ZD500DX

®

Deluxe Hot Tip

Desoldering Station

(self-contained)

• COMPLIES WITH MIL-S-45743E, MIL-STD-2000-1B, WS6536E AND

ESD SPEC, DOD-STD-1686, DOD-HDBK-263

• UL listed

MADE

IN

U.S.A.

Instruction manual

ZD500DX

®

Deluxe Hot Tip

Desoldering Station

Contents at a Glance

Page 3 - 4 Features & Specications

Page 5 Operation

Page 6 - 8 Tip Usage & Replacement

Page 9 Maintenance

Page 10 Trouble Shooting & Maintenance

Page 11 Calibration

Page 11 - 13 Spare Parts List for Power Supply

Page 14 - 15 Spare Parts List for Hand Tool

Page 2

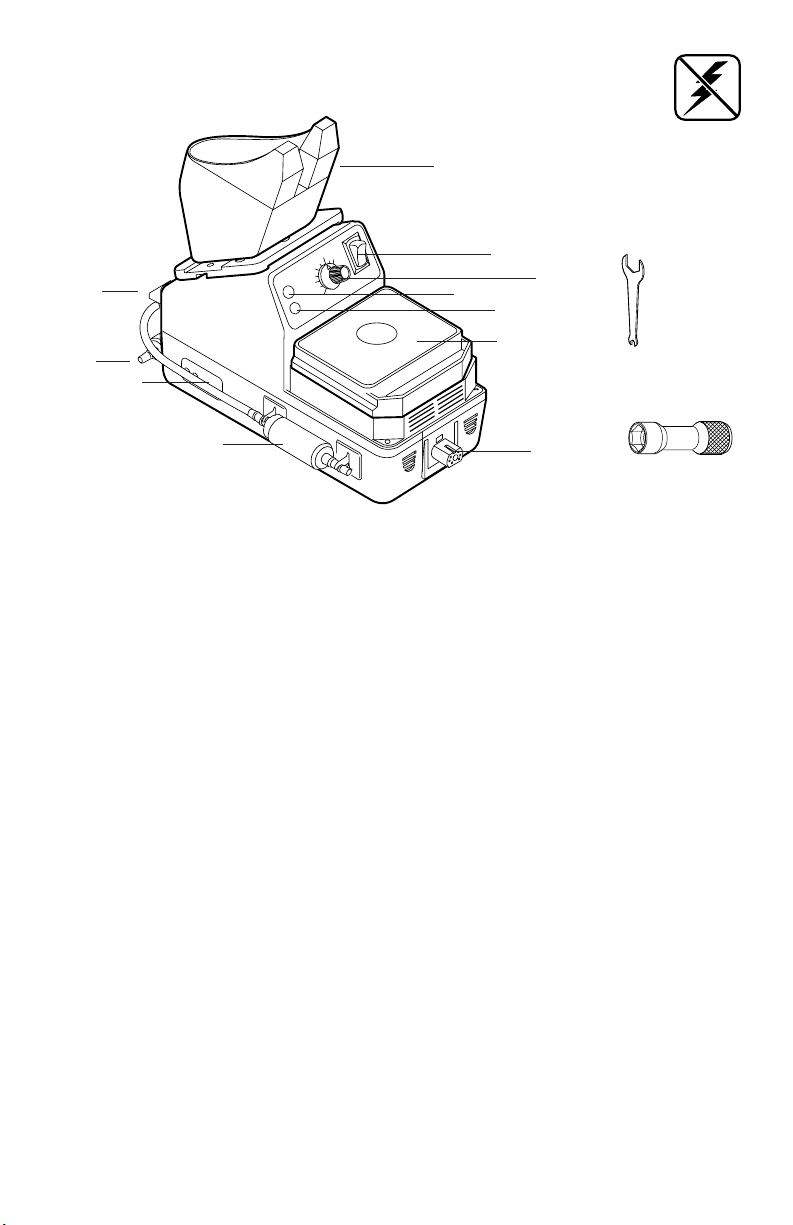

FEATURES

POWER SUPPLY

J

H

I

Static Safe

A

B

D

C

E

F

K

L

H

A) Tool Pod, equipped with micro-switch to activate pump.

B) Power Switch, to activate WorkStation.

