24Q Ark Tape Library

48Q

Setup and User’s Guide

Ark Tape Library

Copyright and Disclaimer

Copyright © 2018 by EditShare

This document, as well as any software described in it, is furnished under either a license or a confidentiality

agreement, is confidential to EditShare, and may be used or copied only in accordance with the above

mentioned agreements. The information in this document is furnished for your use only and is subject to

change without notice. EditShare assumes no responsibility or liability for any errors or inaccuracies that may

appear in this document.

This document is the property of EditShare and is provided in accordance with an EditShare license

agreement. Copying, modifying, or distributing this document in violation of the license agreement, United

States Copyright Laws, or the Copyright Laws of any applicable foreign jurisdiction is expressly prohibited.

EditShare is a registered trademark of EditShare in the US and other countries. Universal Media File is a

trademark of EditShare in the US and other countries.

Windows is a registered trademark of Microsoft Corporation. All other brand and product names are

trademarks or registered trademarks of their respective companies and are hereby acknowledged.

To the best of our knowledge, the information in this document is accurate; however, EditShare assumes no

responsibility or liability for the accuracy or completeness of this information. Mention of trade names or

commercial products does not constitute endorsement by EditShare except where explicitly stated.

EditShare

3 Brook Street

Watertown, MA 02472

USA

Tel: 617-782-0479

Fax:

Email: sales@editshare.com

http://www.editshare.com

February 25, 2018

617-782-1071

2 TP-00347-01

Warnings and Cautions

Warning - High Voltage

Mains voltages are present in this product. Risk of Electric Shock.

• Do not remove covers (top, bottom or rear).

• Refer servicing to qualified service personnel.

No user-serviceable parts are inside.

Warning - Product Weight

Risk of personal injury. Before lifting a module:

• Observe local health and safety requirements a

handling.

• When moving the unit, remove all tape to reduce the weight.

• When moving the unit, remove all tape drives to reduce the weight.

• Obtain adequate assistance to lift and stabilize the module during installation or

removal.

When placing a module into or removing the

• Extend the rack's levelling jacks to the floor.

•

Ensure that the full weight of the rack rests on the levelling jacks.

• Install stabilizing feet on the rack.

• Extend only one rack component at a time.

nd guidelines for manual material

module from a rack:

Caution - Static Sensitive Devices

Risk of damage to devices:

• A discharge of static electricity damages static-sensitive devices

• Proper packaging and grounding techniques are necessary precautions to

prevent damage.

or micro circuitry.

Caution - Working Environment

Risk of damage to devices:

• Ventilation - Place the product in a location that does not interfere with proper

ventilation.

• Heat - Place the product in a location away from heat sources.

• Power sources - Connect the product to a power source only of the type directed

in the operating instructions or as marked on the product.

• Power cord protection - Place the AC line cord so that it is not possible to be

walked on or pinched by items placed upon or against it.

• Object and liquid entry - Make sure that objects do not fall onto and that liquids

are not spilled into the product's enclosure.

TP-00347-01 3

Warranty

The customer should only perform the service and repair actions on the tape library components

listed in this document. Any other actions needed should only be performed by an authorized

service center.

Warranty

The warranty for the tape library shall not apply to failures of

• The tape library is repaired or modified by anyone other than the manufacturer's personnel or

app

roved agent.

• The tape library is physically abused or used

operating instructions or product specification defined by the manufacturer.

• The tape library fails because of accident, misuse, abuse, neglect, mishandling

alteration, faulty installation, modification, or service by anyone other than the factory service

center or its approved agent.

• The tape library is repaired by an

contrary to the maintenance or installation instructions supplied by the manufacturer.

• The manufacturer's serial number

• The tape library is damaged because of improper packaging on return.

Warranty will become immediately void in

yone, including an approved agent, in a manner that is

tag is removed.

in a manner that is inconsistent with the

the event of unauthorized repairs or modifications.

any unit when:

, misapplication,

4 TP-00347-01

Contents

WARNINGS AND CAUTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

CHAPTER 1: INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Hardware Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supported Tape Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controls and Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tape Drive Back Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Library Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Additional Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . 11

. . . . . . . 11

. . . . . . . 12

. . . . . . . 12

. . . . . . . 13

. . . . . . . 14

. . . 15

. . . . . . . 15

. . . . . . . 16

. . . . . . . . . . . . 16

CHAPTER 2: INSTALLATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Location Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Attached SCSI (SAS) Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Fibre Channel Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unpacking the Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Identifying Product Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Removing the Shipping Lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Library. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rack-Mounting the Library. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Tape Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Library Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . 20

. . . . . . . . . . . . 22

. . . . . . . . . . . . 23

. . 18

19

. . . 20

21

. . . . . . . 22

22

. . . . . . . 23

. . 23

. . . . . . . 24

. . . . . . . 24

. . 25

. . . . . . . 25

. . . . . . . 25

. . 26

TP-00347-01 5

Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Power Cord Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Connecting Fibre Channel Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Connecting SAS Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting an Ethernet Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Connecting a USB device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . 27

. 28

CHAPTER 3: CARTRIDGES AND MAGAZINES . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Use and Care of Tape Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Supported Cartridge Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Labeling Tape Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Write Protecting Tape Cartridges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read/Write Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Magazines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Slot Usage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . 32

. . . . . . . 30

. . . . . . . 30

. . 31

. . . . . . . 32

. . . . . . . 32

CHAPTER 4: OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Powering the Library Up or Down. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Operator Control Panel (OCP). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OCP Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power-Up Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power-Down . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu Flow Charts (OCP) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Management Unit (RMU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Login . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RMU Screen Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Identity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Move Media within the Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Determining Current Media Inventory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Releasing and Replacing Magazines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning Tape Drive(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cartridge Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . 44

. . . . . . . . . . . . . . . . 61

. . . . . . . 33

. . 33

. . . . . . . 34

. . 34

. . . . . . . . . . . . 34

. . . . . . . 35

. . . . . . . 36

. 36

. . 44

. . 44

. . . . . . . . . . . . 45

. . 45

. . . . . . . . . . . 46

. . . . . . . . . . . . 49

. . . . . . . 52

. . . . . . . . . . . . 62

. . . 65

. . 65

6 TP-00347-01

Partitioning the Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

24Q Tape Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

48Q Tape Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . 67

. . . . . . . . . . . . 69

CHAPTER 5: SERVICING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Tools Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Storing and Shipping Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tape Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing a Tape Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing a Tape Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Library Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing a Library Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing a Library Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing a Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacing a Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Servicing a Magazine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Base Chassis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparing to Remove the Base Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Removing the Base Chassis from the Rack . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Packaging the Unit for Transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24Q Ark Tape Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

48Q Ark Tape Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . 72

. . . . . . . . . . . . 73

. . . . . . . . . . . . 74

. . . . . . . . . . . . . . . . 75

. . 71

. . 72

. . . 72

73

73

74

74

. . . . . . . 75

. . 76

. . 77

. . 78

CHAPTER 6: TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Installation Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Backup Application Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Device Driver Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cleaning Cartridge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Errors Displayed on Operator Control Panel (OCP) . . . .

Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

<Media Attention> LED issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Tape Cartridge Movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removing Tape Cartridges from Tape Library. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Emergency Release. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Upgrading the Library Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . 81

. . . . . . . 79

. . . . . . . 79

79

. . . 80

. . . . . . . 80

. . . . . . . 80

. . 80

. . . . . . . . . . . 81

. . . . . . . . . . . 82

83

. . . . . . . . . . . 84

. . 85

TP-00347-01 7

Service Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

System Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Slot-to-Slot Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Library Verify Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

