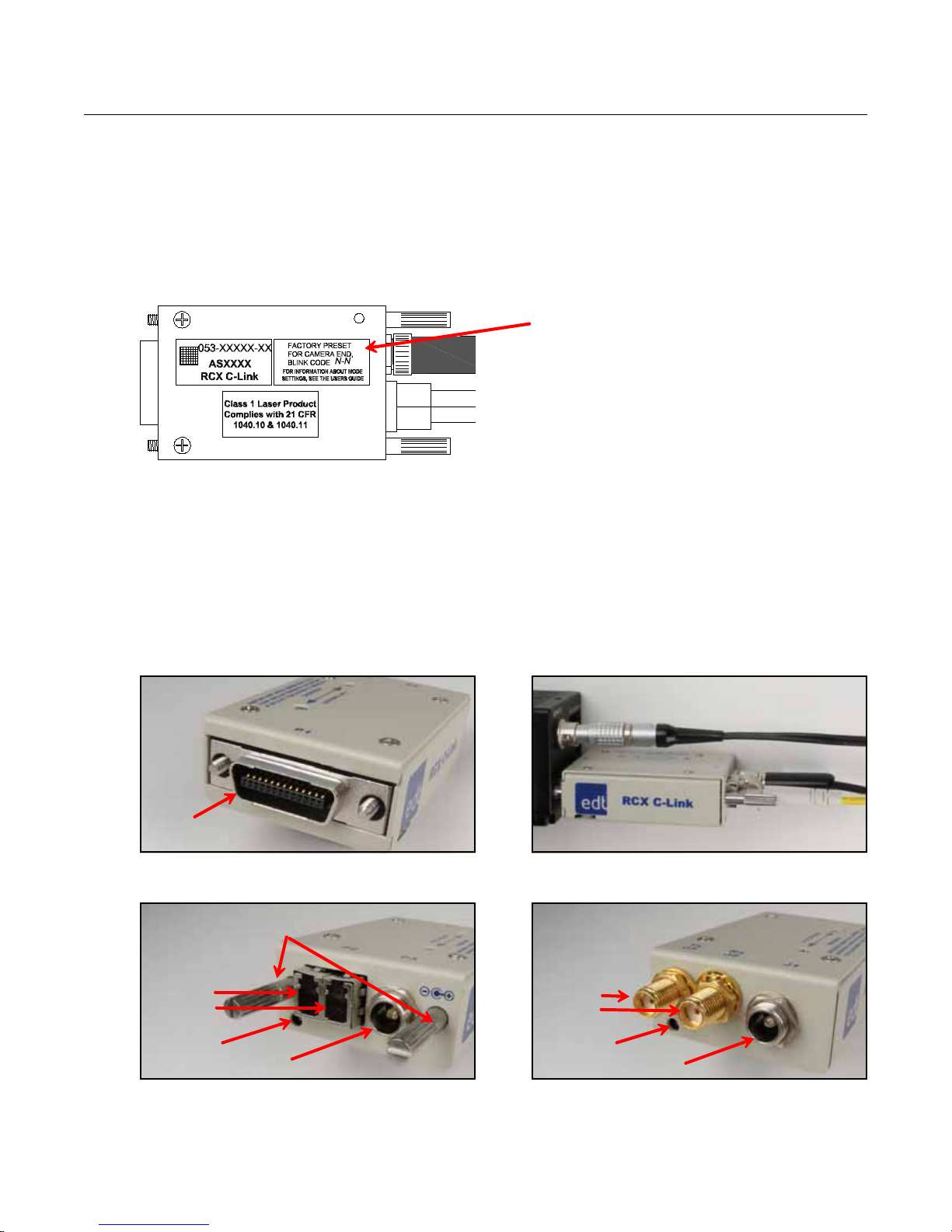

Each extender unit is factory-preset and labeled to connect to either a camera or a framegrabber (Figure 1).

Each unit, in order to work properly, must be connected to the device for which it was preset and labeled.

NOTE If you reconfigure your extender for a different device, relabel the extender to avoid future confusion.

Figure 1. Fiberoptic extender, labeled with factory presets

This label shows the unit’s factory presets, including:

• the end for which the unit was preset (camera end

or framegrabber end);

• the operating mode for which the unit was preset

(see Configuration and LED Configuration Codes

on page 7).

Once you have checked the labeling, you can connect each extender as explained below.

• Device end: Attach the correct device (camera or framegrabber) to the extender’s MDR26 connector.

• Cable end: Attach the correct cable to the extender’s cable connectors.

Figure 2 shows the extender connectors and other features, including the LED (see The LED on page 7).

Figure 2. Connectors and features on EDT extenders

Device end of an extender An extender connected to a camera

Cable end of a fiberoptic extender Cable end of a coaxial extender

EDT, Inc. 2011 June 29 3

Page 8

RCX C-Link Series Connecting the Extender Assembly

Mounting the Extender

To mount an extender, use the thumbscrews or one of the alternative methods detailed in Alternative

Mounting and Connecting Methods on page 21. To mount a coax extender, you must use one of those

alternative methods.

Base Mode

For this setup, you’ll need two extenders (one at the camera end and one at the framegrabber end) or, if

you use an EDT FOX framegrabber, just one extender (at the camera end).

In base mode, each pixel clock transfers 24 bits of video data from the camera’s X channel. The extender

can transfer four camera control signals and has a bidirectional serial interface between framegrabber and

camera.

NOTE The extender generates its own pixel clock, so th e clock rate into the framegrabber may exceed the rate

of the camera. Thus, the amount of time spent in blanking will vary from line to line and frame to frame.