C) Temp. Control Knob

D) Pump LED

E) Heater LED

F) SH232 Sponge Holder, with cleaning sponge.

G) Power output, 24V, controlled

H) AF110 Filter, (note ow direction)

I) External Calibration

J) Pump

K) WT623 Tip Wrench

L) WT619 Tip Wrench

G

SPECIFICATIONS

• 115V, 60 Hz, 150W Power Supply

• 24V, 50/60 Hz, 70W Hand Tool

• Weight; Power Supply: 5 lbs. 12 ozs. (2.6 kg)

Hand Tool: 11 ozs. (312 g)

• Temperature range of 400°F to 800°F (205°C-425°C)

• Voltage leakage from tip to ground, less than 2 MV

• Tip to ground resistance, less than 2 ohms

• COMPLIES WITH MIL-S-45743E, DOD-STD-2000-1B, WS-6536E and

ESD SPEC, DOD-STD-1686, DOD-HDBK-263

Page 3

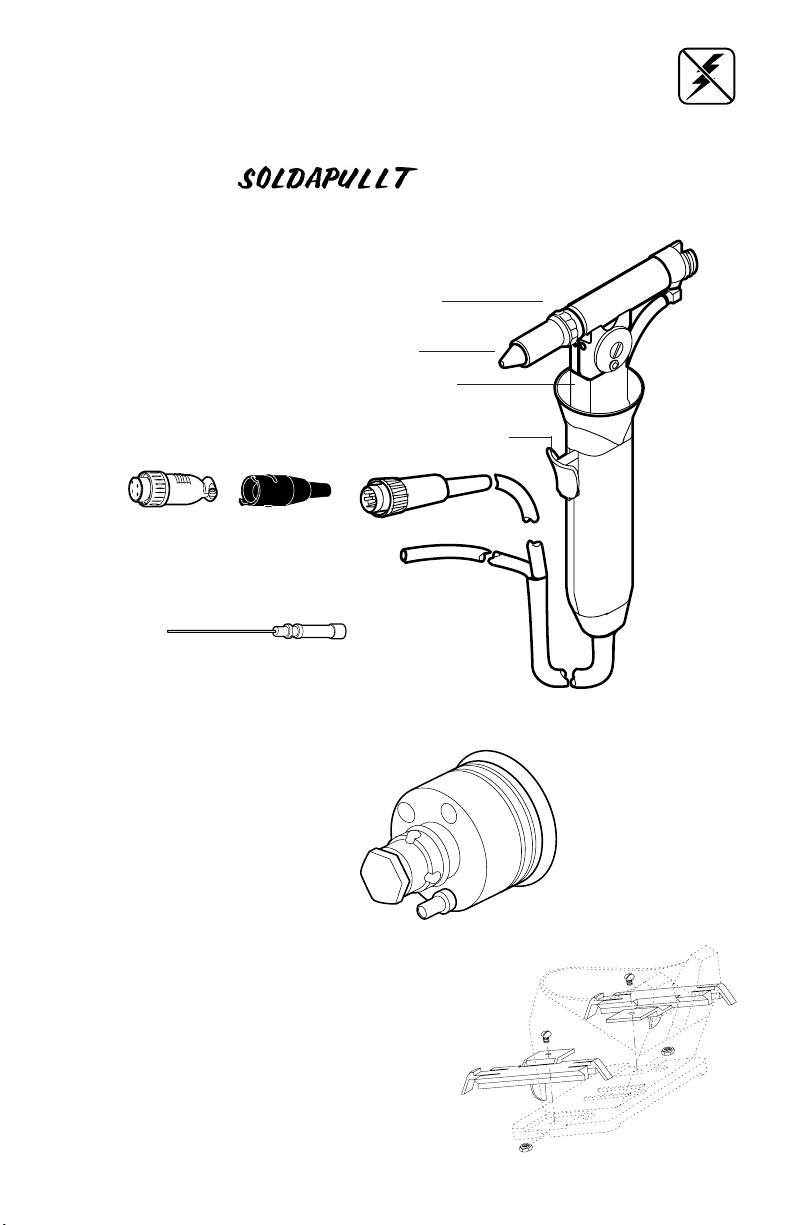

FEATURES

HOT TIP DESOLDERING TOOL

ESD Safe

HT500/-1/-2

Hot Tip Desoldering Tool

A) Head Assembly- Includes the primary

ltering system and solder debri chamber.

