Page 1

RCX C-Link

Fiber Optic Camera

Adapter

for use with Camera Link cameras

November 20, 2006

008-02368-03

Page 2

RCX C-Link User’s Guide

The information in this document is subject to change without notice and does not represent a commitment on the part

of Engineering Design Team, Inc. The software described in this document is furnished under a license agreement or

nondisclosure agreement. The software may be used or copied only in accordance with the terms of the agreement.

Engineering Design Team, Inc. (“EDT”), makes no warranties, express or implied, including without limitation the implied

warranties of merchantibility and fitness for a particular purpose, regarding the software described in this document (“the

software”). EDT does not warrant, guarantee, or make any representations regarding the use or the results of the use

of the software in terms of its correctness, accuracy, reliability, currentness, or otherwise. The entire risk as to the

results and performance of the software is assumed by you. The exclusion of implied warranties is not permitted by

some jurisdictions. The above exclusion may not apply to you.

In no event will EDT, its directors, officers, employees, or agents be liable to you for any consequential, incidental, or

indirect damages (including damages for loss of business profits, business interruption, loss of business information,

and the like) arising out of the use or inability to use the software even if EDT has been advised of the possibility of such

damages. Because some jurisdictions do not allow the exclusion or limitation of liability for consequential or incidental

damages, the above limitations may not apply to you. EDT’s liability to you for actual damages for any cause

whatsoever, and regardless of the form of the action (whether in contract, tort [including negligence], product liability or

otherwise), will be limited to $50 (fifty U.S. dollars).

No part of this manual may be reproduced or transmitted in any form or by any means, electronic or mechanical, without

the express written agreement of Engineering Design Team, Inc.

© Copyright Engineering Design Team, Inc. 1997–2006. All rights reserved.

EDT and Engineering Design Team are trademarks of Engineering Design Team, Inc.

3M is a trademark of 3M Corp.

This device complies with part 15 of the FCC Rules. Operation is subject to two conditions: (1) This device may not

cause harmful interference, and (2) this device must accept any interference received, including interference that may

cause undesired operation.

CAUTION: Changes or modifications not expressly approved by Engineering Design Team, Inc. could void your

warranty to operate this equipment.

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at his or her own expense.

EDT, Inc. November 2006 ii

Page 3

Contents

The RCX C-Link Fiber Optic Camera Adapter 1

Supported Cameras.............................................................................................................................2

References........................................................................................................................................... 2

Using the RCX C-Link in Base Mode ........................................................................................................... 2

Using a Base-mode RCX C-Link With a PCI DV FOX.........................................................................2

Using a Base-mode RCX C-Link As an Extension Cord......................................................................4

Using the RCX C-Link in Medium and Full Modes ....................................................................................... 5

Using a Medium-mode RCX C-Link With a PCI DV FOX .................................................................... 6

Using a Medium- or Full-mode RCX C-Link As an Extension Cord..................................................... 6

Eighty-bit Packing ................................................................................................................................7

LED Status ...................................................................................................................................................8

Configuration ................................................................................................................................................ 8

Operating Modes and Blink Codes ...................................................................................................... 8

Blink Codes for Base-mode Systems.......................................................................................... 9

Blink Codes for Medium- and Full-mode Systems .................................................................... 10

Setting the Blink Code .......................................................................................................................10

Backward Compatibility......................................................................................................................11

Firmware.....................................................................................................................................................12

Verifying the Firmware ....................................................................................................................... 12

Updating the Firmware.......................................................................................................................12

Pinouts........................................................................................................................................................14

Options .......................................................................................................................................................14

Fiber Optic Transceivers.................................................................................................................... 15

Transceiver Care....................................................................................................................... 16

Lemo Connector Option..................................................................................................................... 16

Lemo to Male DB-9 Cable (Base-mode Cameras Only)....................................................................16

Lemo to Female DB-9 RS-232 Cable (Base-mode Cameras Only) ..................................................17

Resync Cable.....................................................................................................................................18

Power Supply .............................................................................................................................................19

Dimensions................................................................................................................................................. 19

EDT, Inc. November 2006 iii

Page 4

RCX C-Link User’s Guide

EDT, Inc. November 2006 iv

Page 5

The RCX C-Link Fiber Optic Camera

Adapter

The RCX C-Link Fiber Optic Camera Adapter is a fiber optic adapter for Camera Link™ cameras. The

RCX C-Link attaches to the back of the camera, taking little more room than an ordinary Camera Link

cable connector. An LC duplex fiber optic cable plugs into the RCX C-Link to allow communication with

a PCI DV FOX frame-grabber, as described in Using a Base-mode RCX C-Link With a PCI DV FOX

on page 2. Or, two RCX C-Link modules can be used as a fiber optic extension cord with a third-party

frame-grabber, as described in Using a Base-mode RCX C-Link As an Extension Cord on page 4.

EDT software drivers provide the same programmer interface to the PCI DV FOX fiber optic framegrabber as to our other frame-grabbers.

