VPE-300 Series

Installation

Information

Manual Number: TP0801-00

Issue: A1

Date: June 1995

Before You Install

Introduction ...............................................................................................................1-1

Receiving Inspection ................................................................................................1-1

Unpacking Instructions ...........................................................................................1-2

Equipment Inspection ..............................................................................................1-4

Facility Checklist .......................................................................................................1-4

Contents

General Information

Introduction ...............................................................................................................2-1

About The Manual ....................................................................................................2-1

Manual Conventions .........................................................................................2-2

Editor Description ....................................................................................................2-2

Computing Chassis ............................................................................................2-2

Single Board Controller (SBC) ...................................................................2-3

Hard Drive .............................................................................................2-3

Floppy Disk Drives ...............................................................................2-3

Fan .................................................................................................................2-4

DC Power Supply ........................................................................................2-4

Backplane ......................................................................................................2-4

Expansion Chassis ..............................................................................................2-5

Keyboard .............................................................................................................2-5

K2 Keyboard .................................................................................................2-6

K3 Keyboard .................................................................................................2-6

K5 Keyboard (VPE-351 Only) ....................................................................2-7

Specifications .............................................................................................................2-8

Safety ..........................................................................................................................2-9

Environmental Requirements .................................................................................2-9

Installing The Editor

Introduction ...............................................................................................................3-1

The Work Space ........................................................................................................3-1

Cable Information .....................................................................................................3-2

Editor Installation .....................................................................................................3-2

Installing The Computing Chassis ..................................................................3-3

iii

Contents

Expansion Chassis Installation .........................................................................3-7

Placing The Keyboard .......................................................................................3-8

Making The Connections .........................................................................................3-9

Computing Chassis Connections .....................................................................3-9

Expansion Chassis Connections .......................................................................3-13

K5 Keyboard Connections ................................................................................3-14

The Start-up Sequence .............................................................................................3-15

Turning Power On .............................................................................................3-15

Menu Selection And Control ............................................................................3-16

Making Basic Checks ................................................................................................3-19

Machine Assignments .......................................................................................3-19

VTR Machine Assignments ........................................................................3-20

AUX and BLK Crosspoint Assignments ..................................................3-22

Fast Column Data Entry .............................................................................3-23

Other Machine Assignments .....................................................................3-24

Communications Testing ............................................................................3-25

Installation Troubleshooting ...................................................................................3-27

Front Panel Status Indicators ............................................................................3-27

Program Execution ............................................................................................3-28

SBC Switches .......................................................................................................3-28

SBC Jumpers .......................................................................................................3-29

Appendix A – System Differences

Appendix B – Port Availability With Options

Appendix C – K3 Keyboard Information

Introduction ...............................................................................................................C-1

K3 Keyboard New Features ....................................................................................C-1

Embedded Functions ...............................................................................................C-2

Embedded Alpha Character Keystrokes ...............................................................C-3

Keyboard Sensitivity Adjustment ..........................................................................C-4

Uploading/Re-uploading Keyboard Software ....................................................C-5

Troubleshooting After Downloading ....................................................................C-5

Internal Keyboard DIP Switch Settings .................................................................C-6

Appendix D – K2 Keyboard Information

Introduction ...............................................................................................................D-1

Manual Override of Jog Knob Automatic Mode .................................................D-1

Keyboard Sensitivity Adjustment ..........................................................................D-2

Appendix E – Interconnecting Diagrams

Appendix F – System Software Installation

Introduction .........................................................................................................F-1

Installing System Software ...............................................................................F-1

iv

Glossary

List of Figures

No. Title Page

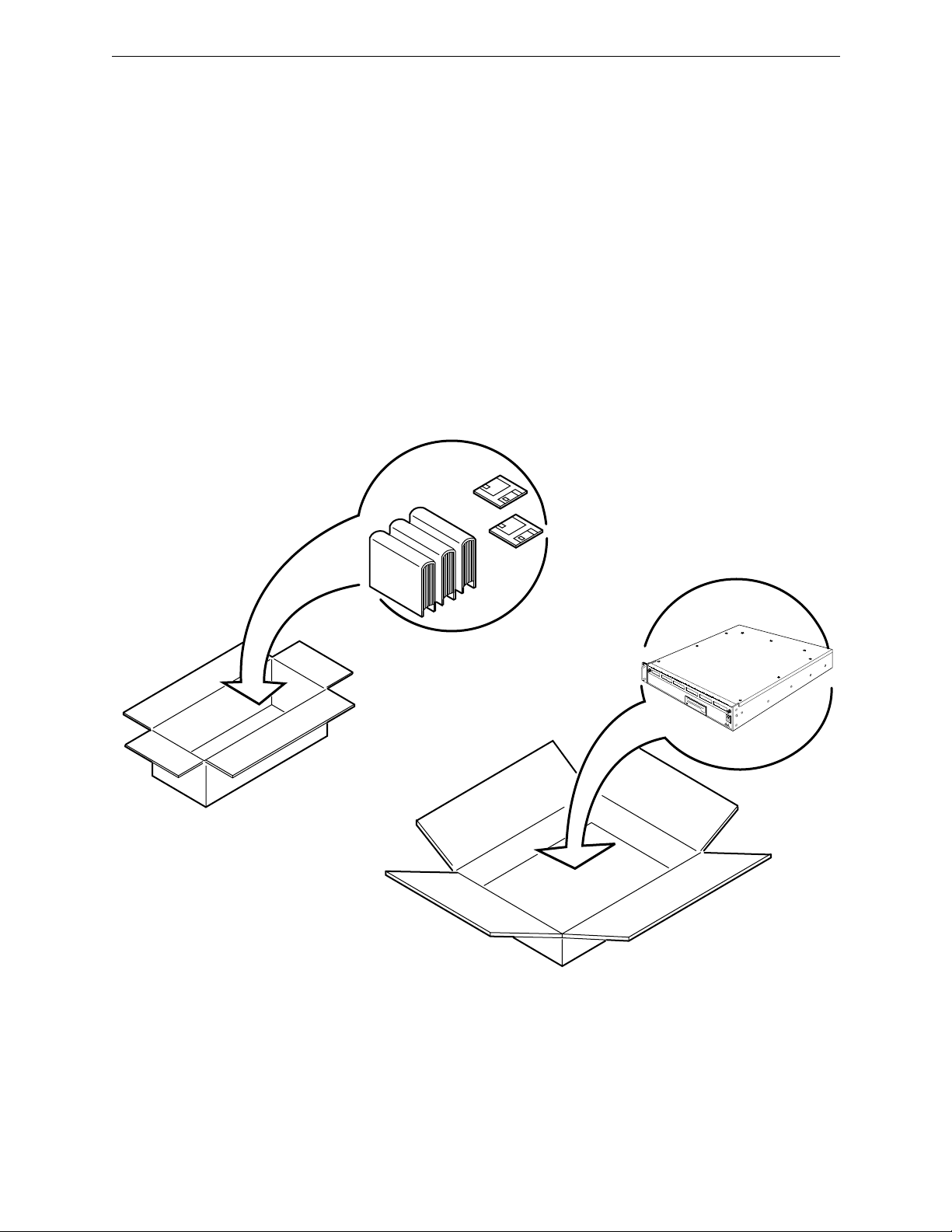

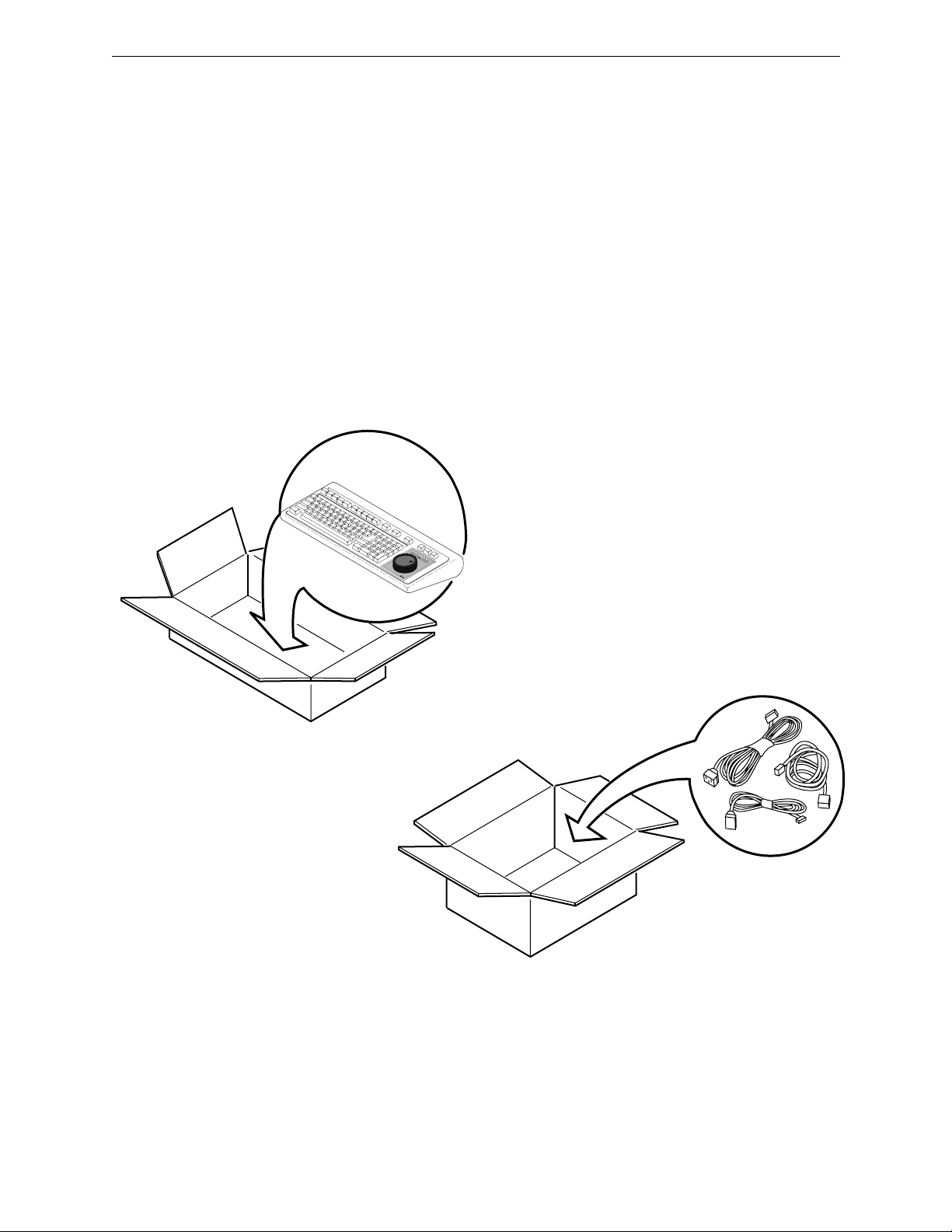

1-1 Unpacking Your Editor.........................................................................1-3