B) Hot Tip Desoldering Tip- Wide range of

desoldering Tips applicable.

C) Head Shaft- Allows 4-point rotation of

Head Assembly.

D) Trigger- Activates vacuum suction.

E) Vacuum Hose- Low Static silicone hose.

Connects to vacuum source.

F) Connector- To 24 V controlled output.

(for HT500) (for HT500-2)

G) Cleaning Shaft- For cleaning Desoldering

Tip orice: .05 (1.3 mm) and .025 (0.6

mm)

OPTIONS

®

A

B

C

F (for HT500-1)

E

D

FC641 Large Filter Cartridge Assembly

Replaces FC640. For use in applications

that require heavy use, or where No-Clean

solder/ux is used at high temperature.

PA233 Dovetail Extension Bracket allows

you to install additional Tool Pods.

1. Insert nut into the slot of adapter plate on both sides.

2. Screw PA233 on the adapter plate.

Page 4

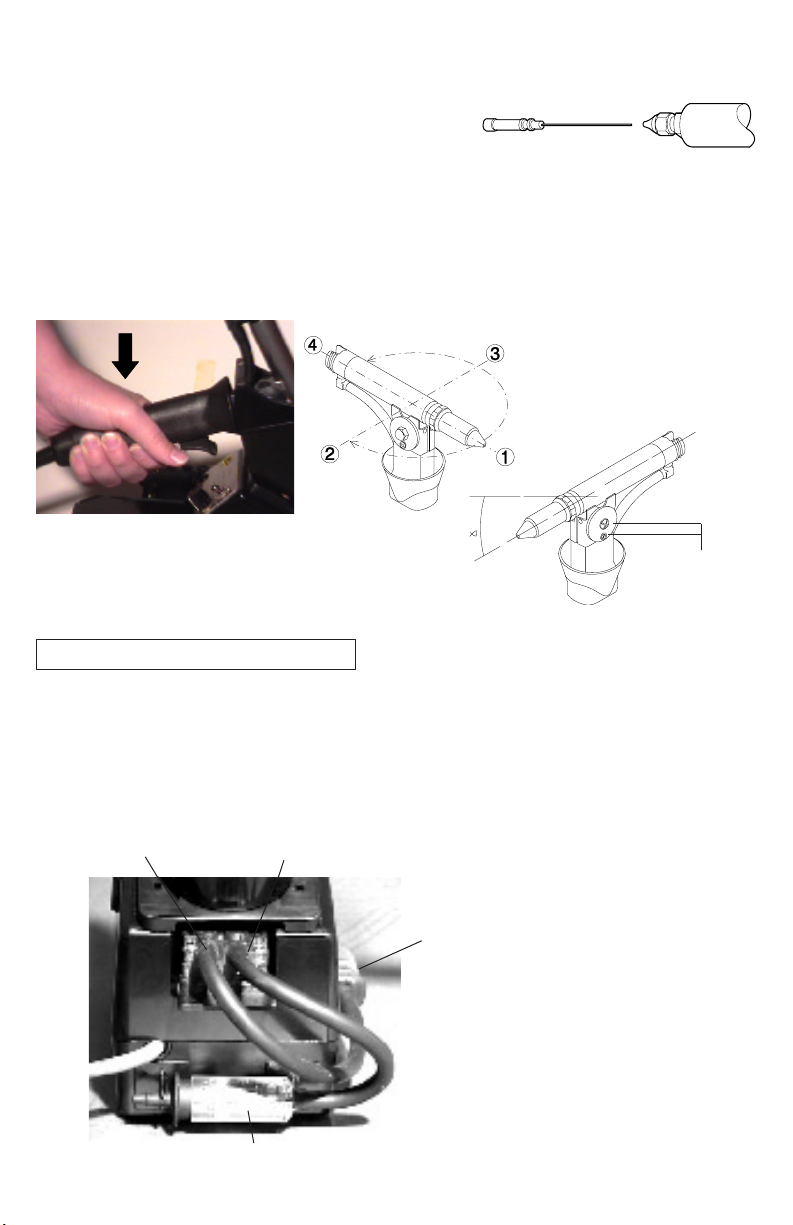

OPERATION

1. Connect HT500 to 24V power supply and vacuum source.

2. Press trigger to activate vacuum.

NOTE: When Tip orice is bloc ked,

use a corr ect size C le ani ng S ha ft

while pressing the Trigger to clear the

obstruction.

