EDPAC Close Control 6, Close Control 12, Close Control 18 Installation, Operation & Maintenance Manual

Page 1

Close Control

Small System Range

Chilled Water Units

Installation, Operation & Maintenance Manual 50/60Hz

Page 2

2

INSTALLATION OPERATION & MAINTENANCE MANUAL

Index

Description

Page

INSTALLATION

General

3

Mechanical Installation

4

Water and Drain Connections

5

General Engineering Data

6

Electrical Connections

7

OPERATION

General

EC Fan910

Heating Operation

11

Cooling Operation

11

Dehumidification Control

12

Humidification Cycle

12

PGD Details

14

Alarms

15

MAINTENANCE

General

18

Common Components

18

Electric Panel – Inspection & Functional Tests

19

Steam Humidifier Canister Cleaning & Removal

20

Fault Finding Guide

21

Monthly Maintenance Inspection Check

23

Annual Maintenance Inspection Check

24

While every precaution has been taken to ensure accuracy and completeness in this manual, EDPAC assumes no responsibility, and disclaims all liability

for damages resulting from use of this information or for any errors or omissions. Document reference E4.19-02-06-04

Page 3

3

GENERAL

On receiving the equipment it should be checked to ensure that it is complete and in perfect condition. The carrier should be notified

immediately, in writing, of any damage that might have been caused in transit.

HANDLING

Always keep the unit vertically upright and do not leave it out in the open. The unit can be moved with a pallet truck. If a forklift is

being used ensure the forks extend beyond the pallet. Care should be taken not to damage the bottom of the unit. If a crane is being

used to move the unit leave the packaging intact and place spreader bars across the top of the unit to prevent the slings causing

damage. The unit should be moved as near as possible to the installation position before removing the cardboard packing and the

pallet.

UNPACKING THE UNIT

1) Cut the three straps binding the unit taking care to avoid any backlash caused by their tightness.

2) Remove the lid.

3) The cardboard sleeve will then unravel itself revealing a plastic dust cover.

4) Remove dust cover. If it is a downflow model, to remove the front panels use the key attached to the sensor on the top of the unit.

5) Remove the two bolts securing the unit to the skid (19 mm spanner).

6) Manoeuvre the unit carefully from the pallet. If it is necessary, use rollers underneath the unit to locate it in its final position.

7) If the unit requires a plenum fix same before final positioning.

8) Ensure the unit is positioned on a level floor.

POSITIONING

Single Circuit Units.

The Modular Range is built on a level base and its positioning is most important. The unit should be firmly supported on the floor

itself or on an optional floorstand.

Ensure that the unit is level in all directions as failure to do so will result in operational problems, particularly with regards to

drainage. Care should be taken in manoeuvring the unit as the paintwork could be damaged. Use rollers where possible and apply

pressure to the bottom of the unit for final positioning. Before final positioning ensure that inaccessible panels are correctly fitted and

plenums are secured.

ATTACHING THE PLENUM

The plenum and unit are pre-drilled. At the time of installation remove the grilles from the plenum and secure the plenum internally by

means of self tapping screws provided. Also secure to the back of the unit.

AIR COOLED CONDENSERS

Locate these as close to their final position as possible before uncrating. A full set of assembly instructions are attached to the unit.

Headers and return bends are not to be used in the moving of the condenser.

When locating the condenser ensure that it is in an open area with unrestricted airflow shaded from direct sunlight.

Install in an environment free of debris to avoid the fins becoming blocked.

Ensure that some form of vibration elimination is installed between the condenser legs and the roof of the building.

Condensers are not to be ducted on either side.

Where noise is critical in relation to the condenser make ensure that this is clearly specified at the time of order.

INSTALLATION

Page 4

4

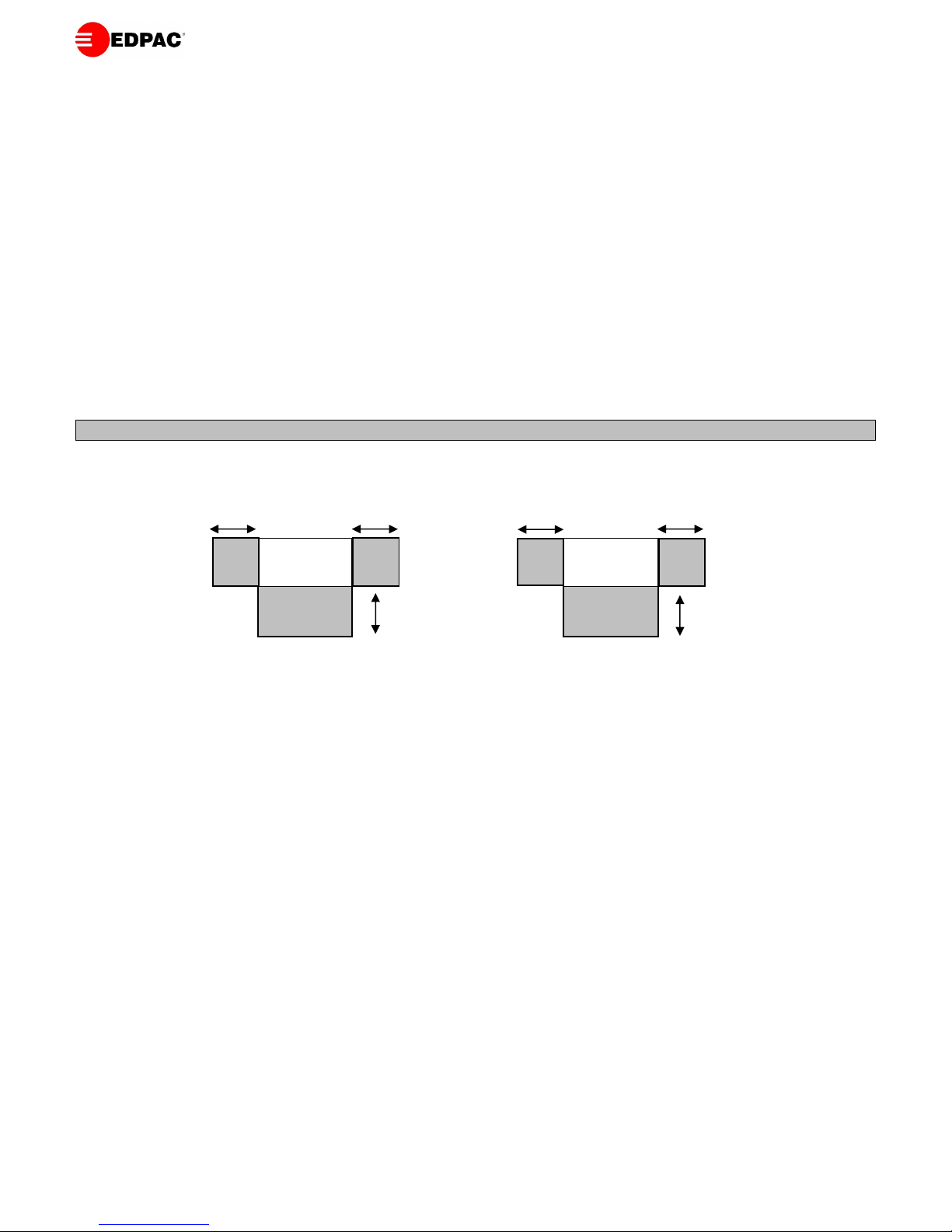

SERVICE ACCESS

Downflow Units

Service of a downflow unit can be generally completed from the front of the unit. To remove certain components from the unit it may

be easier and quicker to have side access to assist in these operations.

When positioned there should be a minimum clearance in front of the unit of 0.6m. If it is feasible, leave a distance of 0.6m at the

side of the unit. Access to the back of the unit is not necessary. It is strongly recommended to leave a distance of 0.6m at both sides of

the unit. There is a minimum distance of 150mm needed above the unit to allow removal of the filters.

Upflow Units

Unlike the downflow, side access is necessary for servicing the upflow. When installing ensure the left-hand side of the unit has access

for the purpose of servicing, especially the motor. On the small frame the motor is actually mounted 'piggy-back' on the blower and on

the mid and large frame the motor is located on the left-hand side of the blower

Access to the back of the unit is not required. It is strongly recommended to leave a distance of 0.6m at both sides of the unit. The

filters are located in the bottom front panel; a minimum distance of 1m is needed to allow the return air to enter the unit.

