Edmunds Gages Trendsetter II User Manual

How to Use This Manual

Acrobat provides various methods for navigating through a PDF document. The

recommended method of navigating this manual is through the use of the Bookmarks.

To browse using Bookmarks:

Show the Bookmarks list.

By default the manual will open with the Bookmarks list open on the left side of the

document. If you do not see the bookmarks list choose Window > Show Bookmarks to

open the list or click the Bookmarks tab to bring the list to the front of its group.

To expand the bookmark list

Bookmarks can be subordinate to other bookmarks in the list. If a bookmark has

subordinate bookmarks under it then it will have a plus sign next to it. To expand the book

mark list click the plus sign. After the list is expanded a minus sign will be displayed next

to the bookmark. To collapse the list click on the minus sign.

To jump to a topic using its bookmark

Click the bookmark’s text in the list and the document will jump to the corresponding page

in the manual.

Additional Navigation Methods:

• To go to the next page, click the Next Page button in the navigation toolbar or status

bar, press the Right Arrow key, press Ctrl (Windows) or Option (Mac OS) and the Down

Arrow key, or choose Document > Next Page.

• To go to the previous page, click the Previous Page button in the navigation toolbar

or status bar, press the Left Arrow key, press Ctrl (Windows) or Option (Mac OS) and the

Up Arrow key, or choose Document > Previous Page.

• To move down one line, press the Down Arrow key.

• To move up one line, press the Up Arrow key.

• To move down one screenful, press Page Down or Return.

• To move up one screenful, press Page Up or Shift+Return.

• To go to the first page, click the First Page button in the navigation toolbar or status

bar, press the Home key, or choose Document > First Page.

• To go to the last page, click the Last Page button in the navigation toolbar or the

status bar, press the End key, or choose Document > Last Page.