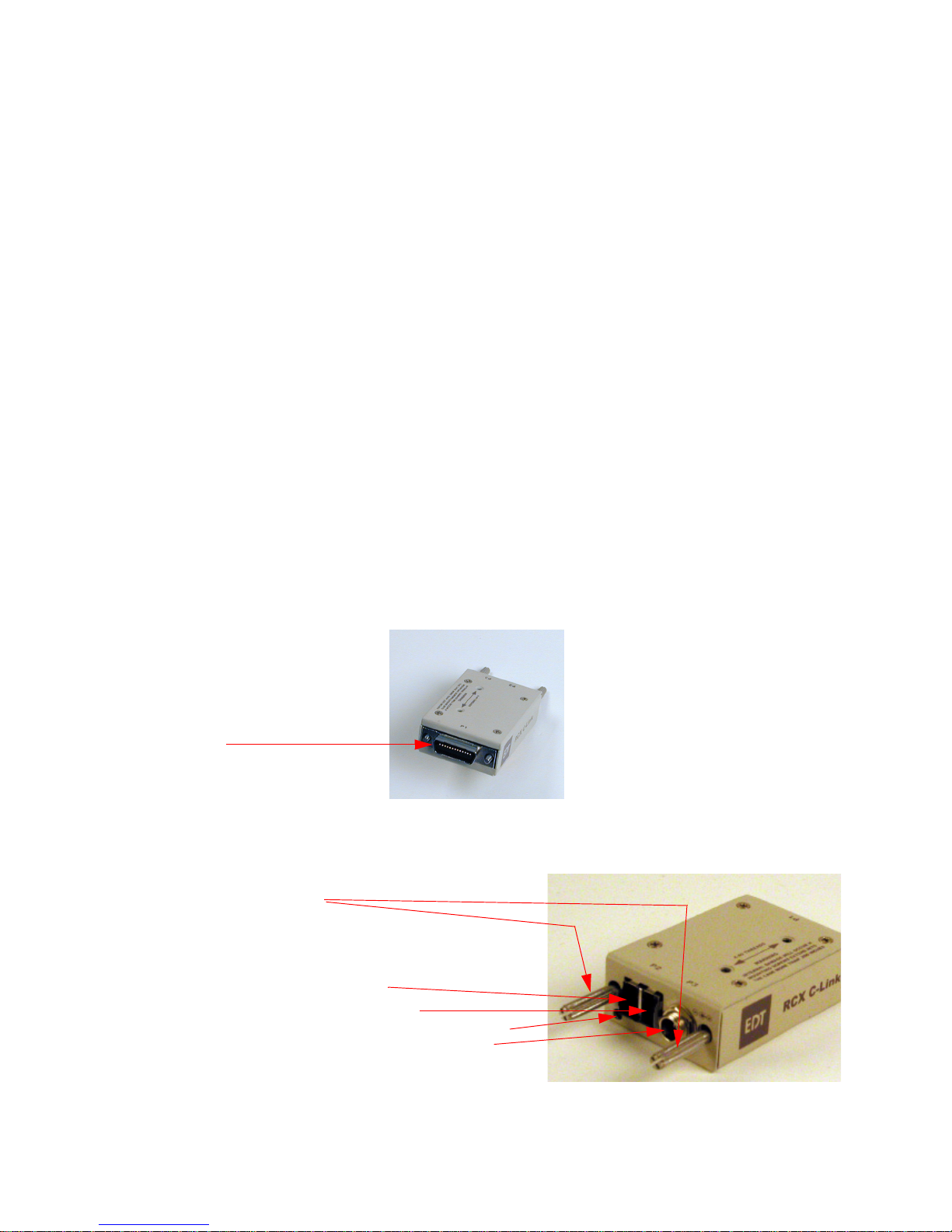

Figure 1 shows the RCX C-Link and its Camera Link connector:

MDR-26 Camera Link

connector

Figure 1. The RCX C-Link and Camera Link Connector

Figure 2 shows the RCX C-Link and its other connectors, and the LED status light:

thumb screws

LC duplex fiber optic connector

transmit

Figure 2. The RCX C-Link and Other Connectors

EDT, Inc. November 2006 1

receive

LED

power supply connector

Page 6

RCX C-Link User’s Guide Using the RCX C-Link in Base Mode

The RCX C-Link data sheet lists the product specifications.

Supported Cameras

The RCX C-Link supports base- and medium-mode Camera Link cameras when used with the

PCI DV FOX frame-grabber within the 200 MB per second bandwidth limitation of the PCI DV FOX

DMA engine. The RCX C-Link supports base-, medium-, and full-mode cameras from 20–80 MHz in

extension cord mode, using third-party frame-grabbers.

Medium- and full-mode extension cord operation requires the use of special versions of the RCX

C-Link.

RCX C-Link modules leave EDT configured for the operating mode specified when they were ordered.

Available operating modes are listed in Table 1 on page 9; instructions for reconfiguring the RCX

C-Link are in Setting the Blink Code on page 10.

References

The following related publication contains additional information on the EDT PCI digital video driver

and the PCI DV FOX frame grabber, including information on acquiring images:

Manual URL

PCI Digital Video User’s Guide www.edt.com/manuals/PDV/pcidv.pdf

Using the RCX C-Link in Base Mode

The RCX C-Link in base mode has one MDR-26 connector. Each pixel clock transfers 24 bits of video

data from the camera’s X channel. In addition, the RCX C-Link can also transfer four camera control

signals, and it has a bidirectional serial interface between frame-grabber and camera.

You can configure a system using the PCI DV FOX as a frame-grabber, or you can use two RCX

C-Link modules to form a fiber optic extension cord, with one module at the camera and the other at

the frame-grabber. Both uses are described below.

Using a Base-mode RCX C-Link With a PCI DV FOX

To configure the RCX C-Link for use with the PCI DV FOX frame-grabber:

1. Install the software driver as instructed in the PCI Digital Video User’s Guide.

2. Configure the RCX C-Link as described in the Setting the Blink Code on page 10.

3. Turn off power to the RCX C-Link, the camera, and the host computer.

4. Install the PCI DV FOX frame-grabber into a host PCI slot as described in the host computer doc-

umentation.