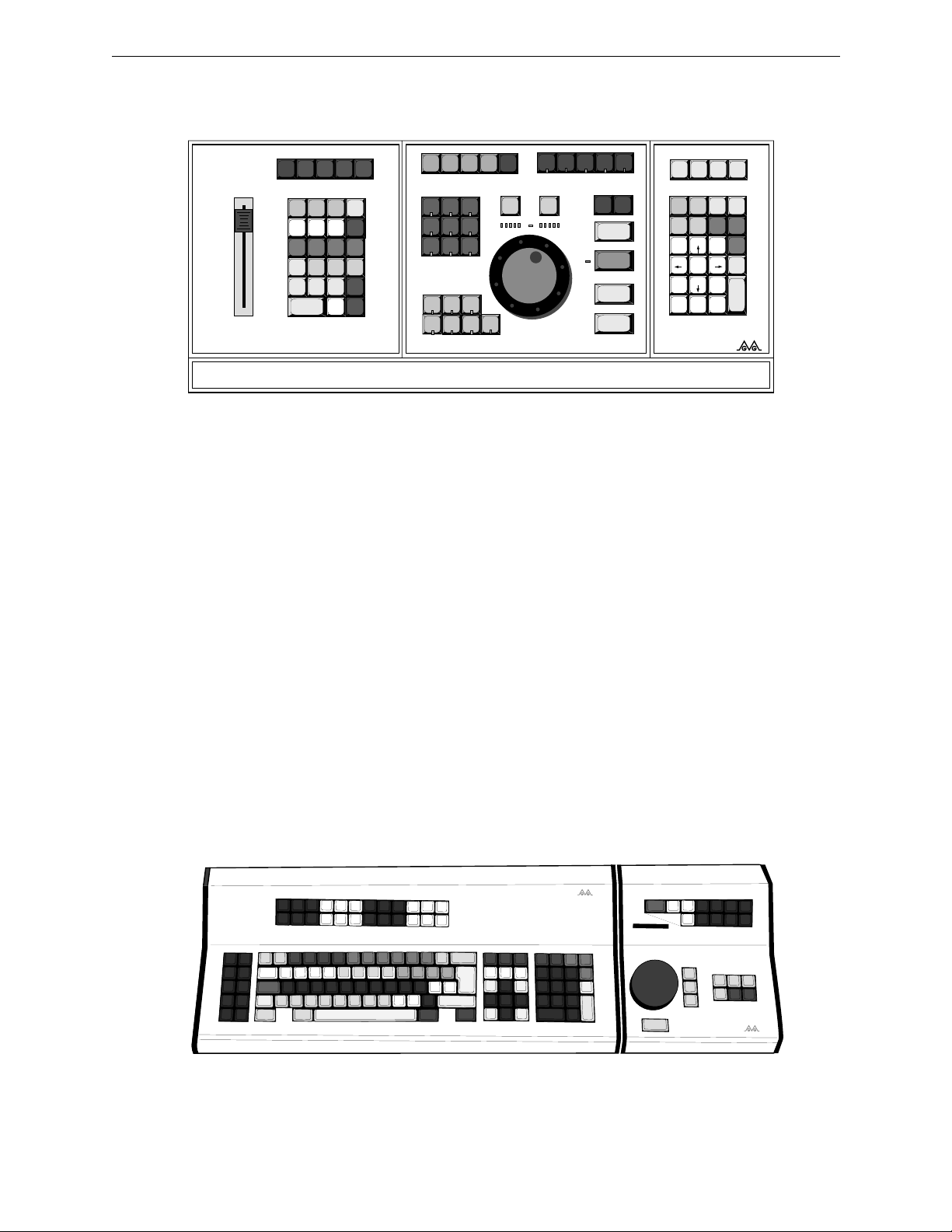

2-1 Editor Computing Chassis....................................................................2-3

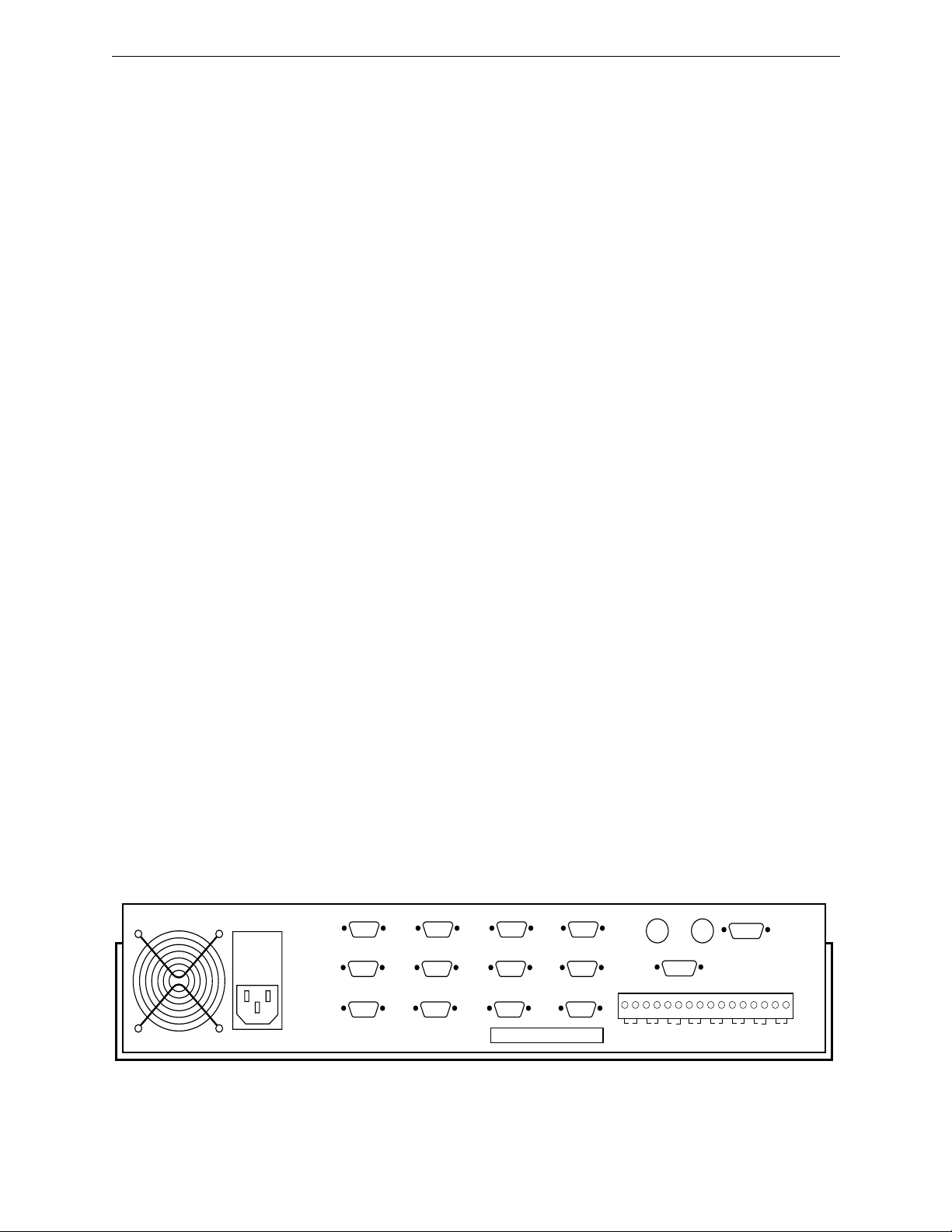

2-2 Computing Chassis Rear Panel............................................................2-4

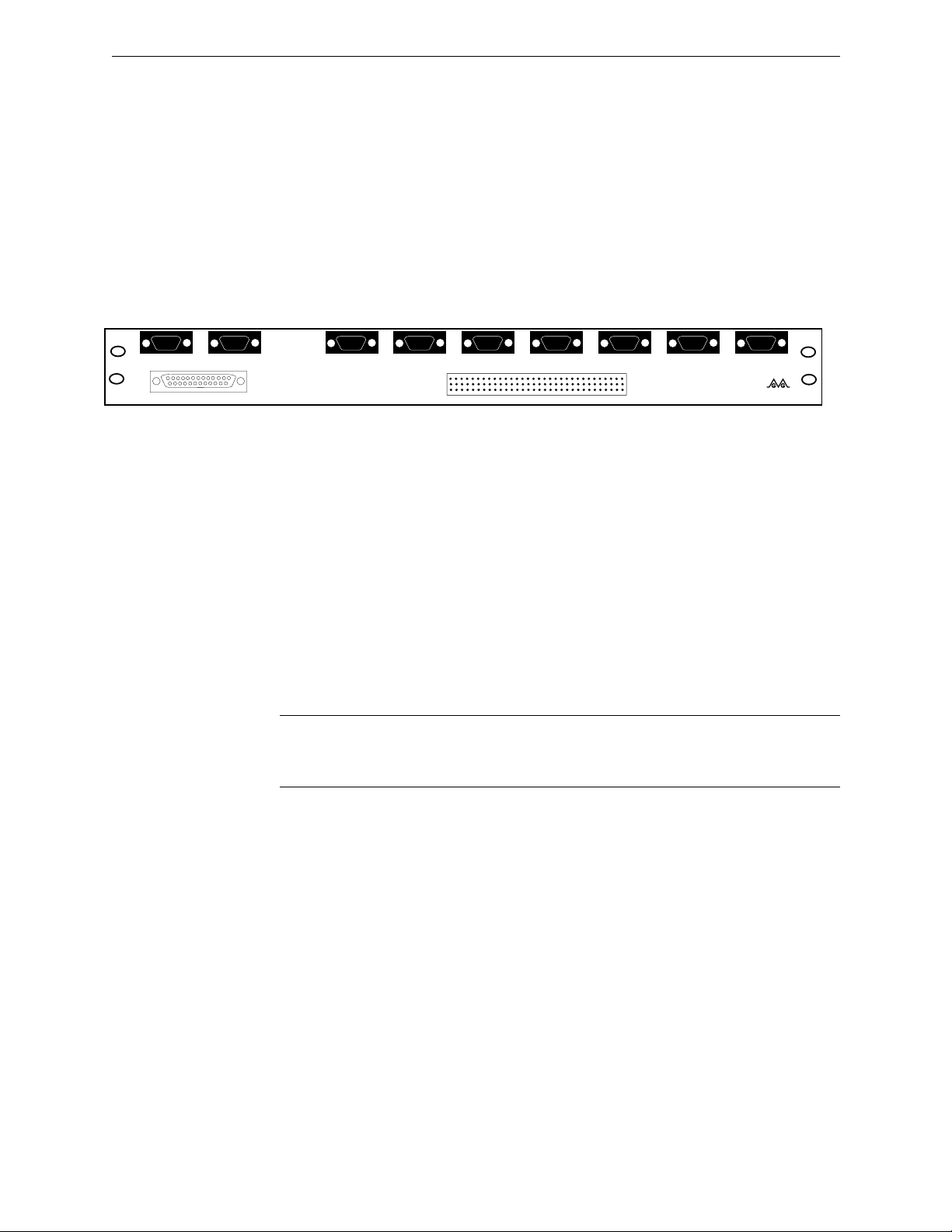

2-3 Expansion Chassis .................................................................................2-5

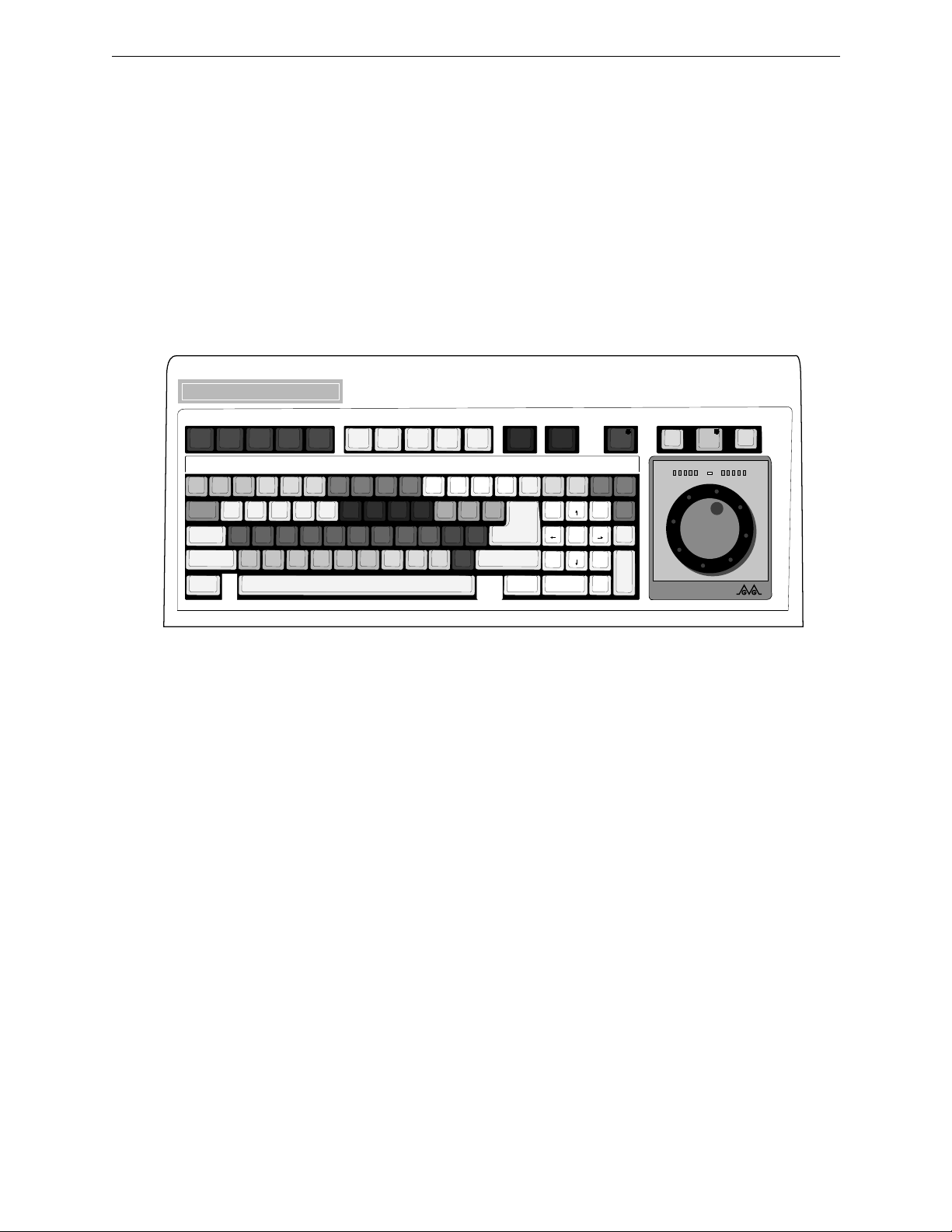

2-4 K2 QWERTY Style Keyboard...............................................................2-6