rend-Setter II User’s Manual

T

T

GAGES

Edmunds

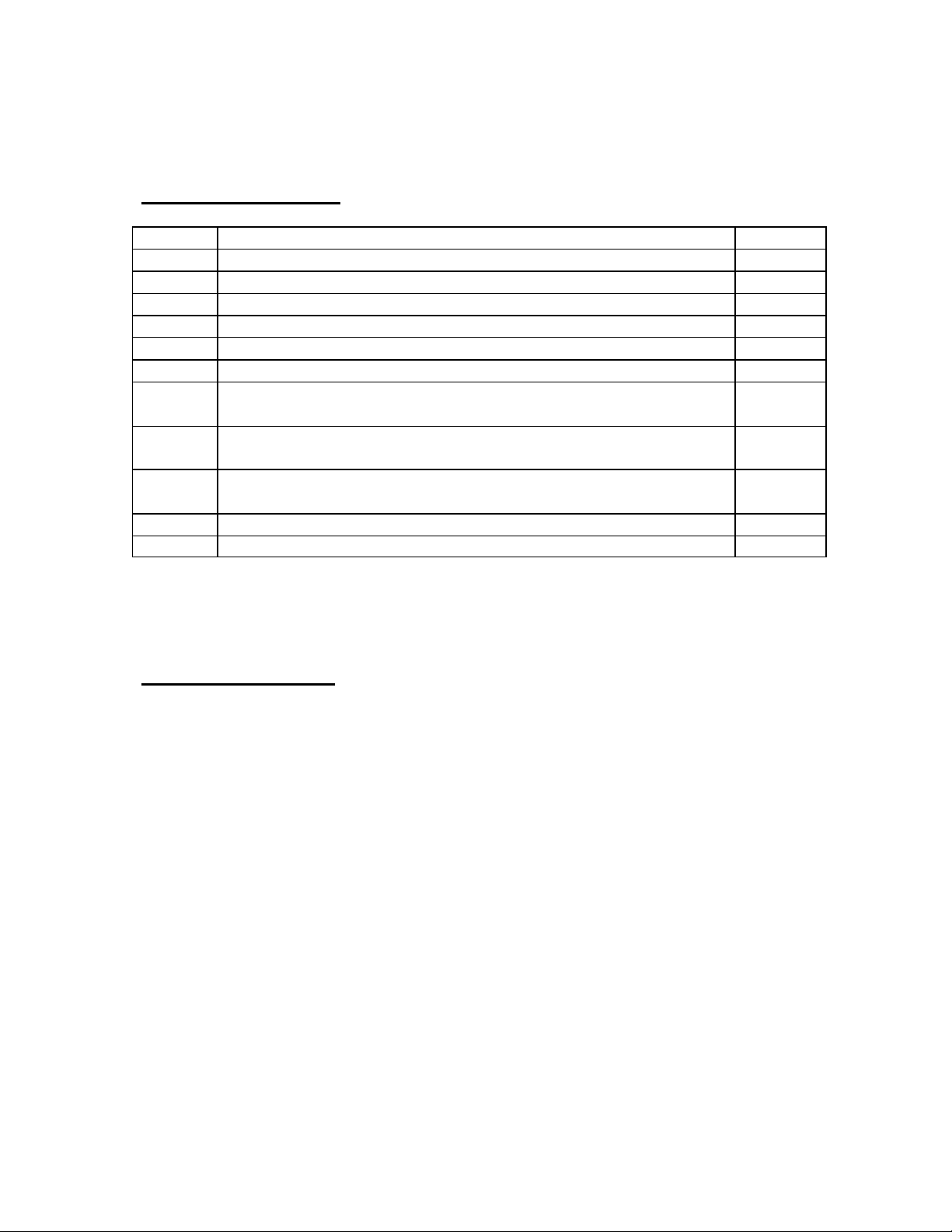

Table of Contents

Preface

Manual Revision History i

Trademark Information ii

Introduction

Summary & Features 1-1

Document Conventions 1-2

Anti-Static Precautions 1-2

Glossary of Terms 1-3

Quick Start Guide 1-5

Programming Reference Guide 1-6

System Description

Number References 2-1

Specifications 2-1

Spare Parts 2-2

Overall Unit 2-3

Front Panel 2-4

Rear Panel 2-6

Rear Panel Pin Assignments 2-8

Input/Output Pin Assignments 2-8

RS-232C 2-10

E8302, LVDT Signal Conditioning Module 2-11

E8303, A/E Signal Conditioning Module 2-13

Filter Regulator Assembly 2-15

Basic Operation

Setup & Operation Summary 3-1

Unpacking & Setting Up 3-2

Signal Conditioning Module Setup 3-6

Programming 3-7

Inputs Setup 3-10

Gage Operation 3-17

Single Unit Setup 3-2

Multiple Unit Setup 3-5

Programming Guide 3-7

Application Setup 3-8

Mode Descriptions 3-9

Setting A/E Mag & Zero 3-10

Setting LVDT Mag & Zero 3-11

LIVE RDG Mode 3-17

TIR Mode 3-17

+PEAK Mode 3-17

-PEAK Mode 3-18

HOLD & RESET 3-18

Advanced Operation

Signal Conditioning Module Setup 4-1

A/E Module Setup 4-1

A/E Maintenance 4-6

LVDT Module Setup 4-8

External Device Communication 4-19

RS232 4-19

Input/Output Board (Optional) 4-22

Description 4-22

Typical I/O Connections 4-24

Installation 4-25

Auto Air Shutoff (Optional) 4-26

Troubleshooting 4-28

Jumper Settings 4-2

Gain 4-2

Polarity 4-3

Output 4-4

Module Installation 4-5

Input Polarity 4-9

Jumper Settings 4-10

Outputs 4-10

Inputs 4-12

Sum/Difference 4-14

Attenuation 4-16

Calibration A and B 4-17

Module Installation 4-18

Index 5-1

Warranty Information 6-1

Service & Support Information 6-1

Table of Figures

Figure 2.1 - Overall Basic unit 2-3

Figure 2.2 - Front Panel 2-5

Figure 2.3 - Rear Panel 2-7

Figure 2.4 - I/O Pins 2-8

Figure 2.5 - I/O Connections 2-9

Figure 2.6 - RS232C Pins 2-10

Figure 2.7 - LVDT Module 2-12

Figure 2.8 - A/E Module 2-14

Figure 2.9 - Supply Air Filter/Regulator 2-15

Figure 3.1 - Base Feet 3-3

Figure 3.2 - Filter Regulator Mounting 3-3

Figure 3.4 - Single Probe Applications 3-12

Figure 3.5 - Two Probe Applications 3-13

Figure 4.1 - A/E Module, E8303 4-1

Figure 4.2 - Gain Jumper 4-2

Figure 4.3 - Polarity Jumper 4-3

Figure 4.4 - Output Pin Jumpers 4-4

Figure 4.5 - A/E Block 4-7

Figure 4.6 - LVDT Module, E8302 4-8

Figure 4.7 - Polarity Switches 4-9

Figure 4.8 - I/O Jumpers 4-11

Figure 4.9 - Sum/Difference Jumpers 4-14

Figure 4.10 - Attenuation Jumpers 4-16

Figure 4.11 - Calibration A & B Potentiometers 4-17

Figure 4.12 - RS232C Pins 4-19

Preface

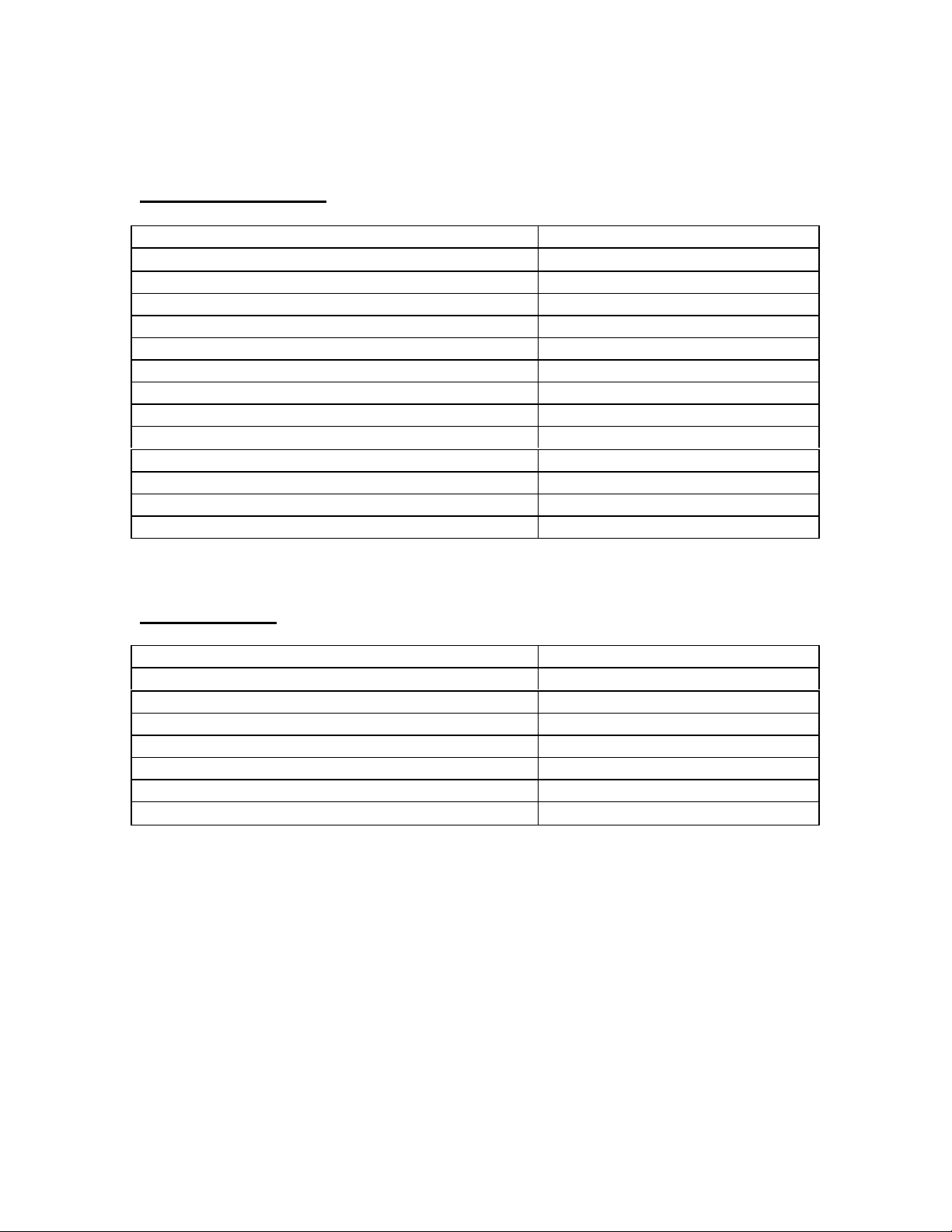

Manual Revision History

Revision Change Date

0 Original Issue 04/07/03

A Section 2.0, Number References - Interface Cable was #4550203 10/14/03

Figure 2.4, I/O Pins, Corrected pin numbers

B Section 2.0, Number References - Added Auto Air Shutoff Kit 4/19/04

Figure 2.4, I/O Pins, Pin numbers for Auto Air Shutoff

Added Section 4.5, Auto Air Shutoff

C Updated Advanced Operation section for new revision of

E8302 board

Corrected I/O cable listed in Advanced Operation section to be

#4550200, was #4550203

Update section 4.5, Auto Air Shutoff – 25 pin connector to

Port “B” only

Trademark Information

“Trendsetter” is a registered trademark of Edmunds Gages

3/10/05

i

Introduction

1.0 Summary and Features

The Edmunds Gages Trendsetter II offers many sophisticated features and benefits for

durable and robust for shop floor operation.

