951SX

LONER®

Temperature Controlled

Soldering Station

• COMPLIES WITH MIL-S-45743E, MIL-STD-2000-1B, WS6536E AND

ESD SPEC, DOD-STD-1686, DOD-HDBK-263

• UL listed

Instruction manual

made

in

U S A

Specications for Model 951SX

Power Requirements 120V, 60 Hz

Power Rating 15W - 220W

Heater Rating 120V, 95W

Temperature Range 400°F-800°F/205°C-427°C

Temperature Regulation ±6°F/±3°C

Tip-to-Ground Voltage

Leakage/Resistance < 2mV/< 2 ohms

Overall Dimension 4.1"W x 8.2"H x 10"D

104 mm x 208 mm x 254 mm

Weight 2.5 lbs/1.1 kg

Contents

951SX includes 1 - LT375 Soldering Tip

PD528 Tool Pod

SH230 Sponge Holder

(Includes RS199 Cleaning Sponge,

RS243 Leveling Pad, LN230 Liner)

WP556 WIGAPRY Low Static Computer Aid

Static Safe

Temp.

Regulation

Indicator

Power Switch

SH230

Sponge Holder

PD528 Tool

Pod

Calibration Pots for HI & LO Temp.

Hollow Threadless Heater

WARNING:

DO NOT HIT OR TAP THE SOLDERING TOOL. THE HEATER ELEMENT WILL BREAK!!!

MAINTENANCE

• Replace RS199 Cleaning Sponge

1. Fill water only up to the top of the RS243

Leveling Pad.

2. Depress RS199 to moisten it completely.

RS199

RS243

LN230

SH230-1

CAUTION:

Over-lling can cause thermal shock

to the tip or heating element during

tip cleaning.

• Replace SC581 Solder Collector

1. Hold the Housing rm and turn Cap

counter-clockwise and pull it away from the

Housing.

2. Remove used SC581 and replace with

a new one.

3. Reassemble Pod with TOP of the Cap in

proper position.

SR042

Thermal

Housing

SC581

Solder Col-

lector

SR043

Front Hous-

ing

TIP CLEANING

To maintain proper Tip to Ground resistance.

1. Remove Tip from Heater Assembly.

2. Using a ST707 Soldering Tool Maintenance Brush, clean Tip and Heater Barrel

at surfaces shown.

3. Install the tip and tighten RS372 Retaining Sleeve. Take note of the gap to ensure

proper tting.

clean these areas

ST707

gap

TIP CARE

1. Set desired temperature. Blinking Neon Lamp means Tool is ready.

2. TIN the Tip. (apply solder)

3. Do not rub, bend or reshape the Tip.

4. Always clean the Tip by wiping it against the saturated sponge and always RE-TIN.

TEMPERATURE CALIBRATION

1. Turn on power and set Temperature Control Knob to 400°F (205°C).

2. Using a clean and well tinned Tip, apply a small amount of solder on the Tip, just enough

to form a bead on top of the Tip.

3. Place the center of the thermocouple wire of the SDS100 on top of the bead.

4. Again, apply a small amount of solder on the center of the thermo-couple wire, just enough

to embed the center.

5. Adjust LO-Temp. Calibration Pot so the Meter will read 400°F (205°C).

6. Set Temperature Control Knob to 800°F (427°C).

7. Adjust Hi-Temp. Calibration Pot so the Meter will read 800°F (427°C).

MS412

TemperatureCalibration System

FX635

METER

SDS100

CHANGING TIP

DO NOT USE the soldering tool if soldering tip is loose. This will cause the heater element to break.