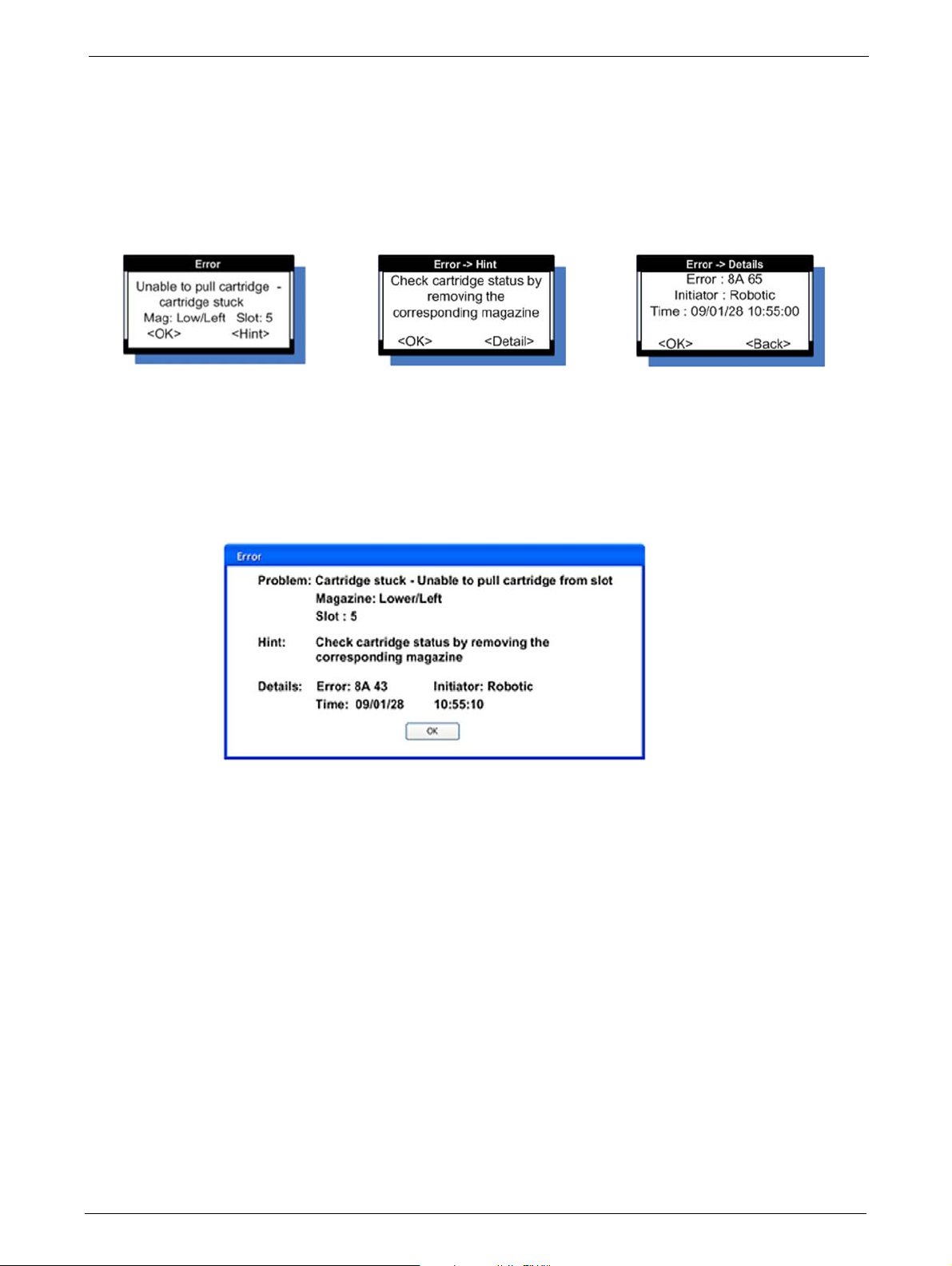

Error Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error Message Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OCP Error Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RMU Error Reporting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sub Error Codes Related to Media Changer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Sub Error Codes Related to Library . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

. . . . . . . . . . . . . . . . 87

. . . . . . . 86

. . . . . . . 86

. . . . . . . 87

. . . 87

. . 88

. . 88

. . . . . . 89

CHAPTER 7: SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Physical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Operating Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Storage Capacity and Data Transfer Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

. . . . . . 104

CHAPTER 8: REGULATORY INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Recycling and Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Device Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CE Mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ETL Mark . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GS Mark. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FCC (United States) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Canadian Verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . 108

. . . . . . . . . . . . . . . . 108

. . . . . . . . . . . . . . . . 108

. . . . . . . . . . . . . . . . 108

. . . . . . . . . . . 109

. . . . . . . . . . 109

8 TP-00347-01

Chapter 1: Introduction

24Q

48Q

This document provides information to install, operate, upgrade, service and troubleshoot the

EditShare 24Q and 48Q Ark Tape Libraries. The instructions are intended for trained system

administrators and trained users who need physical and functional knowledge of these

products.

This document uses the reference 24Q/48Q to refer to either the 24Q or the 48Q Tape Library.

See the following sections:

• "General Information" on page 10

• "Hardware Configuration" on page 11

• "Supported Tape Drives" on page 11

• "Controls and Indicators" on page 12

• "Library Controller" on page 15

• "Technical Support" on page 16

TP-00347-01 9

General Information

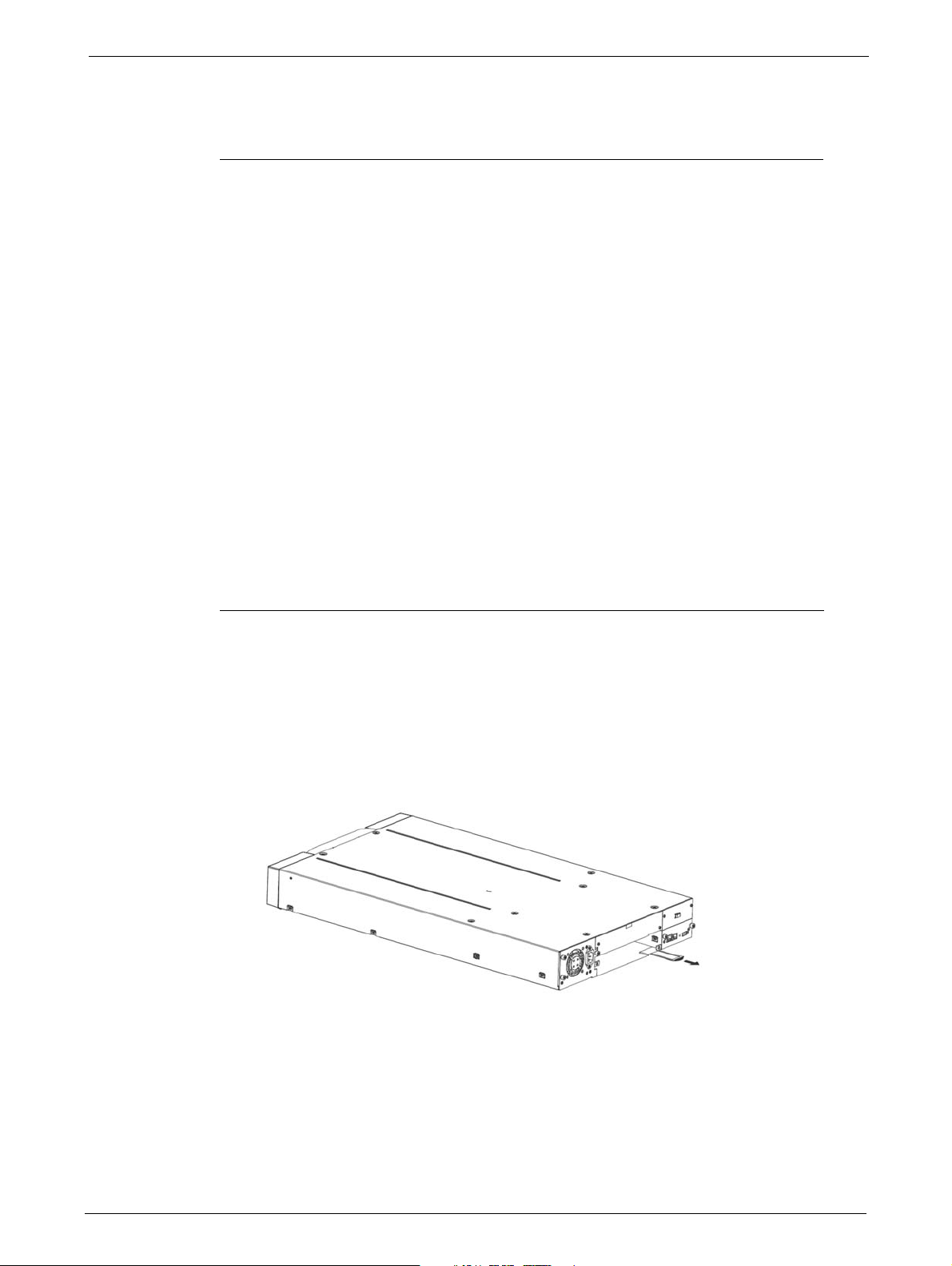

The EditShare 24Q and 48Q Ark Tape Libraries are similar, physically and functionally. The 24Q Ark

Tape Library has the capacity to hold up to 24 LTO tape cartridges and up to two half-height LTO

tape drives in its 2U chassis. The 48Q Ark Tape Library can hold 48 LTO tape cartridges and up to

four half-height LTO tape drives in its 4U chassis.

Chapter 1: Introduction

The Editshare 24Q/48Q Ark Tape Libraries are compa

simple, unattended data backup. When paired with the Editshare Ark Tape Archive application,

users can take full advantage of the many features of these libraries.

Major characteristics of the EditShare 24

• Platform - support for either one to

in a 24Q Tape Library, and one to four drives in a 48Q Ark Tape Library.

• Connectivity - Fibre Channel (FC) and/or Serial Attached SCS

tape drives

• Expandability - additional half-height tape

unused drive slot locations.

• Technology upgrade - tape drive t

LTO-6, etc.)

• Service friendly design - easy access to magazines,

supply for field replacement

• Maximum up time - through advanced error handling and recovery capability

The 24Q/48Q Ark Tape Libraries include the

• USB interface to enable service

customized features (storage on demand) implementation

• The library can be operated via the front operator control panel (OCP), over the network or the

Internet via

connection from the EditShare Ark Tape application

the integral remote management unit (RMU), or via the storage interface

Q/48Q Ark Tape Libraries include:

two half-height LTO-5, LTO-6, LTO-7 or LTO-8 tape drives

echnologies can be upgraded in the field (i.e. LTO-5 to

following features:

ability features (library and drive firmware upgrades) and/or

ct, economical, high-capacity solutions for

I (SAS) depending upon installed

drives may be field-installed in a library that has

tape drives, library controller and power

• Supports industry standard manageme

• The 24Q has one mailslot for import/export of cartridges during library operation while the