2-5 K3 Dedicated Functions Keyboard......................................................2-7

2-6 K5 Keyboard with Jog Panel ................................................................2-7

3-1 Table Top Mounting Foot Installation................................................3-3

3-2 Computing Chassis Handle Installation.............................................3-4

3-3 Handle & Mounting Bracket Attachment ..........................................3-5

3-4 Installing the Computing Chassis Into the Equipment Rack ..........3-6

3-5 Expansion Chassis Installation ............................................................3-7

3-6 Computing Chassis Rear Panel Connectors.......................................3-11

3-7 Expansion Chassis Connectors ............................................................3-13

3-8 K5 Keyboard Connectors......................................................................3-14

3-9 Super Edit Main Menu..........................................................................3-15

3-10 Diagnostics & Test Menu......................................................................3-17

3-11 PROM-based Self-test Results..............................................................3-17

3-12 Boot Device Selection Menu.................................................................3-18

3-13 Machine Assignment Page ...................................................................3-19

3-14 Edit Screen Display................................................................................3-25

3-15 Computing Chassis Front Panel Indicators .......................................3-28

3-16 SBC Switch Locations............................................................................3-28

3-17 Removing the SBC .................................................................................3-29

3-18 SBC Jumper Locations...........................................................................3-30

Contents

E-1 Example of System Interconnection

Without an 8466 Preview Switcher .........................................E-3

E-2 Example of System Interconnection

With an 8466 Preview Switcher ..............................................E-5

v

Contents

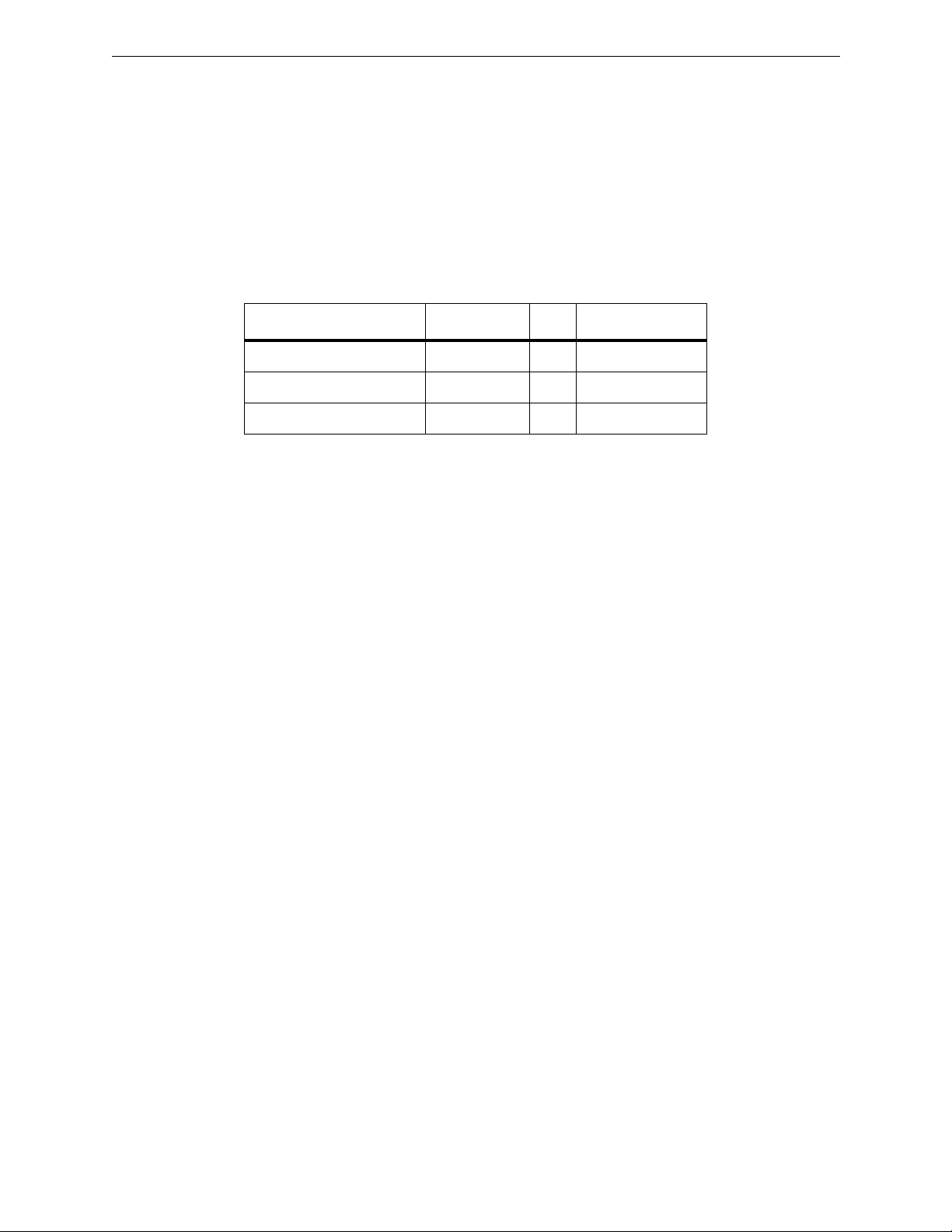

List of Tables

No. Title Page

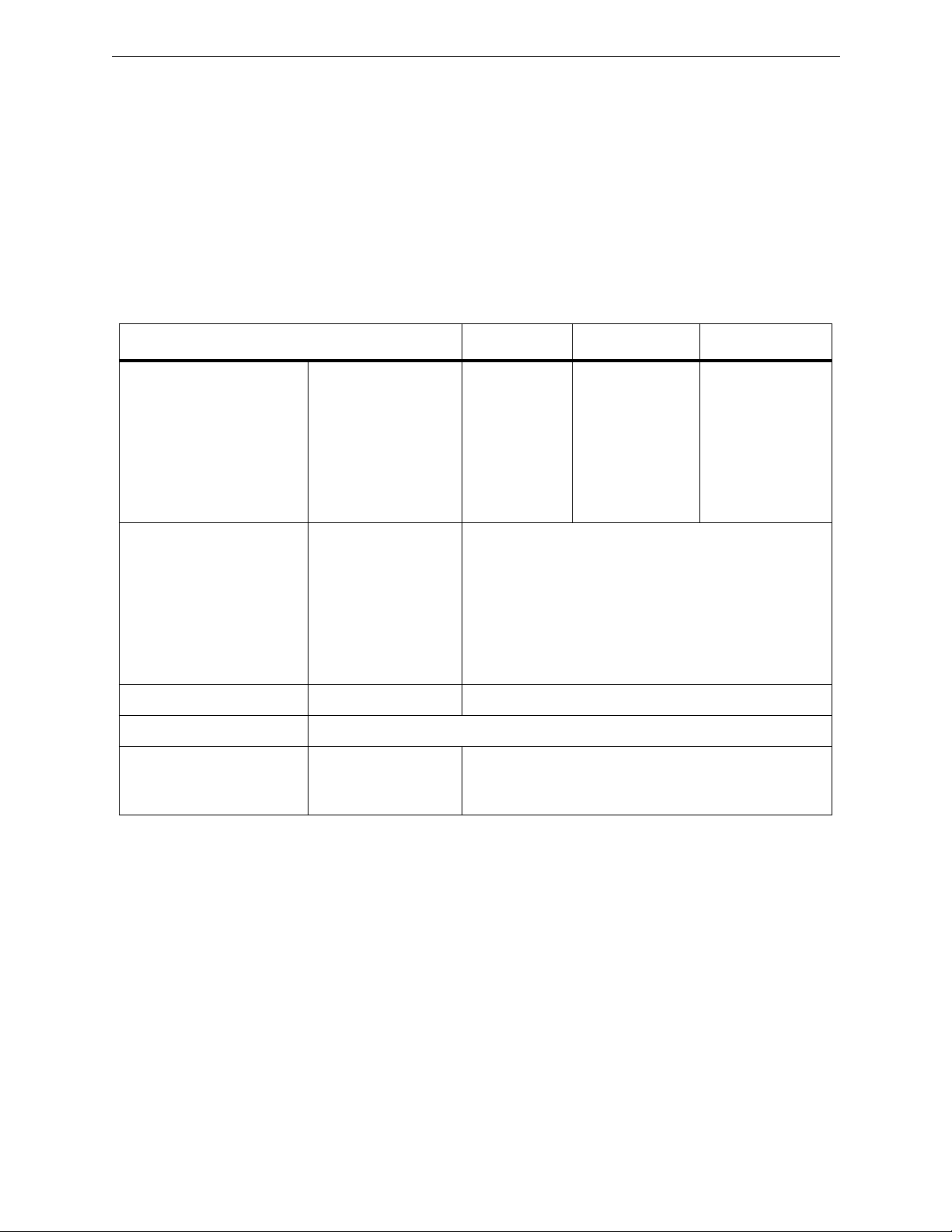

2-1 Physical & Electrical Specifications.....................................................2-8

3-1 Basic Cable Set........................................................................................3-2

3-2 SBC Default Jumper Settings................................................................3-31

3-3 EPROM Selection Jumpers ...................................................................3-32

3-4 Keyboard Baud Rate Selection Jumpers.............................................3-33

A-1 VPE Series Editing Systems Hardware Differences..........................A-1

A-2 VPE Series Editing Systems Software Differences............................A-2

B-1 VPE-SystemVTR Port Availability With GVG Model 100/110, 200

Series, Model 300, 1000, 3000, 4000, GVG Kadenza

or Ampex Vista.......................................................................................B-1

B-2 VPE-SystemVTR Ports Availablility with GVG Ten-XL/Performer,

GVG Model 1600/1680, Ross, CDL, Ampex AVC

or Century ..............................................................................................B-2

vi

Important Safeguards and

Regulatory Notices

Information on the following pages provides important safety guidelines

for both Operator and Service Personnel. Specific warnings and cautions

will be found throughout the manual where they apply, but may not

appear here. Please read and follow the important safety information,

noting especially those instructions related to risk of fire, electric shock or

injury to persons.

WARNING

Any instructions in this manual that require opening the equipment cover or

enclosure are for use by qualified service personnel only. To reduce the risk

of electric shock, do not perform any servicing other than that contained in

the operating instructions unless you are qualified to do so.

Symbols and Their Meanings

The lightning flash with arrowhead symbol, within an equilateral triangle,

alerts the user to the presence of “dangerous voltage” within the

equipment’s enclosure that may be of sufficient magnitude to constitute a

risk of electric shock to persons.

The exclamation point within an equilateral triangle alerts the user to the

presence of important operating and maintenance (servicing) instructions

in the literature accompanying the equipment.

The fuse symbol indicates that the fuse referenced in the text must be

replaced with one having the ratings indicated.

This symbol represents an internal protective grounding terminal. Such a

terminal must be connected to earth ground prior to making any other

connections to the equipment.

v

Safeguards and Notices

Danger

This symbol represents an external protective grounding terminal. Such a

terminal may be connected to earth ground as a supplement to an internal

grounding terminal.

CAUTION

This equipment contains static sensitive components. Use anti-static grounding

equipment whenever handling or servicing modules and components. When circuit

modules are removed from the frame, place them on a flat static-controlled

surface. Failure to follow this precaution can result in component damage due to

electrostatic discharge.

Warnings

Electrical potential is still applied to some internal components even

■

when the power switch/breaker is in the off position. To prevent

electrical shock when working on this equipment, disconnect the AC

line cord from the AC source before working on any internal

components.