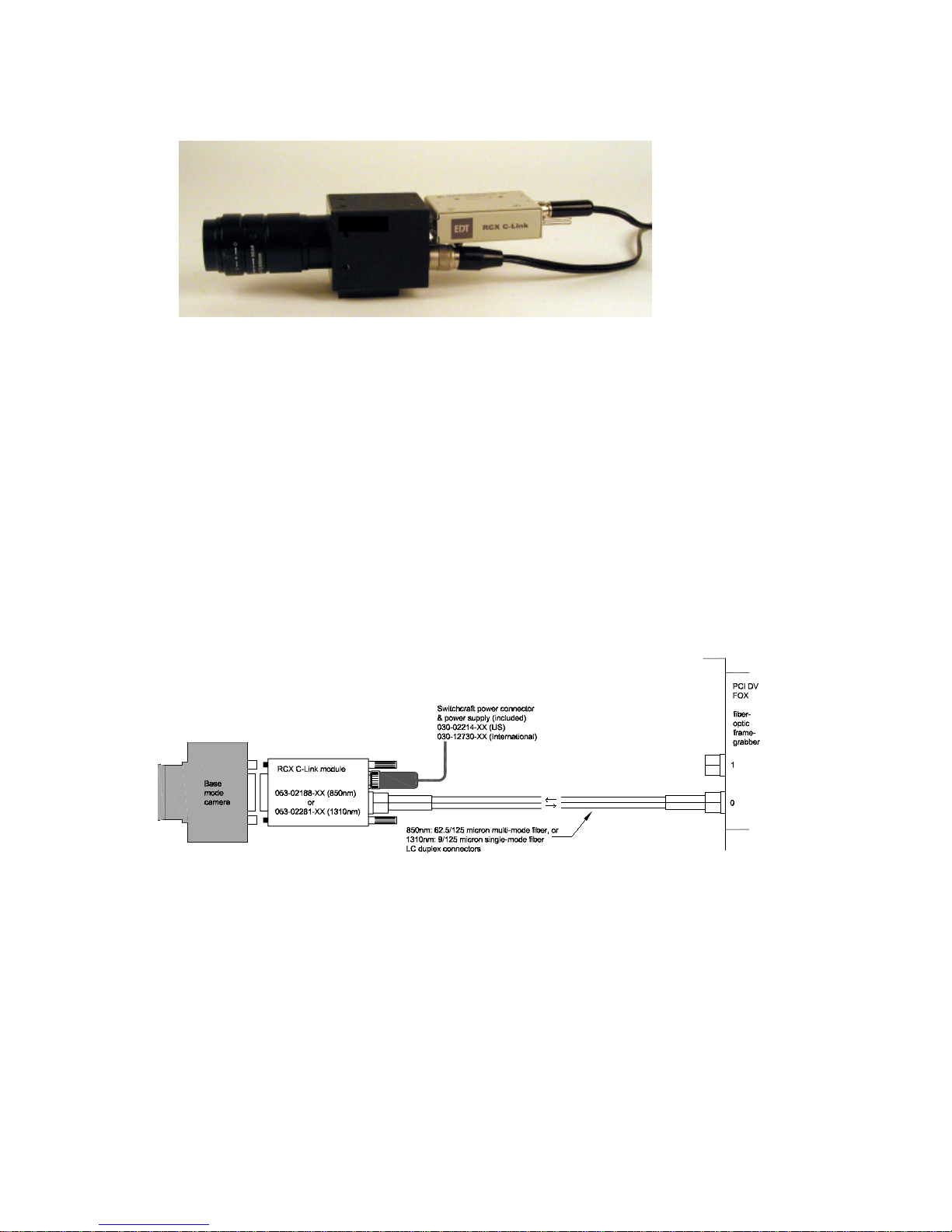

5. Connect the RCX C-Link directly to the MDR-26 connector on the back of the camera, as shown

in Figure 3.

EDT, Inc. November 2006 2

Page 7

Using the RCX C-Link in Base Mode RCX C-Link User’s Guide

Figure 3. Connecting the RCX C-Link to a Camera

6. Attach a fiber optic cable from the RCX C-Link to channel 0 of the PCI DV FOX — channel 0 is

the connector physically closest to the PCI bus.

7. Connect the power supply provided to the power connector on the back of the RCX C-Link.

8. Turn power back on to all devices.

9. Verify that the LED on the RCX C-Link and the Channel 0 LED on the PCI DV FOX show a solid

green light when power is applied to the camera and RCX C-Link. See LED Status on page 8 for

details.

Figure 4. Base-mode System With PCI DV FOX

3 EDT, Inc. November 2006

Page 8

RCX C-Link User’s Guide Using the RCX C-Link in Base Mode

Using a Base-mode RCX C-Link As an Extension Cord

You can use two RCX C-Link modules to form a fiber optic extension cord, with one module at the

camera and the other at the frame-grabber. In this case, the pixel clock rate into the frame-grabber

can be significantly higher than that presented by the camera, and the amount of time spent in blanking

will vary from line to line and frame to frame.

To use two RCX C-Link modules as an extension cord:

1. Install your Camera Link frame grabber and software as instructed by its manufacturer.

2. Configure both RCX C-Link modules as described in Setting the Blink Code on page 10. One RCX

C-Link is for the camera end, and the other is for the frame-grabber end.

3. Ensure that power is off to all devices.

4. Connect the RCX C-Link labeled Camera End to the MDR-26 connector on the back of the cam-

era.

5. Connect the RCX C-Link labeled For Frame Grabber to the MDR-26 connector on the back of

the frame-grabber.

6. Attach a fiber optic cable from one RCX C-Link to the other.

7. Connect the power supplies provided to the power connector on the back of each RCX C-Link

module.

8. Turn power back on to all devices.

9. Verify that both LEDs show a solid green light when power is applied to the camera and RCX

C-Links. See LED Status on page 8 for details.

Frame-grabber and camera operation is the same as when using a standard Camera Link cable.

EDT, Inc. November 2006 4

Page 9

Using the RCX C-Link in Medium and Full Modes RCX C-Link User’s Guide

Base-mode systems are configured as shown in Figure 4. Both 850 nm and 1310 nm systems are

configured in the same way; only the part numbers differ.

Figure 5. Base-mode Extension Cord System

Using the RCX C-Link in Medium and Full Modes

Medium- and full-mode Camera Link cameras have two MDR-26 connectors. The primary connector

operates in the same way as the base-mode interface; each pixel clock transfers 24 bits of video data

from the camera’s X channel. In addition, the primary connector can also transfer four camera control

signals, and it has a bidirectional serial interface between frame-grabber and camera.

The secondary connector transfers video data for the Y and Z channels:

• Medium-mode cameras transfer 24 bits of video data for the Y channel.

• Full-mode cameras transfer an additional 24 bits for the Z channel.

The standard full-mode configuration thus transports 72 bits of video data — 24 bits each for the X, Y,

and Z camera channels.

The X channel RCX C-Links at the camera and frame-grabber ends operate as a base-mode

extension cord, with one fiber to send video data from camera to frame-grabber, and another for

control signals from frame-grabber to camera. The YZ channel RCX C-Link at the camera end has two

fiber optic transmitters. Both fibers carry video data to the frame-grabber.

5 EDT, Inc. November 2006

Page 10

RCX C-Link User’s Guide Using the RCX C-Link in Medium and Full Modes

Many frame-grabbers require that video data presented at the primary and secondary connectors be

synchronized to within a fraction of a pixel clock. The Resync Cable described on page 18 provides a

common pixel clock to both RCX C-Links at the frame-grabber, and other synchronizing signals to

ensure that the starting pixel of each raster lines up across the X, Y and Z channels. The resync cable

also supplies power to the RCX C-Links.

NOTE To avoid damaging a component, ensure that the entire system is properly connected before

applying power to any of the components. In particular, do not apply power to the resync cable

while connecting or disconnecting it from the RCX C-Links.

Using a Medium-mode RCX C-Link With a PCI DV FOX

Full mode with the PCI DV FOX frame-grabber is of limited use due to the PCI DV FOX’s bandwidth

limit of 200 MB per second.

To connect your medium-mode system:

1. Install the software driver as instructed in the PCI Digital Video User’s Guide.

2. Configure the RCX C-Links as described in the Setting the Blink Code on page 10.

3. Turn off power to the RCX C-Links, the camera, and the host computer.

4. Plug the RCX C-Link labeled X Channel Camera into the camera’s primary MDR-26 connector.

5. Plug the RCX C-Link labeled Y Channel Camera into the camera’s secondary MDR-26 connec-

tor.