The Trendsetter II is a microprocessor based gaging column that combines a 101 discrete

LED bargraph display for easy visual monitoring of dimensional measurement

characteristics, with an eight digit alpha numeric display for precise size readings and

operator prompting messages. Illuminated range indicators identify which of the eight

inch or eight millimeter ranges have been selected. The tri-color LED bargraph conveys

both measurement size and status. A single rotary entry switch and six dedicated mode

pushbuttons provide all of the operator control functions required.

The unit is housed in a heavy duty reinforced aluminum case with a module bay for

interchangeable plug in modules which will accommodate Edmunds LVDT type gaging

probes or Edmunds and nearly all major brands of air tooling. The rear panel of the

column contains two female DB25 connectors which provide 6 channels for input/output

bussing of analog signals. These connectors also provide various control/status signals

when the I/O accessory board is installed, Edmunds #5911013, sold separately. An RS232C connector allows output of gage results to a data collector. The Trendsetter II will

operate at any supply line voltage between 100 VAC to 240 VAC at either 50 or 60 HZ.

An additional receptacle is provided for power jumper cord connections for multiple

column applications. The serial number with revision letter is identified at the top of the

rear panel of the Trendsetter II. The Trendsetter II allows the user tremendous flexibility

in tailoring the column to match the gaging requirement.

1-1

1.1 Document Conventions

IN/MM = Shortcut Programming Key

“OVER” = Alphanumeric Display

1.2 Anti-Static Precautions

When working inside the Trendsetter II cabinet or handling signal conditioning modules

use caution to protect against damage from static electricity. Use of an anti-static wrist

band or other grounding procedures are recommended.

Power to the column must be turned off prior to installing or removing a signal

conditioning module.

1-2

1.3 Glossary of Terms

An A/E (Air to Electric) transducer converts changes in pneumatic pressure into an

electrical signal.

A part Check is an input or combination of inputs expressed with a gaging mode to

exhibit a part characteristic.

The Gain setting on the A/E signal conditioning module sets the amplification factor of

an input signal to a usable value that can be interpreted by the readout device

A Gage is a mechanical device used to measure part characteristics.

Gage Readings are the input values obtained during the gage cycle.

A High Level Signal is an amplified +/-2.5VDC signal that reflects the number of bars

illuminated on the bargraph display.

An Input is the assigned name given to a signal that is to be utilized in a gaging formula.

In LIVE RDG (Live Reading) mode the input signal is directly displayed on the

alphanumeric and bargraph displays in real time.

A Low Level Signal is the raw unamplified voltage from an LVDT or A/E transducer.

An LVDT (Linear Variable Differential Transformer) is an electromechanical

transducer that converts the linear motion of its contact tip to an AC voltage which can be

interpreted by a readout device.

Magnification is the enlargement of an input signal to a usable value that can be

interpreted by the readout device.

A Maximum (MAX) Master is a precision replica of the gaged part manufactured to the

upper specification limit of the part features, inspected and certified to size, for use in the

calibration of the gage.

A Minimum (MIN) Master is a precision replica of the gaged part manufactured to the

lower specification limit of the part features, inspected and certified to size, for use in the

calibration of the gage.

Mode is the user programmable function controlling how the results are displayed on the

readout.

The Over limit is the part print upper specification limit for the checked feature.

Polarity is the signed value (+ or -) applied to the magnification of an input to determine

the direction of the input value change.

1-3

In +PEAK (or -PEAK) modes the largest (or smallest) size reading since the last reset is

displayed.

Range is the full scale value of the bargraph display.

An R & R is a statistical study performed on a gage to determine the gages repeatability

and reproducibility.

Repeatability is the measurement variation of a gage when used by one operator or

under one set of environmental conditions.

Reproducibility is the variation in measurement averages of a gage when used by more

than one operator or under varying environmental conditions.

The Resolution of a gage is the smallest significant digit of the measurement data that is

displayed.

A Signal Conditioner is a circuit board that modulates and amplifies the LVDT or A/E

signal used by the readout device.

In TIR (Total Indicator Reading) mode the difference between the largest and smallest

readings measured is displayed.

The Under limit is the part print lower specification limit for the checked feature.

A Zero (or Mean) Master is a precision replica of the gaged part manufactured to the

nominal dimensions of the part features and calibrated to size for use in the calibration of

the gage.

A Zero adjustment knob allows operator to drive the displayed readout value to a

desired setting within a limited range.

1-4

1.4 Quick Start Guide

The following steps must be taken to prepare the Trendsetter II for operation.

1) Unpack and setup the unit.

• Rotate the front foot 90° from its shipping position.

• For air gaging applications, rotate the rear foot 180° from its shipping position and

install the filter regulator assembly. Connect 60 psi min supply air to the filter

regulator assembly

Note: See "Basic Operations, Unpacking & Setup" for additional information, page 3-1

2) Setup and install the signal conditioning module if it was not installed before

shipment and connect the gage tooling.

• Check that the jumpers and switches on the LVDT or A/E signal conditioning board

to be used are properly setup for the application to be run.

• Install the signal conditioning module into the lower bay and secure with the two

thumb screws on the front panel.

• Plug in the LVDT(s) or airline from the gaging fixture to the signal conditioning

module.

Power to the column must be turned off prior to installing or removing a signal

conditioning module.

Note: See the "Advanced Operation, Module Setup" section for additional information,

page 4-1.

3) Program Trendsetter II

for the application.

• Plug the power cord into the rear of the unit and to a 100 VAC to 240 VAC 50/60 Hz

power supply. Turn the unit on using the on/off switch on the rear of the unit.

• Using the programming keys and the enter button program the scale, range, mode,

and limits for the application.

Note: See the "Basic Operation, Programming" for additional information, page 3-7

4) Set up magnification and zero for the gage input or inputs.

• Using the masters for the gage tooling and the mag and zero adjustments on the signal

conditioning modules setup the LVDT(s) or air inputs.