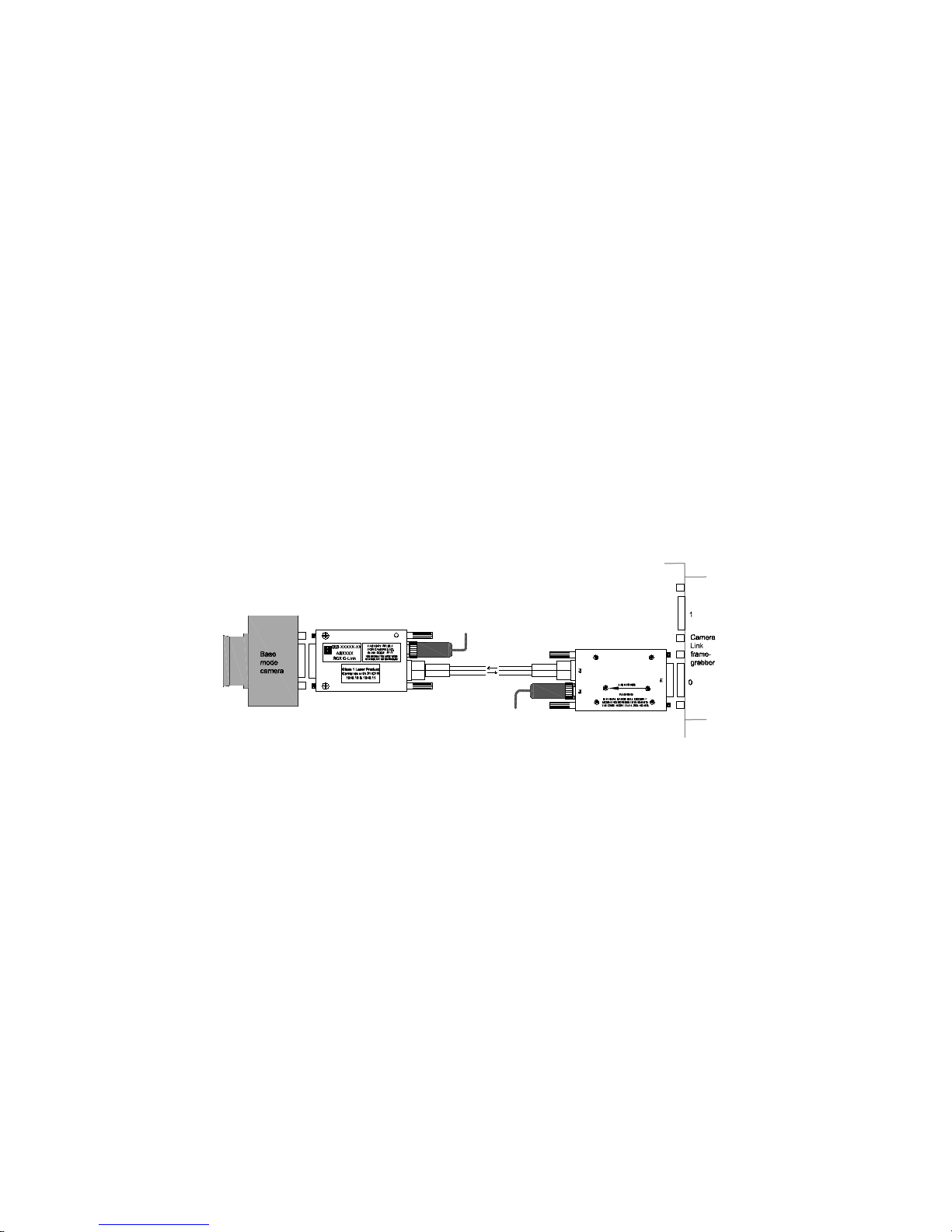

With a standard framegrabber

For a base-mode system with a standard framegrabber, you will need two extenders: one at the camera

end and one at the framegrabber end (see Figure 3).

Figure 3. Base mode: multiple extenders + standard framegrabber

To set up this system:

1. Install the framegrabber according to its user’s guide (for EDT user’s guides, see Related Resources

on page 2).

2. Verify the extenders are configure d prop e rly (se e Configuration and LED Configuration Codes on

page 7) – one for the camera end, and the other for the frame grabber end.

3. Turn off power to all devices.

4. Connect the extender labeled “Camera End” to the MDR26 connector on the camera (see Figure 2).

5. Connect the extender labeled “Framegrabber End” to the MDR26 connector on the framegrabber.

6. Connect the two extenders to each other with the appropriate fiberoptic or coaxial cable.

7. Connect the power supply to the power connector on the back of the extender.

8. Turn on power to all devices.

9. Verify each LED shows a steady light (see Status and LED Status Codes on page 11).

EDT, Inc. 2011 June 29 4

Page 9

RCX C-Link Series Connecting the Extender Assembly

With a FOX framegrabber

A FOX framegrabber has fiberoptics built in, so a base-mode system with a FOX framegrabber requires only

one extender per camera (see Figure 4).

Figure 4. Base mode: one extender + FOX framegrabber

To set up this system:

1. Install the framegrabber according to its EDT user’s guide (see Related Resources on page 2).

2. Verify the extender is configured properly (see Configuration and LED Configuration Codes on page 7).

3. Turn off power to all devices.

4. Connect the extender to the MDR26 connector on the camera (see Figure 2).

5. Connect the extender to the desired transceiver o n the framegrabber (channe l 0 is the transceiver physically closest to the PCI bus) with fiberoptic cable.

6. Connect the power supply to the power connector on the back of the extender.

7. Turn on power to all devices.

8. Verify each LED shows a steady light (see Status and LED Status Codes on page 11).

Medium or Full Mode

A medium- or full-mode system requires multiple extenders, as explained below.

On a medium- or full-mode Camera Link camera, there are two MDR26 connectors.

•The primary connector operates the same way as the base-mode interface: ea ch pixel clock transfers

24 bits of video data from the camera’s X channel. The primary connector also can transfer four camera

control signals, and it has a bidirectional serial interface between framegrabber and camera.