■

A residual voltage may be present immediately after unplugging the

system due to slow discharge of large power supply capacitors. Wait 30

seconds to allow capacitors to discharge before working on the system

■

Heed all warnings on the unit and in the operating instructions.

Do not use this equipment in or near water.

■

Disconnect ac power before installing any options.

■

■

The attachment plug receptacles in the vicinity of the equipment are all

to be of a grounding type, and the equipment grounding conductors

serving these are to be connected to earth ground at the service

equipment.

This equipment is grounded through the grounding conductor of the

■

power cord. To avoid electrical shock, connect the power cord to the

equipment and plug it into a properly wired receptacle before

connecting the equipment inputs and outputs.

Route power cords and other cables so that they are not likely to be

■

damaged.

Disconnect power before cleaning. Do not use liquid or aerosol

■

cleaners; use only a damp cloth.

vi

Safeguards and Notices

■

Dangerous voltages exist at several points in this equipment. To avoid

personal injury, refer all servicing to qualified personnel.

■

Do not wear hand jewelry or watches when troubleshooting high

current circuits, such as the power supplies.

■

During installation, do not use the door handles or front panels to lift

the equipment as they may open abruptly and injure you.

To avoid fire hazard, use only components of the the specified type,

■

voltage and current rating as referenced in the appropriate parts list.

Always refer fuse replacement to qualified service personnel.

■

To avoid explosion, do not operate this equipment in an explosive

atmosphere unless it has been specifically certified for such operation.

Have qualified personnel perform safety checks after any completed

■

service.

Risk of electric shock is present. A grounded circuit conductor (neutral)

■

is provided with over current protection. Test all components before

touching.

vii

Safeguards and Notices

Cautions

To prevent damage to equipment when replacing fuses, locate and

■

correct the trouble that caused the fuse to blow before applying power.

■

Verify that all power supply lights are off before removing the power

supply or servicing equipment.

Use only specified replacement parts.

■

■

Follow static precautions at all times when handling this equipment.

■

Leave the back of the frame clear for air exhaust cooling and to allow

room for cabling. Slots and openings in the cabinet are provided for

ventilation. Do not block them.

■

The front door is part of the fire enclosure and should be kept closed

during normal operation.

■

To prevent damage to this equipment read the instructions in this

document for proper input voltage range selection.

Danger of explosion if battery is incorrectly replaced. Replace only with

■

the same or equivalent type recommended by the manufacturer.

Dispose of used batteries according to the manufacturer’s instructions.

■

Circuit boards in this equipment are densely populated with surface

mount and ASIC components. Special tools and techniques are

required to safely and effectively troubleshoot and repair modules that

use SMT or ASIC components. For this reason, service and repair of

products incorporating surface mount technology are supported

only on a module exchange basis. Customers should not attempt to

troubleshoot or repair modules that contain SMT components. Editware

assumes no liability for damage caused by unauthorized repairs. This

applies to both in- and out-of-warranty products.

viii

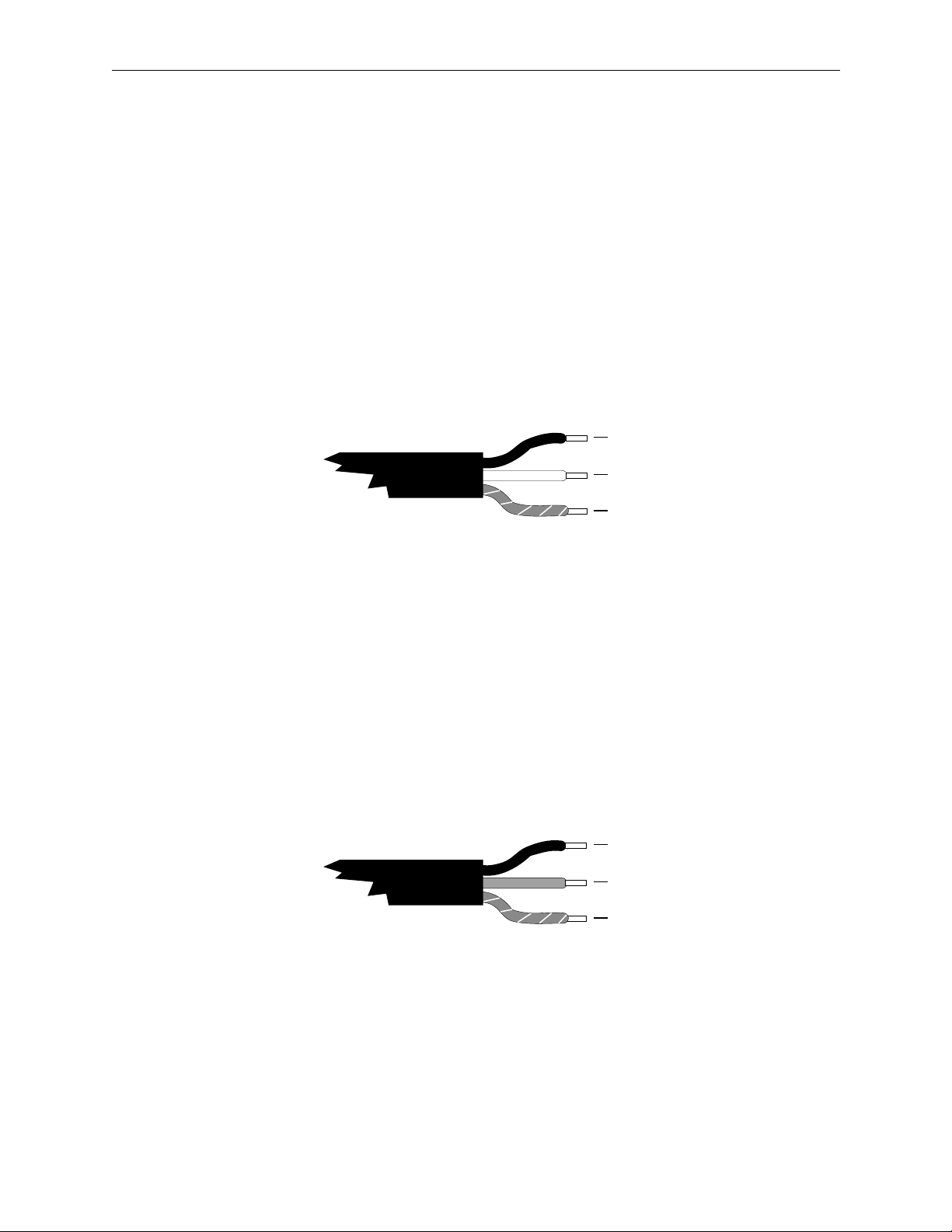

Power Cord Notices

North American Power Supply Cords

Safeguards and Notices

This equipment is supplied with a molded grounding plug (

at one end and a molded grounding receptacle (IEC 320-C13) at the other

end. Conductors are color coded white (neutral), black (line) and green or

green/yellow (ground).

Operation of this equipment at voltages exceeding 130 Vac will require

power supply cords which comply with NEMA configurations.

International Power Supply Cord

This equipment is supplied with a molded grounding receptacle (IEC 320C13) at one end and stripped conductors (50/5 mm) at the other end.

Conductors are CEE color coded—light blue (neutral), brown (line) and

green/yellow (ground). Other IEC 320 C-13 type power supply cords can

be used if they comply with the safety regulations of the country in which

they are installed.

Black

White

Green or Green

with Yellow stripe

Line

Neutral

Ground

(Earth)

NEMA 5-15P

NOTE: The

illustrated U.S. cord

is for 110/125 Vac

only.

For 220 Vac, the line

cord has two hot

lines and no neutral.

)

Brown

Blue

Green with

Yellow stripe

Line

Neutral

Ground

(Earth)

NOTE: This

international cord is

for both 110 and 220

Vac.

Europe uses singleor 3-phase 230 Vac,

with one hot line and

one neutral.

ix

1

Introduction

Before You Install

Introduction

Congratulations on your purchase of one of the finest video tape editing

systems on the market. The Video Production Editor (VPE) is

manufactured by Editware, Inc., the recognized leader in quality

and service for video tape editing systems. This is the Installation

Instructions manual for the VPE. It covers installation of the VPE models

listed below:

VPE-331

■

■

VPE-341

■

VPE-351

Throughout this manual, when information or discussions are inclusive of

all the models listed above, the VPEs are referred to as the Editor. Where

differences exist, they are so noted. In addition, a table listing the

differences between the Editors is provided in Appendix A.

The next few pages provide information about what to look for when you

receive and unpack your Editor. A facilities checklist is included.

Receiving Inspection

Inspect all shipping containers for any signs of damage. If any is found,

notify the shipping company. If there is no obvious damage, continue with

the unpacking instructions.

1-1

Section 1

— Installing The Editor

Unpacking Instructions

Place the containers on a flat level surface with enough room to move the

containers around as needed. In the Manual Set container, locate the

Manual Set Inventory sheet. Remove all the remaining manuals and the

Floppy Disk software set. Compare the manuals against the Inventory

sheet and make a note of any discrepancies.

GRASS VALLEY GROUP

1-2

Unpacking Instructions

Locate the container with a small plastic pouch taped to its top, open the

pouch, and remove the Packing List. In turn, open each of the remaining

containers. One contains the VPE Chassis. Others contain the Keyboard,

cables, and any other installation hardware. See Figure 1-1. (One or more

options may be in any of these containers.)

Carefully remove the contents of each container and place on a flat level

surface. Compare the contents with the Packing List to ensure that there are

no missing items. Make a note of any discrepancies.

GRASS VALLEY GROUP

0354-00-001

Figure 1-1. Unpacking Your Editor

1-3

Section 1

— Installing The Editor

Equipment Inspection

Inspect all equipment for damage. Items to specifically check, and damage

to look for, are listed below:

All connectors for bent or broken pins

■

Cables for crimped or broken wires

■

■

Floppy diskettes for any obvious signs of damage

If any damage is found, contact Editware Customer Service at the telephone

number in the front of this manual. If any item is damaged, DO NOT make

any power or signal connections to the unit unless otherwise advised to do

so by Editware Customer Service.

If there are any discrepancies between the Manual Set Inventory sheet and

the manuals received, or between the Packing List and items received,

contact Editware Customer Service at the telephone number at the front of this

manual. If there are no discrepancies and either no damage, or GVGadvised correction action is made, continue with this manual.

Facility Checklist

The following checklist is a synopsis of information found in the

appropriate Installation Planning Guide. The Planning Guide should be

referred to for detailed site preparation information.

■

If your facility includes an equipment rack, ensure that the rack is

within 50 feet (16 meters) of your work space.

Ensure that there are sufficient AC power outlets of the required 3-

■

prong grounded type and amp rating for the intended equipment.

■

To maintain consistent signal quality throughout your facility, there

should be a minimum of two Distribution Amplifiers (DAs).

■

Depending on the video switcher, you may need Sync, Subcarrier,

and Blanking in addition to Black Burst.

■

Ensure that the work space is at least large enough to accommodate

the following:

The K2, K3, or K5 Keyboard

One or more monitors

Control Panels for any other equipment

1-4

2

Introduction

General Information

Introduction

If you have not had experience with video tape editing, Editing Systems, or

with Editware, Inc., please take a few minutes to get acquainted

with this manual. Also, we recommend that you read all step-by-step

instructions through at least once before performing them.

About The Manual

Your VPE-300 Series Editor is self-contained and this is the Installation

Instructions manual for it. The manual is part of a Manual Set shipped with

your Editor. A list of available manuals can be found at the front of this

book. For ease of use, the manual is divided into topical sections. Sections

are identified and briefly described below.

General Information

about your Editor. It includes a description of the Editor and its

specifications, power requirements, and environmental & safety

information.

Installing The Editor

on installing your Editor. It has cabling information and a start-up

procedure.

- This section provides introductory material

- This section gives you step-by-step instructions

Glossary

manual which you may not be familiar with. This includes acronyms.

The manual may also contain one or more appendices, which are

supplemental information included as a convenience for you.

- The Glossary is an alphabetical listing of terms used in the

2-1

Section 2

— General Information

Manual Conventions

Items of discussions within a topic are indicated by titles in the right-hand

column. Pages, figures (illustrations), and tables are numbered to reflect

the section of the manual within which they are located. For example, in

this section, page, figure, and table numbers begin with 2-.

NOTE:

section) and return to this section at the completion of installation. However, it is

recommended that you become more familiar with your Editor by continuing with

this section.

