Edsal 8000 User Manual

Quick Assemble Storage Cabinets

(A) Right Hand Back

(B) Left Hand Back

(C) Right Hand Side

(D) Left Hand Side

(I) Right Hand Door

(J) Left Hand Door

MODELS

RTA8000

-

1UFE2

-

RTA8000

RTA8000

RTA8005

RTA8005

RTA8005

(L) Kick Plate

(N) Anchor Hardware

(suggested type of hardware, NOT

ALL UNITS ARE SUPPLIED)

1UFE1

-

1UFE2

-

1UFE1

-

1UFE2

-

1UFE1

-

1UFE4

-

1UFE3

-

1UFE4

-

1UFE3

-

1UFE4

-

1UFE3

(M) Handle

Page 1

(K) Door Rods

(H) Shelf Clips

(E) Top

Safety Instructions

Safety Instructions

Safety Instructions

(F) Bottom

(G) Shelves

Required Tools

Required Tools

Required Tools

- Rubber Mallet

- Small Blade Screwdriver

- Small Philips Screwdriver

(handle assembly)

Use Caution when handling and assembling metal parts. The metal may have sharp edges or corners. The

use of protective gloves is recommended. This unit should be securely anchored to a wall with suitable fasteners. Do not use this unit for anything that is outside the designed function of storage. Do not store loose

or heavy items on the top shelves or on the top of the unit, for they create a falling hazard that can injure

yourself or others. Always remember to use proper lifting techniques when moving either the boxed or assembled unit.

General instructions

General instructions

General instructions

It is recommended that the cabinets are assembled by more than one person. The use of a raised flat surface during assembly is highly recommended. During shipping and handling, some of the tabs that are used for assembly

may have closed together. Use a flat tipped screwdriver to either pry up or push from behind the tab to re-open.

Make sure that the unit is placed on a level surface, as this may effect the performance of the unit.

Part List & Product Specification

Part List & Product Specification

Part List & Product Specification

Reference

Reference

Reference

A

B

C

D

E

F

G

H

J

K

L

M

N

I

(patent pending)

(patent pending)

(patent pending)

Description

Description

Description

Right Hand Back

Left Hand Back

Right Hand Side

Left Hand Side

Shelf Clips

Right Hand Door

Left Hand Door

Door Rods

Kick Plate

Anchor Hardware

(IF SUPPLIED)

Bottom

Shelves

Handle

Top

4 Shelf

–

78” h x 18” d x 36” w

4 Shelf

–

78” h x 18” d x 36” w

4 Shelf

–

78” h x 18” d x 36” w

RTA8000

-

1UFE2

-

RTA8000

RTA8000

1

1

1

1

CBBK7818R KA

CBBK7818L KA

CBSD7822R KA

CBSD7822L KA

1

1

4

8

1

CBDO7318R KA

1

CBDO7318L KA

2

1

1

2

1UFE1

-

1UFE2

-

1UFE1

-

1UFE2

-

1UFE1

CBTO3922 KA

CBBO3718 KA

CCSH3719

7000CLP

CCDR3625 KA

CBKP3606 KA

201L

TB2

4 Shelf

–

78” h x 24” d x 36” w

4 Shelf

–

78” h x 24” d x 36” w

4 Shelf

–

78” h x 24” d x 36” w

RTA8005

RTA8005

RTA8005

1

CBBK7818R KA

1

CBBK7818L KA

1

CBSD7828R KA

1

CBSD7828L KA

1

1

CBTO3928 KA

CBBO3724 KA

4

8

1

CBDO7318R KA

1

CBDO7318L KA

2

1

CCDR3625 KA

CBKP3606 KA

1

2

-

1UFE4

-

1UFE3

-

1UFE4

-

1UFE3

-

1UFE4

-

1UFE3

CCSH3725

7000CLP

201L

TB2

Should you have any comments, damage, missing parts, or problems with assembly of this unit please feel free to contact our Edsal

manufacturing facility at, (773) 475-3000 and reques t customer service. W e can also be reached on the internet at t he following e mail

To obtain replacement part s, please provide the fol lowing information :

- Model # - Part # & Description - Location Purchased - Date Purchased

address : customers ervice@edsal.com.

Consumer Products Division

Edsal Manufacturing Company

4400 South Packers Avenue

Chicago, IL 60609

www.edsal.com

Made In China

Assembly Instructions : Edsal 8000 Series Quick Assemble Storage Cabinets Page 2

Assembly Instructions : Edsal 8000 Series Quick Assemble Storage Cabinets Page 2

Assembly Instructions : Edsal 8000 Series Quick Assemble Storage Cabinets Page 2

Important Please Read First

Important Please Read First

Important Please Read First

This instruction sheet was designed to help you assemble this unit in the proper way, please follow them using all

parts and fasteners provided. Any alteration or deviation from this instruction sheet can result in unit failure. If

you have any assembly problems or questions, please feel free to contact our Edsal manufacturing facility at

(773) 475-3000 during the hours of 9:00 a.m. to 5:00 p.m. central standard time and ask for customer service.

We have people available to assist you if need be with any part of this assembly process.

IT IS HIGHLY RECOMMENDED TO ASSEMBLE THIS UNIT AT EYE LEVEL, AND WITH THE HELP OF AN

ADDITIONAL PERSON. Using a RAISED surface such as a TABLE or DESK, will greatly EASE the ASSEMBLY

PROCESS. Assembly attempted on a much lower surface such as the floor, is still possible but does make the

assembly process longer and harder. During the shipping and handling of this product, some of the panels may

have a MINOR bend such as on a corner, door hinge pin, or a tab. This minor variation can be REPAIRED SIM-

PLY by using a SMALL TOOL or your HAND to move the material back to its designed form. A example will be

outlined in the “GETTING STARTED” section listed below. Some of the materials used in the packaging to protect the parts from damage may leave dust or smudges on the steel panels. It is RECOMMENDED AFTER AS-

SEMBLY IS COMPLETE to use a MILD SOAP and WATER with a SOFT CLOTH to wipe the unit clean, and

use the SUPPLIED OR SUITABLE FASTENERS to PROPERLY SECURE this unit to a WALL.