Space above the unit will be determined by location. If a standard plenum is being installed the overall height of the unit is extended

to 2380mm.

MECHANICAL INSTALLATION

SYSTEM APPLICATION

To achieve maximum performance and efficient energy usage following considerations should be given:

1) The room should be sealed effectively against air and vapour to minimise the loss and infiltration of uncontrolled humidity through

concrete slab, walls, ceiling, roof, doors or any other opening or aperture.

2) Room location and orientation should be considered with regard to heat load and external variables should be reduced to a

minimum.

3) The room should be kept at a positive pressure by introduction of pre-treated fresh air.

4) Low resistance to conditioned air distribution can be achieved by providing the maximum raised flooring height, minimum cable

bunching and correct position of pipework (i.e. parallel to air flow).

5) Pipework that is not isolated or is fastened inadequately can transmit vibration along its full length.

Room Unit

Downflow Small System Unit

Service Access

600

Room Unit

Upflow Small System Unit

Service Access

600

600

Page 5

5

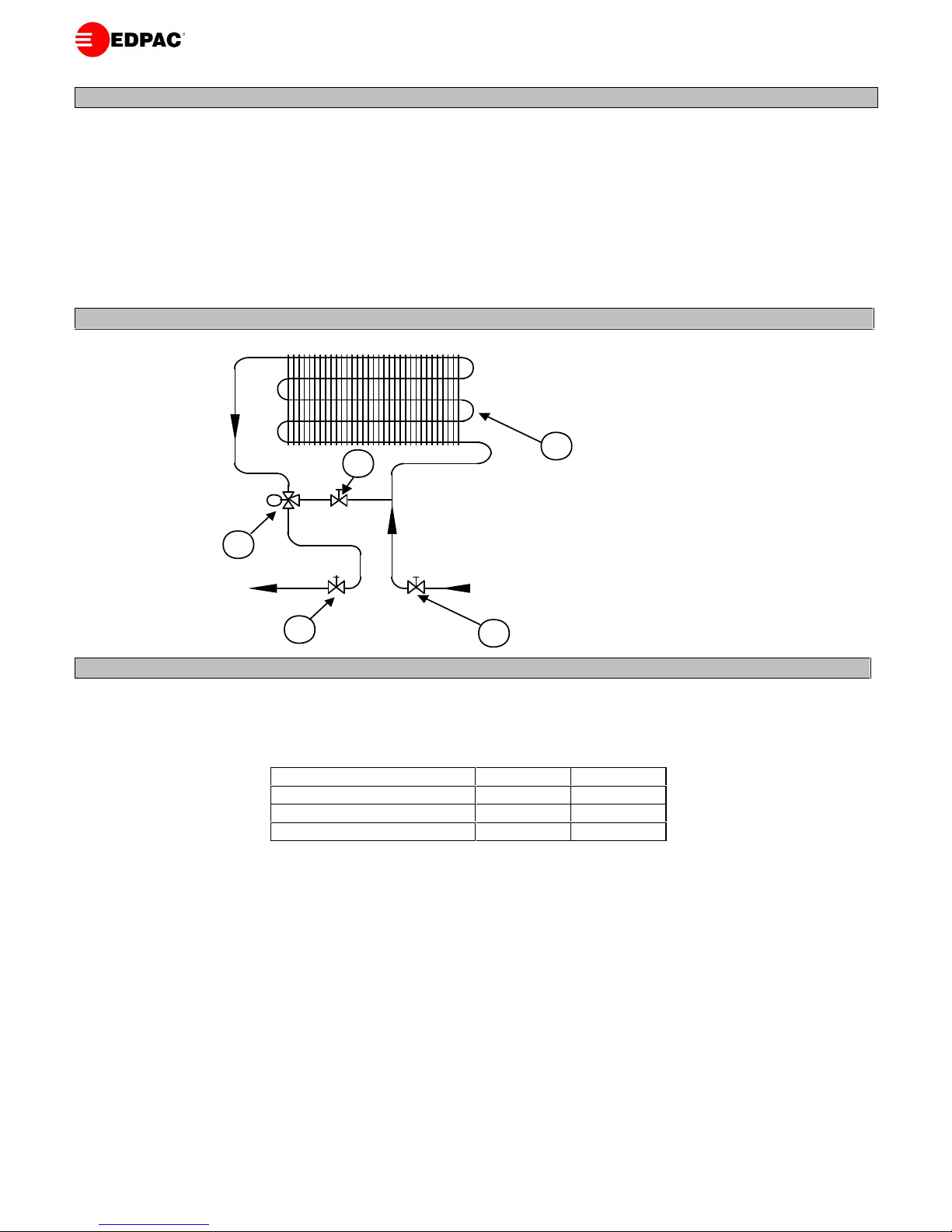

CHILLED WATER UNITS

CHILLED WATER PIPING CONSIDERATIONS

Chilled water units are shipped with the flow and return pipes terminated with soft solder caps. The complete system is pressurised to

75psi with dry nitrogen. This pressure should be rechecked and discharged before caps are unsoldered. Supply and return pipes are

clearly marked. Check the site piping to ensure that the flow is in the proper direction.

The maximum allowable static pressure for the chilled water circuit is 1000kPa. If static pressure exceeds 1000kPa special valves

should be installed. Consideration of the minimum water temperature to be supplied from the chiller will determine if the need exists

to insulate the supply and return lines.

It is recommended that isolating valves be field fitted on both flow and return lines from the unit for isolation and maintenance

operations. Automatic air bleed valves should also be fitted in appropriate locations.

GENERAL ARRANGEMENT DRAWING

System Components

1. Evaporator Coil.

2. Balancing Valve

3. 3 Way Modulating Valve

4. Isolating Valves

Note: Item 4 is field fitted by others.

WATER AND DRAIN CONNECTIONS

WATER SUPPLY

Water is fed from the mains supply to the humidifier inlet solenoid valve. The connection to the solenoid valve is a 3/4” male

connection. The feed water characteristics should comply with the following values:

In the case of high water pressure a pressure reducing valve calibrated to between 3 - 4 bar should be fitted. Inlet water temperature

must not exceed 50oC. It is recommended to install a shut-off valve and a mechanical filter with the wire mesh size less than 50µm.

The humidifier pan drain connection is a 22 mm female connection. The humidifier drain can be discharged into the standard drainage

system via a rubber or plastic hose suitable for temperatures up to 100oC. The hose should have a minimum internal diameter of

22mm. A trap or vertical loop should be fitted in the tubing to prevent blow back or odours and ensure that the drain has a fall of not

less than 1:50.

Note: Do not feed demineralised water into the humidifier.

CONDENSATE DRAIN

Install a drain pipe from the base of the drainpan (typically a 1" female B.S.P. fitting). Insulating this drain pipe is not necessary. It is

advised to fit a trap in this drainpipe. On a twin circuit unit there are knockouts on the side panels to route drain hoses through to a

single outlet. Copper pipe should be used for drains on units with humidifiers. If the system is equipped with a condensate pump,

install a check valve on the discharge line of the pump to prevent backfilling the pump reservoir.