48Q has three

• Media changer with barcode reader

•Rack-mounted

mailslots

nt protocols such as SNMP

10 TP-00347-01

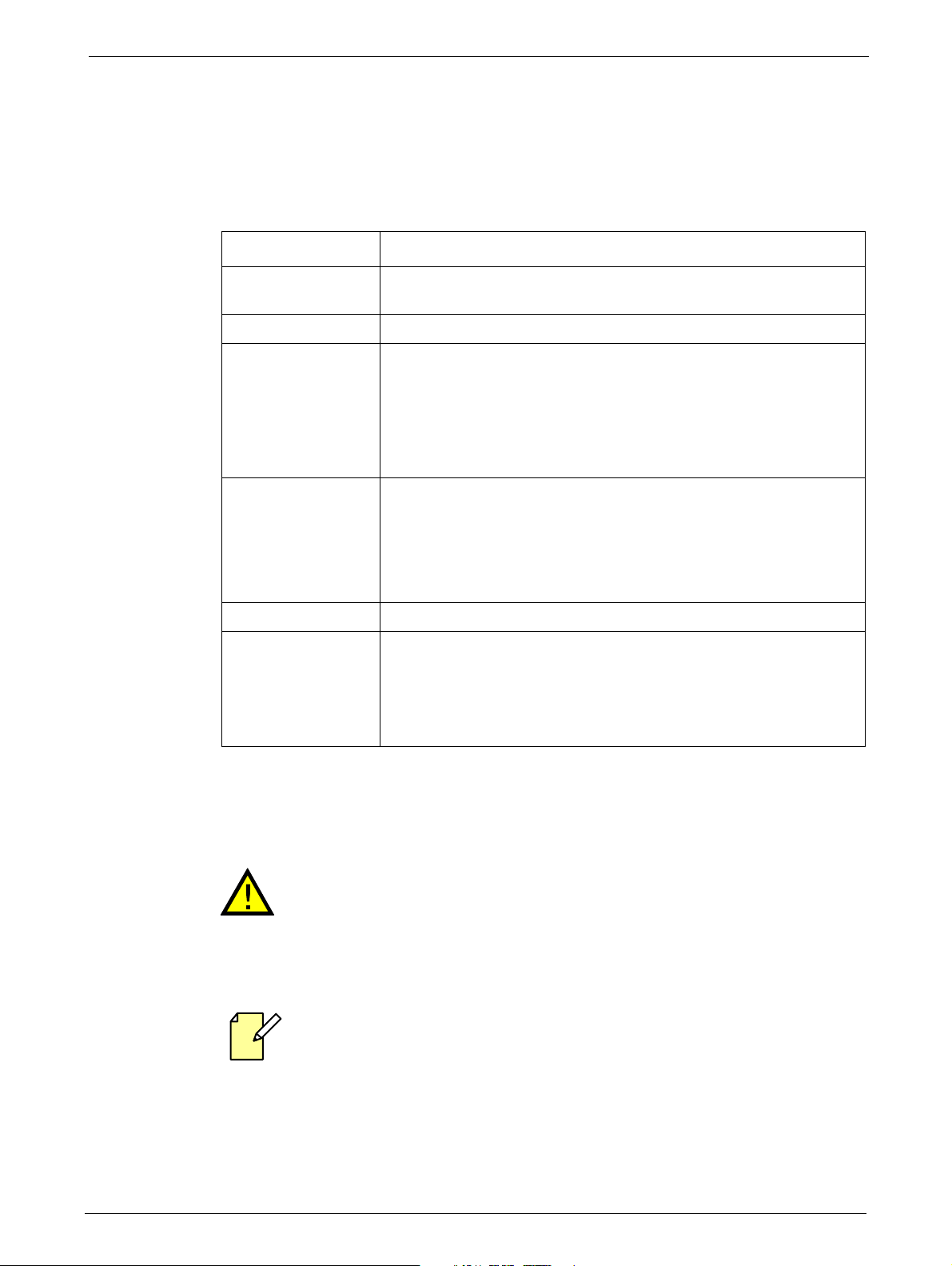

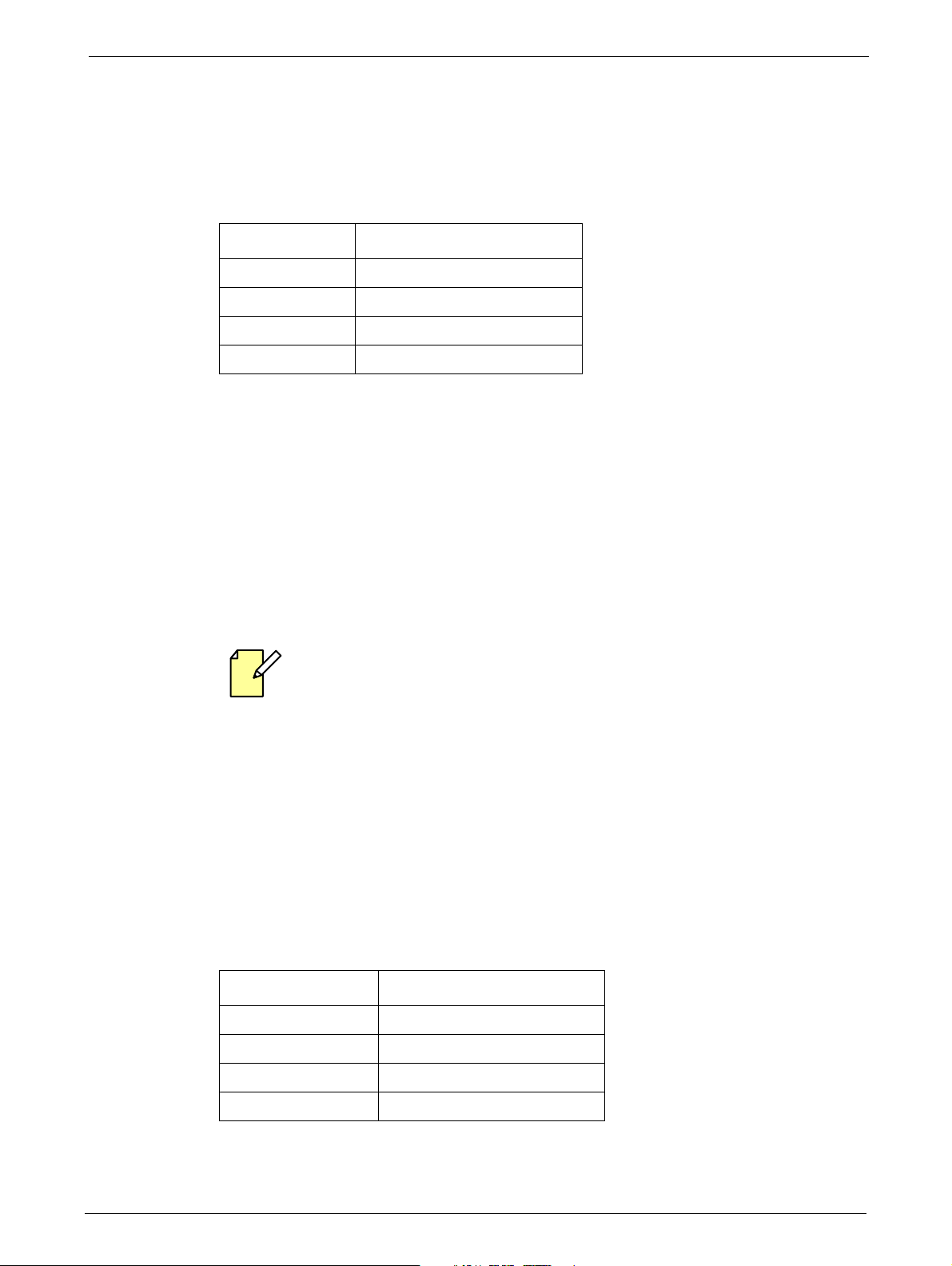

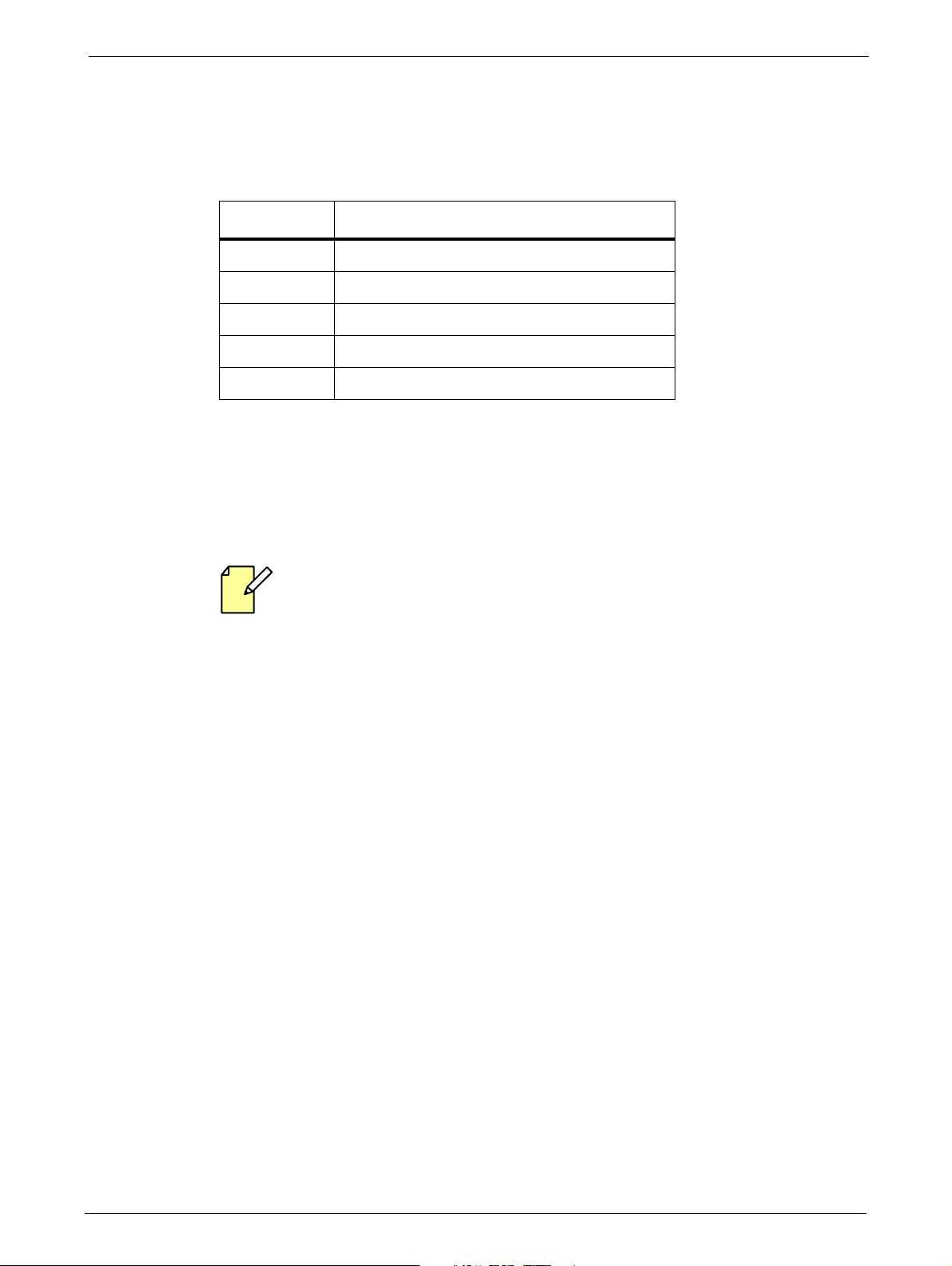

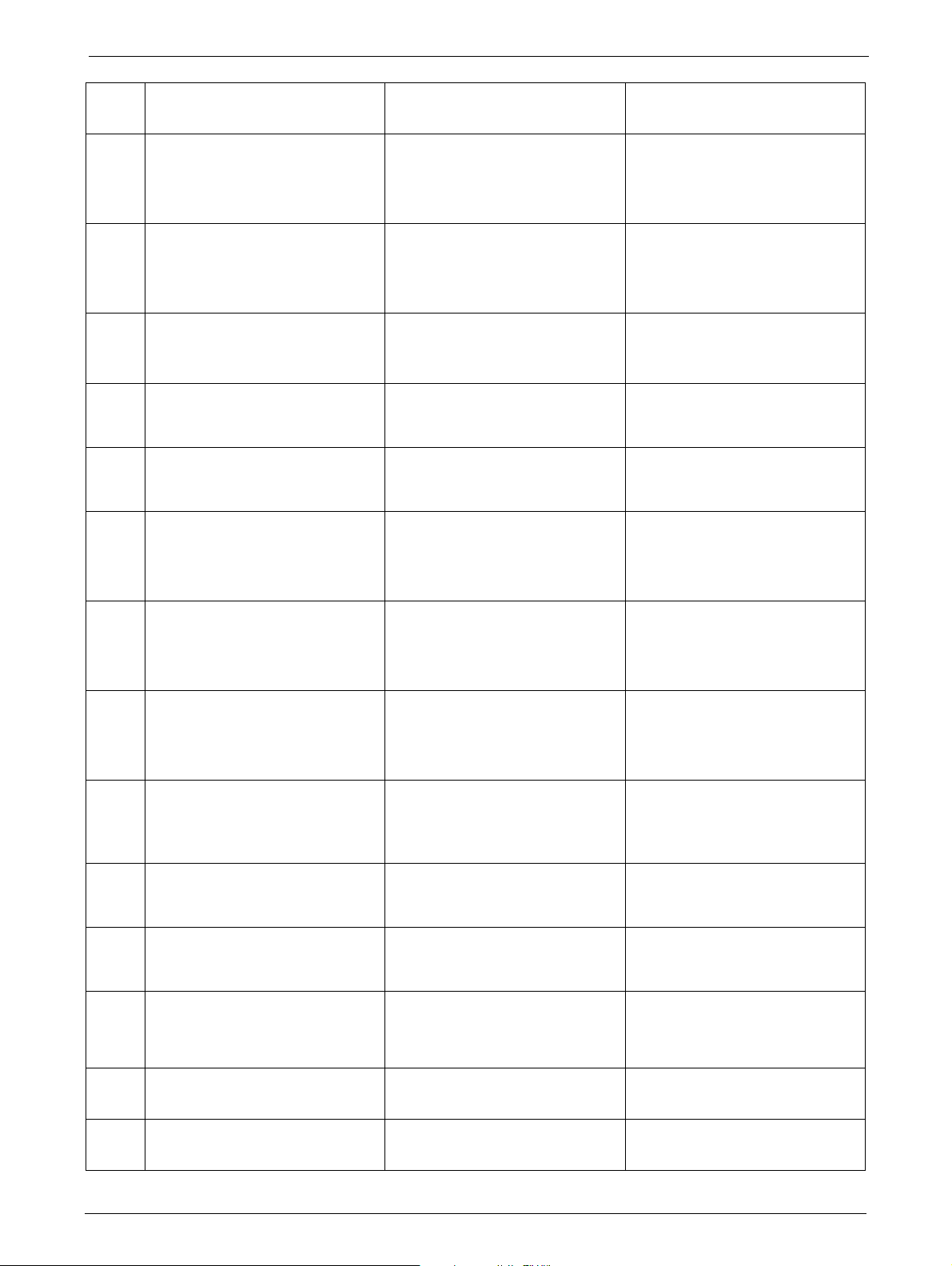

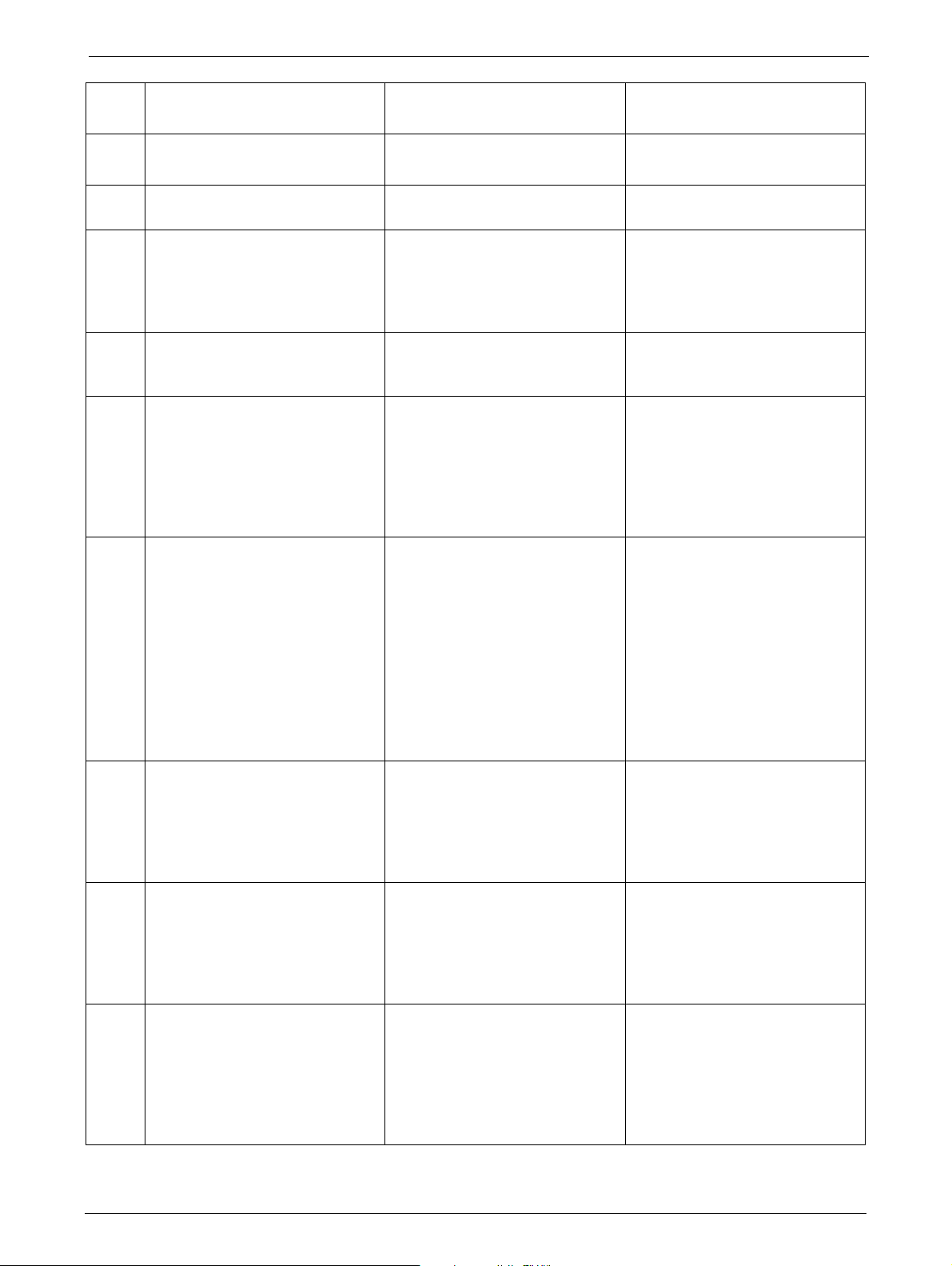

Hardware Configuration

Hardware Configuration

The 24Q and 48Q Ark Tape Libraries have the following configurations:

Height: 2U 4U

Number of magazines: 2 (12 slots each) 4 (12 slots each)

Number of mailslots: 1 3

Number of tape slots: 24 (less mailslots) 48 (less mailslots)

Tape Drives: 1 or 2 half-height drives 1 to 4 half-height drives

Power supply: 1 1

Library controller: 1 1

24Q Tape Library 48Q Tape Library

Supported Tape Drives

EditShare 24Q/4Q Ark Tape Libraries were developed to integrate industry-standard IBM LTO

Ultrium tape drives.