•The secondary connector transfers video data for the Y and Z channels:

— Medium-mode cameras transfer 24 bits of video data for the Y channel.

— Full-mode cameras transfer an additional 24 bits for the Z channel.

Thus, the standard full-mode configuration transfers 72 bits of video data — 24 bits each for the X, Y, and

Z camera channels.

The X-channel extenders (one at the camera end and one at the framegrabber end) operate as a basemode extension cord, with one fiber for video data from camera to framegrabber, and the other for control

signals from framegrabber to camera. The YZ-channel extender at the camera end has two fiberoptic

transmitters, with both fibers carrying video data to the framegrabber.

Many framegrabbers require that the video data presented at the pr imary an d secon dary connector s must

be synchronized to within a fraction of a pixel clock. The section entitled Cable assembly – Lemo resync on

page 18 describes a common pixel clock for both extenders at the framegrabber end, and other

EDT, Inc. 2011 June 29 5

Page 10

RCX C-Link Series Connecting the Extender Assembly

synchronizing signals to ensure that the starting pixel of each raster lines up across the X, Y and Z channels.

The resync cable also supplies power to the extenders.

CAUTION To avoid damaging your components, you should verify that the entire system is connected properly

before you apply power to any component. In particular, do not apply power to the resync cable while

you are connecting it to, or disconnecting it from, an extender.

With a standard framegrabber

For medium- or full-mode operation with a standard framegrabber, you will need four extenders: two at the

camera end, and two at the framegrabber end (see Figure 5).

NOTE Each extender unit is physically different from the others, so you cannot simply change the configuration

codes and use the units interchangeably.

Figure 5. Full mode: multiple extenders + standard framegrabber

To set up this system:

1. Install your Camera Link framegrabber and software as instructed by its manufacturer.

2. Verify extenders are configured properly (see Configura tion a nd LED Configura tion Cod es on page 7).

3. Turn off power to all devices.

4. Connect the extender labeled X Channel Camera to the camera's primary MDR26 connector.

5. Connect the extender labeled YZ Channel Camera to the camera’s secondary MDR26 connector.

6. Connect the extender labeled X Channel FG to the framegrabber’s primary MDR26 connector.

7. Connect the extender labeled YZ Channel FG to the framegrabber’s secondary MDR26 connector.

8. Connect the two power supplies with coaxial power connectors to the two camera-end exten ders.

9. Verify that you have the correct resync cable for your camera (see Figure 5) and connect the cable to

both extenders at the framegrabber end. The two ends of the resync cable are interchangeable.

10. Connect the power supply with the 9-pin D-shell connector to the resync cable connector.

EDT, Inc. 2011 June 29 6

Page 11

RCX C-Link Series The LED

11. Connect an LC duplex fiber from the X-channel extender at the camera end to the X-ch annel extender

at the framegrabber end.

12. Connect an LC duplex fiber from the YZ-channel exten der at the camera end to the YZ-chann el extender at the framegrabber end.

13. Turn on power to all devices.

14. Verify each LED shows a steady light (see Status and LED Status Codes on page 11).

With a FOX framegrabber

A FOX framegrabber for medium and full mode is currently in development.

Eighty-bit packing

Certain full-mode cameras, such as the Basler A04k and Mikrotron MC1310 and MC1311, will reassign the

Spare, Data-valid, and Frame-valid control signals to allow a tr ansfer of up to 80 bits of data per pixel clock.

Your extender can be configured with a configuration code to accommodate these cameras. Configuration

codes of 1-5 (at the camera end) and 2-5 (at the framegrabber end) allow 80-bit packing at frequencies of

60–72 MHz. The 72 MHz upper limit is determined by the bandwidth available over the fiber, but is sufficient

to support all modes currently available on the cameras specified above.

The LED

Each extender has a light-emitting diode (LED), as in Figure 2. By displ aying various patterns of blinks (blink

codes), the LED communicates information about the extender’s configuration and status, as follows.

At power-on, the LED blinks a configuration code (indicating the operating mode for which the extender is

configured) one time, and then blinks rapidly as the firmware loads. After power-on, the LED continuously

displays a status code (indicating whether the unit is working properly or has errors). The LED also is used

when resetting or changing the operating mode.

The two types of LED codes are explained more fully in Configuration and LED Configuration Code s on

page 7 and Status and LED Status Codes on page 11.

Configuration and LED Configuration Codes

Your EDT extender can support a wide range o f camer a models and data tran sfer rates, d epending on the

extender model and operating mode selected. For fiber extenders, standard firmware will support most

base-mode cameras from 20 to 80 MHz, with UART data rates of up to 19.2 KBaud, and full-mod e operation

at 60–80 MHz. For coax extenders, standard firmware will support most base-mode cameras from 20 to 60

MHz, with UART data rates of up to 19.2 KBaud.

Each extender is factory-preset for the operating mode that was specified in the product order . The

operating mode is selected and indicated through LED configuration codes, as explained below.

Each extender is configured for the desired operating mode through a pattern of blinks called the LED

configuration code. This code, displayed once at power-on, consists of two digits, each represented by a

certain number of blinks. The two digits are separated by a pause, shown in this guide as a hyphen. For

example, a configuration code of “one blink, pause, one blink” is shown in this guide as 1-1.

EDT, Inc. 2011 June 29 7

Page 12

RCX C-Link Series Configuration and LED Configuration Codes

A first digit of 1 indicates that the unit is configured for the camera end; a first digit of 2 indicates that the unit

is configured for the framegrabber end. The second digit must be the same for both ends (camera and

framegrabber). With a FOX framegrabber, there is no extender at the framegrabber end, so the

configuration code is set at the camera end only.

For a typical base-mode system, a configuration code of 1-1 at the camera end and 2-1 at the fr amegrabber

end permits standard base-mode operation at clock frequencies of 20–40 MHz. For a typical full mode

system, a configuration code of 1-4 on both extenders at the camera end, and a configuration code of 2-4

on both at the framegrabber end, allows standard full-mode operation at clock freq uencies of 60–80 MHz.

