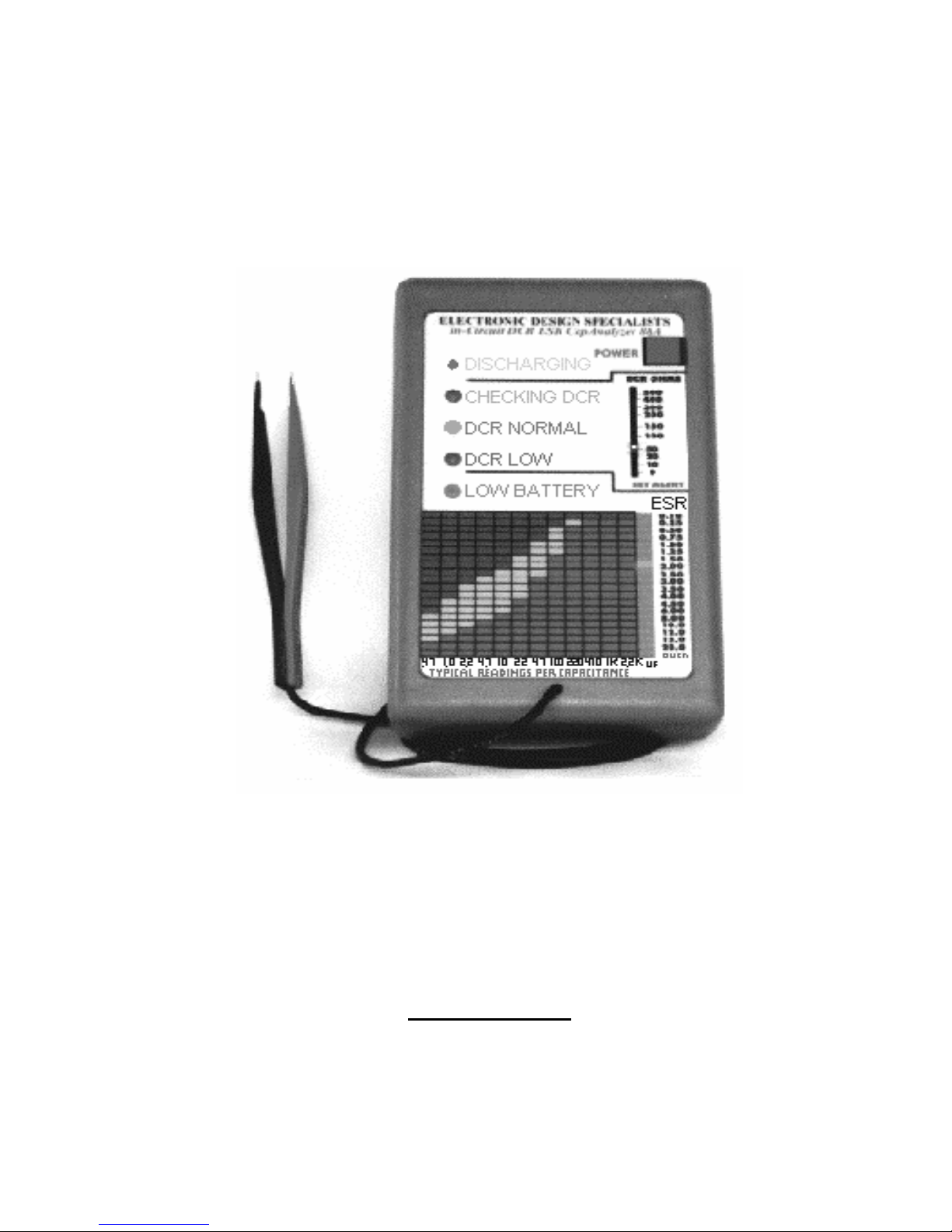

EDS CapAnalyzer 88A Series II, EDS-88A Operating Instructions And Owner's Manual

EDS-88A

CapAnalyzer Series II

In-Circuit Electrolytic Capacitor DCR/ESR Tester

OPERATING INSTRUCTIONS

and

OWNER’S MANUAL

©EDS-Inc 1997-2018

For Technical Assistance

parts or FAQs go to

www.eds-inc.com

TROUBLESHOOTING CAPACITOR-

RELATED PROBLEMS

using the CapAnalyzer 88A

ATTENTION: THIS UNIT IS DESIGNED TO CHECK ELECTROLYTIC

CAPACITORS IN OR OUT OF CIRCUIT WITH POWER DISCONNECTED FROM

THE CIRCUIT UNDER TEST. IF THE UNIT UNDER TEST IS POWERED UP,

THE POWER WILL BACKFEED INTO YOUR CAPANALYZER AND DAMAGE

BOTH UNITS!