Mixed drive generations

The tape drives that have been implemented and qualified f

Libraries are as follows:

• LTO-5 Half-Height FC

• LTO-5 Half-Height SAS

• LTO-6 Half-Height FC

• LTO-6 Half-Height SAS

• LTO-7 Half-Height FC

• LTO-7 Half-Height SAS

• LTO-8 Half-Height FC

• LTO-8 Half-Height SAS

and mixed interfaces are supported.

or use in EditShare 24Q/4Q Ark Tape

TP-00347-01 11

Controls and Indicators

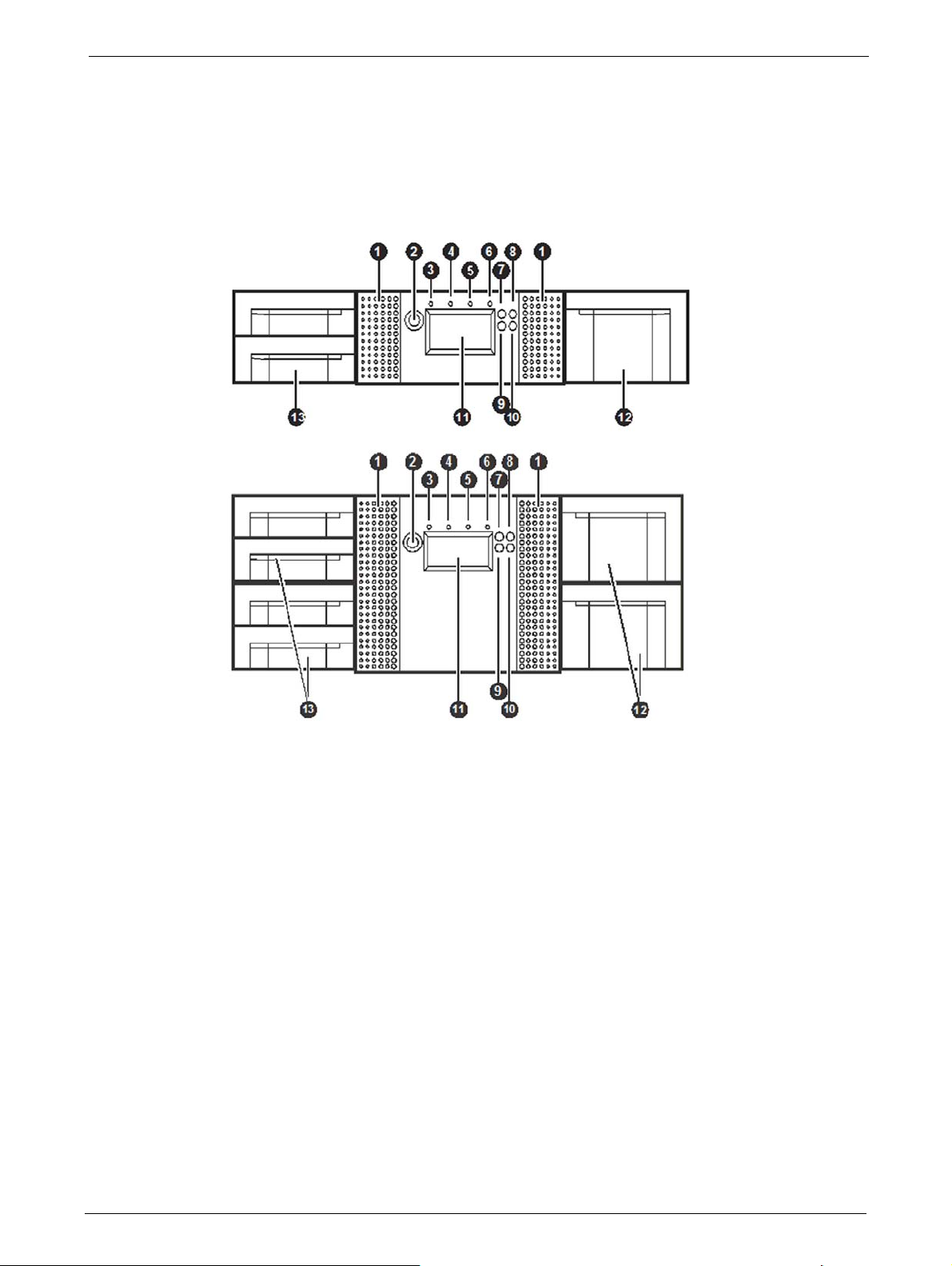

Front Panel

Chapter 1: Introduction

1. Air vents

2. Power button: Pressing the button will initiate a controlled power down of the library (soft

pow

er down)

3. LED <READY> (green): is illuminated during power on

changer activity.

4. LED <CLEAN> (amber): is illuminated when the tape drive has determined that a cleaning

tape sh

cleaning is not necessary.

5. LED <ATTENTION> (amber): is illuminated when th

requires attention by the operator.

6. LED <ERROR> (amber): is illuminated wh

occurs. A corresponding error message is shown on the LCD screen.

7. <UP> button [▲]: is used to na

8.

<CANCEL> button [

9. <DOWN> button [►]: is used t

10. <ENTER> button [ ]: is used to enter to a sub menu or execute an action.

11 Operator control panel (OCP) consisting of a 128

and status information, menu items or error messages relevant to the operational mode.

12 Right magazine(s)

13 Left magazine with mailslot(s)

ould be used. Cleaning is only necessary when the library directs to do so. Additional

en an unrecoverable tape drive or library error

vigate backward through menu items.

X]: is used to cancel a user action and return to the last menu item.

o navigate forward through menu items.

; blinking during tape or library media

e library has detected a condition that

64 pixel screen. The OCP displays actions

x

12 TP-00347-01

Controls and Indicators

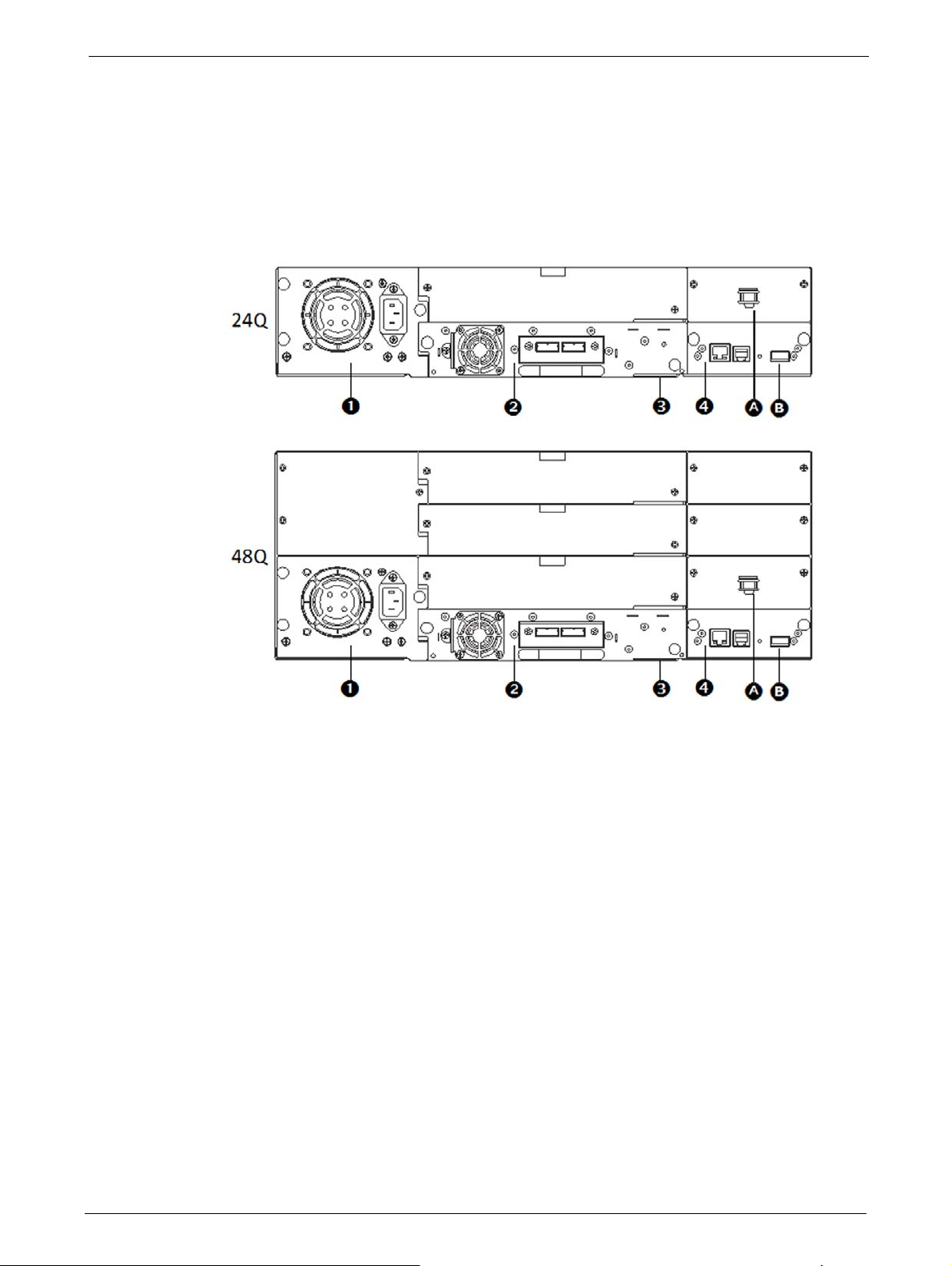

Rear Panel

The rear panels of both tape libraries provide access to the drive interface connectors (either SAS

or Fibre Channel), the power connector, Ethernet, serial and USB ports and the magazine release

holes.