Getting Started

Getting Started

Getting Started

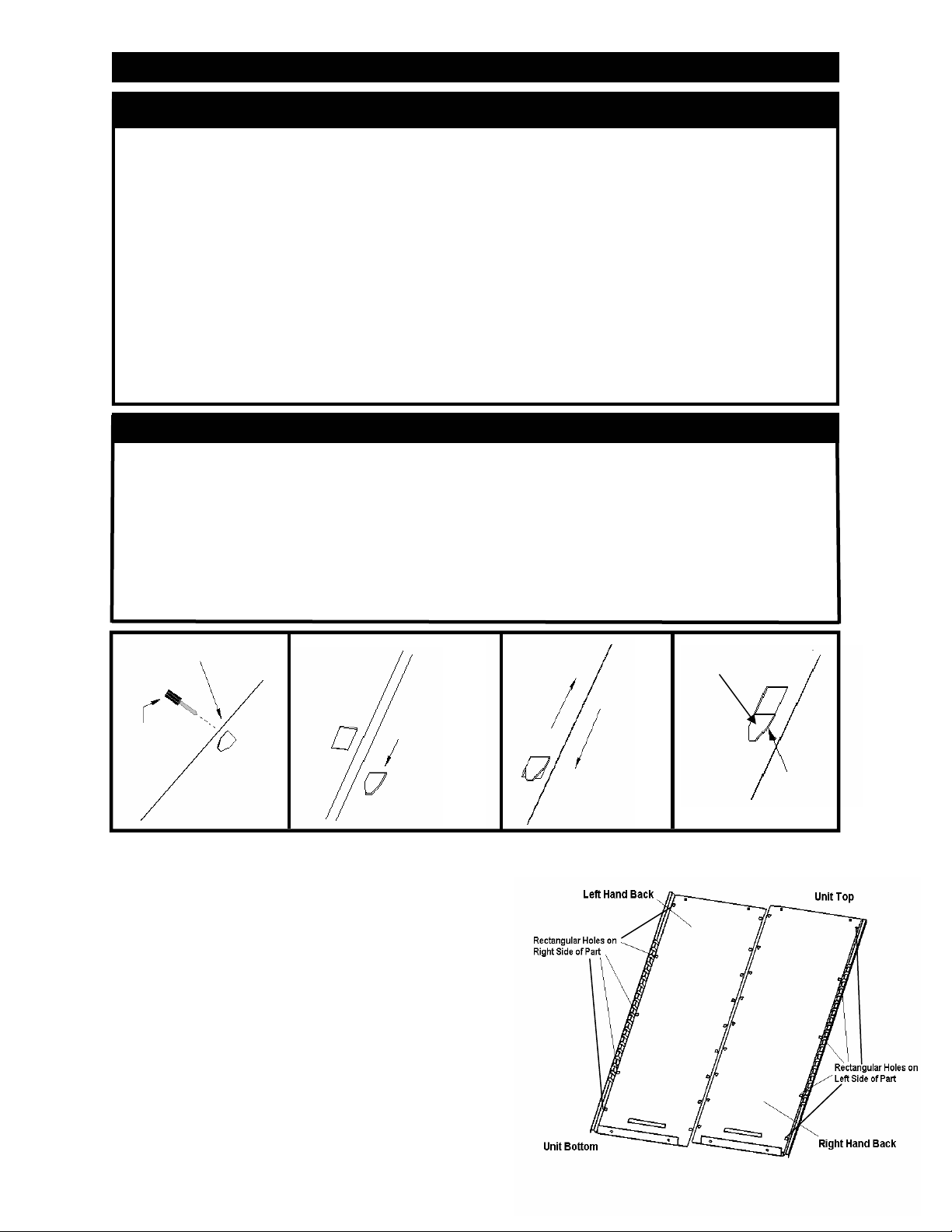

The assembly process uses tabs, notches, rectangular, and square holes to hold the parts together. To

speed the assembly process, have a rubber mallet, small blade screwdriver, and a small phillips screwdriver

ready. After unpacking all the panels, visually inspect the corners. These are the most susceptible to damage through the shipping and handling process. If you find a corner bent out of place, use your hand and

gently move the corner back to the designed shape. Also during shipping and handling some of the tabs

used for engaging the panels together may have become closed. Visually inspect all panels and if found that

some are closed, use a small blade screwdriver to push the tabs from behind to open slightly (it is recommend to push tabs out slightly for ease of assembly, and then tap back down with a rubber mallet, to tighten

engagement). A example of pushing the tabs out and how the engagement process works, is shown below.

Push tab slightly

from back side

to open

Piece with tab

goes under piece

with rectangular

Small blade

screwdriver

hole

Step 1 - Back Assembly

Place the left and right hand backs on a level surface.

Position the parts so that all the tabs are facing up.

Place the part with the rectangular holes (left hand back)

over the part with the tabs (right hand back). Making

sure the tabs ride into the rectangular holes, slide the

backs together. Check to make certain that all the tabs

and rectangular holes have engaged completely, then

tap the tabs down for a tight engagement (see figure 1

for references).

Slide part

Tap tab with rubber

mallet to tighten

engagement

Slide part

Figure 1– Back Assembly

Tab fully engaged

Loading...

Loading...