DO NOT ATTEMPT TO BEND THE TWEEZER PROBE ENDS, THEY ARE

HARDENED BERYLLIUM COPPER AND WILL SNAP OFF.

Troubleshooting and locating defective electrolytic capacitors has been a thorn in the

side of all technicians for many years. The CapAnalyzer 88A will help solve problems

caused by electrolytics in audio, video, power supply, and system control circuits. This

manual will also show how to locate these bad capacitors easily without having to unsolder

and test, or cut up the pc board, and without needing the service manual, by using

specialized test equipment specifically designed to make you more productive. Although

you will have to unlearn your old-fashioned, slower methods, those who will be progressive

enough to learn these tricks will have much more time on their hands to spend with their

family and friends.

There are several ways a capacitor can fail. High temperatures usually cause electrolytics to

dry up. In high-frequency circuits such as digital pulse-width power supplies, the capacitors

tend to leak. In low-voltage circuits such as system control and low-voltage supplies,

capacitors tend to short, partially or completely. Therefore, the technician must first check

all electrolytics for DCR (DC Resistance) shorts or leakage, then check for physically leaky

or dried-up capacitors by measuring high-frequency ESR (Equivalent Series Resistance).

These methods will not require a soldering iron, a service manual, or any cutting tools. It

will require some logical reasoning, good eyesight, and some specialized equipment; your

$29 DVM won't help you find the tough dogs. With the CapAnalyzer 88A (and the

LeakSeeker 82B or LeakSeeker 89), hours can turn into minutes, and repairs that were once

considered "no-fixers" can now be profitable.

DRIED UP and PHYSICALLY LEAKY CAPACITORS

As a capacitor dries up internally, it can become electrically leaky. As the cap dries up, it

can cause strange problems in the particular circuit it is in. For example, in the TV's vertical

section, it can cause vertical overlap, insufficient vertical, too much overscan, or non-linear

scanning. If the cap is in the power supply, jail bars or "hairy" interference may ride on the

2

video and power semiconductors can keep failing. In the audio section it can cause

distortion, feedback or low audio. In the system control supply it can cause intermittent

functions and microcontroller confusion, shutdown, even a blank display. In the video

circuits it can cause incorrect colors, distortion, even a fully scrambled picture.

Usually, the problem will be less noticeable if the unit is left on for some time. That's

because a dried-up capacitor will usually decrease its ESR with higher temperature.

Other consumer electronic components can also have these problems, but with a different

culprit: surface mounted capacitors. Most camcorders, VCRs, and big screen TVs now use

surface mounted electrolytic capacitors in modules. In VCRs, they are usually in the sound

MPX decoder module. In big screen TVs, they can be in the sound module and in the video

PIP and video convergence circuits as well. In camcorders they are everywhere, usually

showing up as varying speeds if they are in the servo circuits, color or sync problems if in

the video, and low, distorted, or missing audio if in the audio circuits.

Most technicians already know these symptoms, and have an idea where on the board to

start. The first step is visual observation; vacuum all debris off of the board and look for

dark areas under each cap, for bulging tops, and for splitting vinyl covers. On surface mount

caps, look for the solder connections under the cap to have a cloudy look. After replacing

the obviously defective caps, it is important to clean the board with a stripper solvent and to

check all local feedthroughs, as these type of capacitors leak an acidic electrolyte that loves

copper!

After visual observation and replacement of the obvious offenders, it will be necessary to

measure the rest of the caps. The problem of measuring each capacitor is more difficult than

measuring resistors, which can be measured in circuit quite easily with any cheap DVM.

That is because any circuit that encompasses an electrolytic already has some DC resistance

and some capacitance from other parts of the circuit. Some "capacitor checkers" claim to

work in circuit, but since they actually measure circuit capacitance and resistance, they give

such erroneous readings that caps usually have to be unsoldered and re-measured out of

circuit anyway. In fact, even some of the most expensive capacitor meters (over $2000) will

not always measure capacitors accurately in circuit. Some meters measure the capacitance at

two different frequencies, and show it as two different readings. Most ESR meters will show

a partially or fully shorted cap as "perfect".

Speaking of "ESR" meters, their designers already know that the trick to locating bad

capacitors in circuit is not to measure capacity at all! Years of testing by many technicians

and engineers has shown that as a capacitor ages, its Equivalent Series Resistance increases.

What is ESR? Without going through the math, a perfect capacitance will measure as an

3

Loading...

Loading...