The power supply is on the left side, tape drives are in the middle and the library controller is on

libraries.

the right side of

these

1. Power supply (lower left) A Storage location for shipping lock.

2. Tape drive(s) B USB port (firmware upgrades, key storage)

3. Pull-out tab containing the product

inf

rmation

o

(Serial Number/Model/Customer)

4. Library controller

TP-00347-01 13

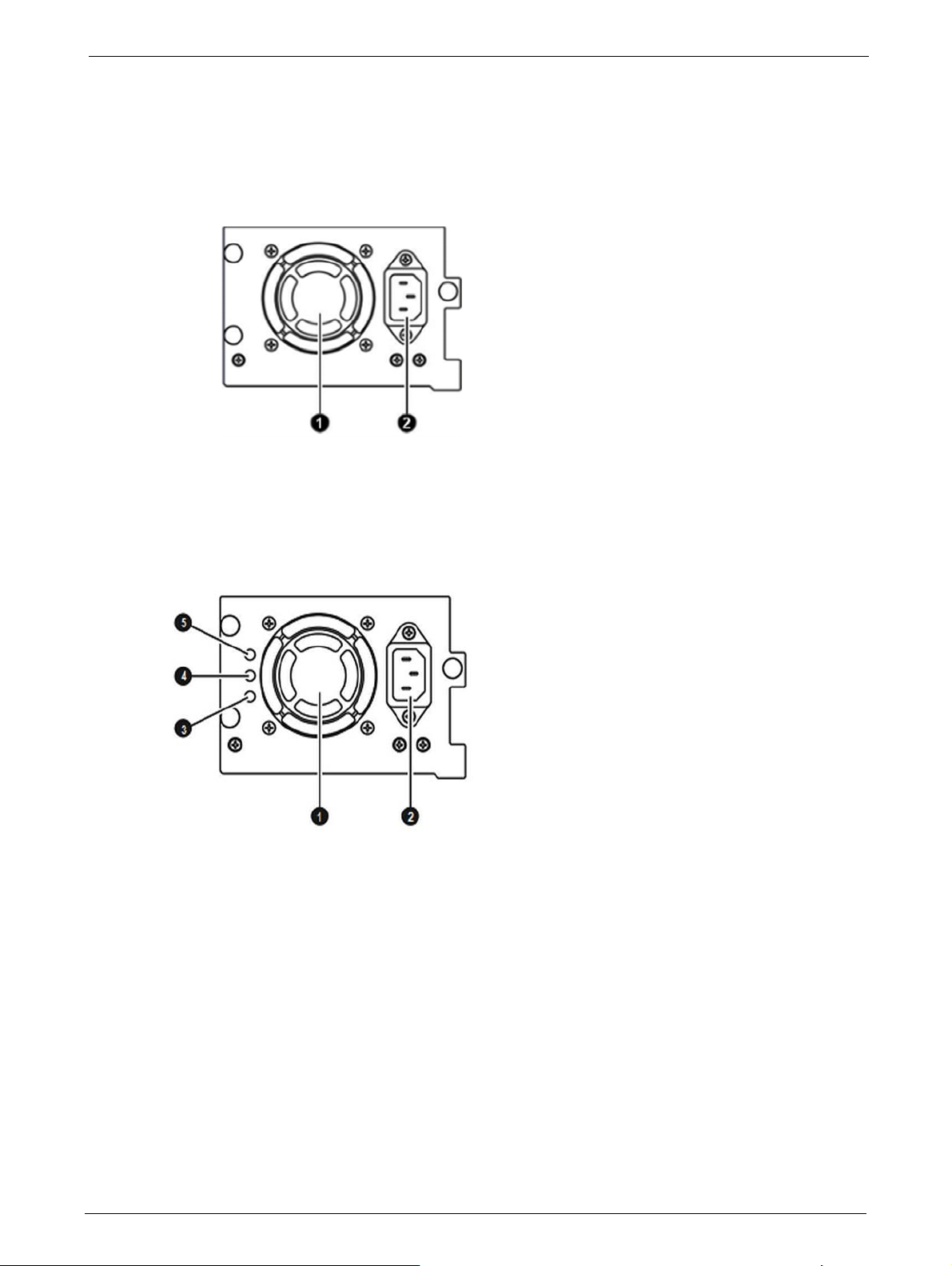

Power Supplies

1. Fan Vent

2. Power connector (110-220 V AC

1. Fan Vent

2. Power connector (110-220 V AC

3. LED (blue) - AC power

4. LED (amber) -Fan Failure

5. LED (green) - Power

24Q Library

Chapter 1: Introduction

48Q Library

14 TP-00347-01

Controls and Indicators

Tape Drive Back Panels

For best performance, use the appropriate HBA for your tape drive. A lower throughput HBA

might result in performance degradation when backing up high

higher throughput tape drive.

In a SAN installation, all switches between the host and the library must be of the

appropriate type. A lower throughput switch

degradation. Configure zoning so only the backup servers may access the library.