Note: See "Basic Operation, Input Setup" for additional information, page 3-10

5) Select the proper gaging mode using the programming keys, see page 3-17. The

unit is ready for gaging.

1-5

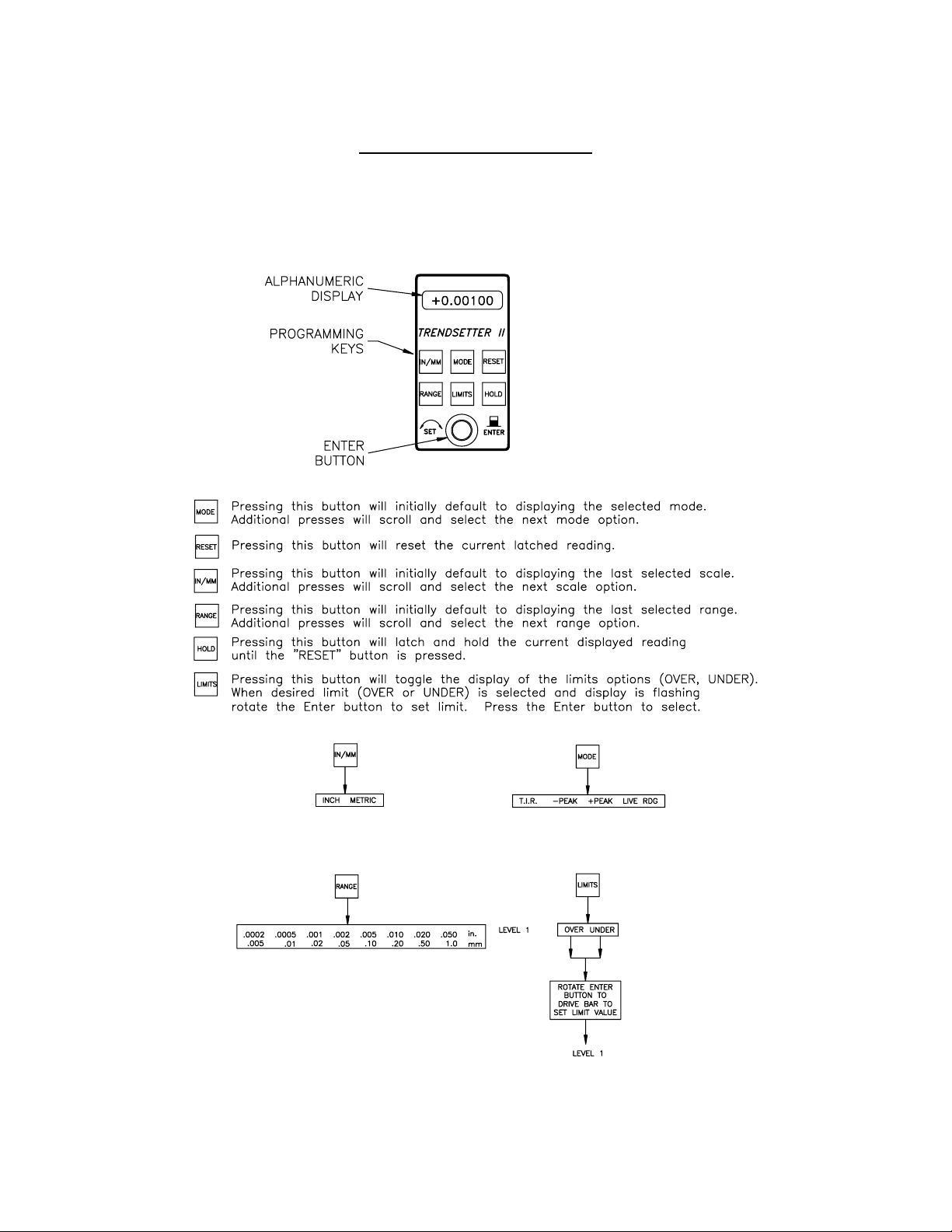

Programming Reference Guide

The following reference guide briefly outlines the functions of the programming buttons

for the Trendsetter II.