6. Connect the two power supplies with coaxial power connectors to the two camera-end RCX

C-Links.

7. Connect an LC duplex fiber from the X channel RCX C-Link at the camera end to channel 0 of the

PCI DV FOX — the connector physically closest to the PCI Bus.

8. Connect an LC duplex fiber from the YZ channel RCX C-Link at the camera end to channel 1 of

the PCI DV FOX — the connector physically farthest to the PCI Busd.

9. Verify that the LEDs on the RCX C-Links and the Channel 0 LED on the PCI DV FOX show a solid

green light when power is applied to the camera and RCX C-Links. See LED Status on page 8 for

details.

Using a Medium- or Full-mode RCX C-Link As an Extension Cord

Cameras operating in Camera Link medium or full modes require two RCX C-Link modules at each

end for data transfer. Each of the four RCX C-Link modules in a full-mode system is physically different

from the others. They are not interchangeable simply by changing blink codes.

To connect your system:

1. Install your Camera Link frame grabber and software as instructed by its manufacturer.

2. Configure the RCX C-Links as described in the Setting the Blink Code on page 10.

3. Turn off power to the RCX C-Links, the camera, and the host computer.

4. Plug the RCX C-Link labeled X Channel Camera into the camera's primary MDR-26 connector.

5. Plug the RCX C-Link labeled YZ Channel Camera into the camera's secondary MDR-26 connec-

tor.

6. Plug the RCX C-Link labeled X Channel FG into the frame-grabber's primary MDR-26 connector.

EDT, Inc. November 2006 6

Page 11

Using the RCX C-Link in Medium and Full Modes RCX C-Link User’s Guide

7. Plug the RCX C-Link labeled YZ Channel FG into the frame-grabber’s secondary MDR-26 con-

nector.

8. Connect the two power supplies with coaxial power connectors to the two camera-end RCX

C-Links.

9. Connect the resync cable with two Lemo connectors to each of the two RCX C-Links at the frame-

grabber end. The resync cable’s two Lemo connctors are interchangeable.

10. Connect the power supply with the 9-pin D-shell connector to the resync cable connector.

11. Connect an LC duplex fiber from the X channel RCX C-Link at the camera end to the X channel

RCX C-Link at the frame-grabber end.

12. Connect an LC duplex fiber from the YZ channel RCX C-Link at the camera end to the YZ channel

RCX C-Link at the frame-grabber end.

13. g3g3Verify that all four LEDs show a solid green light when power is applied to the camera and

RCX C-Links. See LED Status on page 8 for details.

Full-mode extension cords systems are configured as shown in Figure 6. Both 850 nm and 1310 nm

systems are configured in the same way; only the part numbers differ.

Figure 6. Full-mode Extension-cord System

Eighty-bit Packing

Certain full mode cameras, such as the Basler A04k and Mikrotron MC1310 and MC1311, reassign

the Spare, Data-valid, and Frame-valid control signals to allow the transport of up to 80 bits of data

per pixel clock. The RCX C-Link can be configured with a blink code to accommodate these cameras.

Blink codes of 1-5 (at the camera end) and 2-5 (at the frame-grabber end) allow 80-bit packing at

frequencies of 60–72 MHz. The 72 MHz upper limit is determined by the bandwidth available over the

fiber, but is sufficient to support all modes currently available on the cameras specified above.

7 EDT, Inc. November 2006

Page 12

RCX C-Link User’s Guide LED Status

LED Status

• When first powered on, the LED displays the current blink code, then blinks erratically for a few

seconds while the firmware is loading.

• In normal operation, a solid green light indicates the RCX C-Link is working properly.

• Slow blinking indicates the RCX C-Link is not receiving a correct fiber optic signal.

• Rapid blinking indicates the RCX C-Link is not locked into the camera clock.

• If the RCX C-Link displays a combination of slow and rapid blinks, both errors are present.

NOTE When used as an extension cord, the RCX C-Link on the frame-grabber end generates its own

camera clock; therefore, a rapid blink indicates a hardware fault in the RCX C-Link, or, in a full- or

medium-mode system, possibly the resync cable.

A slow blink indicates a problem with the fiber optic connection from the remote device to the device

with the slowly blinking LED. Common causes are:

• no power at the transmitting end;

• blink codes with incompatible link rates (see Table 1);

• a broken fiber or an incorrect fiber type; or

• dust or dirt in the fiber optic transceivers (see Fiber Optic Transceivers on page 15).

Configuration

The standard firmware for the RCX C-Link supports most Camera Link base-mode cameras from 20

to 80 MHz, UART data rates of up to 19.2 KBaud. (Higher baud rates are possible.) By setting the

operating mode using the LED’s blink code, you can configure the RCX C-Link to support many

different kinds of cameras for use with a PCI DV-FOX fiber-optic frame-grabber, or for use at either

end of an extension cord.

Each RCX C-Link leaves EDT configured with the appropriate blink code to support its required

operation. For a typical base-mode system,a blink code of 1-1 at the camera end and 2-1 at the framegrabber end permits standard base-mode operation at clock frequencies of 20–40 MHz. For a typical

full mode system, a blink code of 1-4 on both RCX C-Links at the camera end, and of 2-4 on both at

the frame-grabber end, permits standard full-mode operation at clock frequencies of 60–80 MHz.

Each RCX C-Link leaves EDT labeled with that blink code with which it has been configured. On such

labels for medium- or full-mode systems, X Channel refers to the primary MDR-26 connnector on the

camera or frame-grabber, and YZ Channel to the secondary.

Operating Modes and Blink Codes

The RCX C-Link can transfer camera data at various speeds, depending on the operating mode

chosen. You select an operating mode by setting a pattern of blinks — the blink code — for the

module’s LED.

A blink code consists of two digits: for those blink codes that begin with 1 or 2, the first indicates

whether the module is at the camera end (a blink code first digit of 1) or the frame-grabber end (a blink

code first digit of 2). The second digit of the blink code must be the same for both camera and framegrabber ends.

EDT, Inc. November 2006 8

Page 13

Configuration RCX C-Link User’s Guide

If you’re using the RCX C-Link with a PCI DV FOX fiber optic frame-grabber, you need to set a blink

code at the camera end only.

Blink Codes for Base-mode Systems

An RCX C-Link module running firmware revision 11 or higher with base-mode cameras offers the

operating modes shown in Table 1.