3. Always clean the Tip with wet sponge and

always re-tin (add fresh solder) during and after each

operation.

CS468 is .05 in. dia.

CS468-1 is .025 in. dia.

ADJUSTMENTS

The HT500 Head assembly can be adjusted into varying positions to suit the operator.

While Tool is in the Pod, push handle

down and twist handle until it locks

into 1 of it's 4 positions. Twisting

counter-clockwise will permit a 1800

turn. Twisting clockwise will permit

a 900 turn.

Note: Head Assembly does not make a full 3600 turn

To tilt the Head assembly, loosen (2)

Adjustment Screws. Tilt the Head assembl y to d e sire d po s itio n . Ret i ght e n

Screws.

adjustment

screws

AIR FLOW DIRECTION

Vacuum

Air out

Air out

Hoses must be clean and not

kinked or cracked

Vacuum

For Factory repair:

Specify the problem and ship the

unit to EDSYN INC.

Customer Service

15958 Arminta Street

Van Nuys, CA 91406-1896

Page 5

DESOLDERING POINTERS

1. When desoldering small

holes on at areas, tilt

Tool to allow adequate

air ow to lift solder into

chamber.

2. When using SMD Tips, heat

up the connections by posi-

tioning the Tool perpendicu-

larly. When solder melts tilt

the Tool and depress trigger.

(SMD Tips are recomended

fo r HT 500 u sing ext e rna l

vacuum).

3. Extra-heavy duty desoldering on a multi-layeredboard

is done by using a Heavy Duty Desoldering Tip and

a Hi-Heat Soldering Tip simultaneously. Although

pre-heating of the circuit board will speed up the

process, it is not always necessary.

Heavy Duty Desol-

dering Tip

Multi-Layered

Board

REPLACING DESOLDERING TIPS

1. Remove RS383. Use WT619.

2. Replace Tip and install new Tip.

3. Apply AN112 (in tube) or AN122 (in syringe) Anti-Seize

Compound before assembling.

INSPECT DAILY

4. Install RS383.

install

remove

WT619

Tip Wrench

Page 6

Hot Tip Desoldering Tips

Fractional dimensions are approx.

Extra-heavy duty desoldering

on a multi-l ayere d boar d is

done by using a Medium Life

Desoldering Tip.

To reach deep, dense and

compact areas, use a Long

Funnel tip

DESCR IPTION

Standard Tip

(High Heat Transfer)

HOLE

DIA.

Funnel

HOLE

DIA.

Long Funnel

PART

NO.

HOLE DIAMETER

in.

mmin.

B

in. in.

mm

ZD12 .03 1/32 0.8

ZD13 .04 3/64 1.0

ZD14 .06 1/16 1.5 .50 1/2 12.7

ZD18 .07 5/64 1.8

ZD19 .12 1/8 3.2

ZD107 .02 1/64 0.5

ZD112 .03 1/32 0.8 . 48 31/64 12.2

ZD113 .04 3/64 1.0

ZD118 .07 5/64 1.8

ZD111 .03 1/32 .08 1 .2 2 17/ 32 31

ZD115 .07 5/64 1.8

Replacement*

When using a Replacement

Desoldering Tip to desolder

smal l ho les on flat ar eas ,

tilt Tool to allow adeq uate

air flow t o lift sold er i nt o

chamber.

When using SMD Tips, heat up the

connections by positioning the Tool

perpendicularly. When solder melts,

tilt the Tool and depress trigger.

HOLE

DIA.

SMD**

(FO R Z D50 5/905 se rie s)

HOLE

DIA.

ZD25 .03 1/32 0.8

ZD26 .04 3/64 1.0 .39 32/6 4 9.9

ZD27 .07 5/64 1.7

ZD57 .10 7/64 2.5

ZD58 .13 1/8 3.2

ZD60 .15 5/32 3.8 .55 9/16 13.9

ZD61 .25 1/4 4.5

Page 7

Hot Tip Desoldering Tip

DESCR IP TION

PAR T

N O.