Characteristic

Minimum

Maximum

Feed Water Pressure

1 bar

10 bar

Electric Conductivity at 25oC

400 µS/cm

800 µS/cm

Impurity Size

-

0.1 mm

M

1

Chilled Water Flow

Chilled Water Return

1

2

3

4

4

Page 6

6

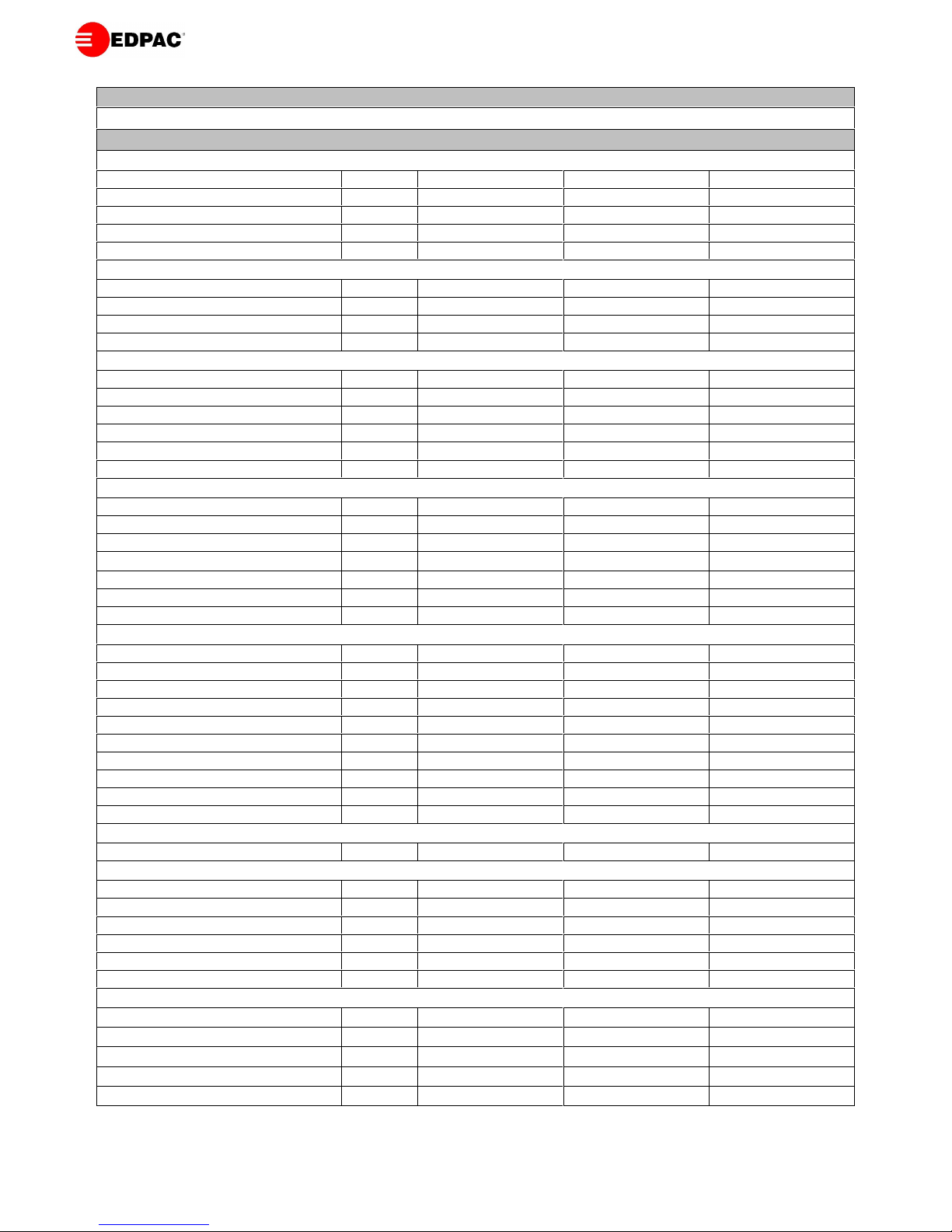

GENERAL ENGINEERINGDATA

Model0612

18

Air Side Data

Air Volume

m3/hr

1,800

3,600

5,400

m3/s

0.5

1.0

1.5

External Static Pressure ESP

Pa7575

75

No. of Fans

No.11

1

Fan MotorkW0.55

1.10

1.50

Optional EC Plug Fan

Quantity

No.11

1

Fan Diameter

mm

450

450

450

Fan Motor

kW

1.0

1.0

1.0

Fan Absorbed Power

kW

0.3

0.5

0.9

Filter Data

Downflow Filter Size

mm

495 x 535

495 x 535

495 x 695

Downflow Filter Quantity

No.22

2

Upflow Filter Size

mm

775 x 300

775 x 300

775 x 460

Upflow Filter Quantity

No.11

1

Filter Depthmm100

100

100

Filter Efficiency

-G4G4

G4

Water Side Data

Control Valve Size

mm2025

25

Control Valve Kv

-

4.0

6.3

6.3

Chilled Water F&R Pipe Size

mm2228

28

Cooling Coil Data

Coil Face Area – DX and C. Water

m20.4

0.6

0.6

Coil Rows

No.44

4

Coil Drain Connection BSPF

inch11

1

Air Cooled Units

Discharge Line Pipe Size

mm1616

16

Liquid Line Pipe Size

mm1212

12

Condenser Conns. Inlet/Outlet 30°C

mm

22/16

22/16

28/22

Condenser Conns. Inlet/Outlet 35°C

mm

22/16

28/22

28/22

Condenser Conns. Inlet/Outlet 40°C

mm

22/16

28/22

35/28

Condenser Conns. Inlet/Outlet 45°C

mm

22/16

35/28

35/28

Condenser Conns. Inlet/Outlet 50°C

mm

28/22

35/28

35/28

Scroll Compressor – 50Hz

-

ZR34K

ZR61K

ZR81K

Scroll Compressor – 60Hz

-

ZR28K

ZR48K

ZR72K

Compressor Quantity

No.11

1

Noise Data

Free field SPL @ 3m

dBA5255

57

Optional Humidifier Data

Capacity

kg/hr22

3

Inlet Connection BSPM

inch11

1

Drain Connection BSPM

inch11

1

Water Feed Pressure

Bar

1-10

1-10

1-10

Water Feed Electrical Conductivity

μS

400 – 800

400 – 800

400 – 800

French Degrees Water Hardness

-

15-30

15-30

15-30

Optional Electric Reheat Data

Capacity - 400V/3Ph/50Hz

kW

7.5

7.5

9.6

Capacity - 220V/3Ph/60Hz

kW

7.5

7.5

9.6

Capacity - 380V/3Ph/60Hz

kW

6.8

6.8

8.7

Capacity - 460V/3Ph/60Hz

kW

10.0

10.0

12.8

No.of Stages

No.22

2

Notes

1. Indoor unit Free field SPL dBA levels are measured at 3m.