On the configuration code label for a medium- or full-mode system, X Channel refers to the primary MDR26

connnector on the camera or framegrabber, and YZ Channel refers to the secondary connector.

Base Mode

Table 1 shows the operating modes of an extender in base mode (EDT firmware revsion 11 or higher).

Table 1. LED configuration codes – base mode

Code End Camera Clock Rate Constraints Link Rate Extender Type

1-1 camera 20–40 MHz 24 bits 1.25 GBaud Fiber & coax

1-2 camera 20–60 MHz 16 bits 1.25 GBaud Fiber & coax

1-3 camera 20–60 MHz 24 bits 2.5 GBaud Fiber only

1-4 camera 60–80 MHz 24 bits 2.5 GBaud Fiber only

2-1 framegrabber 40 MHz 24 bits 1.25 GBaud Fiber & coax

2-2 framegrabber 60 MHz 16 bits 1.25 GBaud Fiber & coax

2-3 framegrabber 60 MHz 24 bits 2.5 GBaud Fiber & coax

2-4 framegrabber 80 MHz 24 bits 2.5 GBaud Fiber only

3-3 firmware update (see Firmware on page 12) 1.25 GBaud Fiber & coax

2 fast, 2 slow, 2 fast Error: unsupported configuration code entered

Cameras operating between 40 and 60 MHz are usually best served by configuration codes 1-3 and 2-3. If

the camera needs only 16 data bits or fewer transferred per clock cycle (instead of all 24), it is possible to

use configuration codes 1-2 and 2-2 instead, and thus operate the link at 1.25 GBaud for longer range and

lower power dissipation. The selection of 16-bit mode is made only at the framegrabber end through

configuration code 2-2, or through the directive

mode16: 1 in a FOX configuration file; this information is

communicated over the fiber to the extender at the camera end. (At the camera end, configuration codes

1-1 and 1-2 are identical.)

At reset (and whenever the extender cannot lock to the camera clock), the extender initializes to assume

that the Camera Link Data-Valid signal is never asserted, and ignores it. Many Pulnix cameras do not assert

Data-Valid, so this behavior is useful for those using such cameras. The first occurrence of Data-Valid true

from the camera causes the extender to use Data-Valid to qualify video data from that point on.

In the case of a dual-tap camera, the Camera Link p ixel clock is half the camera’s pixel rate. For example,

a dual-tap 12-bit camera with a 40 MHz Camera Link clock sends 80 million pixels per second. This camera

is compatible with the extender in configuration code 1-1.

EDT, Inc. 2011 June 29 8

Page 13

RCX C-Link Series Configuration and LED Configuration Codes

Medium or Full Mode

Table 2 shows the operating modes of an extender in medium or full mode (EDT firmware rev. 11 or higher).

NOTE This table is for the fiberoptic extender only, as the coaxial extender is available for base mode only.

Table 2. LED configuration codes – medium or full mode

Code End Camera Clock Rate Constraints Link Rate

1-1 camera 20–40 MHz 72 bits 1.25 GBaud

1-2 [undefined] – – –

1-3 camera 20–60 MHz 72 bits 2.5 GBaud

1-4 camera 60–80 MHz 72 bits 2.5 GBaud

1-5 camera 60–72 MHz for 80-bit full-mode cameras 2.5 GBaud

2-1 framegrabber 20–40 MHz* 72 bits 1.25 GBaud

2-2 [undefined] – – –

2-3 framegrabber 20–60 MHz* 72 bits 2.5 GBaud

2-4 framegrabber 60–80 MHz* 72 bits 2.5 GBaud

2-5 framegrabber 60–72 MHz* for 80-bit full-mode cameras 2.5 GBau d

3-3 firmware update (see Firmware on page 12) 1.25 GBaud

2 fast, 2 slow, 2 fast Error: unsupported configuration code entered

* For camera clock rate, the resync cable determines the actual frequency.

For full-mode cameras, which typically operate at 60 to 80 MHz, configuration codes of 1-4 (camera end)

and 2-4 (framegrabber end) should work. For full-mode camera s that transfer 80 bits per clock cycle, use

configuration codes of 1-5 (camera end) and 2-5 (framegrabber end).

For medium-mode cameras, which typically operate at 40 MHz, configuration codes of 1-1 (camera end)

and 2-1 (framegrabber end) should work.

For instructions on verifying and updating the firmware, see

Firmware on page 12.

Resetting or Changing the Operating Mode

Your extender is factory-preset for the operating mode that was specified in the product order. However, if

you need to reset or change the operating mode, you can do so by setting the LED configuration code.

NOTE If you change the operating mode, be sure to relabel the extender to prevent future confusion.

To reset or change the operating mode (configuration code ):

1. Turn off the power to the extender, and disconnect the extender from everything except a power supply.

NOTE EDT recommends connecting the power supply to a po wer strip or some other device that allows e asy

access to both the power and the extender at the same time. This is because, as you follow the steps

below, it may become necessary to turn off the power and restart the process (see step 4).

2. Press the recessed button on the bottom of the extender with a fine, blunt point – such as the tip of a

ballpoint pen – as in Figure 6.

EDT, Inc. 2011 June 29 9

Page 14

RCX C-Link Series Configuration and LED Configuration Codes

Figure 6. Pressing the recessed button

3. Still pressing the button, turn on the power; the LED will turn on.

4. Release the button within two seconds (if you press the button longer than two seconds, the LED will

start blinking diagnostically and you will need to restart the process from step 1).

5. Release the button; the LED will turn off.

NOTE Before proceeding, be sure you know which configuration code you want (see Configuration and LED

Configuration Codes on page 7), because you’ll need to enter it quickly when the LED starts blinking.