Figure 1.1

1-6

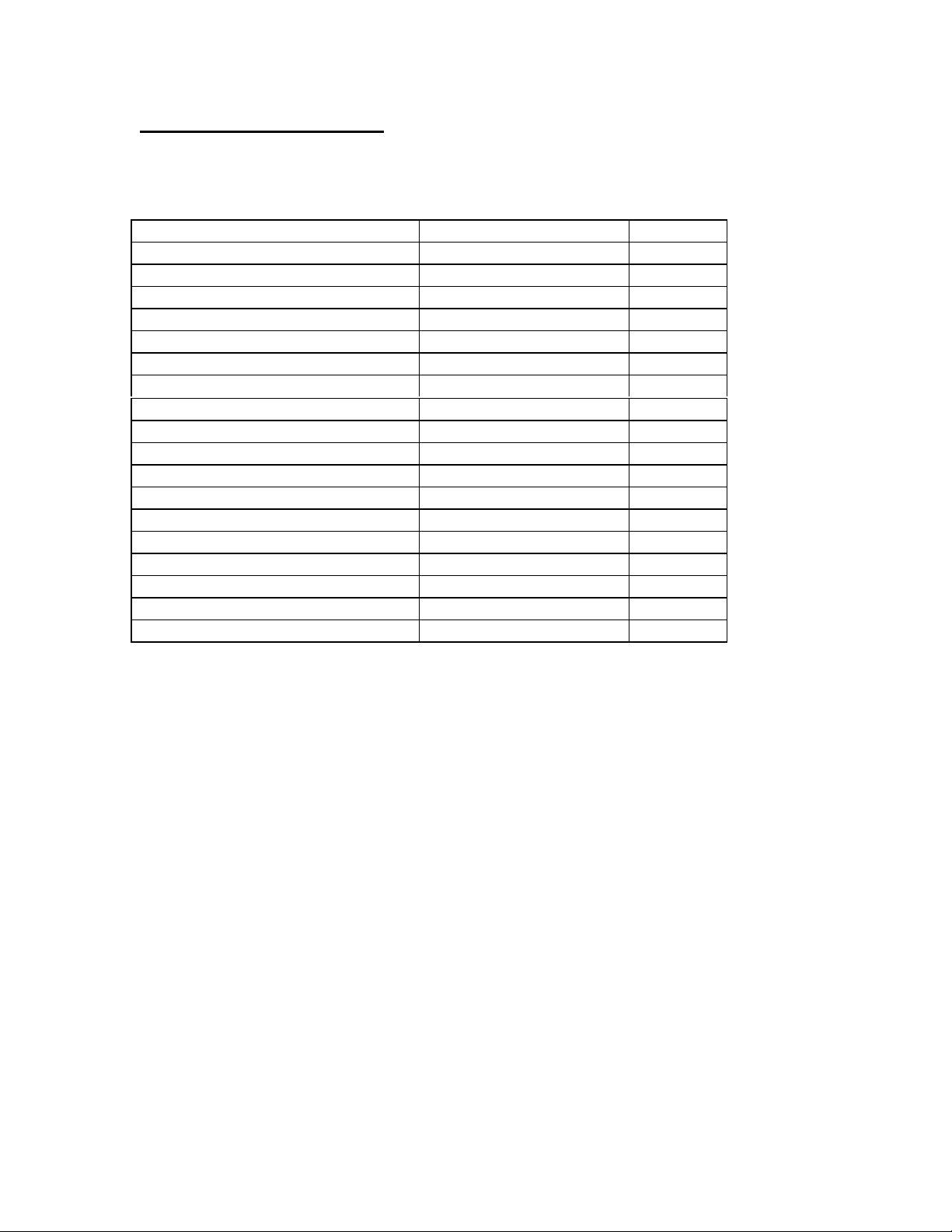

System Description

2.0 Number References

Component Edmunds Gages Number

Basic Trendsetter II Unit

(2) Channel LVDT Signal Conditioning Module E8302

(1) Channel A/E Signal Conditioning Module E8303

Power Cable 4550111

Air Filter/Regulator Assembly 5801302

Interface Cable 4550200

Printer Cable 5809060

Power Jumper Cable 4550120

I/O Accessory Board (Optional) 5911013

Auto Air Shutoff Kit (Optional) 5912250

Includes: Valve Assembly 5911200

I/O Accessory Board 5911013

Shutoff Cable 5911018

E8300

2.1 Specifications

Overall Dimensions 21.25” x 2.50” x 9.00”

Power Requirements 100 VAC to 240 VAC 50/60 Hz

Power Consumption 12 Watts @ 120 VAC, 100 mA

Air Requirements (E8303 Module Only)

Pressure 60 psi

Flow Rate 1.6 scfm/air tooling nozzle

Environmental Operating Conditions

Max Temperature

50°C/120°F

2-1

2.2 Recommended Spare Parts

Below is a list of recommended spare parts for the Trendsetter II. These items may be

ordered separately from Edmunds Gages, they are not included with the basic unit.

Part Edmunds Gages P/N Qty.

Basic Unit

10 Amp Fuse 4190135 2

Limit Pointer Assembly 5809508-BM 2

E8302 LVDT Module

2 Position Shunt, .100 Spacing 4570117 1

E8303 A/E Module

A/E Block 3101500 1

Needle Valve Assembly 3101045 1

O-Ring, Restriction Screw 5900026 1

O-Ring, Body 5900027 1

Bias Restrictor Assembly 3101188-B 1

Filter Disc 3101130-B 2

Bias Restrictor O-Ring 5900026 2

Transducer O-Ring 5900043 2

Air Filter Replacement Element SMC #KT-AF2000-5B 1

2 Position Shunt, .100 Spacing 4570117 1

2-2

2.3 Overall E8300Unit

Figure 2.1 - Trendsetter II Basic Unit

2-3

2.4 Front Panel

The Trendsetter II front panel consists of the following items:

Bargraph display - The 10 inch, 101 point, three color LED bargraph display is the

primary readout for the Trendsetter II. When over and under limits are programmed, the

bargraph will change colors to visually indicate over (red), under (yellow), or good parts

(green).

Range Annunciators - Located next to the bargraph, the half scale indicators display the

bargraph values for the various ranges.

Adjustable Limit Pointers - Mechanically positioned limit indicators.

Range Indicator - Displays the currently selected full scale range. Inch ranges are

displayed in green. Metric ranges are displayed in amber.

Alphanumeric Display - During gaging operation the alphanumeric display provides a

digital readout of the bargraph value. During programming the alphanumeric display

shows information on the current programming selections.

Programming Keys - Provide a shortcut to the various programmable options.

Rotary Enter Button - The enter button can be either pressed or rotated and is used

during the programming of the Trendsetter II.