1. MAKE SURE YOUR TOOL IS COOL!

2. Turn Retaining Sleeve counter-clockwise to remove.

3. Remove old Soldering Tip.

4. Insert new Tip.

5. Install Retaining Sleeve. (should be "nger" tight only.)

Retaining Sleeve

Soldering Tip

Iron Plated for long life•Nickel and Chrome Plated for optimum heat transfer

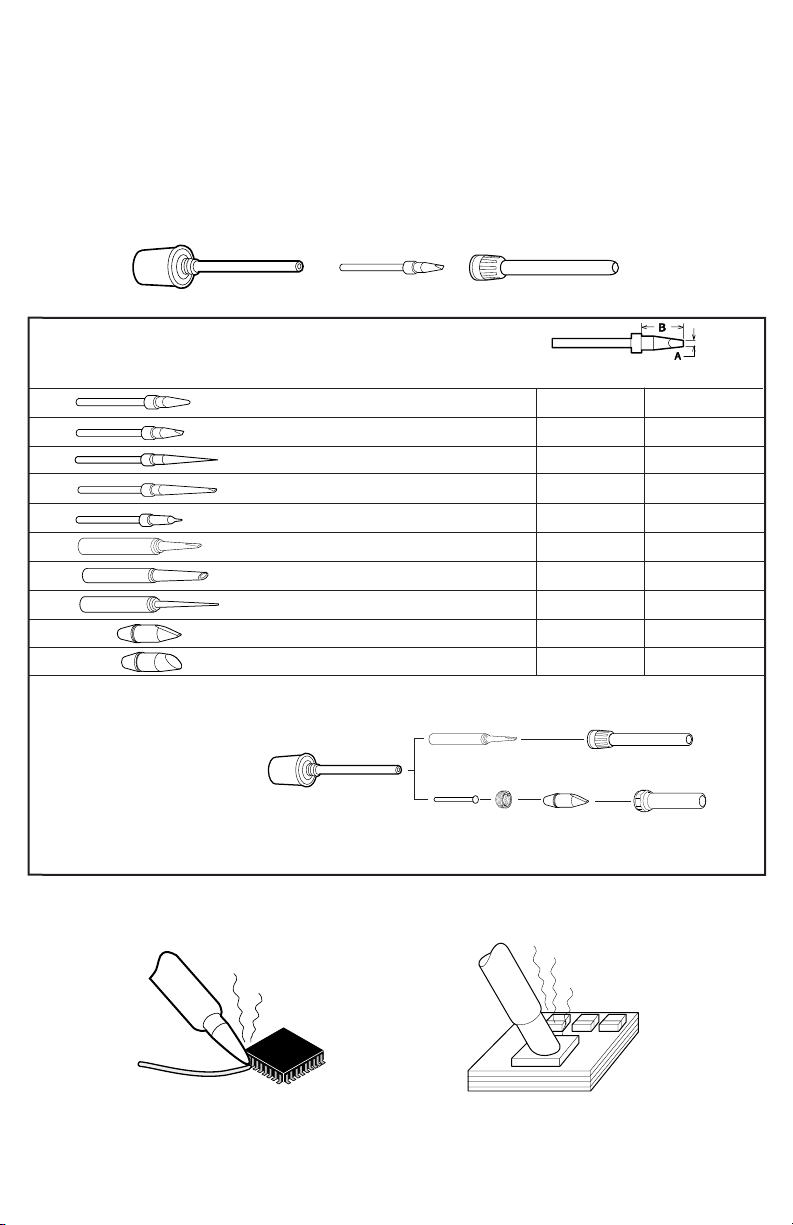

SOLDERING TIPS

CONTACT EDSYN FOR MORE SELECTIONS

LT374 Standard Probe

LT375 Standard Spade

LT392 Extra-Long Needle Point

LT394 Extra-Long Spade

LT446 SMD Probe

LT337BC Heavy Duty Terminal Spade

LT223BC Heavy Duty Fine Spade

LT222BC Extra long Needle Point

LT153BH Jumbo Spade

LT155BH Jumbo Angle Spade

SET-UP & REQUIRED ACCESSORIES FOR HEAVY DUTY AND JUMBO TIPS

Apply

AN112 or AN122* Anti-Seize

Compound

to Heater and area of Tip contact.