HOLE DIAMETER

B

in. in. mm in. in mm

Surface Sweep Tips

removes excess solder

on pads for atter surface,

prior to SMD remounting.

Si de S w eep Tips

al l ows re mova l of

solder from the component side of the

board.

Hot Tip set-up

Economy**

HOLE

ZD28 .03 1/3 2 .08

DIA.

ZD29 .04 3/6 4 1.0

ZD30 .06 1/16 1.5

Surface

Sweep**

W

in. in. mm .30 5/16 7.6

ZD70

Hole Dia. = .06 in.

Side Sweep**

.08 3/32 2.0

ZD71

Hole Dia. = .06 in.

*Tin New Iron Tips at Low Temperaturebefore using.

**Non-Plated Alloy

Medium & Long Life

Desoldering Tip

SMD Desoldering Tip

Heater Set-up

AC736

Tip Adapter

Replacement

Desoldering Tip

Side Sweep

Desoldering Tip

HC273

Threaded

Retaining

Collar

AC737

Accumulator Bushing

HT01

RS383

Retaining

Sleeve

Page 8

DAILY MAINTENANCE

• Remove and inspect Tip and Heater Assy.

• Inspect all Filters

• Remove solder debri from Desoldering Head

Housing

TO REPLACE FILTER & O-RING INSIDE

DESOLDERING HEAD ASSY.

1. Pull out FC639 from Housing.

2. Unscrew SC525 from FC639 to remove AF625.

3. Insert new AF625 inside SC525 and screw back

on.

4. Clean and apply OL111 on OS731 & OS132

O-Ring.

WEEKLY MAINTENANCE

• Inspect Valve Assy.

• Inspect all O-Rings and Seals

© - Clean

® - Replace

OS731

©

FC639

©

OS132

OPTIONAL FC641

Large Filter Cartridge Assembly

1. Pull out FC641 from Housing.

2. Unscrew FC641 remove old AF041.

3. Insert new AF641 inside FC641 and

screw back together.

4. Clean and apply OL111 on OS731 &

OS132 O-Ring.

TO REPLACE O- RINGS INSIDE VALVE ASSEMBLY

a) Unscrew Lock Nut at the end of the HT500

Handle.

b) Remove Handle Cover.

c) Slide out Valve Assembly while placing your

nger over the Spring Seat. BE CAREFUL NOT

TO LET THE SPRING AND THE SPRING SEAT

SHOOT OUT FROM THE HOUSING

d) Clean all parts with alcohol only.

e) Replace OS730 O-Ring Set (set of 3).

AF625

©

®

SC525

OS730 O-ring set

®

MS229

®

OS133

Desoldering

©

Head Housing

HT01

OS133

When installing OS133, the HT01

should go thru the OS133.

Valve Assembly

Handle

Cover

Lock Nut

CA UTI ON: Mak e

sure the wires are

not pinched by

Valve Assembly.

Spring Seat

Page 9

TROUBLE SHOOT-

Symptoms Cause Remedy

a) Pump micro switch is stuck.

Pump won't run

Pump running but

weak or no vacuum

generated.

b) Vacuum inside hose (normal)

a) Loose connections between

joints or connectors.

b) Dirty lters.

c) Leaky or sticky valve.

d) Wrong hose connection.

e) Broken pump diaphram.

Blown fuseNo power Replace fuse. See spare parts list

Problems that occur aside from those listed below

should be handled by our factory technicians.

a) Use a pair of tweezers to release

the switch.

b) Squeeze trigger to release

vacuum.

a) Make sure all connections are

tight.

b) Inspect and clean all lters.

Replace elements if needed.

c) Clean parts and replace

O-Rings if needed .

d) HT500 Hose should be

connected to AF110.

e) Ship back to factory

FUSE REPLACEMENT

3.15A fuse inside

SPONGE MAINTENANCE

Replace RS199 Cleaning Sponge

Pour water on RS199 to moisten it completely.

DO NOT OVERFILL.

FILTER MAINTENANCE

Filters should be kept clean

AF629 Felt Filter

End Cap

Tip Wrench can be use

to remove lter cap.

AF040 Foam Filter

Housing

Page 10

CALIBRATION

AIR MOVEMENT WILL AFFECT THE TEMPERATURE READING.