2-4

Figure 2.2 - Front Panel

2-5

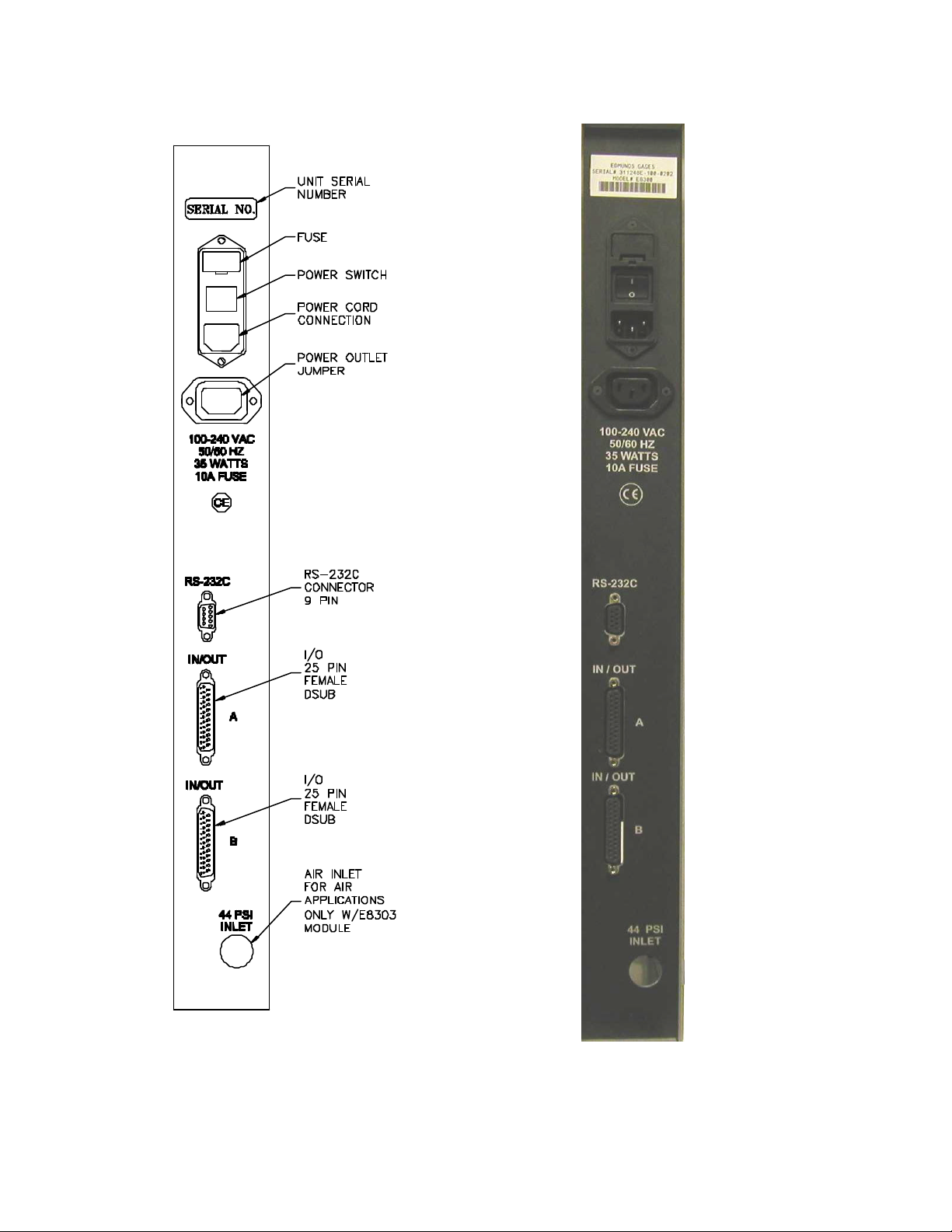

2.5 Rear Panel

The Trendsetter II rear panel contains the following items:

Serial Number - The Edmunds Gages serial number is listed at the top of the rear panel.

Fuse Locator - Contains a 10 Amp fuse.

Power Switch - Use to switch the unit on or off.

Power Connector - Plug the power cable (Edmunds #4550111) into the power connector

and connect to input line voltage from 100 to 240 VAC at 50 or 60 Hz. The Trendsetter

II contains a universal power supply that will automatically adjust to any line voltage in

the above range.

Power Outlet Jumper - In a multiple Trendsetter II setup, plug power jumper cables

(Edmunds #4550120) from the power outlet jumper on one unit to the power connector

on the next unit.

RS-232C Connector - Use to output gage results to an external data collector.

IN/OUT A (25 Pin) - Use to input/output parallel and analog signals from another

Trendsetter II or to an external device using interface cable, Edmunds #4550203. See

figure 2-3 for pin assignments.

IN/OUT B (25 Pin) - Use to input/output parallel and analog signals from another

Trendsetter II or to an external device using interface cable, Edmunds #4550203. See

figure 2-3 for pin assignments.

44 PSI Inlet - When the air to electric module is installed in the lower bay, an air hose

fitting will extend out the 44 psi inlet port on the rear of the Trendsetter II. An air line is

connected to this fitting and to the outlet side of the air filter/regulator assembly.

2-6

Figure 2.3 - Rear Panel

2-7

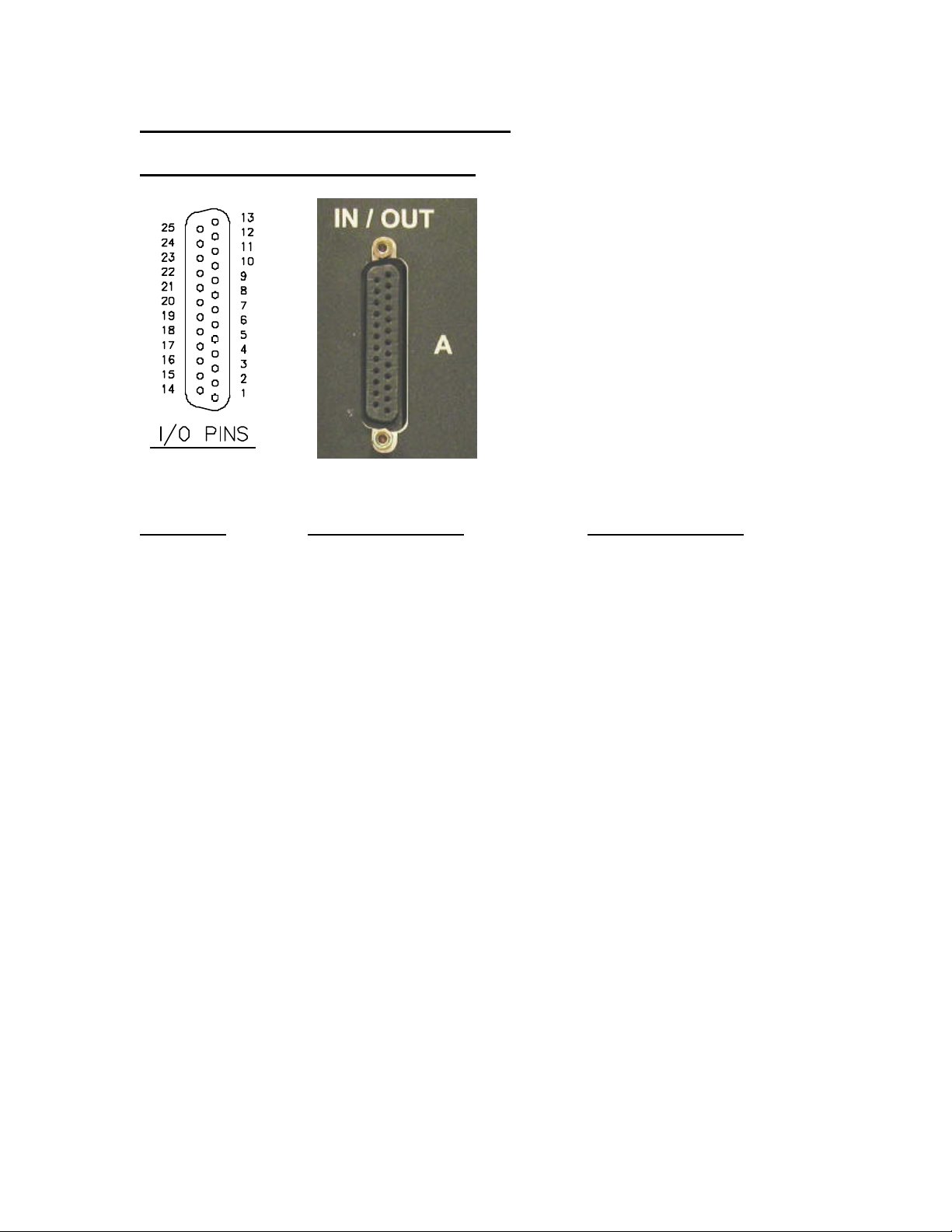

2.6 Pin Assignments for Rear Panel connectors

In/Out A, In/Out B (25 Pin Female DSUB)