Table 1. Base-mode Blink Codes and Operating Modes

Camera

Blink Code End

1-1 camera 20–40 MHz 24 bits 1.25 GBaud

1-2 camera 20–60 MHz 16 bits 1.25 GBaud

1-3 camera 20–60 MHz 24 bits 2.5 GBaud

1-4 camera 60–80 MHz 24 bits 2.5 GBaud

2-1 frame-grabber 40 MHz 24 bits 1.25 GBaud

2-2 frame-grabber 60 MHz 16 bits 1.25 GBaud

2-3 frame-grabber 60 MHz 24 bits 2.5 GBaud

2-4 frame-grabber 80 MHz 24 bits 2.5 GBaud

3-3 firmware update ( See Updating the Firmware on page 12.) 1.25 GBaud

2 fast, 2 slow, 2 fast Error: unsupported code entered

For additional LED blinking behavior, see LED Status on page 8.

Clock Rate

Constraints Link Rate

Most base-mode Camera Link cameras operate between 20 and 40 MHz, so use blink codes of 1-1

at the camera end and 2-1 at the frame-grabber end.

Blink code 2-1 at the frame-grabber end of an extension cord regenerates a constant 40 MHz pixel

clock to the frame-grabber asynchronous to the camera’s actual clock; this is also suitable for cameras

operating between 20 and 40 MHz. Data for an entire raster is accumulated, then sent to the framegrabber in one burst. The regenerated clock at the frame-grabber end must be at least as fast as the

camera clock at the camera link interface; for each frame-grabber blink code, this regenerated clock

rate is given in the Camera Clock Rate column.

If the raster is very long and if the regenerated frame-grabber end clock is much faster than that of the

camera, the frame-grabber end RCX C-Link may have to drop Data-Valid mid-raster and wait for

additional data from the camera. This seldom occurs, and most frame-grabbers can handle it and

continue normal operation.

Cameras operating between 40 and 60 MHz are usually best served by blink codes 1-3 and 2-3. If the

camera needs only 16 data bits or fewer transferred per clock cycle (instead of all 24), it is possible to

use blink codes 1-2 and 2-2 instead, and thus operate the link at 1.25 GBaud for longer range and

lower power dissipation. The selection of 16-bit mode is made only at the frame-grabber end through

blink code 2-2, or through the mode16: 1 directive in a PCI DV FOX configuration file; this information

is communicated over the fiber to the RCX C-Link at the camera end. (At the camera end, blink codes

1-1 and 1-2 are identical.)

At reset (and whenever the RCX C-Link cannot lock to the camera clock), the RCX C-Link initializes

to assume that the Camera Link Data-Valid signal is never asserted, and ignores it. Many Pulnix

cameras do not assert Data-Valid, so this behavior is useful for those using such cameras. The first

occurrence of Data-Valid true from the camera causes the RCX C-Link to use Data-Valid to qualify

video data from that point on.

9 EDT, Inc. November 2006

Page 14

RCX C-Link User’s Guide Configuration

In the case of a dual tap camera, the Camera Link pixel clock is half the camera’s pixel rate. For

example, a dual-tap 12-bit camera with a 40 MHz Camera Link clock sends 80 million pixels per

second. This camera is compatible with the RCX C-Link in blink code 1-1.

Blink Codes for Medium- and Full-mode Systems

An RCX C-Link module running firmware revision 11 or higher with medium- and full-mode cameras

offers the operating modes shown in Table 2.

Table 2. Medium- and Full-mode Blink Codes and Operating Modes

Camera

Blink Code End

1-1 camera 20–40 MHz 72 bits 1.25 GBaud

1-2 undefined

1-3 camera 20–60 MHz 72 bits 2.5 GBaud

1-4 camera 60–80 MHz 72 bits 2.5 GBaud

1-5 camera 60–72 MHz for 80-bit full-mode cameras 2.5 GBaud

2-1 frame-grabber 20–40 MHz* 72 bits 1.25 GBaud

2-2 undefined

2-3 frame-grabber 20–60 MHz* 72 bits 2.5 GBaud

2-4 frame-grabber 60–80 MHz* 72 bits 2.5 GBaud

2-5 frame-grabber 60–72 MHz* for 80-bit full-mode cameras 2.5 GBaud

3-3 firmware update ( See Updating the Firmware on page 12.) 1.25 GBaud

2 fast, 2 slow, 2 fast Error: unsupported code entered

*The resync cable determines the actual frequency.

For additional LED blinking behavior, see LED Status on page 8.

Clock Rate

Constraints Link Rate

Most full-mode Camera Link cameras operate between 60 and 80 MHz, so use blink codes of 1-4 at

the camera end and 2-4 at the frame-grabber end. Full-mode cameras that transfer 80 bits per clock

cycle can use blink codes 1-5 (camera end) and 2-5 (frame-grabber end).

Many medium-mode Camera Link cameras operate at 40 MHz, so use blink codes of 1-1 at the

camera end and 2-1 at the frame-grabber end.

See Firmware on page 12 for instructions on verifying and updating the firmware.

Setting the Blink Code

You select the operating mode of an RCX C-Link by setting the appropriate blink code, if necessary.

(RCX C-Link modules leave EDT configured with the blink code that’s correct for the operating mode

specified when they were ordered.)

To set the blink code:

1. Turn off power to the RCX C-Link module. Only a power supply need be connected to it, nothing

else. It may be helpful, however, to connect the power supplyto a power strip, or otherwise arrange

matters so that you can easily turn the power back on while accessing the recessed button.

2. Press the recessed button on the RCX C-Link with a blunt object such as a ballpoint pen (see pic-

ture below).

EDT, Inc. November 2006 10

Page 15

Configuration RCX C-Link User’s Guide

3. Still keeping the button pressed, turn the power back on, perhaps using the switch on a power

strip. The green LED turns on, then turns off when the button is released.

NOTE If pressed longer than two seconds, the LED blinks a series of diagnostic blinks. If this occurs, turn

the power off again and then restart the procedure.

Figure 7. Setting the Operating Mode

4. Press and hold the button. The LED blinks slowly.

5. Release the button after the LED has blinked the correct number of times for the first digit of the

required blink code, as specified in Table 1. For example, if you want to set the mode to 2-3, wait

for the LED to blink twice before releasing the button.

6. Press the button again and release it after the LED has blinked the correct number of times for the

second digit of the required blink code. For example, if you want to set the mode to 2-3, wait for

the LED to blink three times before releasing the button.

The RCX C-Link saves your selection into flash memory immediately after you enter the second

digit of the code. The LED now blinks in the pattern selected.

NOTE If the LED blinks the error blink code of two fast, two slow, and two fast, an error has occurred and

the code has not been saved to memory.