2. For correct installation pipe sizes refer to refrigerant and water pipe sizing tables.

Page 7

7

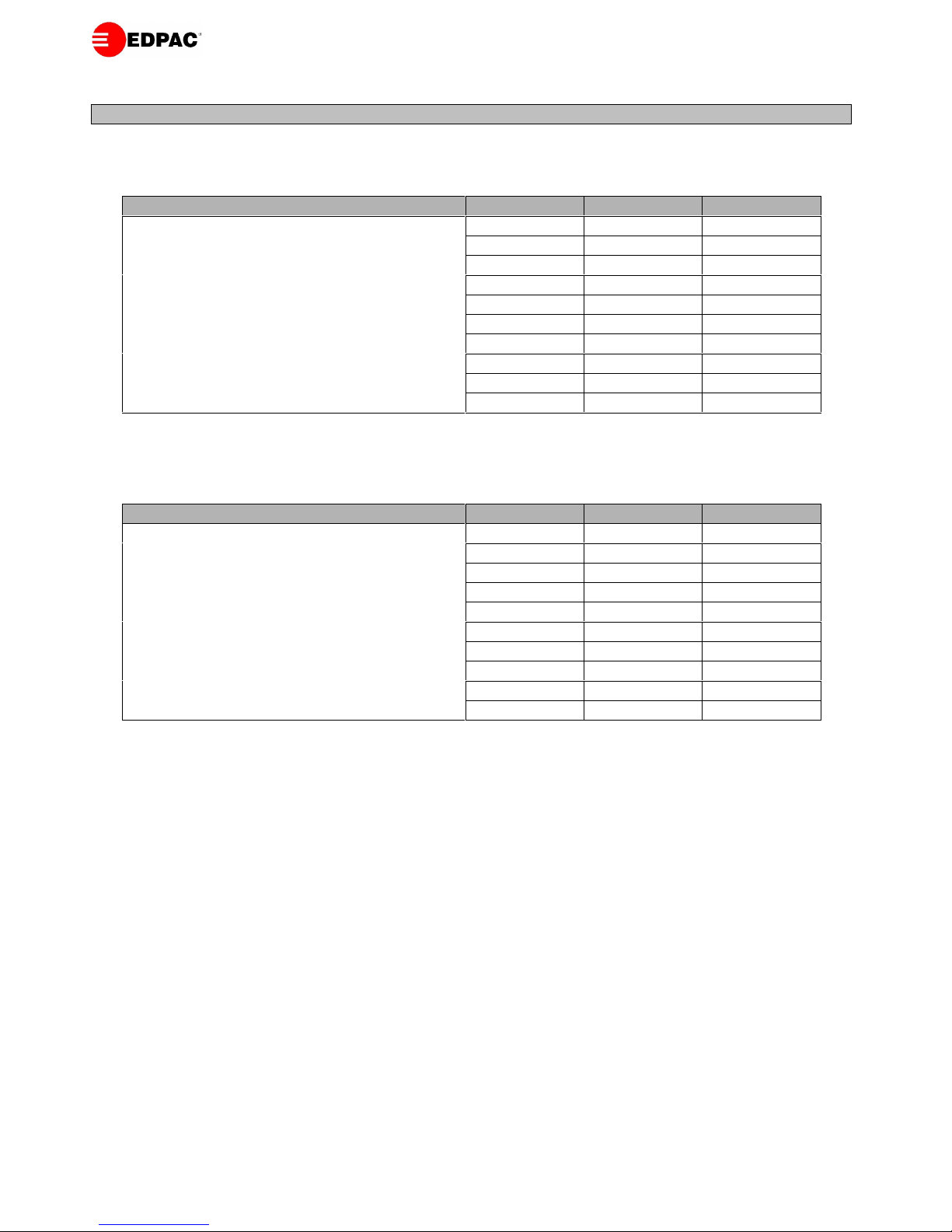

400V/3PH/50Hz

Model

61218

Controls FLA

1.0

1.0

1.0

Fans FLA

1.5

2.7

3.6

Reheat FLA

10.9

10.9

13.9

Humidifier FLA

2.2

2.2

3.2

Max Unit FLA - Cooling only

2.5

3.7

4.6

Max Fuse FLA

10.0

10.0

10.0

Max Unit FLA - Cooling & Dehumidification

13.4

14.6

18.5

Max Fuse FLA

20.0

20.0

25.0

Max Unit FLA - Heating and Humidification

15.6

16.8

21.7

Max Fuse FLA

20.0

25.0

30.0

220V/3PH/60Hz

Model

61218

Controls FLA

1.0

1.0

1.0

Fans FLA

2.7

4.9

6.6

Reheat FLA

19.8

19.8

25.3

Humidifier FLA

4.0

4.0

5.8

Max Unit FLA - Cooling only

3.7

5.9

7.6

Max Fuse FLA

10.0

15.0

20.0

Max Unit FLA - Cooling & Dehumidification

23.5

25.7

32.9

Max Fuse FLA

30.0

35.0

45.0

Max Unit FLA - Heating and Humidification

27.5

29.7

38.7

Max Fuse FLA

35.0

40.0

50.0

Notes:

1. FLA = Full Load Amps.

2. Unit maximum FLA is the total of the components, which operate during maximum electrical load conditions.

3. Max FLA of Cooling only unit : FLA = Controls + Fans

4. Max FLA of unit with reheat only in dehumidification : FLA = Controls + Fans + Reheat.

5. Max FLA of units with heating & humidifiers : FLA = Controls + Fans + Reheat + Humidifier.

6. Max Fuse is the recommended value of the unit overcurrent protection device.

ELECTRICAL DETAILS – CHILLED WATER UNITS

Page 8

8

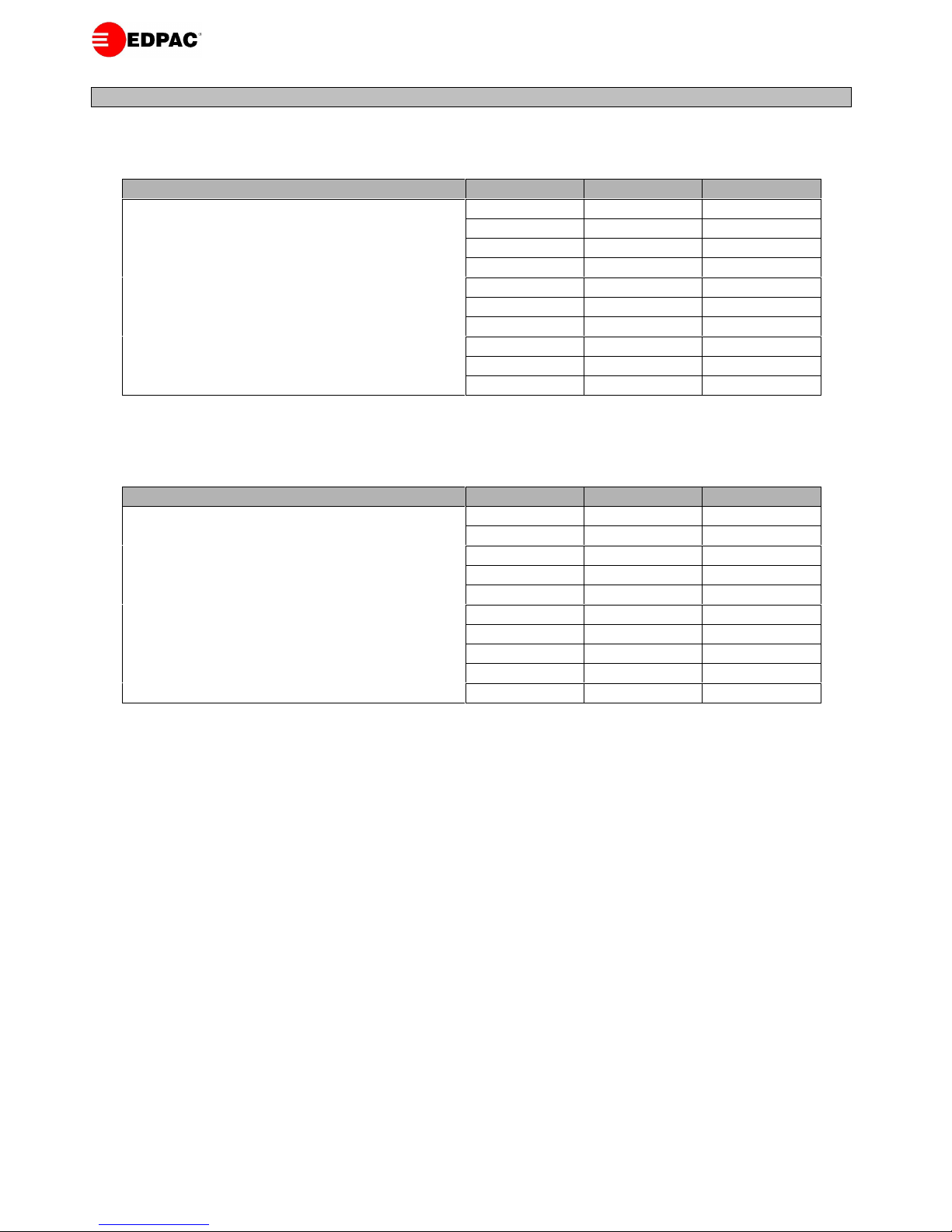

380V/3PH/60Hz

Model

61218

Controls FLA

1.0

1.0

1.0

Fans FLA

1.6

2.9

3.8

Reheat FLA

10.3

10.3

13.2

Humidifier FLA

2.3

2.3

3.4

Max Unit FLA - Cooling only

2.6

3.9

4.8

Max Fuse FLA

10.0

10.0

10.0

Max Unit FLA - Cooling & Dehumidification

12.9

14.2

18.0

Max Fuse FLA

15.0

20.0

25.0

Max Unit FLA - Heating and Humidification

15.2

16.5

22.8

Max Fuse FLA

20.0

25.0

30.0

460V/3PH/60Hz

Model

61218

Controls FLA

1.0

1.0

1.0

Fans FLA

1.3

2.3

3.1

Reheat FLA

12.6

12.6

16.1

Humidifier FLA

1.9

1.9

2.8

Max Unit FLA - Cooling only

2.3

3.3

4.1

Max Fuse FLA

10.0

10.0

10.0

Max Unit FLA - Cooling & Dehumidification

14.9

15.9

20.2

Max Fuse FLA

20.0

20.0

25.0

Max Unit FLA - Heating and Humidification

16.8

19.2

23.0

Max Fuse FLA

20.0

25.0

30.0

Notes:

1. FLA = Full Load Amps.

2. Unit maximum FLA is the total of the components, which operate during maximum electrical load conditions.

3. Max FLA of Cooling only unit : FLA = Controls + Fans

4. Max FLA of unit with reheat only in dehumidification : FLA = Controls + Fans + Reheat.

5. Max FLA of units with heating & humidifiers : FLA = Controls + Fans + Reheat + Humidifier.

6. Max Fuse is the recommended value of the unit overcurrent protection device.

ELECTRICAL DETAILS – CHILLED WATER UNITS

Page 9

9

OPERATION

GENERAL

MICROPROCESSOR CONTROLS

All Units shall be fitted as standard with the latest Delta range of DIN rail mounted Microprocessor Controls. The Control

System utilises a main Microprocessor Interface Board equipped with a set of terminals necessary to connect the Board to the

controlled devices.All software is permanently stored in flash RAM and is therefore protected even in the event of a power

failure. Unit software is uploaded to the Microprocessor using a RAM key. On multi unit sites, this quickens unit

commissioning. The software can also easily be changed or upgraded on site by qualified service personnel.

Note:

For more detailed information refer to Detailed Controls Manuals.

1)

DELTA

RANGE MICROPROCESSOR CONTROLLER SYSTEM PROGRAMMING MANUAL.

GENERAL SYSTEM OPERATION

Unit operation is completely automatic. The sequence below explains how the unit operates:

The air, drawn in by the fan(s), enters the unit through top of the unit or the inlet grille.

The air is immediately filtered.

The temperature & relative humidity sensor verifies the condition of the inlet air and relays this to the microprocessor

controller.

The controller compares this information to the set point and proportional band values programmed into its memory. it

then commands the air conditioner to treat the air as appropriate.

CUSTOMER CONNECTIONS

Power cables to the load break switch should be sized in compliance with local codes (see electrical data for permissible fuse

size). Power cables required are 3 phase and a neutral (2.5mm minimum size neutral) and appropriately sized ground. The

ground connection is vital. External device control connections to the control section are as follows:

a) Connections to the condenser/dry cooler are is via terminals 27 & 28.

b) Connection to the remote shutdown feature is via terminals 15 & 16. Normally Closed N/C Unit On, Normally Open N/O

Unit Off by Remote. A relay is required for this option.

c) Connections for the external alarm relay's are via terminals 18, 19 & 20, (250 VAC rated - 10 Amps). Volt Free Contacts.

d) Externally required A.C. voltage supplies are not to be taken from the unit, interface relays are to be utilised for these

applications.

INITIAL START UP

a) On initial start-up the controller will display the following message:

b) After a 5 second delay the controller will display the following:

The unit is now ready for operation.

SYSTEM BOOT

PLEASE WAIT

13:58 12/02/97 MOI

Temperature: 23.4 deg.C

Humidity: 37.7 RH%

UNIT ON

Page 10

10

AIRFLOW OPERATION

a) When the electrical power has been energised for at least 3 hours, the unit may be energised by pressing the "On/Off" key

on the keypad. The fan contactor KM1 (& KM2-Duplex) will energise establishing airflow.

POWER FAILURE, INTERRUPTION OR SYSTEM RESET

a) Should a `brownout' (where voltage is low enough to cause the electronics to fail) or electrical power failure occur, the

controller will be alerted as the voltage begins to drop. It will then de-energise all contactors. During power failure all data

entered through the keypad will be held in a memory back-up which is supported by an Eprom. The Eprom will retain data

indefinitely without external power.

b) If a unit is in the "RUN" mode when a power failure occurs, then, upon power restoration the unit will automatically

commence "RUN" operation. The settle timer will count down to zero and at zero the unit will then continue as outlined in

the Airflow, Temperature Control and Humidity Control sections.

EC FAN OPERATION

GENERAL

The EC plug fan is a backward curved fan with an integrated EC electrically commutated motor which is controlled directly

from the microprocessor using a 0-10V output. Options on setup are:

Strategy 1: Fixed speed

Strategy 2: Track temperature band

Strategy 3: Maintain pressure setpoint

Strategy 4: Control from BMS

Strategy 5: Maintain airflow setpoint

Dehumidification control mode

FIXED SPEED

A fixed 0-10V signal is set through the user display to operate the fan at a constant speed.

TRACK TEMPERATURE BAND

The unit is set up to track the heating and cooling bands with set voltage limits. Max voltage / fan air volume is at set point plus

control band & min voltage / fan air volume at set point

Max voltage / air volume is typically design air volume and min air volume is typically around 60% for chilled water units.

Minimum value needs to insure that there are no hot spots due to lack of airflow and that there is no loss of sensible cooling

capacity to latent cooling capacity at the cooling coil.

MAINTAIN PRESSURE SETPOINT

The microprocessor reads the underfloor pressure via a pressure transducer. The fan speed is then controlled to maintain a

fixed underfloor pressure at all times. Pressure setpoint and min & max voltages are input through the user display. A reading

of the underfloor pressure can also be viewed.

CONTROL FROM BMS

The speed of the fan can be controlled directly from a BMS if one of the optional BMS interface cards are installed in the unit.

The BMS writes a value of between 0 & 100.0% to an analog BMS address. The fan then operates to this speed. Min and max

voltage can be input through the user display to insure the fan operates within acceptable limits.

MAINTAIN AIRFLOW SETPOINT

The microprocessor calculates the airflow through the unit with the use of a pressure transducer and a special inlet ring across

one of the fans designed for measuring airflow. PID control in then utilized to control the speed of the fans to insure a steady

supply air volume. Airflow setpoint and min & max voltages are input through the user display. A reading of the total airflow

through the unit can also be viewed.

DEHUMIDIFICATION CONTROL MODE

Unit set up to give a reduced fan air volume in dehumidification mode to conserve energy in dehumidification while quickly

achieving the dehumidification effect at the cooling coil. This output voltage is again user selectable.

Page 11

11

GENERAL

This can take one of two forms:

Electrical heating: The electric elements heat the air passing over them. Heating is supplied by 3 elements configured to

support 2 stages of heating. Airflow has to be established before the elements are energised. The heaters are protected

by a manual reset thermostats. This thermostat is a capillary type stat positioned across the coil near the elements.

Hot Water Heating (optional): If hot water is available this flows through the hot water coil thus heating the air passing

over it. The hot water flow is controlled by an on-off (2 or 3-way) valve.

On a Duplex unit the heating operation is carried out in the master module only.

NOTE: Heating and cooling cannot occur simultaneously.

ELECTRIC HEATING

CAUTION: When commissioning the heater stage, be aware that the electric heater elements may at first give off smoke and

may cause smoke detectors on site to alarm, e.g. Halon System.

ELECTRIC HEATER PROTECTION & ALARMS

a) The electric heaters are protected by one high temperature stats (RS1) which is fitted in the heater termination box.

b) RS1 is a capillary type temperature stat. This capillary wrapped around the electric heater elements. If the temperature of

the heater elements rises above 145 Deg. C the stat contacts will open and electric heating will be terminated.

c) When the return air temperature drops sufficiently RS1 can be manually reset. Electric heating will continue as normal.

Hot Water Reheat

a) Hot Water Heating occurs when the return air temperature falls below the return air temperature setpoint. The solenoid

valve or modulating valve will energise.

b) As the return air temperature rises above the return air setpoint the controller will cancel the heating process by de-

energising the solenoid valve or modulating valve.

Note: Heating can occur when compressor 1 is operating in the dehumidification mode and the return air temperature is below

the return air temperature setpoint by the appropriate amount.

COOLING OPERATION

GENERAL

Note 1: Cooling can only occur when airflow is established.

Note 2: Modulating valves are fitted as standard on all units.