6. Press the button, let the LED start blinking, and release the button after the correct number of blinks for

the first digit; then repeat for the second digit. For example, for a configuration code of 2-1, press the

button for two blinks, and release; then press the button for one blink, and release.

As soon as you enter the second digit, the extender saves your selection into flash memory and the LED

starts blinking in that pattern. If the pattern is not what you wanted, start over from Ste p 1.

NOTE If an unsupported code is entered, the LED will display two fast, two slow, and two fast blinks, indicating

that an error has occurred and the code has not been saved to memory.

7. Cycle power to the extender without pressin g the bu tt on .

When the extender is powered on without the button pressed, the LED blinks the configuration code once

and blinks rapidly as the firmware loads; then it continuously displays the extender’s status (see Stat us and

LED Status Codes on page 11).

Backward Compatibility

For details on backward compatibility, see Firmware on page 12.

EDT, Inc. 2011 June 29 10

Page 15

RCX C-Link Series Status and LED Status Codes

Status and LED Status Codes

As previously discussed, at power-on the LED blinks the extender’s configura tion code o ne time, and then

blinks rapidly as the firmware loads. After power-on, the LED continuously displays the extender’s status

code, which indicates whether the unit is working properly or has errors (see Table 3).

Table 3. LED status codes

If LED shows... It means...

Steady light All OK – everything is working properly.

Slow blinks

(1Hz)

Fast blinks

(10Hz)

Both slow and

fast blinks

2 fast + 2 slow +

2 fast blinks

No light The extender has no power or is faulty.

There is an error from the other end. The typical causes are:

• The extender at the other end has no power, or its operating mode does not match the operating

mode on this extender (see Configuration and LED Configuration Codes on page 7).

• The cable connection is compromised, either by incorrect or damaged cabling, or by moisture or

debris in the extender’s cable connectors (see Care and Cautions on page 1).

There is an error from the camera to the extender, related to the camera’s pixel clock.

If the fast blink is on the camera-end extender: either the camera has no power, or the operating

mode on the extender does not match the operating mode on the camera (see Configuration and

LED Configuration Codes on page 7).

If the fast blink is on the framegrabber-end extender: either the extender or the resync cable is faulty.

There is at least one slow-blink error and at least one fast-blink error.

The extender is configured with an unsupported operating mode (see Configuration and LED

Configuration Codes on page 7).

EDT, Inc. 2011 June 29 11

Page 16

RCX C-Link Series Firmware

Firmware

To avoid version problems, EDT recommends against doing a firmware u pdate unless you are convinced it

is necessary. If it is necessary, you can use the utility

provided firmware file, and update the firmware.

Versions

EDT extenders are factory-preset with the files shown in Table 4.

Table 4. FPGA configuration files for RCX-series extenders (as of February 2009)

Operating mode Channel FPGA configuration file

Base [no channels] rgb11.rcx

Medium X mx11.rcx

YZ my11.rcx

Full X fx11.rcx

YZ fyz11.rcx

If your extender unit is using standard firmware older than revision 11, the unit will support camera speeds

of only 20–40 MHz at 1.25 GBaud, using a configuration code of 1-1 (ignore Data-Valid), 1-2 (use DataValid), or 2-1 (framegrabber end).

rcxload to query the firmware, verify it against a

For backward compatibility, firmware revisions of 11 or later will behave identically for configuration codes

1-1 and 1-2. As of firmware revision 11, Data-Valid is automatically detected. If you use configuration code

2-2 at the framegrabber end for 16-bit mode, you can use the corresponding configuration code of 1-2 at

the camera end.

NOTE To determine whether your firmware is revision 11 or later, you can enter configuration code 3-5 (see

Configuration and LED Configuration Codes on page 7). If the LED then blinks two fast, two slow, two

fast (indicating an unsupported configuration code), then you have firmware of revision 11 or later.

Querying, Verifying, and Updating

For base or medium mode, follow the steps below to query, verify, and update the firmware.

NOTE This procedure works only if you are using EDT FOX or PCI Express framegrabbers and fiber extenders

in base or medium mode. If you are using anything else, contact EDT to update the firmware.

CAUTION To avoid corrupting the firmware on the extender, do not interrupt the update by pressing Ctrl-C or

turning off the power while the update is in progress.

1. Set up your system as instructed in this guide (see Connecting the Extender Assembly on page 3).

2. Run

pciload with no arguments to ensure that the system recognizes the EDT framegrabber. Typical

output appears thus:

pdv unit 0 (pci dv fox):

XC2S200 PCI FPGA, AMD 29LV081B 8MB FPROM

s/n AP0064, p/n 019-02103-11, i/f fpga xc2s400e, rev 11 clock 40 Mhz, opt f2

Sector 0

Sector 1

Sector 2 PROM id: <dvtlk4_3v.ncd 2s200fg456 2005/06/10 14:58:10>

Sector 3 PROM id: <dvtlk4_5v.ncd 2s200fg456 2005/06/10 14:58:16>

3. Configure the extender with code 3-3 (see Configuration and LED Configuration Codes on page 7).

EDT, Inc. 2011 June 29 12

Page 17

RCX C-Link Series Firmware

4. Power-cycle the extender.

5. If you are using a FOX framegrabber, ensure the fibe roptic cable is connected to channel 0 (the channel

physically closest to the PCI bus). The extender need not be connected to a camera.