RS372- for General Purpose Tip

RS271- for Heavy Duty Tip

"BC"

HEAVY DUTY TIP

AC735

A

.03 (0.8 mm) .48 (12.2 mm)

.06 (1.5 mm) .48 (12.2 mm)

.02 (0.5 mm) 1.13 (28.8 mm)

.07 (2.0 mm) .93 (23.6 mm)

.03 (0.8 mm) .48 (12.2 mm)

.10 (2.5 mm) .74 (18.8 mm)

.06 (1.5 mm) 1.21 (30.7 mm)

.04 (1.0 mm) 1.21 (30.7 mm)

.20 (4.9 mm) .93 (23.6 mm)

.32 (8.3 mm) .97 (21.1 mm)

RS271

JUMBO

TIP

RS351

B

*AN122 Anti-Seize Compound comes in syringe dispenser.

Fine point tip for

SMD soldering.

Large and heavy tip for

heavy duty soldering.

1A

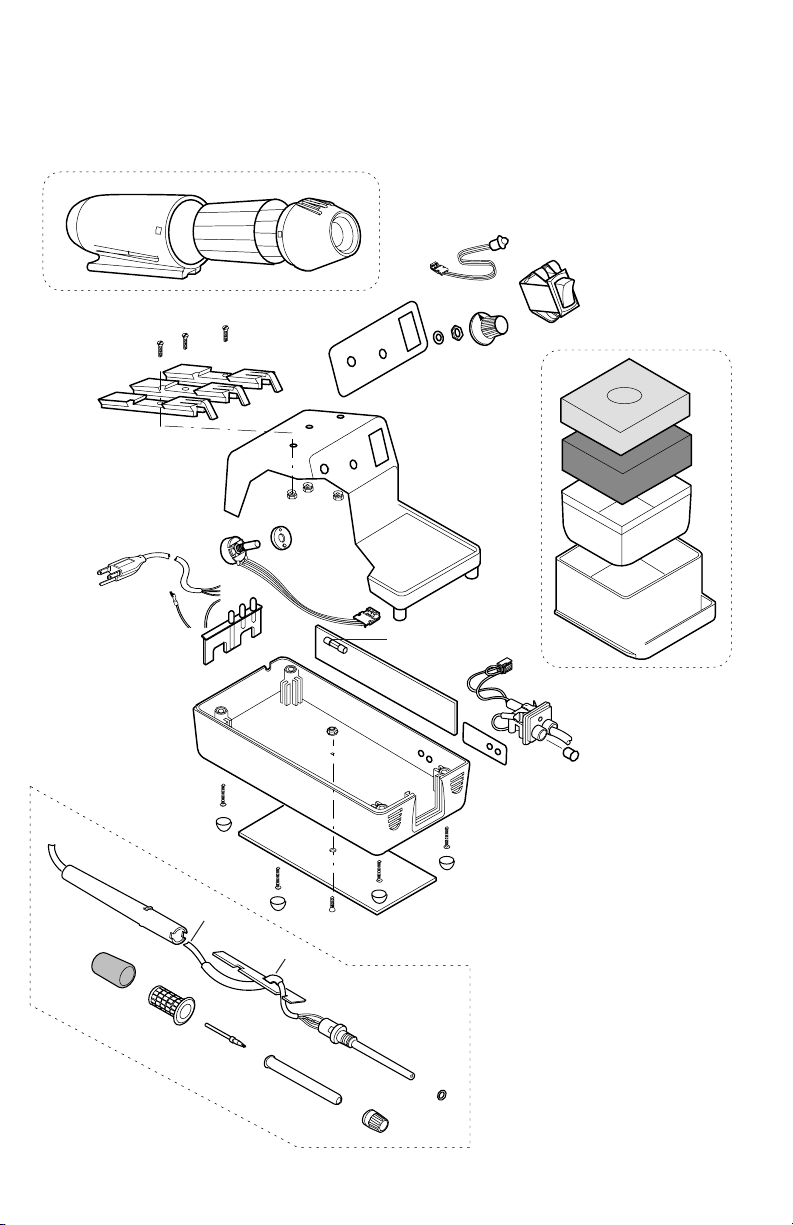

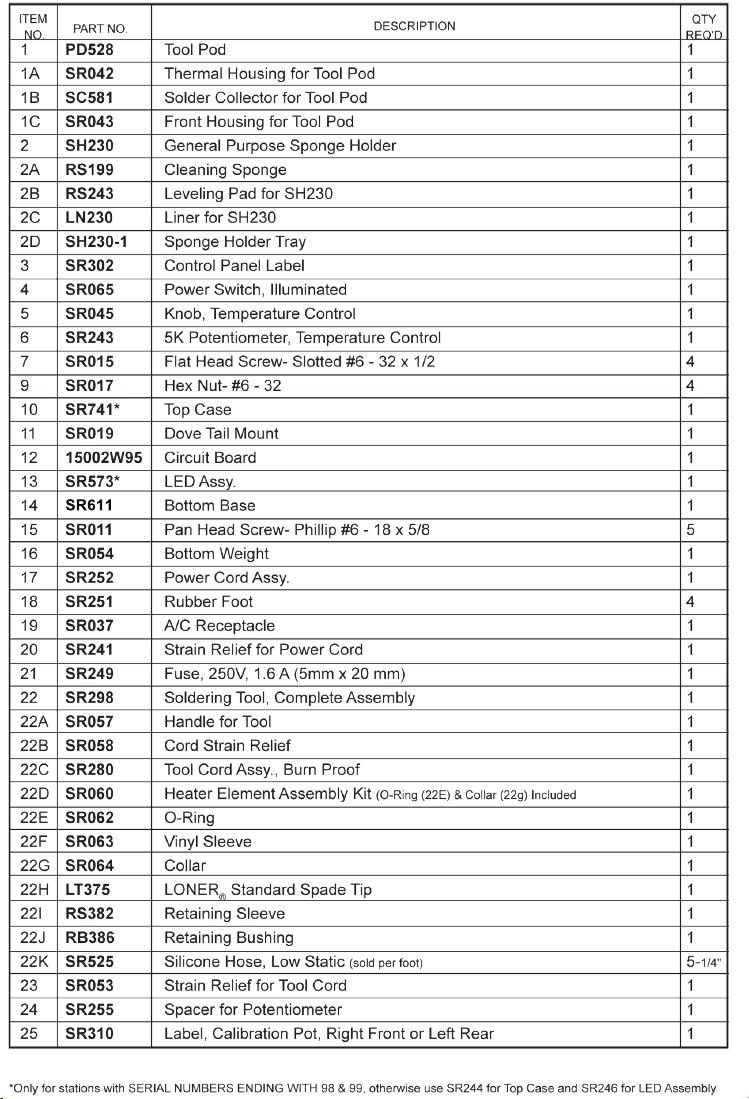

951SX LONER® SOLDERING STATION

SPARE PARTS LIST

1

13

1B

1C

4

11

22A

17

7

5

3

10

9

24

6

20

9

14

21

12

23

15

18

25

19

23

2

2A

2B

2C

2D

22F

22G

22C

22H

22B

22I

7

16

22

22D

22E

22J

SR611

951SX instruction manual

NO PART OF THIS PUBLICATION INCLUDING THE INDIVIDUAL ICONS

MAY BE REPRODUCED OR UTILIZED IN ANY FORM OR BY ANY MEANS

THE NAMES LONER, SOLDAPULLT, SOLDAVAC, ATMOSCOPE

AUTO-VAC, IDLE-REST, PIXTER, FUMINATOR, OCTAVAC AND KLATCH

Intellectual

Property

TIP STYLE ON SOLDERING, DESOLDERING AND HOT AIR TOOLS MAY VARY.

WITHOUT THE PERMISSION OF EDSYN, INC.

ARE REGISTERED TRADEMARKS OF EDSYN, INC.

MOST PRODUCTS ARE COVERED BY U.S. AND

FOREIGN PATENTS AND PENDING APPLICATIONS.

SUBJECT TO CHANGE WITHOUT NOTICE.

ALL RIGHTS RESERVED.

DESIGN, COLOR AND MATERIALS

PRINTED IN U.S.A.

©Copyright EDSYN, Inc. 2002

951SXi .pdf

FORM.655 Rev G

Loading...

Loading...