Editor Description

At this point, you may want to go directly to Installing The Editor (the next

Your Editor is designed to control videotape machines, video switchers,

and audio mixers in a post-production environment. It can also control

other devices such as a printer. The Editor consists of a Computing Chassis

and a Keyboard, and, for the VPE-351, an Expansion Chassis. A color

monitor is required (purchased separately from Editware and an optional

printer may also be used.

Computing Chassis

The Computing Chassis, illustrated in Figure 2-1, houses the following

components of the Editor:

Single Board Controller

■

Fan

■

■

DC Power Supply

Backplane

■

2-2

Editor Description

0354-00-002

DRIVE 1

DRIVE 0

Figure 2-1. Editor Computing Chassis

Single Board Controller (SBC)

The Single Board Controller, mounted inside the Computing Chassis,

contains the controller and data processing circuitry for the Editor. It

contains all the controls and indicators (except power ON/OFF) for the

Editor.

Hard Drive

All VPE models use a Hard Disk Drive, mounted on the SBC board, for

long term EDL storage.

Floppy Disk Drives

Two 3.5-inch floppy disk drives, mounted on the SBC board and

designated DRIVE Ø (DFØ) and DRIVE 1 (DF1), are standard

equipment. The Drive fronts extend through the front panel for easy

insertion and removal of floppy disks, and viewing the Run indicator

LED on the drives’ fronts. They are designed for use with 720K double-

sided micro-floppy disks (or diskettes).

NOTE:

Do not use high density (1.4Mb) diskettes.

2-3

Section 2

— General Information

Fan

Cooling the Computing Chassis interior is accomplished by a fan mounted

on the rear panel. Fan power is +12 VDC from the DC Power Supply

through the Backplane. Ambient air is drawn in through a filter in the front

and warm interior air is exhausted out the rear of the chassis.

DC Power Supply

The DC Power Supply is mounted on the right-hand side of the Computing

Chassis. It receives 115/230 VAC power from the AC line connector on the

Input Power Filter Housing at the rear of the chassis. The Power Supply

provides the +5 and ±12 VDC voltages required by the Editor. These

outputs are distributed to other components through the Backplane.

Backplane

This is a printed circuit board mounted vertically at the interior rear of the

chassis. The interior side of the Backplane has connectors which interface

power and signals for the Computing Chassis components. For all the

Editors, inputs/outputs for external devices are interfaced to the

Backplane by connectors attached to its exterior side. These connectors

extend through slots on the rear panel. For the VPE-351, the Expansion

Chassis provides additional interfaces for external devices.

Figure 2-2 shows the rear panel of the Computing Chassis. Backplane

connectors provide signal interfaces between the Computing Chassis, the

Keyboard, the Monitor, peripheral devices, and, for the VPE-351, the

Expansion Chassis. Backplane Connectors are:

■

Fourteen (14) 9-pin D connectors

Two (2) BNC connectors

■

■ A Serial I/O connector.

■ A GPI terminal strip

KEYBOARD

PORT 0

VIDEO CTL PORT 6

AUDIO CTL

PORT 5

PORT 3

PORT 2

PRINTER/COMM

COLOR MONITOR

CFID INSYNC IN

4-00-003

2-4

PORT 7CHAR GEN

PORT 4

PORT 1

Figure 2-2. Computing Chassis Rear Panel

EDIT GPI

8 7654321

Expansion Chassis

The Expansion Chassis (VPE-351 only), shown in Figure 2-3, consists of

eight (8) 9-pin D connectors and a 64-pin Serial I/O connector. These

connectors provide the signal interfaces between the Expansion Chassis,

the Computing Chassis, peripheral devices, and, if desired, the K5

Keyboard.

Editor Description

1234

5

9876

JOG IN

KBD IN

1234

5

9876

KBD OUT

VPE PORT EXPANDER

Keyboard

The standard Keyboard for your Editor is a model K2 QWERTY style

keyboard. (QWERTY refers to the style of keyboard, similar to a

typewriter, where the top row of letters, from the left, begins with the

letters QWERTY.) An optional K3 style keyboard is available for all models

and an optional K5 Keyboard is available for the VPE-351.

NOTE:

instructions for the AUTO CAL and MANUAL OVERRIDE features of the

Keyboard. See Section 2 of the User’s Guide for additional information.

5

9876

1234

5

9876

1234

5

9876

1234

5

9876

1234

PORT 18 PORT 17 PORT 16 PORT 15

5

9876

1234

5

9876

1234

5

9876

1234

PORT 14 PORT 13 PORT 12

0353-00-060

Editware VPE Series

Figure 2-3. Expansion Chassis

The K2 Keyboard has a sticker on the bottom which provides brief operation

2-5

Section 2

— General Information

K2 Keyboard

The K2 Keyboard, illustrated in Figure 2-4, includes a Jog Knob. The

Keyboard connects to the KEYBOARD connector at the chassis rear panel.

QWERTY keys are used for normal text entries and for some editing and

control functions. Other keys provide special functions.

The Jog Knob provides efficient machine control. It is a motion sensitive

device allowing quick access to different motion control modes without the

need for additional keystrokes.

VPE-131 Video Production Editor

LEARNMODIRM1INPUTM2OUTPTM3AUTO

OPEN

ASGNSLVSPEGS

END

AUTO

RECORD

CTRL

ALT

RPLAY

ASMB

R-VTR A-VTR B-VTR C-VTR D-VTR E-VTR F-VTR AUX BLK

REW FF PLAY STOP SLOW SRCH

SHIFT

M4

PKUP

CLEAR

SAVE

MARKS

VVV BVB VBV A/V AUDIO VIDEO SPLIT CUT DISS

RESET

RECAL

Figure 2-4. K2 QWERTY Style Keyboard

K3 Keyboard

The K3 Keyboard, illustrated in Figure 2-5, is a dedicated keyboard

designed for fast, news-style functional applications. It also connects to the

KEYBOARD connector. Key layout is designed for maximum speed. This

Keyboard is an option for your Editor. The Jog Knob function is identical

to the one on the K2 keyboard. (See Appendix C for additional information

about the K3 Keyboard.)

RECD

INIT EJECT YES NO

OFF

INSRT

REPL

MOVE

DEL

RIPPL

MARK

MARK

IN

IN

MARK

OUT

INPUT

EDL

CONST RESET

OUTPT

ALT

TC

MARK

VAR

OUT

TRIM

OUT

SET

DUR

-

MARK

IN

GRASS VALLEY GROUP

MATCH

MATCH

MENU

TITLE

UNDO

EDL

EDL

NOTE

KEY

WIPE

MULTI

FILL

SHIFT

RETURN

SET

SET

IN

7

4

1

0 00

TRIM

OUT

IN

98

PG UP

65

SEEK

32

PG DN

ENTER

BKSP

BEGIN

END

FR

2-6

Editor Description

LEARN

VTR

BLK

B

E

SPLITCUT DISS WIPE KEY

MARKINMARK

CUE

OUT

DIR

OUTPT

AUTO

LOAD

M0

M1

M3

M4

M2

PEGS

INPUT

EDL

PKUP

RECAL

AUTO

ASMB

ALT

SHIFT

GANG

SLVS

OUTPT

EDL

INSRT

REPL

SAVE

MARKS

CTRL

ASGN INIT

UNDO

EDL

DEL

CLEAR

RESET

REC

OFF

TITLE

NOTE

MOVE

RPPL

OPEN

MULTI

RESET

ALT

TC

END

FILL

A

REC

VTR

VTR

C

VTRDVTR

VTR

F

AUX

VTR

REW FF PLAY

SLOW VAR

STOP

MATCH

REPLAY

RECORD

PREVIEW

VVV

ALL STOP

MENU

PMTCH

A4VA1A2 A3

BVB VBV YES NO

SRCH CONST CLR BKSP

SET

TRIM

SET

OUT

IN

IN

7

89

BEGIN

PG UP

45

6

SEEK

23

1

PG DN

END

FR

:

000

ENTER

TRIM

OUT

SET

DUR

-

GRASS VALLEY GROUP

Figure 2-5. K3 Dedicated Functions Keyboard

K5 Keyboard (VPE-351 Only)

The K5 Keyboard, illustrated in Figure 2-6, consists of an expanded

keyboard and a separate Jogger panel. The expanded keyboard has special

function keys which replace multiple keystrokes which would otherwise

be needed with other keyboards. This Keyboard has three connectors on its

rear panel. One is for the cable which connects to the Expansion Chassis

and one is for the cable from the Jogger panel. The third connector is for

power to the Keyboard and, through the Keyboard, to the Jogger panel.

The Jogger panel has a Jog Knob and keys which are duplicates of those on

the Keyboard. It also has a direction (forward/reverse) and speed

indicator. The Jogger panel is normally connected to the Keyboard and,

when so connected, receives power from it. However, the Jogger panel

may be connected to the Jogger connector on the Expansion Chassis and

then receives power from the Editor.

0353-355

GRASS VALLEY GROUP

VPE

Figure 2-6. K5 Keyboard with Jog Panel

2-7

Section 2

— General Information

Specifications

The physical and electrical specifications for the Editors are listed in Table

2-1 below.

Table 2-1. PHYSICAL & ELECTRICAL SPECIFICATIONS

Height Width Depth

Dimensions Computing Chassis

Expansion Chassis

K2 Keyboard

K3 Keyboard

K5 Keyboard

Jogger Panel

Weight Computing Chassis

Expansion Chassis

K2 Keyboard

K3 Keyboard

K5 Keyboard

Jogger Panel

Power Consumption VPE-300 Series 50W

Input Voltage/Frequency 90 to 264VAC, 47 to 64Hz

DC Power Supply Output 1

Output 2

Output 3

3.5”(8.9cm)

1.6”(4.1cm)

2.0”(5.1cm)

2.0”(5.1cm)

4.0”(10.2cm)

4.0”(10.2cm)

25.0lbs(11.4kg)

1.2lbs(0.5kg)

5.4lbs(2.5kg)

4.8lbs(2.2kg)

7.0lbs(3.2kg)

4.0lbs(1.8kg)

+5VDC, ±0.05VDC, 5.5A

+12VDC, ±0.6VDC, 2.5A

-12VDC, ±0.06VDC, 0.5A

17.0”(43.2cm)*

17.0”(43.2cm)

21”(53.3cm)

21”(53.3cm)

21.8”(55.2cm)

8”(20.3cm)

19.0”(40.0cm)**

1.0”(2.5cm)

9.0”(22.9cm)

9.0”(22.9cm)

9.5”(24.1cm)

9.5”(24.1cm)

* Add 2.0”(5.1cm) for brackets on rack mounted unit.

** Add 1.5”(3.8cm) for brackets on rack mounted unit.

NOTE: Dimensions do not include clearances for cabling and air flow.

2-8

Safety

Your Editor has been designed to meet UL1419 (3rd Revision) Safety

standards. It has also been designed to conform to the emission standards

of FCC Part 15, sub-part J for Class A computing equipment.

Environmental Requirements

Your Editor has been designed to operate efficiently in an environment

with temperatures of from 0 to 50 degrees Celsius in up to 90% noncondensing humidity.

Safety

2-9

3

Introduction

The W ork Space

Installing The Editor

In this section you are given step-by-step instructions on how to install

your Editor. We recommend that you read all instructions thoroughly at

least once before doing them. The section includes:

■ Things to consider when selecting a work space

■ Information on cables

■ The physical installation of the Editor

■ A start-up/power on procedure

The following is a synopsis of work space considerations when installing

your Editor. For more complete information, consult the appropriate

Installation Planning Guide. The Computing Chassis for your Editor is

designed such that it may either be mounted in a standard 19" electronic

equipment rack or placed on a level desk or table top. This, along with

room for the Keyboard, are considerations in determining the work space.

Other considerations are:

■ The proximity of electrical outlets. (The power cord for the

Computing Chassis is 6' long.)

■ Signal cables are 16 meters (approximately 52') long.

■ Routing of power cords and signal cables so that they do not

present a hazard to personnel.

3-1

Section 3

— Installing The Editor

Cable Information

Your Editor system was shipped with a set of cables. The number of cables

depends on which Editor you ordered and what, if any, options were

ordered in addition to the basic system. Cables supplied with a basic

system are listed in Table 3-1.

Echo Plug 054557-00 1 for maintenance

Printer Cable 054591-16 1 to a printer

Machine Control Cable 054602-16 * to VTRs/ATR

* 4 for the VPE-331

7 for the VPE-341

14 for the VPE-351

Table 3-1. BASIC CABLE SET

Name Part Number Qty Destination/Use

Editor Installation

Installing your Editor consists of installing the Computing Chassis and, for

a VPE-351, the Expansion Chassis; placing the Keyboard in the work space;

and then making the power cord and signal cable connections. These are

discussed in turn on the following pages.