6. Query the extender, to ensure it is there and recognized, by entering

you start

rcxload, the LEDs on both devices will be lighted and not blinking.

rcxload with no arguments. After

Typical output appears thus:

pdv unit 0 (pci dv fox) chan. 0 RCX module:

sector 0 [10000]: <rgb11cm60_a01.ncd 2vp2fg256 2006/03/30 20:05:34>

sector 1 [38000]: <rgb11cm80_a01.ncd 2vp2fg256 2006/03/30 20:12:36>

sector 2 [60000]: <rgb11fg40_a01.ncd 2vp2fg256 2006/03/30 19:57:41>

sector 3 [88000]: <rgb11fg60_a01.ncd 2vp2fg256 2006/03/30 20:02:08>

sector 4 [b0000]: <rgb11fg80_a01.ncd 2vp2fg256 2006/03/30 20:09:30>

sector 5 [d8000]: <fud02b.ncd 2vp2fg256 2006/03/28 15:59:19>

If your output appears faulty, check the configuration code, cables, and connections. If you still have

problems, email the output to tech@edt.com.

7. Assuming correct output from step 6 above, you can perform either or both of the following oper ations.

— To verify (compare) the firmware in your EDT installation package against the firmware already

loaded on your extender via flash memory, run...

rcxload -u 0 -v flash/rcx/file.rcx

...replacing file.rcx with the filename of the current firmware revision. The utility compares the

firmware in the extender with the firmware in the specified firmware file. If they are the same, the

utility reports

verified and 0 errors; if not, it reports not verified and lists the errors.

— To update the firmware, if you determine that an update is necessary, run...

NOTE If

rcxload -u 0 flash/rcx/file.rcx

...replacing file.rcx with the filename of the current firmware revision.

The filename must be a valid

flash/rcx subdirectory. The README file in the package has information about any .rcx file updates,

.rcx file. EDT software packages ship with the current .rcx files in the

including the specific filename of the current revision.

After a successful update, configure the extender for the desired operating mode (see Configuration

and LED Configuration Codes on page 7).

rcxload reports an error within a section flagged as “critical,” do not power-cycle the extender;

instead, repeat the procedure. If you still get errors, leave the extender powered on and contact EDT.

You can turn off the power to the computer and came ra, and leave the extender powered on in definitely.

EDT, Inc. 2011 June 29 13

Page 18

RCX C-Link Series Transceivers

Transceivers

The fiberoptic extender supports various types of transceivers and fiber, as shown in Table 5.

Table 5. Transceiver + Fiber Combinations

Range Fiber Type Thickness

Standard Multi-mode fiber (MMF) 62.5 850 nm 300 150

Extended Single-mode fiber (SMF) 9.0 1310 nm 10,000 5000

Alternatively, the following transceivers are available as options.

• Single fiber transceivers (distances up to 60 km): These have an integrated passive op tical multiplexer

and transmit data in each direction over one fiber using different colors of light – especially useful when

going through an optical rotary joint.

• CWDM transceivers (extended range of 5 km or more, 1310 nm, single-fiber PON) – These use up to

16 different colors of light, with the light split and combined by passive optical multiplexers that are external to the extender. They support up to twelve different cameras simultaneously over a single fiber.

• DualTX and DualRX transceivers – In full mode, these are used on the secondar y Camera Link connector because it must carry twice as much data as the primary connector.

Coaxial Cable

The coaxial extender has two SMA connectors – one for data in, and one for data out. The cable used must

have a corresponding SMA connector at each end.

Wavelength Maximum length (meters)

(microns)

50.0 8 50 nm 50 0 250

at 1.25 GBaud at 2.5 GBaud

The maximum range is determined by the dB of loss at 625 MHz. EDT recommends using a cable that

keeps the amount of loss under 20 dB at 625 MHz.

The cabling must have an impedance of 50 ohms.

One cable type that meets all of these requirements is 50-ohm RG58, which has an SMA connector a t each

end and a typical loss of 11 to 15 dB per 100 feet.

EDT, Inc. 2011 June 29 14

Page 19

RCX C-Link Series Pinouts

Pinouts

This section provides pinout information for the Camera Link and power connectors.

Camera Link

Table 6 shows the MDR26 connector pinout for Camera Link signals (base, medium, and full mode).

Table 6. Pinout – MDR26 Connector

Camera

end

1 1 inner shield inner shield inner shield

14 14 inner shield inner shield inner shield

2 25 X0– Y0– Y0–

15 12 X0+ Y0+ Y0+

3 24 X1– Y1– Y1–

16 11 X1+ Y1+ Y1+

4 23 X2– Y2– Y2–

17 10 X2+ Y2+ Y2+

5 22 Xclk– Yclk– Yclk–

18 9 Xclk+ Yclk+ Yclk+

6 21 X3– Y3– Y3–

19 8 X3+ Y3+ Y3+

7 20 SerTC+ unused 100 ohms

20 7 SerTC– unused terminated

8 19 SerTFG– unused Z0–

21 6 SerTFG+ unused Z0+

9 18 CC1– unused Z1–

22 5 CC1+ unused Z1+

10 17 CC2+ unused Z2–

23 4 CC2– unused Z2+

11 16 CC3– unused Zclk–

24 3 CC3+ unused Zclk+

12 15 CC4+ unused Z3–

25 2 CC4– unused Z3+

13 13 inner shield inner shield inner shield

26 26 inner shield inner shield inner shield

Framegrabber

end

Camera Link signal

base mode

(primary connector)

Camera Link signal

medium mode

(secondary connector)

Camera Link signal

full mode

(secondary connector)

EDT, Inc. 2011 June 29 15

Page 20

RCX C-Link Series Pinouts

5

6

7

1

4

2

3

(Lemo)

1

(Switchcraft)

Pins 1, 3, 4, 5, and 6

(defined by firmware used

in extender) typically are

used at CMOS +3.3 V

signal levels, although

pins 1,6 and 3,4 can be

configured as LVDS pairs.

Pin 2 is power to

extender (+4.75

to +18 V DC).

Key in connector

barrel (at top)

Pin 7 is ground

(for signals and power).

Outer ring is ground.

Pin 1 is power to

extender (+4.75

to +18 V DC).

Power

The power connector on the extender is either a standard coaxial Switchcraft or an optional Lemo. Pin

information for both is shown in Figure 7.