WORK IN AN AREA WHERE THIS IS MINIMAL.

1. Using a clean Tip, turn on power

and set Temperature Control Knob

to approx. 500°F (260°C). Allow

Tip to warm up.

2. Tin the tip properly and place center

of the thermo-couple wire on tip.

3. Apply a small amount of solder on

the center of the thermo-couple

wire, to form a good contact

between the tip and the thermocouple wire.

4. Set Temperature Control Knob to

400°F (205°C).

5. Adjust LO-Temp. Calibration Pot

so the Meter will read 400°F

(205°C).

6. Set Temperature Control Knob to

800°F (427°C).

7. Adjust HI-Temp. Calibration Pot so

the Meter will read 800°F (427°C).

Temperature

Control Knob

HI LO

Calibration Pot

1. Set knob at 400°F.

2. Adjust LO to 400°F.

3. Set knob at 800°F.

4. Adjust HI to 800°F.

ZD500DX Spare Parts List

ITEM

PART NO. DESCRIPTION

NO.

44 SR011 Screw, Round Head Phillips, 6-18 x 5/8 4

45 SR012 Bump-Ons 4

46 SR026 Power Cord Only 1

47 WT623 Tip Wrench, Dual Open End, 1/4" & 3/4" 1

48 SR416 Holder, Tip Wrench Hanger 1

49 SR776 Fan 1

See next page for illustration

QTY

REQ'D

Page 11

17

10

3

15

18

6

6

14

13

11

16

2

4

23

5

8

9

20

19

33

43

33A

46

33B

34

33C

25

21

41

40

31

36

34

33D

28

42

49

5

27

24

31

39

31

35

44

45

12

7

1

48

32

37

26

47

29

Page 12

ITEM

NO.

PART NO.

DESCRIPTION

REQ'D

1 SR566 Top Cover, Power Supply 1

2 SR065 Power Switch, 120V 1

3 SR073 Tool Holder 1

4 SR817 Adapter plate 1

5 SR467 Nut, Square Cone 3

6 SR367 Screw, Flat Head Phillips, 6-32 x 5/8 2

7 SH232 Sponge Holder 1

8 SR137 Washer, #8 1

9 SR009 Screw, Pan Head Slotted, 8-32 x 7/8 1

10 SR759 LED Assy. Yellow, for pump 1

11 SR573 LED Assy. Green 1

12 RS199 Cleaning Sponge 1

13 SR567 Label, Front Panel 1

14 SR115 Retainer Plate for Micro Switch 1

15 SR114 Push Rod for Micro Switch 1

16 SR045 Knob, Temperature Control 1

17 SR112 Flange, Retainer for Tool Pod 1

18 SR568 Micro Switch Assy. 1

19 SR243 Potentiometer Assy. 1

20 SR255 Spacer, for Potentiometer Assy. 1

21 SR050 Cable Tie 1

23 HL603 Hose, Low Static Silicone, 3/16 ID. (sold per foot) 2@

7" and 10"

24 SR484 Bottom Base 1

25 SR535 Pump / Motor Assy. 120V 1

26 SR138 Transformer, Dual Primary, 24V output 1

27 15242W70 Circuit Board 1

28 SR569 Fuse Holder, Panel Mount 1

29 SR711 Connector Assy. 1

31 SR016 Washer, #6 6

32 SR017 Nut, 6-32 3

33 AF110 Filter, In-Line Vacuum 2

33A SR266 End Cap 2

33B AF629 Felt Filter (set of 10) 2

33C AF040 Foam Filter (set of 10) 2

33D SR533 Barrel, Clear, for AF110 2

34 SR439 Holder, Clip 4

35 SR561 Screw, Round Head Phillips, 6-32 x 3/4 1

36 SR468 Screw, Round head Phillips, 6-32 x 7/8 4

37 SR139 Washer, Star 4

39 SR144 Screw, Round Head Slotted, 6-32 x 1/2 1

40 SR469 Spacer, for Pump Mounting 4

41 SR470 Well Nuts, for Pump Mounting 4

42 SR563 Fuse, 3.15A 1

43 SR310 Label, Calibration, Left Rear 1

QTY

Page 13

HT500/-1 HOT TIP

DESOLDERING TOOL

SPARE PARTS LIST

49

47

4

2

1

3

43

32

28

46

25

25

45

14

17

50

29

16

30

30

31

47

15

24

21

20

18

22

19

10

9

11

12

13

26

8

7

5

6

33

40

38

39

36

34

44

37

42

27

41

48

35

ITEM

NO.