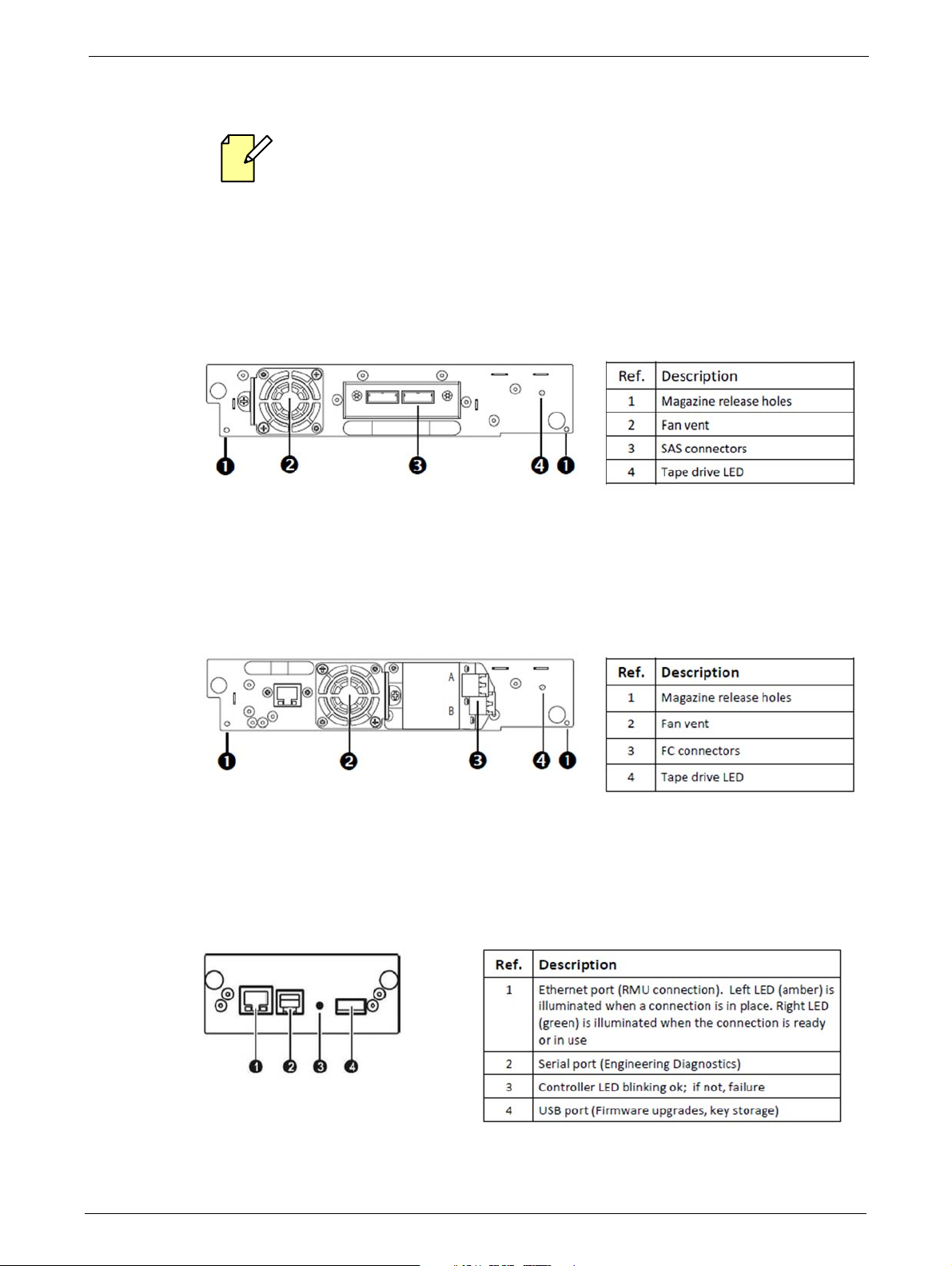

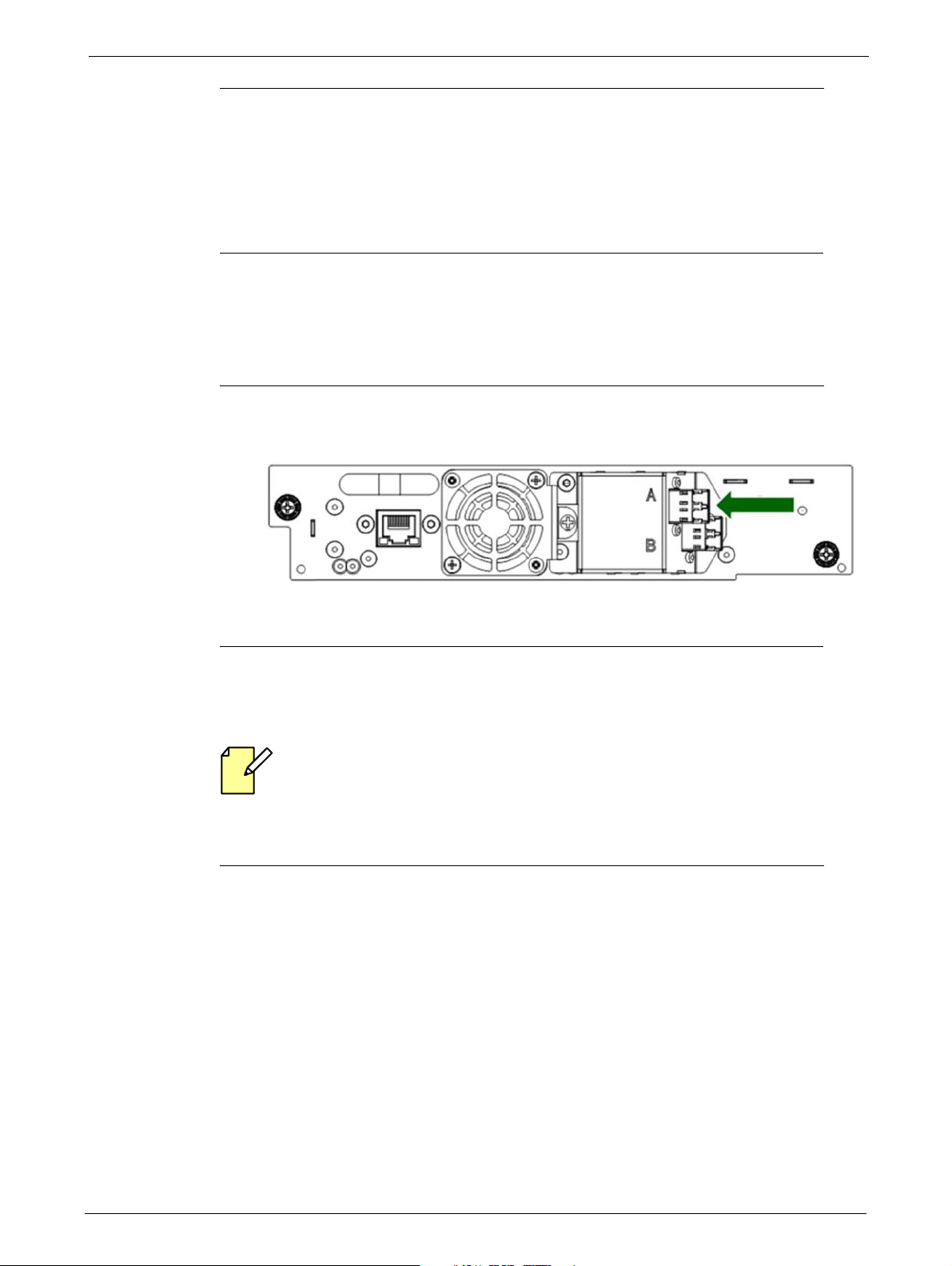

IBM LTO-5/6/7/8 HH SAS

ly compressible data to a

in the path may result in performance

FC Half-Height Drive

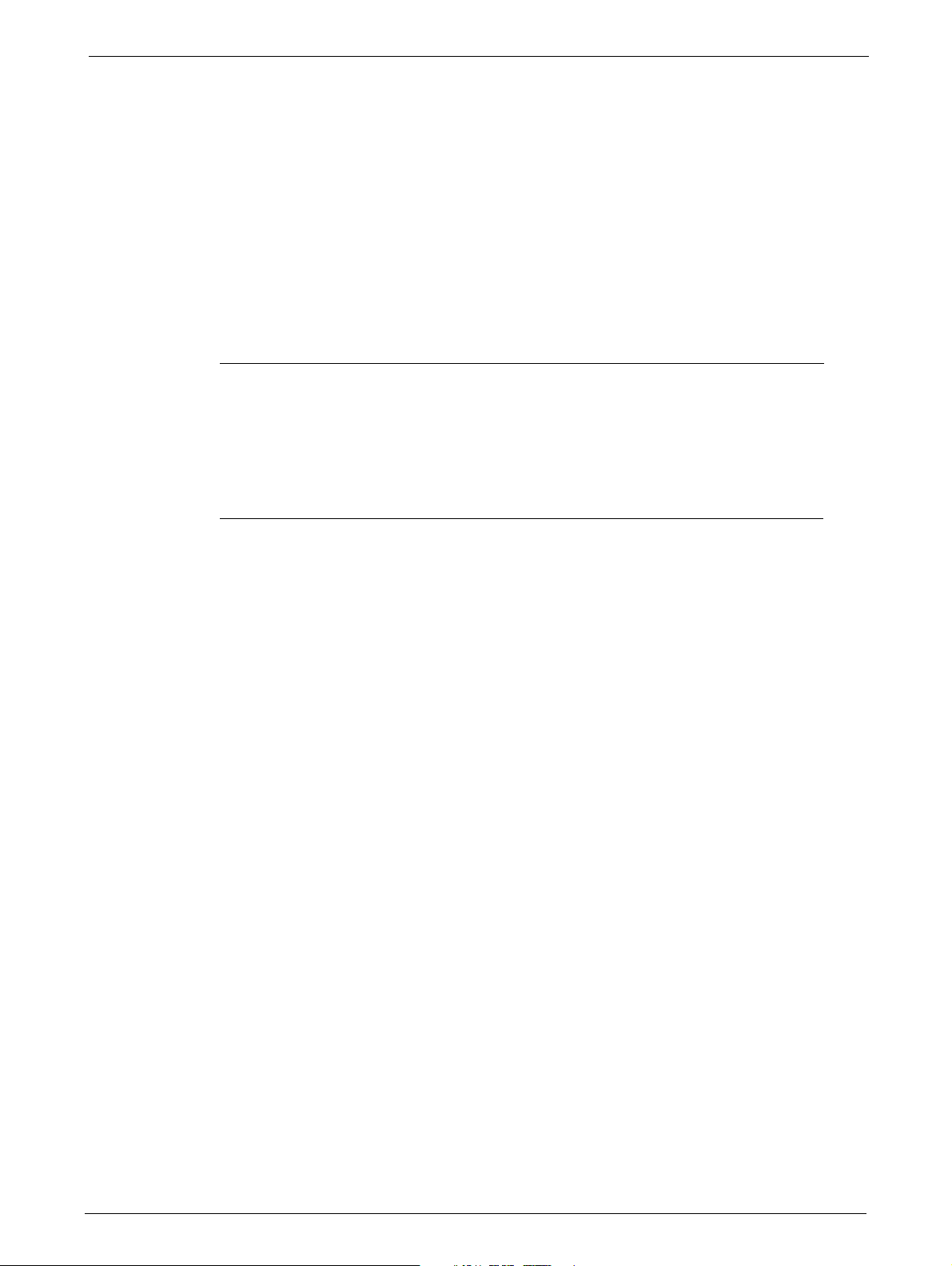

Library Controller

TP-00347-01 15

Additional Documentation

STEPS

Additional information regarding your EditShare tape library may be found in the following

documents:

• EditShare Ark Setup and User’s Guide

Chapter 1: Introduction

• EditShare Storage

• EditShare Storage

• EditShare

These documents are in PDF format and you can access them

follows:

1. Open your web browser and navigate to the web address for your EditShare server, for

example,

2. On the page that displays, under ‘EditShare Documentation’, click on Manuals.

3. A page opens that displays the available user documentation for your system. Click on the

link corresponding to the document you wish to read.

These documents are also included on the Support USB stick included with the server. If you

cannot find or access your manuals, please contact EditShare Technical Support.

Technical Support

/ Ark Installation Guide and ReadMe

Editor’s Guide

Storage Administrator’s Guide

from the server’s status web page as

http://192.168.0.27

For questions not addressed in our documentation, contact EditShare Technical Support. Have the

exact version number of your EditShare implementation, workstation operating system, and

editing software ready.

EditShare strongly recommends that you purchase

Please contact EditShare Technical Support at the following URL:

http://www.editshare.com/support

Information about new features and bug fixes are

server’s version, the EditShare update web site (http://updates.editshare.com/) or your server’s

Status Page.

a support agreement for your system.

available in the EditShare ReadMe for your

16 TP-00347-01

Chapter 2: Installation

Always observe the Safety Warnings and Cautions described on page 3.

This section provides instruction

following sections:

• "Preparation" on page 18

• "Serial Attached SCSI (SAS

• "Fibre Channel Requirements" on page 19

• "Unpacking" on page 20

• "Installing the Library" on page 22

• "Installing Tape Drives" on page 23

• "Installing the Library Co

• "Power Supply Installation" on page 25

• "Cable Connections" on page 26

s for installing the 24Q and 48Q Ark Tape Libraries. See the

) Requirements" on page 18

ntr

oller" on page 24

TP-00347-01 17

Preparation

Location Requirements

The 24Q and 48Q Ark Tape Libraries require the following environmental conditions:

Criteria Definition

Rack requirements Standard 19-inch rack with vertical space of 2U available for the Q24 or

Room temperature 10-35°C (50-95°F)

Power source AC power voltage: 100-127 VAC; 200-240 VAC

Air quality Place the library in an area with minimal sources of particulate

Chapter 2: Installation

vert

ical space of 4U available for the Q48.

Line frequency: 50-60 Hz

Place the library near to an AC outlet.

The AC power cord is the library's main AC disconnect device and must

be

easily ac

contamina

cessible at all times.

tion.

Avoid areas near frequently used doors and walkways, stacks of

sup

plies that collect dust, printers, and smoke-filled rooms.

Excessive dust and debris can damage tapes and tape drives.

Humidity 20-80% relative humidity non-condensing

Clearance Back: Minimum of 15.4 cm (6 inches)

Front: Minimum of 30.8 cm (12 inches) - for mailslot

Minimum of 60 cm to remove magazines (24 in)

Sides: Minimum of 5.08 cm (2 in)

For further information, see "Chapter 7: Specifications" on page 103.

Serial Attached SCSI (SAS) Requirements

High quality SAS cables rated at the transfer rate of the SAS drives are required.

Always verify that the SAS cable you are using is rated for the data transfer

of the interface of your components. SAS cables described as "equalized" may

not support 6 Gb/s data rates and should not be used with LT0-5 or later

generation tape drives without first verifying that they are suitable for 6Gb/s

data rates.

speed

The library has a mini-SAS connector on each SAS tape drive. Mini-SAS connectors are

keyed.

Serial Attached SCSI (SAS) is a computer bus technology mainly used to transfer data to and from

storage devices, including disk drives and tape drives. SAS is designed to transfer data at up to 6

gigabits per second.