Figure 7. Pinout – Standard Switchcraft Connector and Optional Lemo Connector

With the Lemo, you can use various cables that allow auxiliary signals. (On medium- and full-mode systems

using the resync cable option, the extenders at the framegrabber end must use Lemo connectors.)

Cable assembly – Lemo to loose wire

The Lemo to loose wire (EDT part #016-02650) can be wired as needed or connected to various types of

connectors, depending on what you need for your application.

Table 7. Pinout – Lemo to loose wire

Lemo

Pin Color

1 green AUX_TX, primary auxiliary transmit UART CMOS +3.3 V

2 red power to extender +4.75 to +18 V

3 orange AUX2_TX, secondary auxiliary transmit CMOS +3.3 V

4 brown AUX2_RX, secondary auxiliary receive CMOS +3.3 V

5 white SYNC, can be configured as an outgoing

6 blue AUX_RX, primary auxiliary receive UART CMOS +3.3 V

7 black ground ground

Standard Firmware (rgb11.rcx)

copy of the camera’s frame-valid signal

Signal LevelComments

All five CMOS 3.3 V

signals go to FPGA I/O

3.3V pins using series

100-ohm resistors.

CMOS +3.3 V

Custom firmware can be

used to configure these

pins as input or output.

Cable assembly – Lemo to male DB9

The male DB9 (EDT part #016-02718) supports signals that can be used as an auxiliary signaling system

for a variety of purposes.

For example, custom firmware could allow the auxiliary signals to be used to control the camera’s pan and

servo motors. It is also possible to set up a hardware trigger that is local to either end. If you wish to explore

these options, contact EDT.

Unlike the DB9 in the female assembly, this DB9 has no looped-back signals or integrated level conver sion.

EDT, Inc. 2011 June 29 16

Page 21

RCX C-Link Series Pinouts

Table 8 shows the pinout and how the standard firmware uses each wire.

Table 8. Pinout – Male DB9 Cable

Lemo

Pin

––1[unused] –

––6[unused] –

1 green 2 AUX_TX, primary auxiliary transmit UART CMOS +3.3 V

2 red 9 power to extender +4.75 to +18 V

3 orange 7 AUX2_TX, secondary auxiliary transmit CMOS +3.3 V

4 brown 8 AUX2_RX, secondary auxiliary recei v e CMOS +3.3 V

5 white 4 SYNC, can be configured as an outgoing

6 blue 3 AUX_RX, primary auxiliary receive UART CMOS +3.3 V

7 black 5 ground ground

Color DB9

Pin

Standard Firmware (rgb11.rcx)

copy of the camera’s frame-valid signal

Signal LevelComments

All five CMOS 3.3 V

signals go to FPGA I/O

3.3V pins using series

100-ohm resistors.

Custom firmware can be

used to configure these

pins as input or output.

CMOS +3.3 V

Cable assembly – Lemo to female DB9 RS232

The female DB9 (EDT part #016-02445) supports integrated CMOS +3.3 V to RS232 level converters on a

small circuit board inside the DB9 connector shell.

This cable is designed to plug in directly to a host computer serial port. The cable offers an auxiliary UART

connection over the fiber, in addition to the UART normally associated with the Camera Link standard. This

auxiliary UART can be used, for example, to control the camera’s pan and zoom servo motors from the host

at 19.2 KBaud or less. Alternatively, it can be used for other low bandwidth signals.

Unlike the DB9 in the male assembly, this DB9 does not supply power to the extender. Instead, a r ed wire

(power) and a black wire (ground), both 24 inche s long, are left loose so you can hook up your own power

source. The required power is 4.75 to 18 V DC.

Table 9 shows the pinout and how the standard firmware (in

rgb11.rcx) uses each wire. DB9 pins 1, 4, and

6 are wired together and unconnected, 7 and 8 also are wired together, and 9 also is unconnected; these

signals are not otherwise used.

Table 9. Pinout – Female DB9 Cable

Lemo

Pin

––1[unused] –

––6[unused] –

1 green 2 AUX_TX, primary auxiliary transmit UART RS232 (at DB9) to CMOS +3.3 V (at Lemo)

2 red 9 power to extender +4.75 to +18 V (red wire out)

3 orange 7 reserved –

4brown8reserved –

5 white 4 reserved –

6 blue 3 AUX_RX, primary auxiliary receive UART RS232 (at DB9) to CMOS +3.3 V (at Lemo)

7 black 5 ground ground (black wire out)

Color DB9

Pin

Standard Firmware (rgb11.rcx)

Signal Level

EDT, Inc. 2011 June 29 17

Page 22

RCX C-Link Series Power Supply

Cable assembly – Lemo resync

The resync cable, for medium or full mode, sends a common clock signal from an oscillator inside the DB9

shell to each of the two extenders at the framegrabber end. This cable also allows the X channel extender

to signal the YZ channel extender when to start each raster.

The two Lemo connectors on the resync cable are interchangeable.

The resync cable must have an oscillator frequency greater than or equal to the camera pixel clock rate.

The pixel clock re-created for the framegrabber is asynchronous to that generated by the camera; thus, the

amount of time spent in horizontal blanking varies from one raster lin e to the next. If the camera's clock rate

is slower than that of the resync cable, a greater percentage of time will be spent in horizontal blanking at

the framegrabber. Resync cables for 40, 60, and 80 MHz are available (see Related Resources on page 2).

From the tables under Configuration and LED Configuration Codes on page 7, select a configuration code

with a frequency range that is included in the frequency generated by the cable assembly.

Table 10 shows the pinout for this cable with a male DB9 connector.

Table 10. Pinout – Resync Cable with Male DB9

Lemo

Pin

1 START_RASTER+, LVDS signal from X to YZ extender [unconnected] —

2 power power 9

3 CLOCK+, LVDS pixel clock into X and YZ extenders [unconnected] —

4 CLOCK-, LVDS pixel clock into X and YZ extenders [unconnected] —

5 reserved [unconnected] —

6 START_RASTER-, LVDS signal from X to YZ extender [unconnected] —

7 ground ground 5

Lemo Signal DB9 Signal DB9

Pin

If you use the resync cable, you will need a power source as well (see Power Supply, below).