7. Cycle power to the module without pressing the button.

When the RCX C-Link is powered up without the button pressed, the LED flashes the current code

once, then show its status (see

Using the RCX C-Link in Base Mode on page 2).

NOTE If you enter an unsupported code, the LED blinks two short blinks, two long blinks, then two short

blinks.

Backward Compatibility

Most RCX C-Links with firmware revisions earilier than revision 11 support only cameras with speeds

of 20–40 MHz at 1.25 GBaud using blink codes 1-1 (ignore Data-Valid), 1-2 (use Data-Valid), and 2-1

(frame-grabber end). (Some were shipped with special firmware to support other types of cameras.)

For backward compatibility, firmware of revision 11 or later, as described in Table 1, behaves

identically for blink codes 1-1 and 1-2. As of revision 11, Data-Valid is automatically detected.

Also, customers using blink code 2-2 at the frame-grabber end for 16-bit mode can use the

corresponding blink code of 1-2 at the camera end.

If blink code 3-5 (not shown in Table 1) does not produce the error blink for an unsupported blink code

(two fast, two slow, two fast), then you have firmware of revision 11 or later.

11 EDT, Inc. November 2006

Page 16

RCX C-Link User’s Guide Firmware

Firmware

RCX C-Links for base, medium, and full modes as of November 2006 are shipped configured with

these firmware files:

Table 3. FPGA Configuration Files for the

RCX C-Link mode / channel FPGA configuration file

base mode rgb11.rcx

medium mode, X channel mx11.rcx

medium mode, YZ channel my11.rcx

full mode, X channel fx11.rcx

full mode, YZ channel fyz11.rcx

If you are using the RCX C-Link with a PCI DV FOX, you can use the rcxload utility to verify or

update the firmware on an RCX C-Link module.

NOTE Without a PCI DV FOX, the rcxload utility is not available. For updated firmware, ship the

module back to EDT.

Contact EDT before updating the firmware on a full-mode system.

RCX C-Link

Verifying the Firmware

Before you update the firmware, you may wish to verify that it’s necessary.You can use the rcxload

utility to verify that the firmware loaded into the module is the same as that in a specified firmware file.

To do so, enter:

rcxload -v file.rcx

substituting the name of a valid RCX C-Link firmware file for file.rcx..

The utility compares the firmware in the RCX C-Link module bit by bit with the firmware in the specified

firmware file. If they are the same, it reports verified and 0 errors; if not, it reports not

verified and lists the errors.

NOTE Avoid updating the firmware unless it’s necessary. If your RCX C-Link module is working correctly,

there’s ordinarily no need to update its firmware.

Updating the Firmware

The instructions below allow you to update the firmware in an RCX C-Link module to the current

firmware revision. However, do so only after reading the information below:

NOTE Field updates of full-mode YZ channel units are not currently possible. Contact EDT to update the

firmware on a full-mode system.

CAUTION

To avoid corrupting the firmware on the RCX C-Link, do not interrupt the update by pressing

Ctrl-C or turning off the power while the update is in progress.

EDT, Inc. November 2006 12

Page 17

Firmware RCX C-Link User’s Guide

To update the RCX C-Link firmware to the current revision:

1. Run pciload with no arguments to ensure that the system recognizes the PCI DV FOX. Typical

output appears thus:

pdv unit 0 (pci dv fox):

XC2S200 PCI FPGA, AMD 29LV081B 8MB FPROM

s/n AP0064, p/n 019-02103-11, i/f fpga xc2s400e, rev 11 clock 40 Mhz, opt f2

Sector 0

Sector 1

Sector 2 PROM id: <dvtlk4_3v.ncd 2s200fg456 2005/06/10 14:58:10>

Sector 3 PROM id: <dvtlk4_5v.ncd 2s200fg456 2005/06/10 14:58:16>

2. Put the RCX C-Link into blink code 3-3. (See Setting the Blink Code on page 10 for instructions.)

3. Power-cycle the RCX C-Link.

4. Make sure the fiber optic cable is connected to channel 0 of the PCI DV FOX — the channel phys-

ically closest to the PCI bus. The RCX C-Link need not be connected to a camera.

5. Query the RCX C-Link to make sure it’s there and recognized, by entering rcxload with no ar-

guments. After you’ve started rcxload, the LEDs on both devices are lighted and not blinking.

Typical output appears thus:

pdv unit 0 (pci dv fox) chan. 0 RCX module:

sector 0 [10000]: <rgb11cm60_a01.ncd 2vp2fg256 2006/03/30 20:05:34>

sector 1 [38000]: <rgb11cm80_a01.ncd 2vp2fg256 2006/03/30 20:12:36>

sector 2 [60000]: <rgb11fg40_a01.ncd 2vp2fg256 2006/03/30 19:57:41>

sector 3 [88000]: <rgb11fg60_a01.ncd 2vp2fg256 2006/03/30 20:02:08>

sector 4 [b0000]: <rgb11fg80_a01.ncd 2vp2fg256 2006/03/30 20:09:30>

sector 5 [d8000]: <fud02b.ncd 2vp2fg256 2006/03/28 15:59:19>

If your output appears faulty, check the blink code, cables, and connections. If you still have

problems, e-mail the output to tech@edt.com.

6. Assuming correct output from step 5 above, update the firmware by running:

rcxload -u 0 flash/rcx/file.rcx

replacing file.rcx with the filename of the current firmware revision.

The filename must be a valid .rcx file. EDT software packages ship with the current .rcx files in the

flash

/rcx subdirectory. The README file in the package has information about any .rcx file

updates including the specific filename of the current revision.

After a successful update, switch the module to the appropriate operating mode for its intended use.

For instructions, see Configuration on page 8.

NOTE If

rcxload reports errors within a section flagged as “critical,” do not power-cycle the RCX C-Link.

Instead, repeat the procedure. If you still get errors, leave the RCX C-Link powered on and contact

EDT.

You can turn off power to the host computer and camera. The RCX C-Link can be left powered on

indefinitely.

13 EDT, Inc. November 2006

Page 18

RCX C-Link User’s Guide Pinouts

Pinouts

Table 4 shows the MDR-26 connector pin assignments for base-, medium-, and full-mode systems.