3-2

Installing The Computing Chassis

In installing the Computing Chassis, the first thing to determine is whether

it is to be mounted in an equipment rack or placed on a console or table top.

Console or Table Top Installation

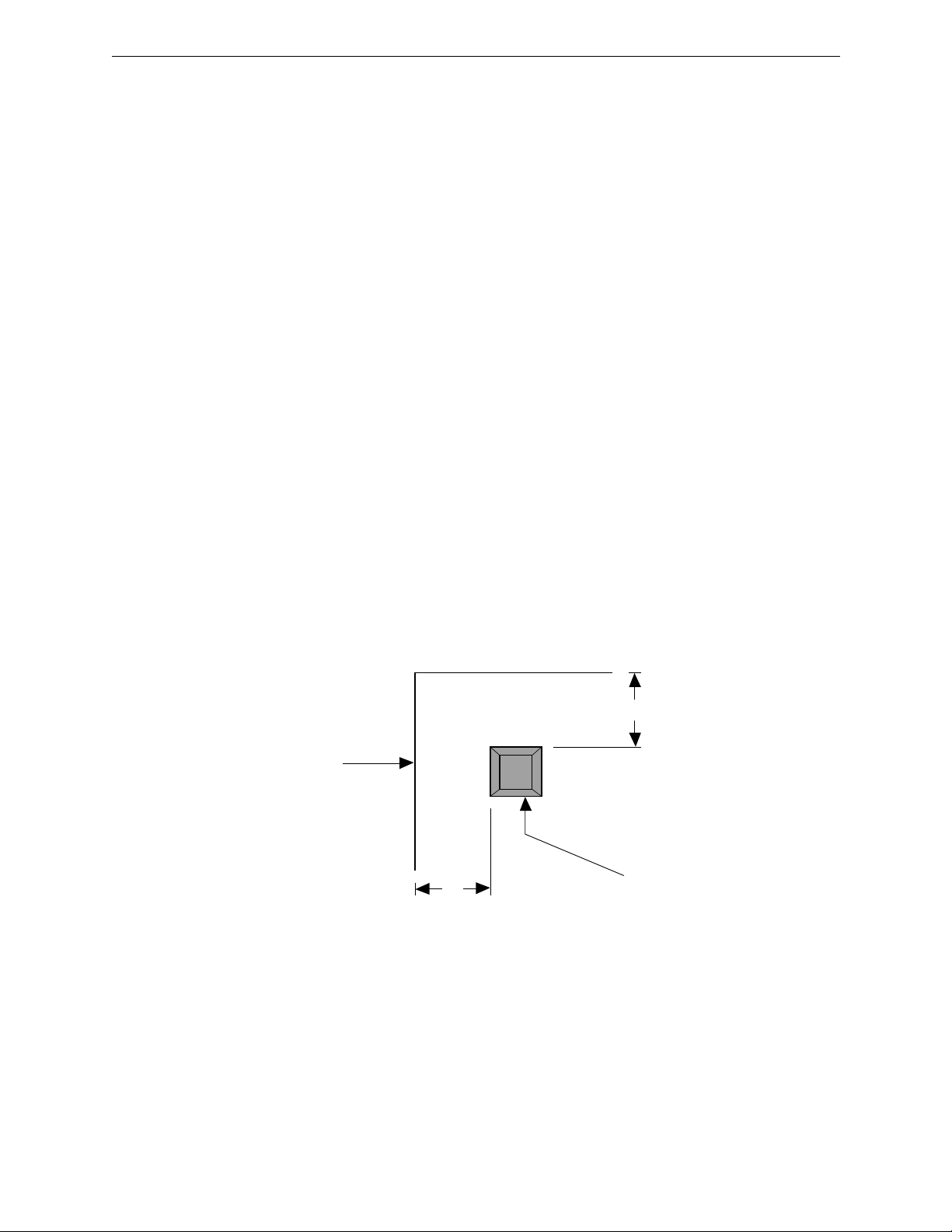

If the Chassis is to be placed on a console or table top, you may want to

protect that surface by installing the four rubber feet provided as

illustrated in Figure 3-1. To install the rubber feet, refer to Figure 3-1 and

perform the following procedure:

1. Locate the bag containing four grey mounting feet and remove

them from the bag.

2. Carefully turn the Computing Chassis over and place it on a flat

level work area on its top side.

3. One at a time, remove the backing from each foot and firmly press

into place approximately 1" in from each side at the corners on the

bottom plate. (See Figure 3-1.)

Editor Installation

4. Carefully turn the Computing Chassis back over until it is resting

Computing Chassis Side

on the mounting feet.

0354-00-006

1"

Desk-top Mounting Foot

1"

Figure 3-1. Table Top Mounting Foot Installation

3-3

Section 3

— Installing The Editor

Equipment Rack Installation

If the Computing Chassis is to be mounted in an equipment rack, mounting

hardware must first be attached to the unit. Hardware consists of handles,

mounting brackets and support brackets. Figure 3-2 illustrates handle

assembly which must be done before attachment to the Chassis. Figure 3-3

illustrates attachment of the handles and mounting brackets to the Chassis.

Figure 3-4 shows installation of the Chassis into the rack.

To attach the hardware and install the Computing Chassis into the

equipment rack, refer to Figure 3-2, 3-3, and 3-4 and proceed as follows:

1. Position the Handle, Face Plate, and Mounting Bracket together as

shown in Figure 3-2.

Mounting Bracket

Handle

Face Plate

6-32 X .50

screws

0354-00-007

Figure 3-2. Computing Chassis Handle Installation

3-4

2. Attach the parts using two of the provided 6-32 x.50 screws.

3. Repeat Steps 1 and 2 to assemble the second Handle.

4. Position one Handle against the chassis and attach it with two of the

provided 6-32 x .25 screws as shown in Figure 3-3.

5. Repeat Step 4 to attach the second Handle.

Editor Installation

6. Position one of the mounting brackets at the side of the unit as

shown in Figure 3-3 and attach it with six of the provided 8-32 x.25

screws.

7. Repeat Step 6 to attach the other mounting bracket.

Mounting Brackets

(one each side)

PGM

NO

SYNC

DC

LOW

FAIL

RUN

POWER

DRIVE 0

GRASS VALLEY GROUP

Handle Assembly

(one each side)

8-32 x 0.25

(six each side)

0354-00-308

6-32 x 0.25

(two each side)

Figure 3-3. Handle & Mounting Bracket Attachment

NOTE: Due to differences in racks, screws for attaching equipment to the rack are

not provided.

3-5

Section 3

— Installing The Editor

8. Attach one of the support brackets to the back of the equipment

rack at the height for the Chassis when installed in the rack. (See

Figure 3-4.)

PGM

NO

SYNC

DC

LOW

FAIL

RUN

POWER

DRIVE 0

Support Brackets

(one each side)

GRASS VALLEY GROUP

Figure 3-4. Installing The Computing Chassis Into The Equipment Rack

9. Repeat Step 8 to attach the other support bracket, being sure it is at

the same height.

10. Supporting the unit, slide the rear of the mounting brackets on the

Computing Chassis into the support brackets attached in Steps 8

and 9 and secure it to the equipment rack with two screws on each

side at the handles.

This completes installation of the Computing Chassis into the equipment

rack. If you are installing a VPE-351, proceed to Installing The Expansion

Chassis. Otherwise, proceed with placing the Keyboard in the work space

and then making power cord and signal cable connections.

0354-00-309

3-6

Expansion Chassis Installation

Although the Expansion Chassis may be placed on a desk, it is

recommended that it be installed in the equipment rack, preferably at the

rear of the rack. This will ensure that cables connected to the Chassis do not

impede access to the front of the rack. The Expansion Chassis must be

within 3 ft. (1 meter) of the Computing Chassis.

Figure 3-5 illustrates installation of the Expansion Chassis. To install the

Expansion Chassis, refer to Figure 3-5. With the Chassis at a convenient

height, use two rack mounting screws on each side to secure the Chassis to

the equipment rack.

Editor Installation

0354-01-009

5

4

3

2

9

1

8

7

6

JOG IN

5

4

3

2

9

1

8

7

6

KBD OUT PORT 18 PORT 17 PORT 16 PORT 15

KBD IN

VPE PORT EXPANDER

5

4

3

2

9

1

8

7

6

5

4

3

2

9

8

7

Figure 3-5. Expansion Chassis Installation

1

6

5

4

3

2

9

1

8

7

6

5

4

3

2

9

1

8

7

6

5

4

3

2

9

1

8

7

6

PORT 14 PORT 13 PORT 12

5

4

3

2

9

1

8

7

6

Grass Valley Group

5

4

3

2

9

1

8

7

6

3-7

Section 3

— Installing The Editor

Placing The Keyboard

The Keyboard is essentially the control panel in the editing environment.

As such, you want to place it in a central location where other equipment

is both visually and physically at hand. Ensure that it is within 16 meters

(approximately 52 feet) of the Computing Chassis and, if using the optional

K5 Keyboard, within 2 meters (6 feet) of a power source.

NOTE: If you are using the K2 Keyboard extension cable, you must attach the

cable grounding wire to an earth ground.

3-8

Making The Connections

For the VPE-300 Series, connections are made at connectors on the rear

panel of the Computing Chassis. For the VPE-351, additional connections

are made to the Expansion Chassis. Also, for a VPE-351 using the K5

Keyboard, connection for that Keyboard is made on the Expansion Chassis.

Appendix E contains some typical interconnecting diagrams.

Computing Chassis Connections

Figure 3-6 illustrates the rear panel of the Computing Chassis and

identifies the connections which will be made to it. To make these

connections, refer to Figure 3-6 and proceed as follows:

Making The Connections

CAUTION

Ensure that the routing of signal cables and power cords does not present a hazard

to personnel or equipment.

1. Ensure that power switches of all equipment to be connected are

OFF.

2. Connect AC power cords of all equipment to AC power outlets.

NOTE: The remainder of this procedure is the suggested order of making

connections. However, there is no recommended priority for connections.

3. If you have a Character Generator, attach the signal cable from it to

the CHR GEN connector.

4. Attach the provided VTR cables from the VTRs to the appropriate

PORT 1 - PORT 7 connectors. (See the NOTES on Figure 3-6 and

especially Appendix B for additional information on VTR port

availability and connections.)

Note that connection to these ports does not assign VTRs to the ports. That

is done through software during the Start-up Sequence.

3-9

Section 3

— Installing The Editor

For Connection of a K2 or

K3 Keyboard (not used

with a K5 Keyboard)

5. If using a peripheral device, such as a Zaxcom, attach the cable from

it to the PORT Ø connector.

6. Attach a K2 or K3 Keyboard cable to the KEYBOARD connector.

(The K5 Keyboard installation will be made later.) Note that if you

are using the K2 Keyboard extension cable, you must attach the

cable grounding wire to an earth ground.

For Connection of

For Connection

of the Audio

Mixer

the Video Switcher

or the 8466 Preview

Switcher

The AC Power

Cord Connector

For Connection of

a peripheral (such

as a Zaxcom)

KEYBOARD

PORT Ø

For Connection

of the Character

Generator

For Connection of

either a VTR, the 8465

Preview Switcher, or a

VIDEO CTL

AUDIO CTL

PORT 7CHAR GEN

Preview Preselector

NOTES

With the VPE-331, neither a Preview Preselector nor the 8465 Preview Switcher can be used. Although

you may connect VTRs to as many ports as are available, you may only assign up to 4 ports.

With the VPE-341 and -351:

If using an 8465 Preview Switcher and a Preview Preselector, the 8465 is connected to

PORT 7 and the Preview Preselector is connected to PORT 6.

If using a Preview Preselector and NOT an 8465, the Preview Preselector is connected to PORT 7.

3-10

Making The Connections

7. Attach the signal cable from the Audio Mixer to the AUDIO CTL

connector.

8. If using an 8466 Preview Switcher with a GVG serial video

switcher, attach the signal cable from the 8466 to the VIDEO CTL

connector. If not, attach the Video Switcher to the VIDEO CTL

connector. (Also see Appendix B.)