SINGLE CIRCUIT COOLING

MODULATING VALVES.

a) A rise in return air temperature above the return air setpoint (default 22.0°C) will prompt the controller to call for cooling.

b) The chilled water modulating control valve will energise. The modulating valve will modulate to balance the load as the

temperature increases.

c) As the return air temperature falls the controller will calculate the optimum use of the modulating valve.

d) As the return air temperature drops to above the return air setpoint, the controller will modulate the valve until completely

closed.

TWIN CIRCUIT COOLING

MODULATING VALVES.

a) A rise in return air temperature (default 0.7°C) above the return air setpoint (default 22.0°C) will prompt the controller to

call for cooling.

b) The chilled water modulating control valves will energise. The modulating valves will modulate to balance the load as

temperature increases.

c) As the return air temperature falls the controller will calculate the optimum use of the modulating valves.

d) As the return air temperature drops to (default 0.6°C) above the return air setpoint, the controller de-energise the

modulating valves.

HEATING OPERATION

Page 12

12

DEHUMIDIFICATION CONTROL

a) With the airflow established, an increase in return air relative humidity above the return air relative humidity setpoint

(default 50.0%) will prompt the controller to call for dehumidification.

b) The chilled water proportional valve opens 100% to produce 100% cooling.

b) Should the return air relative humidity drop the return air relative humidity setpoint, the controller will cancel the

dehumidification stage.

c) Heating can only occur when the cooling valve is operating in the dehumidification mode and the return air temperature is

below the return air temperature setpoint by the appropriate amount. Cooling/Heating take priority control over

Dehumidification

DEHUMIDIFICATION OVERRIDE

During dehumidification, should the return air temperature drop below temperature setpoints then the controller will override

the call for dehumidification until the heaters cause the return air temperature to be within setpoint tolerances and will then

re-energise the dehumidification stage if it is required.

HUMIDIFICATION

When a call for humidification exists, the microprocessor controller sends a 24V ac signal to the humidifier contactor

supplying power to the boiler cylinder electrodes. The electric power dissipated in the boiler is kept constant by measuring the

amount of current flow on phase (L3) via a current transformer.

As evaporation proceeds, the controller opens the fill valve allowing water to enter the cylinder via a filter and a capacity

regulator to the filling cup, and from there, by gravity, to the boiler. When the water level is so high that it touches the

electrodes at the top of the boiler, the fill valve is closed and the excess water is drained through overflow tube.

The drain valve opens periodically to drain water and reduce salt concentration in the boiler. It is also used to drain the

humidifier completely under alarm conditions.

SYSTEM OPERATION

The humidifier interface PCB maintains the electric current dissipated in the boiler at the programmed set point. The PCB

therefore changes the immersion level of the electrodes by adding or draining water from the boiler through the respective

valves. The operating current may be programmed on the front display panel between 30% and 100% of the rated value of the

equipment. The functions of the equipment are described below:

FILL VALVE - maintains absorbed current between -10% and +10% of set point (percentages refer to rated current) by opening

or closing respectively, with the first or second thresholds. The fill valve is automatically closed when:

The drain valve is opened

The free surface of the water reaches the level electrodes

The system is in a state of alarm

DRAIN VALVE - this is opened when:

The absorbed electrical current reaches set point +30% (it closes as soon as current falls set point +10%)

The washing cycle (initial or periodic) is activated

The system is in a state of alarm

TOP LEVEL ELECTRODES - these prevent water overflowing from the boiler. When they are covered with water for approx.

three seconds the valve is closed. After the level electrodes have been out of water for approx. 25 seconds, the fill valve opens

again. The level electrodes also control topping-up when absorbed current does not reach the programmed threshold because:

The water conductivity is too low

The electrodes are partially or totally encrusted

WASHING CYCLE - this prevents excessive salt build-up inside the boiler. It is activated as follows:

At regular intervals, programmable according to the size of the equipment on the basis of cumulative time of

humidification, memorised while the equipment is supplied with power

Page 13

13

ALARM CONDITION

- The red ALARM button on the front display panel lights up, the drain valve opens and electrical supply to the boiler is cut off

when:

Absorbed current exceeds 1.8 times the rated current (generally due to the fill valve overload)

The valve remains open for more than 10 minutes without the threshold of current set point +10% being reached and

without the level electrodes intervening (e.g., due to failure in the water supply, blocked intake filter, defective fill valve,

power probe current transformer, contactor, blown fuses, encrusted electrodes, etc.)

Page 14

14

PGD DISPLAY

Turning the unit On/Off : Pressing the “ ESC” & the “ Enter / Return” arrow buttons together

turns on and off the unit at the display. Pressing the up arrow button followed by the “ Enter /

Return” arrow button also turns unit on/off. Follow on screen instruction.

Alarm button: By pressing this button you can display the alarm that has occurred & reset it manually. When the red

led indicator lights up, at least one alarm condition has occurred. If there are multiple alarms then using the arrow “

up ” & “ down ” buttons lets you scroll through them.

Up arrow button: Displays the program windows and allows the user to set the value of the control parameter

Down arrow button: Displays the program windows and allows the user to set the value of the control parameter. In

default menu, pressing down arrow button displays unit operating mode.

Enter / Return arrow button: Confirms the set data.

Escape button: By pressing this button, you go back one level from where you are.

Program button: By pressing this button, you get a range of sub-menu’s.

+

Page 15

15

ALARMS

The following alarms can be activated in an alarm condition & displayed on the display screen. All alarms can be set as serious

or non-serious through the keypad

ALARM LIST

AL 01

Compressor 1 HP / Thermal Overload

AL 02

Compressor 2 HP / Thermal Overload

AL 03

Compressor 1 LP

AL 04

Compressor 2 LP

AL 05

Air Flow Alarm (Serious Alarm)

AL 06

Air Flow Alarm – Slave

AL 07

Alarm Electric Reheat High Temp Trip

AL 08

Condensate Pump / High Water Level

AL 09

Smoke/Fire (Serious Alarm)

AL 10

Alarm Air Filter

AL 11

High Temperature Alarm

AL 12

Low Temperature Alarm

AL 13

High Humidity Alarm

AL 14

Low Humidity Alarm

AL 15

High Entering Water Temperature

AL 16

Low Entering Water Temperature

AL 17

Compressor 1 Run Hours

AL 18

Compressor 2 Run Hours

AL 19

Fan Run Hours

AL 20

Return Air Temperature Probe Fault Or Offline

AL 21

Entering Water Temperature Probe Fault Or Offline

AL 22

External Air Temperature Probe Fault Or Offline

AL 23

Supply Air Temperature Probe Fault Or Offline

AL 24

Return Air Humidity Probe Fault Or Offline

AL 25

Leaving Water Temperature Probe Fault Or Offline

AL 26

High Leaving Water Temperature

AL 27

Low Leaving Water Temperature

AL 28

High Current Into Humidifier

AL 29

Lack Of Water Into Humidifier

AL 30

Lack Of Current Into Humidifier

AL 31

Alarm Clock

AL 32

Spare / Custom

AL 33

Spare / Custom

AL 34

Spare / Custom

AL 35

Water Under Floor

AL 36

Loss of Water Flow Alarm

Default List: Actual Alarms Model Dependant

Page 16

16

ALARMS

Default List: Actual Alarms Model Dependant

AL 37

Alarms Probe B00 Air pressure fault or disconnected

AL 38

Alarms Probe B00 fault Head press. circuit 1

AL 39

Alarms Probe B00 fault Head press. circuit 2

AL 40

Desiccant Dryer Alarm

AL 41

Alarm clock

AL 42

Permanent memory Read/Write error Contact factory

AL 43

EC Fan Fault or Offline

AL 44

Alarms EVO n1 - EEV Motor Error

AL 45

Alarms EVO n1 - MOP (high temperature of evaporation)

AL 46

Alarms EVO n1 - LOP (low temperature of evaporation)