Table 4. MDR-26 Pin Assignments

Camera end Frame-grabber

end

1 1 inner shield inner shield inner shield

14 14 inner shield inner shield inner shield

2 25 X0– Y0– Y0–

15 12 X0+ Y0+ Y0+

3 24 X1– Y1– Y1–

16 11 X1+ Y1+ Y1+

4 23 X2– Y2– Y2–

17 10 X2+ Y2+ Y2+

5 22 Xclk– Yclk– Yclk–

18 9 Xclk+ Yclk+ Yclk+

6 21 X3– Y3– Y3–

19 8 X3+ Y3+ Y3+

7 20 SerTC+ unused 100 ohms

20 7 SerTC– unused terminated

8 19 SerTFG– unused Z0–

21 6 SerTFG+ unused Z0+

9 18 CC1– unused Z1–

22 5 CC1+ unused Z1+

10 17 CC2+ unused Z2–

23 4 CC2– unused Z2+

11 16 CC3– unused Zclk–

24 3 CC3+ unused Zclk+

12 15 CC4+ unused Z3–

25 2 CC4– unused Z3+

13 13 inner shield inner shield inner shield

26 26 inner shield inner shield inner shield

Camera Link signal

base mode

(primary connector)

Camera Link signal

medium mode

(secondary connector)

Camera Link signal

full mode

(secondary connector)

Options

Your RCX C-Link can be customized in various ways. Some of these options can be ordered from

EDT; others are available from third-party vendors.

NOTE The final two digits of EDT part numbers indicate the revision level; specify a final

the most recent revision of a product.

• Custom transceivers (extended range of 5 km or more, 1310 nm, CWDM, single-fiber PON).

• DualTX and DualRX RCX C-Link versions for use on the secondary port of full-mode cameras.

EDT, Inc. November 2006 14

-xx to obtain

Page 19

Options RCX C-Link User’s Guide

• A 7-pin Lemo connector instead of our standard coaxial power connector, allowing:

— a Lemo connector to DB-9 with RS-232 drivers for an extra UART port across the fiber, or

— local triggering directly into the camera, using a DB-9 to Lemo cable.

• Resync cable for use at frame-grabber end of medium- and full-mode extension cords.

• A two-foot Camera Link extender cable is available. Contact EDT for a quote on EDT part number

016-02563-00. Other lengths are possible from 3M Corp; their website lists this as a 3M™ Mini D

Ribbon (MDR) Cable Assembly, .050". Search for part numbers that include the string TZLB, and

choose a result that refers to 1W226-TZLB-XXX-0LC.

If the RCX C-Link is attached to a cable rather than the camera, you might need to secure it as

needed using the mounting holes on the RCX C-Link module case.

NOTE The mounting nuts in the top of theRCX C-Link case use 4-40 threads. To avoid damaging the

RCX C-Link, mounting screws must not extend more than 0.2 inch into the case.

Fiber Optic Transceivers

Our standard RCX C-Link currently uses the 850 nm Stratos Lightwave SLC-25-C-1-E fiber optic

transceiver. An extended-range option uses the 1310 nm Finisar FTRJ11319F1GTL. Transceivers

from other vendors may be substituted without notice.

CAUTION

Though the transceivers we use conform to regulated limits, to avoid damaging your eyesight,

never look directly into a fiber optic transceiver of any kind.

These transceivers can be used with different kinds of optical fiber, as shown in Table 5:

Table 5. Transceiver and Fiber Combinations

Thickness

(microns)

62.5 multimode 850 nm 300 150

50 multimode 850 nm 500 250

9 single-mode 1310 nm 10,000 5000

Fiber Type Wavelength Maximum length (meters)

at 1.25 GBaud at 2.5 GBaud

Other types of transceivers are also available as options:

Single fiber transceivers

These have an integrated passive optical multiplexer and transmit data in each

direction over one fiber using different colors of light. This is especially useful when

going through an optical rotary joint. Some operate at distances up to 60 Km.

CWDM transceivers

These use up to 16 different colors of light, split and combined by passive optical

multiplexers external to the RCX C-Link. With these, it’s possible to operate a

dozen different cameras simultaneously over a single fiber.

DualTX and DualRX transceivers

These are used in our full-mode solutions, as the secondary camera link connector

must carry twice as much data as the primary connector.

15 EDT, Inc. November 2006

Page 20

RCX C-Link User’s Guide Options

Transceiver Care

Dust in the connectors can cause problems with transceivers. If you suspect such a problem:

1. Direct a blast of compressed air away from any electronic components to blow out any water that

may have condensed in the air nozzle.

2. Blow a blast of compressed air directly into the transceiver ports to dislodge any dust particles that

may have collected in them.

NOTE It is critical to keep the transceivers clean and dust-free.

Lemo Connector Option

Our standard power connector is a coaxial Switchcraft that locks into place through a threaded sleeve.

We can substitute a 7-pin Lemo connector, EDT part number 016-02445-01, as an option to make the

RCX C-Link more versatile. With the Lemo connector, you can use either of two cables that allow

auxiliary signals.

(On medium- and full-mode extension cord systems, the RCX C-Links at the frame-grabber ends use

the Lemo connectors for the resync cable.)

When looking into the Lemo connector on the end of the RCX C-Link module, you see the pins laid

out as shown in Figure 8, using Lemo pin numbering. Pin 2 is always power to the RCX C-Link, +4.75

to +18 V DC. Pin 7 is always ground (for both signals and power). The other five pins are defined by

the firmware installed on the RCX C-Link. These pins are normally used at CMOS +3.3 V signal levels,

though the RCX C-Link can be configured with minor hardware modifications to use pins 1,6 and 3,4

as LVDS signal pairs.

==

1 6

2 7 5

3 4

key in the connector barrel at the top

Figure 8. Lemo Pin Layout

Lemo to Male DB-9 Cable (Base-mode Cameras Only)

EDT offers an optional Lemo to DB-9 cable (part number 016-02718-00) for use with the above Lemo

connector. This cable provides signals that can be used as an auxiliary signaling system for a variety

of purposes; it also supplies power to the RCX C-Link.

Custom firmware could allow the auxiliary signals to be used, for example, to control the camera’s pan

and servo motors. It’s also possible to set up a hardware trigger local to either end. Contact EDT if you

wish to explore these options.

Unlike the Lemo to Female DB-9 RS-232 Cable (Base-mode Cameras Only) discussed below, the DB9 connector in this cable has no integrated level conversion, nor looped back signals.