PORT 6

PORT 5

PORT 4

For connection of

either a VTR or a

Preview Preselector

PORT 3

PORT 2

PORT 1

For Connection

of the Sync

Source

PRINTER/COMM

8 7654321

For Connection of

the Color Frame

ID (CFID)

COLOR MONITOR

CFID INSYNC IN

EDIT GPI

For Connection

of the Color

VGA Monitor

0354-00-010

PORT 1 - PORT 5 for

Connection VTRs

For connection

of the VPE-351

Expansion Chassis

Figure 3-6. Computing Chassis Rear Panel Connectors

For Connection of

an Optional Printer

For Connection of

Devices for General

Purpose Interface (GPI)

Triggered Events

3-11

Section 3

— Installing The Editor

9. See the NOTES on Figure 3-6 if using an 8465 or 8466 Preview

Switcher and/or a Preview Preselector. Also see Appendix B.

10. Make appropriate connections to the EDIT GPI connector.

11. If using a Printer, attach the provided cable from the printer to the

PRINTER/COMM connector.

12. Attach a cable with BNC connectors from a composite video Sync

generator to the SYNC IN connector.

13. If a CFID signal is available, attach a cable with BNC connectors

from the CFID source to the CFID IN connector.

14. Attach the cable from your VGA Monitor to the COLOR MONITOR

connector.

This completes the physical installation of the Computing Chassis for the

VPE-300 Series. If you are installing a VPE-351, continue on with making

the Expansion Chassis connections. Otherwise, proceed to the Start-up

Sequence.

3-12

Expansion Chassis Connections

Figure 3-7 illustrates the rear panel of the Expansion Chassis and identifies

the connections which will be made to it. To make these connections, refer

to Figure 3-7 and perform the following procedure:

1.Attach the provided ribbon cable from the Computing Chassis I/O

connector to the Expansion Chassis 96-pin connector.

2.Attach the provided VTR cables from the VTRs to the PORT 12 PORT 18 connectors.

This completes physical installation of the VPE-351 Editor. However, if you

are using a K5 Keyboard, continue with K5 Keyboard Connections listed

on the following page. Otherwise, proceed to the Start-up Sequence.

Making The Connections

Not used at

connector on the Computing Chassis

this time

1234

5

9876

JOG IN

KBD IN

5

9876

KBD OUT

For the optional

K5 Keyboard cable

For the cable to the KEYBOARD

if using the optional K5 Keyboard

1234

5

9876

PORT 18 PORT 17 PORT 16 PORT 15

VPE PORT EXPANDER

1234

5

9876

1234

Figure 3-7. Expansion Chassis Connectors

For VTR machine

control cables

5

9876

1234

5

9876

1234

1234

5

9876

1234

5

9876

PORT 14 PORT 13 PORT 12

1234

5

9876

Editware VPE Series

0353-00-360

For the cable to the

Computing Chassis

3-13

Section 3

— Installing The Editor

K5 Keyboard Connections

Figure 3-8 illustrates the rear panel of the K5 Keyboard and identifies the

connections which will be made to it. To make these connections, refer to

Figure 3-8 and proceed as follows:

1. Attach the keyboard cable from the RACK connector on the

Keyboard to the KEYBOARD connector on the Expansion Chassis.

2. Attach the power cable from the POWER connector on the Keyboard to an AC Power outlet.

3. Attach the cable from the Jogger panel to the JOG connector on the

Keyboard.

JOG (J5)

POWER (J2)

RACK (J1)

0353-359

Rear View - K5 Keyboard

Figure 3-8. K5 Keyboard Connectors

4. If using the K5 Keyboard

a. Attach the K5 Keyboard cable to the KBD IN connector.

3-14

b. Attach the provided cable from the KBD OUT connector on the

Expansion Chassis to the KEYBOARD connector on the

Computing Chassis.

This completes physical installation of the K5 Keyboard. Proceed to the

Start-up Sequence.

The Start-up Sequence

The following provides information to ensure that your Editing system is

properly installed and ready for use. It begins with turning power on and

Monitor Settings, goes on to Making Assignments and Basic Checks, and

then concludes with installation troubleshooting.

Turning Power On

The recommended order for turning the power on to your editing system

is as follows:

■ All VTRs and ATR(s)

■ The video switcher and the audio mixer

■ The printer, monitor(s), and peripheral equipment

The Start-up Sequence

■ The Editor Computing Chassis

After power up the Super Edit™ Main Menu, illustrated in Figure 3-9,

appears on the screen. (Super Edit is the software program for your Editor.)

If the Main Menu does not appear, see Installation Troubleshooting and/

or Appendix F, System Software Installation.

Grass Valley Group - Video Tape Editing Systems

VPE-351 menu (V7.1)

Super Edit

EDL Utilities

System Utilities

Diagnostics & tests

Index of menu items

Use arrows for up or down, [->] to select, [-<] to deselect.

Super Edit

Run Super Edit

Initialize a disk

Format, Init disk

Install SE from disk

Super Edit

>Return to edit

TP0353-59

Press the [RESET] key for help information here.

Figure 3-9. Super Edit Main Menu

3-15

Section 3

— Installing The Editor

Menu Selection And Control

The MENU is divided into three sections on the editor screen. Use the [→]

and [←] keys to move through the sections and use the [↑] and [↓] keys to

move the cursor (>) up and down within the selected section.

T o execute a MENU item, select it with the cursor and pr ess [ENTER]. This

accesses the feature, or in some instances, presents you with a sub-menu or

prompt. Prompts appear at the bottom of the screen and request user

specific information (e.g, FROM DRIVE), TO DRIVE), etc.).

Pressing [←] with the cursor in the left column, places the system in the

RT-11 operating system environment. To return to the Main Menu with a

K2 Keyboard, type MENU at the RT> prompt and press [ENTER]; with a

K5 Keyboard, press [MAIN MENU]; with a K3 keyboard press [SHIFT]

[MENU].

Running PROM-based Self Test

1. Use the [←], [→], [↑], and [↓] keys until the Diagnostics & Tests

selection in the left hand column is highlighted and press [ENTER].

The Diagnostics & tests menu appears. (See Figure 3-10 for an example.)

2. Use the [←], [→], [↑], and [↓] keys until the PROM-based self-test

selection is highlighted and press [ENTER]. After a few moments,

test results appear. (See Figure 3-11 for an example.)

3-16

Grass Valley Group - Video Tape Editing Systems

The Start-up Sequence

TP0353-23

VPE-351 menu (V7.1)

Super Edit

EDL Utilities

System Utilities

Diagnostics & tests

Index of menu items

Diagnostics & Tests

>Sync Test

Printer test

Keyboard test

Jogger test

Serial port test

String utility

GPI exerciser

System configuration

PROM-based self-test

Use arrows for up or down, [->] to select, [-<] to deselect.

Press the [RESET] key for help information here.

Figure 3-10. Diagnostics & Test Menu

TP0353-24

DIAGNOSTICS SELFTEST V4.0

VPE-351

CONNECTED

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

OK

VIDEO DISPLAY CONTROLLER---------PROCESSOR------------------------HARDWARE IS AN SBCIV--------SYSTEM PROM----------------------KEYBOARD PORT--------------------RAMDISK ADDDRESS ---030000

DMA CONTROLLER-------------------MAIN MEMORY 512K-----VIDEO DISPLAY 64K-----FLOPPY DISK CONTROLLER-----------SYNC INTERRUPT-------------------COLOR FRAME ID------------ALL I/O PORTS--------------------MODEM RESPONDED------------------CALENDAR CLOCK-------------------GPI CONTROL-----------------------

PRESS: [ANY KEY] WHEN READY TO CONTINUE

Figure 3-11. PROM-based Self-test Results

3-17

Section 3

— Installing The Editor

3. Press any key. The Boot Device Selection menu appears. (See Figure

3-12 for an example.)

DIAGNOSTICS: BOOT DEVICE SELECTION MENU

CONTINUE: MORE DIAGNOSTICS

RERUN POWER-UP DIAGNOSTICS

BOOT FROM RAMDISK VM0:

BOOT FROM FLOPPY DISK DF0:

BOOT FROM FLOPPY DISK DF1:

BOOT FROM HARD DISK DH0:

BOOT FROM HARD DISK DH1:

TP0353-47

[ ARROWS ] = UP AND DOWN [ ENTER ] = MAKE SELECTION [ TRIM ] = VIEW ERROR

Figure 3-12. Boot Device Selection Menu

4. Use the [←], [→], [↑], and [↓] keys until the BOOT FROM

HARD DRIVE DH0: selection is highlighted and then press

[ENTER]. After a few seconds, the Main Menu appears.

This concludes the Turning Power On procedure. Continue on to Making

Basic Checks.

3-18

Making Basic Checks

Making Basic Checks consists of making the assignments listed below and

discussed on the following pages and then doing Communications Testing.

■ Assign VTR control ports

■ Assign video crosspoints

■ Assign audio crosspoints

■ VTR Model/Manufacturer Assignments

■ Set VTR Sync QC

Machine Assignments

Machine assignments allow you to assign control ports, video crosspoints,

and audio crosspoints, and to identify the VTR model/manufacturer to the

software. These assignments are made from the Assignment Page and

must be done prior to editing. An example of an Assignment Page is

illustrated in Figure 3-13.

Making Basic Checks

LABEL REEL PORT MODEL QC VIDX AUDX PSLX CFRM TYPES AVAILABLE

R-VTR 001 01 -- 03 000 000 01 00 00 = BETA-SP

A-VTR 002 02 -- 03 001 001 02 00 01 = VPR3

B-VTR 003 03 -- 03 002 002 03 00 02 = AJD350

C-VTR --- -- -- -- --- ---

D-VTR --- -- -- -- --- ---

E-VTR --- -- -- -- --- ---

F-VTR --- -- -- -- --- ---

AUX AUX 007 007

BLK BLK 000 000

PVWSW 8466 PORT 09 38.4 ODD

VIDSW GVG100 PORT 09 38.4 ODD

MIXER AMX170 PORT 08 38.4 ODD

PRSEL GV10XL PORT -PERIF NONE PORT -CHRGN NONE PORT --

ASGN=GREEN KEYS OR ALLSTP NO=DEASGN SCROLL=ARROWS RESET=EXIT

Figure 3-13. Machine Assignment Page

TP0353-80

3-19

Section 3

— Installing The Editor

The Assignment Page consists of essentially three sections. The first

section, headed by LABEL, REEL, PORT, etc., identifies machines (and

AUX and BLK) to be assigned. Note that the lower portion of this section is

used to identify devices other than VTRs and the headings do not apply.

The second section, TYPES AVAILABLE, lists the models of VTRs (and

codes) to which you have protocols included in your Super Edit™

software. Basic instructions for the Assignment Page are in the third section

at the bottom.

Note the following:

■ A [NO] to a question de-assigns the selected VTR (i.e., makes it

unavailable).

■ For a VTR, AUX, and BLK to appear in the Mark Table, VTRs must

be assigned via the Assignment Page, and AUX and BLK must have

crosspoints.

■ Pressing [ENTER] at a prompt accepts the factory default setting.

■ You may exit the Assignment Page by pressing either [RESET] or

an invalid key at any time as long as you ar

■ Cable connections between the VTRs and the video switcher and

audio mixer must be known before making video and audio

crosspoint assignments.

VTR Machine Assignments

To make Machine Assignments, follow the steps listed below:

1. With a K2 Keyboard, press [SHIFT][ASGN]; with a K5 Keyboard, pr ess

[VTR ASGN]. A display similar to Figure 3-13 appears with the

R-VTR device (top line) highlighted.

2. If you are making assignments for the R-VTR, press [ENTER] or

[SPACEBAR] (K2 /K5), or [ALL STOP] (K3). Otherwise, either press

the appropriate green key or use [↑] and [↓] to highlight the desired

machine and press [ENTER]. At the bottom left hand corner , the system

prompts:

e not at a prompt.

ENTER REEL #

3-20

3. Enter up to six alphanumeric characters, and then press [ENTER]. The

Reel ID you entered appears on the line with the selected device and the

REEL ID in the Mark Table changes accordingly. The system prompts:

PORT = ?

Making Basic Checks

Before making port assignments, note the following items:

■ You cannot assign more software ports than hardware ports

connected.

■ Multiple keys may not be assigned to the same port.

■ VTR (green) keys should be assigned to only those ports having

machines attached and set for remote operation.

■ For the VPE, the following are factory set port assignments:

PORT 8 - Audio mixer

PORT 9 - Video Switcher

PORT 10 - Character Generator

■ For the VPE-351, the factory set assignment for PORT 11 is the

JOGGER panel.

4. Enter the port number to which the selected machine is connected at

the Editor chassis rear panel (e.g., if the R-VTR is connected to PORT 1,

enter 01) and then press [ENTER]. The port number you entered

appears on the line with the selected device and the system prompts:

MODEL = ?