AL 47

Alarms EVO n1 - Low superheat alarm

AL 48

Alarms EVO n1 - Low suction temperature

AL 49

Alarms EVO n1 - High condensing temperature

AL 50

Alarms EVO n1 - EEPROM error alarm

AL 51

Alarms EVO n1 - EEV probe S1 fault

AL 52

Alarms EVO n1 - EEV probe S2 fault

AL 53

Alarms EVO n1 - EEV probe S3 fault

AL 54

Alarms EVO n1 - EEV probe S4 fault

AL 55

Alarms EVO n1 - EEV driver offline

AL 56

Alarms EVO n1 - EEV driver battery discharged

AL 57

Alarms EVO n2 - EEV Motor Error

AL 58

Alarms EVO n2 - MOP (high temperature of evaporation)

AL 59

Alarms EVO n2 - LOP (low temperature of evaporation)

AL60

Alarms EVO n2 - Low superheat alarm

AL 61

Alarms EVO n2 - Low suction temperature

AL 62

Alarms EVO n2 - High condensing temperature

AL 63

Alarms EVO n2 - EEPROM error alarm

AL 64

Alarms EVO n2 - EEV probe S1 fault

AL 65

Alarms EVO n2 - EEV probe S2 fault

AL 66

Alarms EVO n2 - EEV probe S3 fault

AL 67

Alarms EVO n2 - EEV probe S4 fault

AL 68

Alarms EVO n2 - EEV driver offline

AL 69

Alarms EVO n2 - EEV driver battery discharged

AL 70

Alarm Compressor 1 VSD

Page 17

17

ALARMS

Default List: Actual Alarms Model Dependant

AL 71

Alarm Compressor 2 VSD

AL 72

Alarms Probe B00 External humidity fault

AL 73

Alarm External smoke alarm (Freecooling disabled)

AL 74

Alarm Ziehl-Abegg fan n1

AL 75

Warning Ziehl-Abegg fan n1

AL 76

Alarm Ziehl-Abegg fan n1 Offline

AL 77

Alarm Ziehl-Abegg fan n2

AL 78

Warning Ziehl-Abegg fan n2

AL 79

Alarm Ziehl-Abegg fan n2 Offline

AL 80

Alarm Ziehl-Abegg fan n3

AL 81

Warning Ziehl-Abegg fan n3

AL 82

Alarm Ziehl-Abegg fan n3 Offline

AL 83

Alarm Ziehl-Abegg fan n4

AL 84

Warning Ziehl-Abegg fan n4

AL 85

Alarm Ziehl-Abegg fan n4 Offline

AL 86

Alarm Ebmpapst fan n1

AL 87

Warning Ebmpapst fan n1

AL 88

Alarm Ebmpapst fan n1 Offline

AL 89

Alarm Ebmpapst fan n2

AL 90

Warning Ebmpapst fan n2

AL 91

Alarm Ebmpapst fan n2 Offline

AL 92

Alarm Ebmpapst fan n3

AL 93

Warning Ebmpapst fan n3

AL 94

Alarm Ebmpapst fan n3 Offline

AL 95

Alarm Ebmpapst fan n4

AL 96

Warning Ebmpapst fan n4

AL 97

Alarm Ebmpapst fan n4 Offline

AL 98

Analog outputs incorrectly configured check unit config.

AL 99

Alarm Refrigerant leak

AL 100

Low pressure circuit 1 (transducer)

AL 101

Low pressure circuit 2 (transducer)

AL 102

Phase rotation alarm

AL 103

High pressure prevent active. Compressor capacity reduced

Page 18

18

MAINTENANCE

GENERAL

CHECKLIST

The following should be incorporated in a planned maintenance schedule to ensure that the equipment is well maintained. In all

cases the various sections of the equipment should be examined and any defects logged for replacement/repair. For

performance analysis a detailed service/maintenance log book should be kept outlining problems encountered and defects

found during routine maintenance. Examples can be found at the end of this section.

GENERAL COMMON COMPONENTS

CABINET AND FRAME - EXAMINE

1) Examine the cabinet exterior for any obvious defects or damage and repair as necessary.

2) Remove the front, side and rear panels and examine the cabinet interior for signs of damage or corrosion. Repair any

damage found and restore the surface finish where corrosion has occurred.

3) Refit the front, side and rear panels and restore the electrical supply to the unit.

4) Record and report any defects found during the inspection.

DRIVE PACKAGE

1) Remove the unit front panels and inspect the fan motor for any loose electrical connections and retighten as necessary.

2) Inspect the fan impellers and remove any debris.

3) Check that the fan impellers are securely mounted on the fan shaft. Rotate the impellers and ensure freedom of movement.

4) Inspect the bearings for signs of wear. If any excessive movement is noticed the bearings must be renewed.

5) Check the drive belts monthly for signs of wear and proper tension. Pressing on the belts midway between the sheave and

pulley should produce approx. 12.5mm of movement. Belts that are too tight can cause excessive bearing wear.

DRIVE BELT RE-TENSIONING

1) Correctly tension the belts by adjusting the fan motor slide base as necessary.

2) After adjusting or renewing the belts, always check that the motor mounts are tight. Loose mounts will produce vibration

that may damage the unit.

Note: If belts appear cracked or worn, they should be renewed with matched belts (identically sized). On units with twin belt

drives both belts should be renewed at the same time. With proper care, belts should provide a long service life.

AIRFLOW SWITCH

1) Open the unit front panel and inspect the airflow switch located below the electric panel for any loose electrical connections

and retighten as necessary.

2) Examine the pressure sensing tube between the switch and the fan casing for defects, damage and loose connections.

Renew the tube if necessary.

3) Refit the unit front panel and restore the electrical supply to the unit.

4) Record and report any defects found during the inspection.

SAFETY NOTE

This equipment is designed for safe operation provided it is installed, maintained and serviced in

accordance with the guidelines laid down in this section of the manual. They should therefore be studied

in advance by any person wishing to work on the equipment

The equipment contains electrical components at high voltage. The main power isolation switch should

therefore be opened before access is gained to the equipment

Care should be taken to avoid hands and clothing becoming entangled in the rotating parts.

Care should be taken when working near the steam outlet pipe. This can remain hot for some time after

the unit is shut down.

Any service and maintenance operations requiring access to the inside of the equipment while in

operation should be carried out by an appropriately qualified or experienced person who is fully aware of

the potential dangers and precautions to be taken.

Page 19

19

AIR FILTERS

To maintain efficient operation, the air filters should be checked monthly and renewed as required. Because renewal intervals

may vary with environmental conditions and filter type, each unit is equipped with a filter clog switch which warnsof restricted

air flow through the filter compartment by activating the 'Change Filter' alarm.

1) On downflow models the filters can be removed from the top of the unit, whereas on upflow units the bottom front panel

contains the filters.

2) Fit new filters, refit the unit front panel on upflow units and restore the power supply.

STEAM GENERATING HUMIDIFIER

Remove the unit front panels and examine the humidifier for any loose electrical connections. Retighten any loose connections.

Examine all pipes and connections for defects, damage and security of attachment.

Ensure that the steam generating canister is properly secured to the unit frame. Refit the unit front and side panels and restore

the electrical supply to the unit. Record and report any defects found during the inspection.

CHILLED WATER COIL

1) Remove the unit front panels and inspect the coil for defects, damage or corrosion.

2) Check that the coil fins are in good condition. If they are found to be bent, they should be carefully straightened using a

proprietary fin comb.

3) Inspect the pipework connections for any signs of leaks.

4) Refit the front panels and restore electrical supply to the unit.

5) Record and report any defects found during the inspection.

CHILLED WATER VALVES

1) Remove the unit front panels.

2) Visually inspect the valve(s) for damage and ensure that the connections are not leaking.

3) Ensure that the valve(s) are securely mounted in position.

4) Ensure that the actuator(s) are securely fitted to the valve body.

5) Refit the unit front panels and restore the electrical supply to the unit.

6) Record and report any defects found during the inspection

ELECTRICAL PANEL – INSPECTION AND FUNCTIONAL CHECKS

Open the unit front, inspect the electric panel for any damage or loose electrical connections and re-tighten as necessary.

Note: -The functioning of all control circuits can be tested by actuating each of the main functions, by adjusting the set points.

COOLING FUNCTIONAL TEST

Select a set point for a temperature of 6oC below room temperature.

a) A call for cooling should be observed.

b) The chilled water valve should open, and the equipment should begin to cool.

c) A high temperature alarm may enunciate. Disregard it.