Table 6 shows the color coding for the Lemo to DB-9 power cable, and how the standard firmware

uses each wire:

EDT, Inc. November 2006 16

Page 21

Options RCX C-Link User’s Guide

Table 6. Lemo to Male DB-9 Cable Pinout

Lemo Pin

Number Color

1 green 2 AUX_TX, primary auxiliary transmit UART CMOS +3.3 V

2 red 9 power to RCX C-Link 4.75 – 18 V

3 orange 7 AUX2_TX, secondary auxiliary transmit CMOS +3.3 V

4 brown 8 AUX2_RX, secondary auxiliary receive CMOS +3.3 V

5 white 4 SYNC, can be configured as an outgoing copy of the

6 blue 3 AUX_RX, primary auxiliary receive UART CMOS +3.3 V

7 black 5 ground ground

DB-9 Pin

Number Standard Firmware (rgb11.rcx) Signal Level

CMOS +3.3 V

camera’s Frame-valid signal

All five CMOS 3.3 V signals go to FPGA 3.3 V I/O pins using series 100-ohm resistors. Custom

firmware can configure these pins as input or output.

NOTE DB-9 pins 1 and 6 are spare.

Lemo to Female DB-9 RS-232 Cable (Base-mode Cameras Only)

EDT offers an optional Lemo to DB-9 RS-232 cable (part number 016-02445-01), with integrated

CMOS +3.3 V to RS-232 level converters on a small circuit board inside the DB-9 connector shell. This

cable is designed to plug in directly to a host computer serial port.

It offers an auxilliary UART connection over the fiber, in addition to the UART normally associated with

the Camera Link standard. This auxilliary UART can be used, for example, to control the camera’s pan

and zoom servo motors from the host at 19.2 KBaud or less. Alternatively, they can be used for other

low bandwidth signals.

Unlike the Lemo to Male DB-9 Cable (Base-mode Cameras Only) discussed above, the DB-9

connector does not supply power to the RCX C-Link. Instead, a red wire (power) and a black wire

(ground), both 24 inches long, are left loose for you to hook up your own power source. The required

power is +4.75 to 18 V DC.

Table 7 shows the color coding for the Lemo to DB-9 RS-232 cable, and how the standard firmware

(in

rgb11.rcx) uses each wire. DB-9 pins 1, 4, and 6 are wired together and unconnected; 7 and 8

are also wired together, and 9 is also unconnected — these signals are not otherwise used.

Table 7. Lemo to Female DB-9 RS-232 Cable Pinout

Lemo End DB-9 End

Pin Purpose Signal Level Pin Purpose Signal Level

1 UART_TX, auxiliary transmit

UART from RCX C-Link

2 power red wire out

3 reserved

4 reserved

5 reserved

6 UART_RX, auxiliary receive

UART from

7 ground 5 black wire out

RCX C-Link

CMOS +3.3 V 2 data transmit RS-232

CMOS +3.3 V 3 data receive RS-232

17 EDT, Inc. November 2006

Page 22

RCX C-Link User’s Guide Options

Resync Cable

When used for medium- and full-mode extension cords, two RCX C-Links are needed at the framegrabber end. The EDT resync cable sends a common clock signal from an oscillator inside the DB-9

shell to each of the two RCX C-Links at the frame-grabber end. This cable also allows the X Channel

RCX C-Link to signal the YZ channel RCX C-Link when to start each raster.

The two Lemo connectors on the resync cable are interchangeable.

The resync cable must have an oscillator frequency greater than or equal to the camera pixel clock

rate. The pixel clock re-created for the frame-grabber is asynchronous to that generated by the

camera; thus, the amount of time spent in horizontal blanking varies from one raster line to the next.

If the camera's clock rate is slower than that of the resync cable, a greater percentage of time will be

spent in horizontal blanking at the frame-grabber.

Three resync cables are available, offering 40, 60, and 80 MHz clock rates:

Clock Rate EDT Part Number

40 MHz 016-02673-00

66.666 MHz 016-02675-00

80 MHz 016-02613-00

Choose a blink code from Table 1 whose frequency range includes the frequency generated by the

cable assembly.

Table 8 shows the signal assignments:

Table 8. Resync Cable Pinout With Male DB-9

Lemo

Pin

Lemo Signal DB-9 Signal DB-9

Pin

1 START_RASTER+, LVDS signal from X to YZ RCX C-Link — unconnected —

2 power power 9

3

CLOCK+, LVDS pixel clock into X and YZ RCX C-Links

4 CLOCK-, LVDS pixel clock into X and YZ RCX C-Links — unconnected —

5 reserved — unconnected —

6 START_RASTER-, LVDS signal from X to YZ RCX C-Link — unconnected —

7 ground ground 5

— unconnected —

If you’re using the resync cable, you will also need a power source, such as the International Power

Supply With DB-9 Connector described on page 19.

EDT, Inc. November 2006 18

Page 23

Power Supply RCX C-Link User’s Guide

Power Supply

The RCX C-Link at the camera end of a base-mode system has the following power requirements:

Table 9. U.S. Power Supply

Voltage in 100–240 V, 50–60 Hz from AC mains

Voltage out 5 V DC, 1 A

Power supply connector Switchcraft 760K

The 5 V power supply is small and comes with a U.S.-standard power plug.

Table 10. International Power Supply

Voltage in 100–240 V, 50–60 Hz from AC mains

Voltage out 12 V DC, 0.84 A

Power supply connector Switchcraft 760K

The 12 V power supply includes four international power plug adaptors.

Table 11. International Power Supply With DB-9 Connector

Voltage in 100–240 V, 50–60 Hz from AC mains

Voltage out 12 V DC, 0.84 A

Power supply connector DB-9 female

Power required on a full mode system has been measured at under 6 watts for each end — camera

and frame-grabber. This power is spread across two RCX C-Links: typically, two watts for the X

channel RCX C-Link, and 3.5 watts for the YZ channel RCX C-Link. A switching regulator inside the

RCX C-Link allows us to accept anything from 4.75–18 volts DC; however, lower voltages are

recommended to avoid running hot.

The two RCX C-Links at the camera end of a full-mode system can use either of the two power

supplies with the Switchcraft connectors. The two RCX C-Links at the frame-grabber end of a fullmode system receive power from our resync cable through a female DB-9 connector. The resync

cable connects to the RCX C-Links through two Lemo 7-pin connectors.

Dimensions

The RCX C-Link box has the dimensions shown in Figure 9.

NOTE With respect to the dimensions shown in Figure 9:

Connector dimensions are approximate — refer to manufacturer’s specifications for precise

dimensions.

The power connector dimension of 0.31 inch is for the standard 2-conductor connector; the

optional Lemo connector is approximately 0.35 inch.

19 EDT, Inc. November 2006

Page 24

RCX C-Link User’s Guide Dimensions

Figure 9. RCX C-Link Dimensions

Figure 10 shows the cable clearance. Cable clearance for optical fiber can vary, depending on the fiber

used; the value shown is typical.

Figure 10. Cable Clearance

EDT, Inc. November 2006 20

Loading...

Loading...