5. Enter the number from the right-hand column of Figure 3-15 which

corresponds to the VTR you are using for the selected VTR and press

[ENTER]. (For example, if the R-VTR is a VPR-3, you would enter 01.)

The model code you entered appears on the line with the selected

device and the system prompts:

QC VALUE = ?

6. The default QC value is 3. To accept this value, press [ENTER] or enter

a value from -1 to 5 and then press [ENTER]. Note that a QC value

of -1 tells Super Edit™ to make every attempt to synchronize the

machine right up to the IN-point, but DO NOT abort the edit if the

source is not properly positioned. The edit will occur and, based on the

machine assignment, Super Edit™ will attempt to have the source

properly positioned for the event. The QC value you entered appears

on the line with the selected device and the system prompts:

VID XPNT = ?

Before making video crosspoint assignments, note the following items:

■ Color bars, digital effects systems, cameras, and other special video

signals can also be assigned to switcher crosspoints.

■ For E-E previewing, the R-VTR cannot be changed from crosspoint

zero.

3-21

Section 3

— Installing The Editor

7. Enter the desired video crosspoint and press [ENTER]. The video

crosspoint you entered appears on the line with the selected device and

the system prompts:

AUD XPNT = ?

Before making audio crosspoint assignments, note the following items:

■ Non-audio sources are assigned to crosspoint 0.

■ For E-E previewing, the R-VTR cannot be changed from crosspoint

zero.

8. Enter the desired audio crosspoint and press [ENTER]. The audio

crosspoint you entered appears on the line with the selected device.

9. If you have the Preview Preselector option, the system prompts:

PRSEL XPNT = ?

10. Enter the desired Preview Preselector crosspoint and press [ENTER].

Your entry appears on the display.

11. Super Edit provides PAL users the opportunity to assign a color frame

offset. Enter the desired color frame offset value (fr om 0 to 3) and press

[ENTER]. The frame offset you entered appears on the display.

12. Repeat Steps 1 through 11 for all connected VTRs.

AUX and BLK Crosspoint Assignments

Default video and audio crosspoints are 007 for AUX and 000 for BLK. To

change the AUX and BLK assignments, perform the following steps:

1. Use [↑] and [↓] to highlight AUX or BLK. The system prompt indicates:

VID XPNT = ?

2. Enter the desired video crosspoint and press [ENTER]. The crosspoint

you entered appears on the selected AUX or BLK line and the system

prompts:

AUD XPNT = ?

3-22

3. Enter the desired audio crosspoint and press [ENTER]. The crosspoint

you entered appears on the selected AUX or BLK line.

Fast Column Data Entry

The Assignment Page also provides a fast mode of entering data by

column. That is, all vertical column data (reel, port, model, etc.) can be

entered at the same time without having to go through the dialog for each

source line-by-line.

This mode is activated by selecting a column with the [→] or [←] keys and

pressing [ENTER]. You may now enter data vertically in the selected

column. To go from one line to the next in the column, either after entering

data or to skip a line, press [ENTER].

There are two ways to terminate the column mode. One is to press

[ENTER] when at the bottom of the column. The other, which is a fast way

of terminating the column mode, is by pressing either [→] or [←] while in

the column.

Making Basic Checks

3-23

Section 3

— Installing The Editor

Other Machine Assignments

Other machines are listed below the AUX and BLK assignment sections. If

the protocol for a particular machine is built into your software, it is

identified. If a machine protocol is not built into your software, NONE

appears next to it.

For example, if (as in Figure 3-13) you have the protocol for a GVG Model

100 Video Switcher, but not a Character Generator, GVG100 appears next

to VIDSW and NONE appears next to CHRGN. Assignment choices are

limited to port number, baud rate, and EVEN or ODD parity. The

assignment procedure is:

1. Use [↑] and [↓] to highlight the desired machine and then press

[ENTER]. The system prompts:

PORT # = ?

2. Enter the port number the selected machine is connected to and press

[ENTER]. The port number you selected appears on the display next to

the selected machine and the system prompts:

0 = 38.4 1 = 9600 BAUD =

3. Press, as applicable, either [Ø] for 38.4K baud or [1] for 19.6K baud and

then press [ENTER]. The baud rate you selected appears on the display

on the same line as the selected machine and the system prompts:

0 = NONE 1 = ODD 2 = EVEN PARITY =

4. Press, as applicable, either [Ø], [1], or [2] and then press [ENTER]. The

EVEN/ODD parity selected appears on the display on the same line as

the selected machine.

5. Repeat Steps 1 - 4 for the remaining machines.

NOTE: Press [SHIFT][RESET] (all keyboards) to re-establish communication

between the Edit System and all peripheral devices.

3-24

Communications Testing

Before performing communications testing, all peripheral equipment

should be set up and timed. Refer to the Peripheral Equipment Setup and

Timing Manual, P/N TP0377-01, for those procedures.

Making Basic Checks

TP0353-54

SUPER EDIT V7.1 "system" Snnnnn EDIT SUITE #1

IN

01:00:25:00

01:02:45:00

02:15:35:03

A12V

CUT TO

A-VTR

SOURCE

R-VTR

>A-001

B-002

AUX

BLK

TITLE

OUT

01:00:30:00

DUR

00:05:00

(MESSAGE AREA)

Figure 3-14. Edit Screen Example

SPD–> POS

N 01:00:28:03

N 01:02:48:01

N 02:15:35:00

T=00:00:25:00

EVENT 0006

(EDIT TIMER)

To do the communications testing, refer to the Edit Screen illustration,

Figure 3-14, and perform the following steps:

1.Load tapes with time code into your machines.

2.Activate the EDIT ENABLE buttons on the video switcher and the

audio mixer.

3.Press [SHIFT] and the dark grey [RESET] key.

4.Alternately press the dark green R-VTR, A-VTR, and B-VTR keys.

The Mark Table cursor (**) moves from source to source, and video

switcher and audio mixer crosspoints switch to the assigned

crosspoints as you press the different keys.

5.Select the A-VTR and press the light blue [FF] key. The A-VTR fast

forwards.

3-25

Section 3

— Installing The Editor

6. When video appears, press the light blue [STOP] key. The A-VTR

stops.

7. Press the light blue [PLAY] key. Video and audio play at normal

speed. In the Mark Table, the time code numbers in the selected

source's POS column increment.

8. Press [STOP]. The A-VTR and the time code numbers in the POS

column of the Mark Table stop.

9. Press the yellow [MARK IN] key. The time code currently

displayed in the A-VTR's POS column appears in its IN column.

10. Press the yellow [MARK OUT] key. The time code currently

displayed in the A-VTR's POS column appears in its OUT column.

11. Press the [FF], [REW], and [SLOW] keys and ensure the VTR reacts

accordingly.

12. Repeat steps 5 through 11 for the remaining VTRs.

If any of the above indications do not occur, check cabling and connections.

If any cabling or connection had to be corrected, repeat the procedure. If

after repeating the procedure, any indication was still in error, or if cabling

and connections were correct, proceed to Installation Troubleshooting.

3-26

Installation T roubleshooting

If any problems arise during the installation, you will want to begin

checking the most obvious possible causes first. Verify the following items

are true:

■ All power cords are connected to the correct power source

■ All power switches are in the ON positions

■ All cables are attached to the correct connectors

■ All machines are in their correct mode of operation (i.e., local or

remote)

If during the Start-up Sequence the Super Edit Main Menu did not appear

on the Monitor, the checks listed below and discussed on the following

pages are starting points for Installation Troubleshooting. Note that if you

suspect the software is the problem, re-install system software before

proceeding. See Appendix F for the System Software Installation

procedure.

Installation Troubleshooting

■ Chassis front panel status indicators

■ Program failed to execute

■ Switches not set correctly

■ Jumpers not placed correctly

NOTE: Make notes of all troubleshooting activities. They will help service

personnel in the event that more detailed troubleshooting is required.

Front Panel Status Indicators

There are six (6) LEDs visible at the front panel. These LEDs provide a

quick check of the Editor status. Figure 3-15 shows their locations and the

following is a brief description of them. (The Service Information Manual

contains a more detailed description of these LEDs.)

■ PGM (Program) - This green LED is not normally lit. It lights to

indicate successful completion of the PROM-based self-test.

■ NO SYNC - This red LED is not normally lit. If lit, it indicates that

either house sync is not connected or has been lost.

■ DC LOW - This red LED is not normally lit. If lit, it indicates that the

+5 VDC output of the DC Power Supply is not within proper operating range.

3-27

Section 3

— Installing The Editor

■ FAIL - This red LED is not normally lit. If lit, it indicates that the

microprocessor failed its internal start-up diagnostics.

■ RUN - This green LED is normally lit. If not, the RUN/HALT toggle

switch on the SBC board may be in the wrong (HALT) position.

■ POWER - This red LED is normally lit when the power switch is in

the On position.

0354-00-014a

DRIVE 1

FAIL

DC

NO

POWER

POWER

PGM

PGM

SYNC

SYNC

NO

LOW

RUN

DC

LOW

FAIL

Figure 3-1. Computing Chassis Front Panel Indicators

Program Execution

Check for the possibility that the program failed to execute. This can be

done by re-booting the Editor from the Distribution Floppy Disk. (See

Appendix F, System Software Installation.)

SBC Switches

There are three switches on the SBC (see Figure 3-16). They are accessible

without removing the SBC from the Chassis. Two are toggle switches

(RUN/HALT and BOOT) and one is a rotary thumbwheel switch (MODE).

RUN

DRIVE 0

Editware VPE Series

3-28

0799-00-02

Boot Switch

Run/Halt Switch

SBC (Top - Front Edge)

Thumbwheel

Switch

Figure 3-2. SBC Switch Locations

SBC Jumpers

There are numerous jumpers on the SBC which set the operating

conditions of the Editor. To check jumper positions, it is necessary to

remove the SBC from the Chassis. Refer to Figure 3-17 below which

illustrates removal of the SBC.

All the jumpers are shown in Figure 3-18 and listed in Table 3-2. The table

describes the default settings of the jumpers, which are set at the factory. A

detailed description of all the jumpers are on the pages following the table.

Front Panel Status Indicators

0355-00-027a

Floppy Disk Drive

DFØ)

Floppy Disk Drive

(DF1)

SBC

Knurled Knob

(one each side)

Front Panel

Figure 3-3. Removing the SBC

3-29

Section 3

— Installing The Editor

J23

J8 J5J6J7J9J10

0799-00-01

J20 J21 J22

3-30

J11 J12

Figure 3-4. SBC Jumper Locations

J1

J4 J3 J2

Front Panel Status Indicators

Table 3-2. SBC DEFAULT JUMPER SETTINGS

Jumper Position Setting

J1 1 Jumper block at pins 1-2. Connects the battery to the circuitry.

J2 1 Jumper block at pins 1-2. With jumpers J3 & J4, selects 27C256 as the

type of EPROM (see Table 3-4).

J3 1 Jumper block at pins 1-2. With jumpers J2 & J4, selects 27C256 as the

type of EPROM (see Table 3-4).

J4 1 Jumper block at pins 1-2. With jumpers J2 & J3, selects 27C256 as the

type of EPROM (see Table 3-4).

J5 1 With jumper J6, selects RS-422 (block at pins 1-2) or RS-232 (block at

pins 2-3) as the Port 7 serial interface.

J6 1 With jumper J6, selects RS-422 (block at pins 1-2) or RS-232 (block at

pins 2-3) as the Port 7 serial interface.

J7 1 With jumper J8, selects RS-422 (block at pins 1-2) or RS-232 (block at

pins 2-3) as the Port 6 serial interface.

J8 1 With jumper J7, selects RS-422 (block at pins 1-2) or RS-232 (block at

pins 2-3) as the Port 6 serial interface.

J9 1 Jumper block at pins 1-2. With jumper J10, selects RS-422 as the Key-

board Port serial interface.

J10 1 Jumper block at pins 1-2. With jumper J9, selects RS-422 as the Key-

board Port serial interface.

J11 1 Jumper block at pins 2-3. Selects 60Hz as the frequency for the on-

board EVENT clock signal. (Also see jumper J23.)

J12 1 Jumper blocks at pins 3-4 and 7-8. Selects 9,600 as the baud rate for

the Keyboard Port. Jumper block must always be at pins 1-2 to enable

programmable baud rate selection through software.

J13 - J19 These jumper numbers not used on this board

J20 1 Jumper block installed. Selects MOTOR-ON line low to the Floppy