Figure 2.4 - I/O Pins

Pin Number IN/OUT A Description IN/OUT B Description

1 Analog Out 1 “

2 Analog Out 2 “

3 Analog Out 3 “

4 Analog Out 4 “

5 Analog Out 5 “

6 Analog Out 6 “

7 Air shut off present (Input) “

8 **Spare 1 (Input) “

9 Air off (Output) “

10 **Spare 2 (Output) “

11 AGND “

12 **Over Relay (Output) “

13 **Good Relay (Output) “

14 **Under Relay (Output) “

15 **Write/Disable (Input) “

16 **Reset (Input) “

17 **Footswitch (Send Data/Input) “

18 NC +V (External Switch)

19 **Relay Output Common “

20 **TIR Reset (Input) “

21 **Reserved Output “

22 **Reserved Output “

23 **Reserved Output “

24 **Isolated Common “

25 NC High Level Analog Out

• NC = Not connected

• Reserved pins should be considered “Do Not Connect”

• ** Functions available with optional I/O board #5911013

2-8

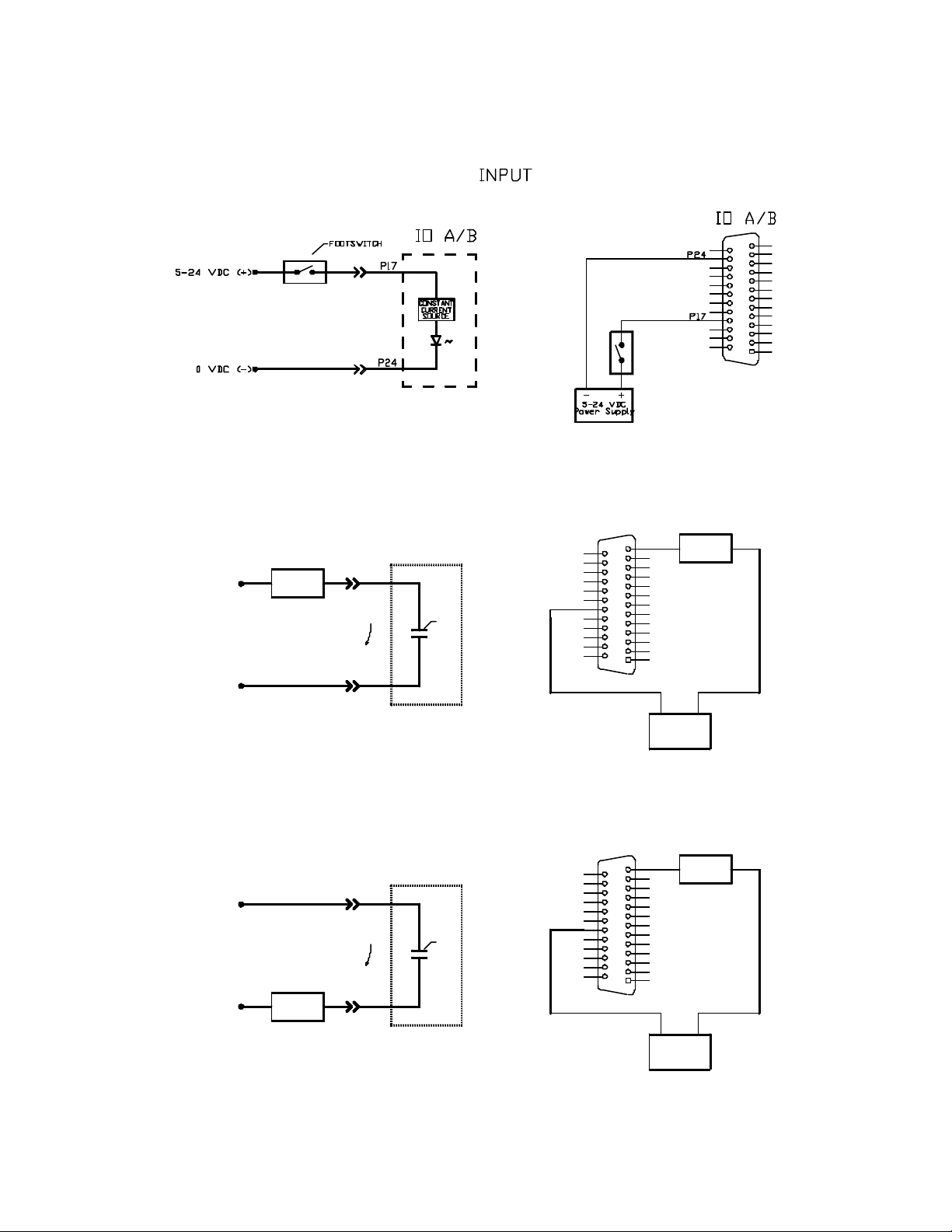

Typical IO Connections - Optional I/O Board #5911013 Required

OUTPUT "SINKING"

IO A/B

IO A/B

P13

LOAD

+24 VDC (+)

0 VDC (-)

+24 VDC (+)

0 VDC (-)

LOAD

LOAD

CURRENT

FLOW

CURRENT

FLOW

P13

GOOD

RELAY

P19

OUTPUT "SOURCING"

IO A/B

P19

GOOD

RELAY

P13

P19

+-

24VDC

Power Supply

IO A/B

P13

LOAD

P19

2-9

24VDC

Power Supply

-+

RS232C (9 Pin Female DSUB)

Figure 2.5

Figure 2.6 - RS-232C Pins

Trendsetter II Cable External Device

Pin 1 = Chassis Ground. ß----------------------------à Chassis Ground.

Pin 2 = Receive (RXD) ß----------------------------à (TXD) Transmit.

Pin 3 = Transmit (TXD) ß----------------------------à (RXD) Receive.

Pin 5 = Signal Ground ß----------------------------à Signal Ground.

Note: Pin2 and 3 are jumper selectable based upon the application.