Power Supply

Each extender has an internal switching regulator that supports voltages of 4.75 to 18 volts DC. For pin

information and polarity on the standard Switchcraft and the optional Lemo connector, see Power on

page 16.

CAUTION To avoid damage to the extender, EDT recommends that you protect it from power spikes over 18 V,

use voltages at the lower end of the range, and never reverse the polarity of the power connector.

EDT, Inc. 2011 June 29 18

Page 23

RCX C-Link Series Power Supply

Table 11 shows the base-mode power supply requirements for an extender at the camera end.

Table 11. Base-mode power supply for extender at camera end

U.S. International International with DB9 connector

Voltage in 100–240 V, 50–60 Hz

from AC mains

Voltage out 5 V, 1 A (DC); power supply

includes a U.S.-standard

power plug.

Connector Switchcraft 760K Switchcraft 760K DB9 female

100–240 V, 50–60 Hz

from AC mains

5 V, 2 A (DC); power supply

includes four international

power plug adapters.

100–240 V, 50–60 Hz

from AC mains

5 V, 2 A (DC); power supply

includes four international

power plug adapters.

In full mode with a standard framegrabber, the power requ ired for each end (cam era and framegrabb er) is

always under 6 watts – and typically closer to 4 watts – per en d. This power is spr ead across two extender

(typically 1.5 watts for the X channel unit, and 2.5 watts fo r th e YZ channel unit). The two extenders at the

camera end can use either of the two power supplies with the Switchcraft connectors, while the two

extenders at the framegrabber end can receive power from the EDT resync cable through a female DB9

connector. The resync cable connects to the extenders through two interchangeable Lemo connectors.

EDT, Inc. 2011 June 29 19

Page 24

RCX C-Link Series Appendix A

Dimensions

This section covers the dimensions for EDT extenders.

Figure 8 shows the dimensions of a typical extender. The power connector dimension of 0.31 inch is for the

standard power connector; the optional Lemo connector on the fiber version is approximately 0.35 inch.

NOTE Connector dimensions are approximate; for precise dimensions, see the manu facturer’s specifications.

Figure 8. Extender Dimensions

Figure 9 shows a typical value for cable clearance; the exact value is dependent upon the cable used.

Figure 9. Cable Clearance

EDT, Inc. 2011 June 29 20

Page 25

Appendix

mounting holes

Alternative Mounting and Connecting Methods

Your setup may require an alternative method to mount an extender to a device. For example, to mount a

coax extender (which has no thumbscrews), you’ll need to use one of these methods.

Mounting Holes

You can mount the extender via its mounting holes, as in Figure 10, and a custom (user-provided) bracket.

Figure 10. Mounting Holes

CAUTION To avoid damage to the extender,

mounting screws must not extend

more than 0.2" into the case. See

Dimensions on page 20.

Adapter Cabling

If you cannot mount your extender directly to your device, you can u se an EDT adapter cable or an optional

third-party cable. Figure 11 shows EDT’s half-meter cables, with part numbers and instructions.

Figure 11. EDT extenders with EDT half-meter adapter cables

Fiber extender + EDT adapter cable #016-02563 Coax extender + EDT adapter cable #016-03946

With this cable, screw the fiber extender’s

thumbscrews through the end of the EDT cable and

firmly into the MDR26 connector on the cable.

Also, for devices with SDR (mini Camera Link) connectors, EDT offers a 3M MDR26 female to SDR26 male

cable in two lengths: 1 meter (EDT part #016-013779); or 2 meters (EDT part #016-13740).

With this cable, screw the screws (with washers) on

the EDT cable through the cable backshell, and firmly

into the MDR26 connector on the coax extender.

Page 26

RCX C-Link Series Alternative Mounting and Connecting Methods

Revision Log

Below is a history of modifications to this guide for EDT’s RCX C-Link Series.

Date Rev By Pp Detail

20110629 03d RH,CH,

TL,PH

20110624 03c RH,PH 14 • Added Coaxial Cable main section (with 50- and 75-ohm information).

20110624 03c RH,PH 14 • Deleted Options main head and moved its two subsections as follows:

20110624 03c RH,PH 16 • Made Camera Link pinout its own subsection (Camera Link) under Pinouts.

20110624 03c RH,PH 16,18 • In sections entitled Pinouts and Power Supply, added clarifying details and a fig-

20110523 03b CH,PH 18 • Under Power Supply, expanded the opening verbiage to: “Each extender has an

20110307 03b PH 16-17 • Under Options - Power Connector:

20110216 03a PH 20 • Added to Appendix: information about SDR cable connectors.

20110211 03 PH All • Added information about new products (coax extender and PCIe framegrabber).

20100000 02 PH All • Updated guide with new page layout and formats.

20000000 01 LW All • Created new guide.

14 • Revised Coaxial Cable main section to include more 50-ohm information and no

75-ohm information (not part-numbered).

- made Transceivers a main section (moved above Pinouts);

- renamed Power Connector (re. Lemo cable options) to Power and moved it under Pinouts.

ure showing the standard Switchcraft vs. the optional Lemo power connector.

internal switching regulator that supports voltages of 4.75 to 18 volts DC. The

polarity for the power connector is center pin positive (+), outer collar negative

(-). CAUTION - To avoid damage to the extender, EDT recommends that you

protect it from power spikes over 18 V, use voltages at the lower end of the

range, and never reverse the polarity of the power connector.”

- Loose wire – added new section and table for this option.

- Male and female – reformatted tables to match loose wire assembly table.

EDT, Inc. 2011 June 29 22

Loading...

Loading...