PART NO.

DESCRIPTION

1 RS383 Retaining Sleeve 1

2 ZD13 Hot Tip Desoldering Tip 1

3 HT01 Hot Tube 1

4 AC737 Accumulator Bushing 1

5 MS229 Mica Sheet 1

6 OS133 Silicone Washer 1

7 SC525 Solder Cone 1

Page 14

QTY

REQ'D

ITEM

NO.

PART NO.

DESCRIPTION

8 AF625 Felt Filter 1

QTY

REQ'D

9 SR148 Housing for End Cap 1

10 OS731 O-Ring for End Cap 1

11 OS132 O-Ring for End Cap Elbow Connector 1

12 SR147 Connector for End Cap 1

13 FC639 End Cap 1

14 SR008 Flat Head Slotted Screw for Index Flange 1

15 SR168 Pan Head Phillip Screw for adjusting Desoldering Head Assy. 1

16 HT500H Desoldering Head Assembly- Repairable by EDSYN Customer Service Dept. 1

17 SR136 Desoldering Head Housing 1

18 SR120 Heater Element 1

19 SR117 Heater Element Bushing (O-Ring included) 1

20 SR118 Retaining Key for Heater Element Bushing 1

21 SR119 Teon Spacer for Heater Element 1

22 OS731 O-Ring for Heater Bushing 1

24 SR121 Grounding Wire 1

25 SR122 Screw, 2-56 x 1/8 Pan Head Slotted 3

26 SR145 Sleeving, Braided Fiberglass 2

27 SR004 Handle Cover 1

28 SR124 Head Shaft 1

29 SR125 Spring for Head Shaft 1

30 SR126 Washer, Nylon 2

31 SR127 Retaining Nut for Head Shaft 1

32 SR128 Trigger 1

33 HL603 Hose, Low Static Silicone, 3/16" I.D. 5"

34 SR335 Valve Assy. 1

35 SR393 Nut, Retaining, for Handle 1

36 OS730 O-Ring Set (Three O-Rings) 1 set

37 SR129 Valve Housing 1

38 SR130 Poppet (O-Ring Included) 1

39 SR131 Return Spring for Poppet 1

40 SR132 Seat for Return Spring 1

41 SR133 Wire Nuts 3

42 SR134 Hose and Wiring Assembly for HT500 1

SR565 for HT500-1 SR635 for HT500-2

43 SR123 Handle Base 1

44 SR143 Wire Guide, Nylon, 3/8" Length 2

45 SR005 Index Flange (Screw Side) 1

46 SR006 Index Flange (Nut Side) 1

47 SR007 Nut, Hex, 2-56 thread 3

48 SR135 Connector for HT500 1

SR353 for HT500-1 SR633 for HT500-2

49 SR170 Cap Nut, Hex #8-32 x 5/16" 1

50 SR169 Washer, Flat, 1/16" thick 1

Page 15

ZD500DX instruction manual

NO PART OF THIS PUBLICATION INCLUDING THE INDIVIDUAL ICONS

MAY BE REPRODUCED OR UTILIZED IN ANY FORM OR BY ANY MEANS

THE NAMES LONER, SOLDAPULLT, SOLDAVAC, ATMOSCOPE

Intellectual

Property

TIP STYLE ON SOLDERING, DESOLDERING AND HOT AIR TOOLS MAY VARY.

WITHOUT THE PERMISSION OF EDSYN, INC.

AUTO-VAC, IDLE-REST, OCTAVAC AND KLATCH

ARE REGISTERED TRADEMARKS OF EDSYN, INC.

MOST PRODUCTS ARE COVERED BY U.S. AND

FOREIGN PATENTS AND PENDING APPLICATIONS.

SUBJECT TO CHANGE WITHOUT NOTICE.

ALL RIGHTS RESERVED.

DESIGN, COLOR AND MATERIALS

PRINTED IN U.S.A.

©Copyright EDSYN, Inc. 2002

ZD500DXi .pdf

FORM.937 Rev C

Loading...

Loading...