Return the set point to the room temperature.

REHEAT FUNCTIONAL TEST

Select a temperature set point for 6oC above the room temperature.

a) A call for heating should be observed.

b) Both heating contactors should energise, and the heating elements should begin to heat.

c) Disregard the low temperature alarm.

Return the set point to the desired temperature.

HUMIDIFICATION FUNCTIONAL CHECK

Set the humidification to 10%RH above the room humidity reading.

a) For a steam generating humidifier, you will immediately hear clicks as it energises. After a short delay, the canister will fill

with water. The water will heat and steam will be produced.

Return the humidity setting to the desired room relative humidity setting.

Page 20

20

DEHUMIDIFICATION FUNCTIONAL CHECK

Set the humidification setpoint to 10%RH below the room humidity reading. Make sure that the temperature set point is at or

above room temperature.

a) The chilled water valve should open, and the system should begin to cool/dehumidify.

Return the humidity setting to the desired room relative humidity setting.

NOTE: - IN CHILLED WATER SYSTEMS THE PROPORTIONAL VALVE OPENS 100%.

THE BASIC CONTROL CHECKS ARE NOW COMPLETED.

1) Replace the unit front panels and restore the electrical supply to the unit.

2) Record and report any defects found during the inspection.

STEAM GENERATINGHUMIDIFIER – CLEANINGAND RENEWAL

NOTE: REGULAR MAINTENANCE IS LIMITED TO DESCALING OR RENEWING THE BOILER. THIS IS NECESSARY WHEN SCALE ON

THE ACTIVE SURFACES OF THE ELECTRODES PREVENTS SUFFICIENT PASSAGE OF ELECTRICAL CURRENT.

1) Drain the water completely. (See Controls Manual for

details on drain procedure).

2) Disconnect the power supply to the equipment.

3) Unscrew the steam pipe from the boiler.

4) Disconnect the wiring to the main electrodes and the

level electrodes.

5) Unhook the holding spring and unscrew the humidifier

bottle by rotating it anti-clockwise on its axis.

6) Remove the bottle.

NOTE: - THE BOILER MAY GENERALLY BE USED AGAIN

AFTER DESCALING.

7) Unscrew the ring nut and extract the bottom filter.

Remove any scale and deposits under a jet of water

and clean the grids mechanically or chemically with a

commercially available cleaner.

NOTE: - WHEN ELECTRODE WEAR IS SUCH THAT

REGENERATION IS INSUFFICIENT, THE BOILER MUST BE

RENEWED.

8) Reassemble the boiler in the reverse sequence after

checking and if necessary, renewing the washer

between the threaded connection and the discharge

outlet.

In the case of serviceable humidifiers the bottle can be dismantled and thoroughly cleaned.

Page 21

21

SYMPTOM

POSSIBLE CAUSE

REMEDY

No Power

(Green On/Off control button not lit)

No power to the unit electric panel

Check that the electrical power source is

live and the main disconnect switch is

closed

No power to the control circuit

1) Check that the control circuit breaker is

closed

2) Check the 24V secondary fuse

THE UNIT DOES NOT OPERATE

The display does not operate the unit

1) Check the display connection.

2) Check the processor connections

3) Refer to the unit electrical schematic and

user control manual

ROOM TEMPERATURE TOO HIGH

Unit high Temperature Alarm

1) Controls not properly set

Check the room temperature setpoint Refer to User Control Manual

2) Lack of airflow

See “LACK OF AIRFLOW” section

3) The chilled water valve does not

work when required by the controller

Check linkage for adjustment and ensure

that it is tight on the valve.

If the valve still does not open, even though

voltage is present, then renew the valve

motor.

4) The control system does not

operate properly

See “User Control Manual”. Check that the

display and processor and/or the sensor

function properly

5) Heat load higher than expected

Check the room heat load

Check the condition and volume of fresh air

make-up

Check the quantity of infiltration of external

air

ROOM TEMPERATURE TOO LOW

Unit High Temperature Alarm

1) Controls not properly set

Check the room temperature setpoint -

Refer to User Control Manual

2) The heater does not work properly

(if fitted)

1) Check the heating elements

2) Check the electric heater MCB

3) In the case if electric heater alarm,

eliminate the cause and re-set the safety

thermostat

5) The control system does not

operate properly

See “User Control Manual”. Check that the

display and processor and/or the sensor

function properly

6) Thermal losses higher than

expected

Check the room heat loss calculations,

Check the quantity of infiltration of external

air

ROOM RELATIVE HUMIDITY TOO HIGH

Controller high humidity alarm

1) Controls not properly set

Check the room humidity setpoint - Refer to

User Control Manual

2) Latent load higher than expected

Check the room latent load, check the

quantity of infiltration of external air

3) The chilled water valve does not

work in the dehumidification mode

Check linkage for adjustment and ensure

that it is tight on the valve.

If the valve still does not open, even though

voltage is present, then renew the valve

motor.

4) The control system is not

functioning properly

See “User Control Manual”. Check that the

display and/or the sensor are functioning

properly

ROOM RELATIVE HUMIDITY TOO LOW

Controller low humidity alarm

1) Controls not properly set

Check the room humidity setpoint - Refer to

User Control Manual

2) Latent load higher than expected

Check the room latent load, check the

quantity of infiltration of external air

3) The humidifier does not function

properly

Check the make-up water pressure

Check the humidifier and cylinder

FAULT FINDING GUIDE

Page 22

22

SYMPTOM

POSSIBLE CAUSE

REMEDY

LACK OF AIRFLOW

Loss of Airflow alarm

1) No power to the fan motor

Check the fan motor MCB and electric

supply at the motor box terminals

2) Clogged filters

Replace the filters

3) The airflow is obstructed

check fan inlets, air intake and supply paths

are free

4) the main fan overload has tripped

check the electrical resistance of the motor

windings. After re-set, measure the supply

voltage and current drawn.

5) The pressure drop in the air

distribution system (ducts, ceilings,

flooring, plenum, grilles, etc.) is too

high

1) Check the design and sizing of the air

distribution system

THE HEATER SAFETY THERMOSTAT

CUTS OUT

1) Lack of airflow

See LACK OF AIR FLOW

(Heater trip alarm)

2) thermostat faulty connection wire

Check the electrical continuity of the safety

thermostat connection to the controller

3) Defective thermostat

replace the heater safety thermostat

Page 23

23

MONTHLY MAINTENANCE INSPECTION CHECK

MODEL NUMBER

SERIAL NUMBER

DATE

INSPECTOR

FILTERS

STEAM HUMIDIFIER

Check filter switch (if fitted)

Check humidifier bottle for deposits

Inspect filters and replace if necessary

Check condition of steam hoses

DRIVE PACKAGE

CHILLED WATER SECTION

Blower impellers moving freely and free of debris

Check that the valve motor is correctly secured

Check belt tension and condition

Check pipework is secure.

Bearings in good condition

Check joints for leaks

Check airflow switch setting and operation.

Check coil for damage

Check pulley and sheave are secure

Inspect blower anti-vibration mounts

GENERAL NOTES AND OBSERVATIONS

Page 24

24

ANNUAL MAINTENANCE INSPECTION CHECK

MODEL NUMBER

SERIAL NUMBER

DATE

INSPECTOR

FILTERS

Check filter switch (if fitted)

AIR DISTRIBUTION

Inspect filters and replace if necessary

Ensure that inlet/return airways are unrestricted

DRIVE PACKAGE

ELECTRIC PANEL

Blower impellers moving freely and free of debris

Check MCB’s

Check belt tension and condition

Check electrical connections

Bearings in good condition

Check operational sequence

Check airflow switch setting and operation

Check pulley and sheave are secure

Inspect blower anti-vibration mounts

STEAM HUMIDIFIER

Check humidifier bottle for deposits

Check condition of steam hoses

Inspect inlet filter

Check fill/drain valves

CHILLED WATER SECTION

Check that the valve motor is correctly secured

Check pipework is secure.

Check joints for leaks

Check coil for damage

Check bypass valve setting

GENERAL NOTES AND OBSERVATIONS

Loading...

Loading...