2-10

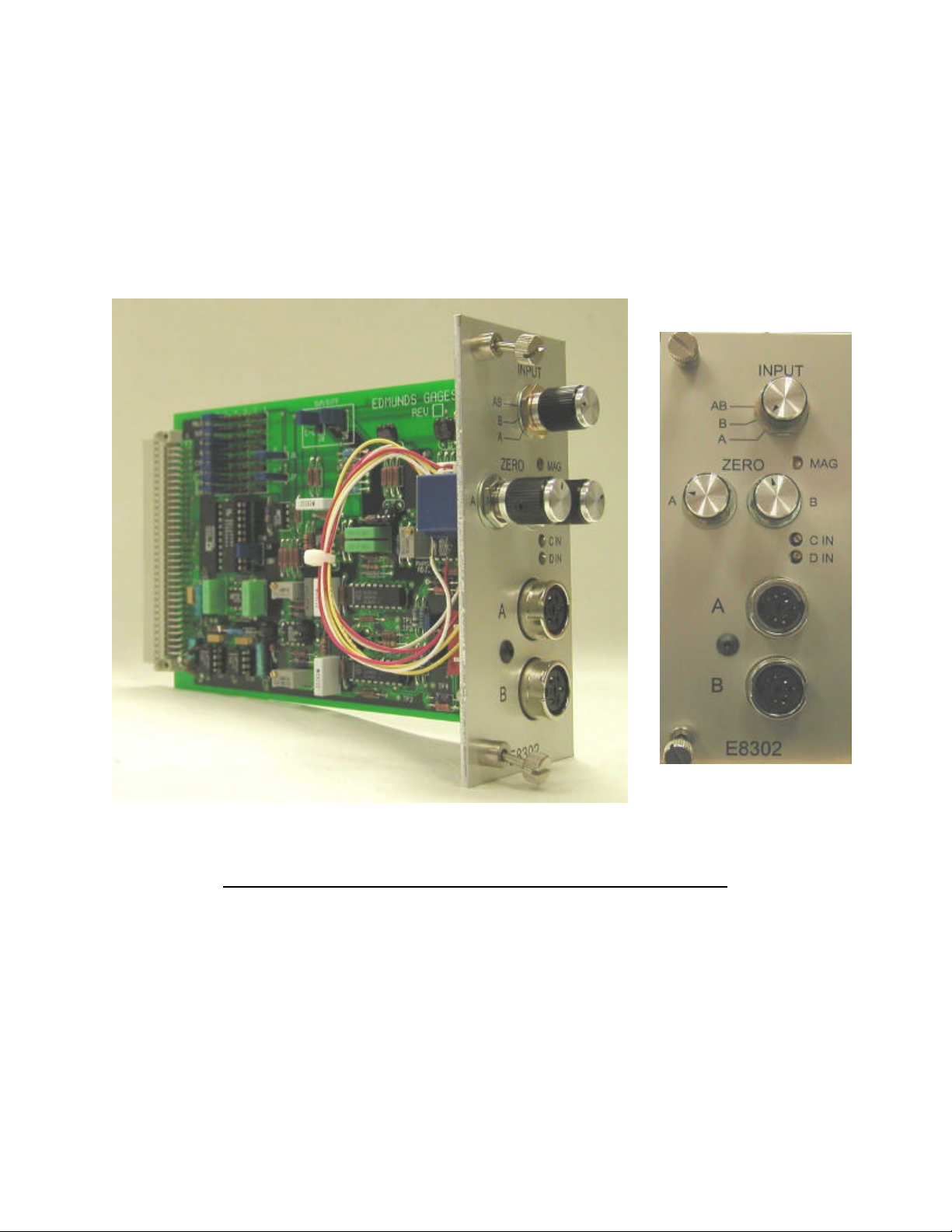

2.7 E8302 (2) Channel LVDT Signal Conditioning Module

The E8302 module is a two-channel signal conditioning amplifier for inductive type

transducers such as LVDTs that converts the outputs of the transducers into a conditioned

signal for the main controller board. The module is mounted in the lower bay of the

Trendsetter II.

The polarity of inputs A and B must be setup using either switches on the original version

of the board or jumpers on the current version of the circuit board. The polarity setting

determines whether the input reads positive or negative when the LVDT tip is depressed.

The input magnification must also be set using jumpers allowing magnification reduction

to be set to 10x for long range transduc ers or 1x for standard transducers.

A jumper matrix on the board allows it to accept signals in or send signals out to the

analog output connector. By placing the jumper pin for the desired signal line on one of

the six buss lines, the signal can now be sent or received by any other units connected to

the buss.

The bussed in signals, C and D, can be added or subtracted using the "SUM/DIFF"

jumpers.

The LVDT module contains a INPUT selection knob. The INPUT selection knob can be

set to A, B, or AB. When set to A the reading of only input A will be displayed on the

bargraph and the alphanumeric display. When set to B the reading of only input B will

be displayed on the bargraph and the alphanumeric display. When set to AB the result of

input A + input B will be displayed. Note: When auxiliary inputs C and/or D utilized,

they will be "summed" together with LVDT inputs A and B.

The LVDT signal conditioning module also contains a ZERO adjustment knob for inputs

A and B, a MAG adjustment screw for the A and B inputs, and a MAG adjustment screw

for inputs C and D bussed in from a separate column or columns.

Power to the column must be turned off prior to installing or removing a signal

conditioning module.

Refer to the Advanced Operation, LVDT Module Setup section for additional

information on jumper settings and see Basic Operation, Setting LVDT Mag & Zero

for additional information on setting Mag and Zero for a particular application.

2-11

Figure 2.7 - E8302 (2) Channel LVDT Signal Conditioning Module

2-12

2.8 E8303 (1) Channel A/E Signal Conditioning Module

The E8303 module is a single channel air/electric amplifier which processes pneumatic

information from the air tooling and delivers a conditioned signal to the controller board

of the Trendsetter II. The module is mounted in the lower bay of the Trendsetter II.

The A/E module also contains a ZERO adjustment knob and a MAG adjustment knob for

initial input setup to accommodate the air tooling used..

The air tooling is connected to the air fitting on the front panel of the module. The

recommended length of air line from the module to the air tool is no more than six feet.

A minimum of 60 psi air must be supplied to the filter/regulator assembly on the rear of

the unit. The regulator is factory set to 44 psi.

The polarity of the input must be setup using jumpers on the circuit board. The polarity

setting determines whether the input reads positive or negative when the air nozzles are

closed off. The input gain must also be set to low, medium, or high use jumpers supplied

on the circuit board. A jumper strip labeled "A OUT" provides the option to select a pin,

1 -6, to output a high level (+/-1.84VDC) signal to the I/O connectors.

Power to the column must be turned off prior to installing or removing a signal

conditioning module.

Refer to the Advanced Operation, A/E Module Setup section for additional

information on jumper settings and see Basic Operation, Setting A/E Mag & Zero

for additional information on setting Mag and Zero for a particular application.

2-13

Loading...

Loading...