18 TP-00347-01

Preparation

SAS uses serial connections, with a direct connection between the host server and each of the

storage devices. This eliminates the need to configure SCSI buses and assign SCSI IDs, as was

required for parallel SCSI devices.

The companion Ark Tape server purchased from Editshare will be configured with a compatible

SAS Host Bus Adapter (H

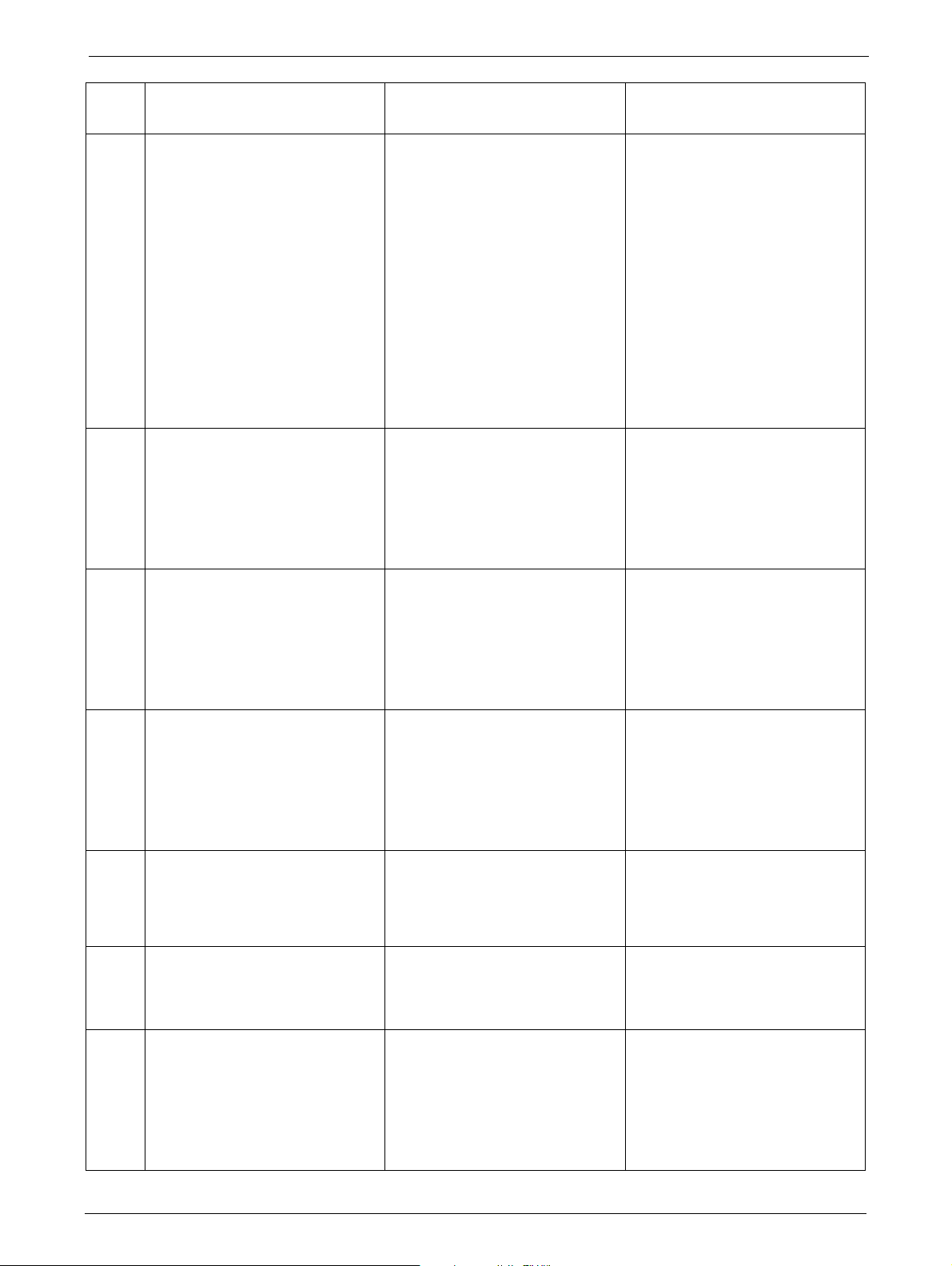

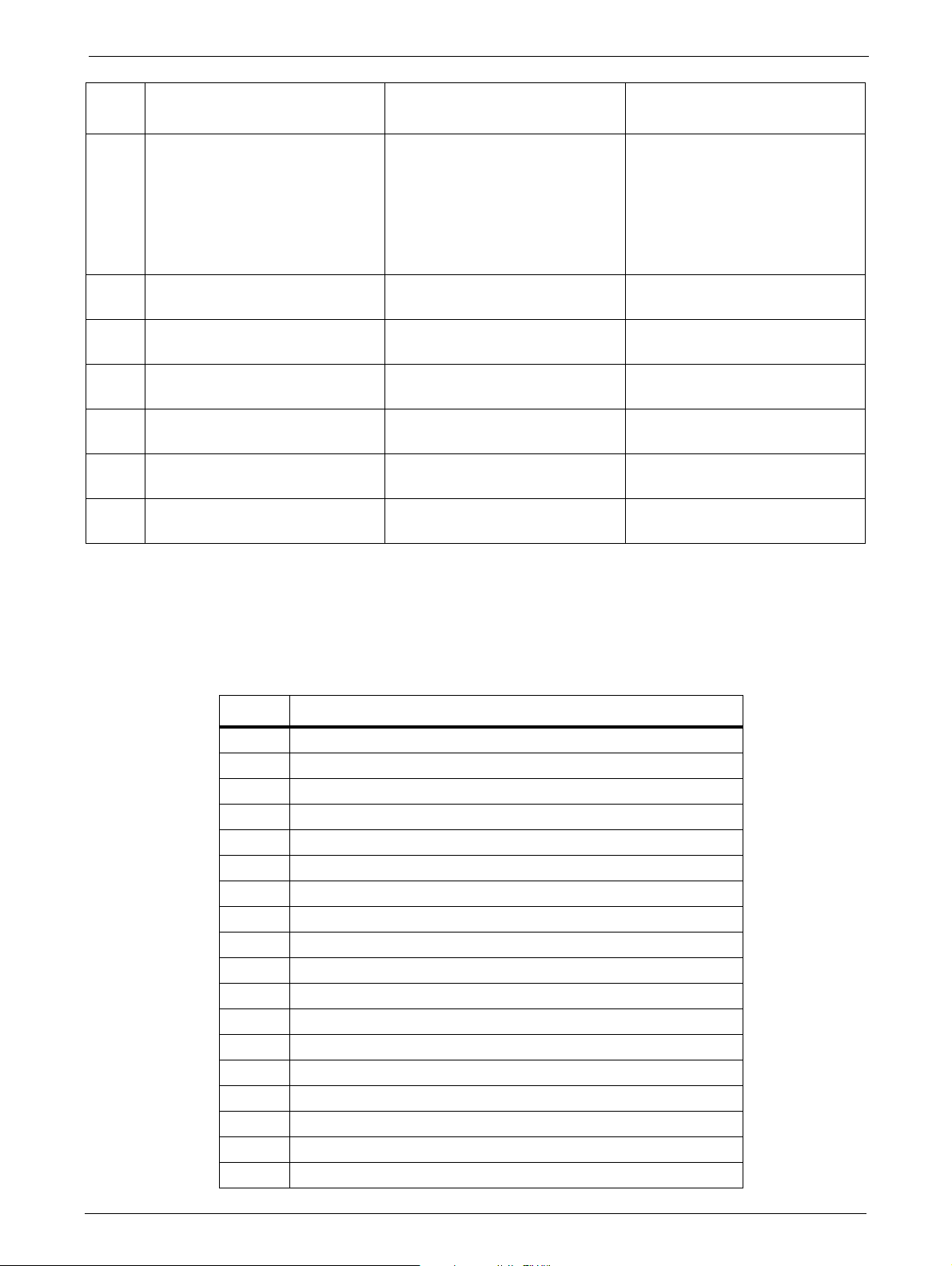

Supported speeds by drive generation are shown in the following table:

LTO G en er a ti on Supported Speeds

LTO - 5 1.5 Gb/s, 3Gb/s, 6Gb/s

LTO - 6 1.5 Gb/s, 3Gb/s, 6Gb/s

LTO - 7 1.5 Gb/s, 3Gb/s, 6Gb/s

LTO - 8 1.5 Gb/s, 3Gb/s, 6Gb/s

BA). Refer to the Ark Setup and User Guide for more information.

A SAS tape drive is identified by a un

Wide Identifier (WWID). The library assigns the WWID to the drive bay. When a tape drive is

replaced, the WWID is re-assigned to the new tape drive.

The operating system tracks the WWID for the tape drive on each HBA channel. Each of the drive

ectors on the fan-out cable is associated with an HBA channel. Once a tape drive has been

conn

plugged in, it should remain on the same channel to retain the association between the HBA

channel and WWID.

Fibre Channel Requirements

For best performance, use the appropriate HBA for your tape drive. A lower throughput

HBA might result in performance degradation

to a higher throughput tape drive.

In a SAN installation, all switches between the host and the library

appropriate type. A lower throughput switch in the path may result in performance

degradation. Configure zoning so only the backup servers may access the library.

The Fibre Channel tape drive can be connected directly to the server with a host bus adapter (HBA).

The installation requires one Fibre Channel cable for ea

LC-style connector. Some drives will have two FC ports, but only one cable connection is needed

per drive. The cable can be connected to either drive FC port.

identifier called a World Wide Name (WWN) or World

ique

when backing up highly compressible data

must be of the

ch tape drive. The tape drives all utilize an

The companion Ark Tape server purc

Host Bus Adapter (HBA). Refer to the Ark Setup and User Guide for more information.

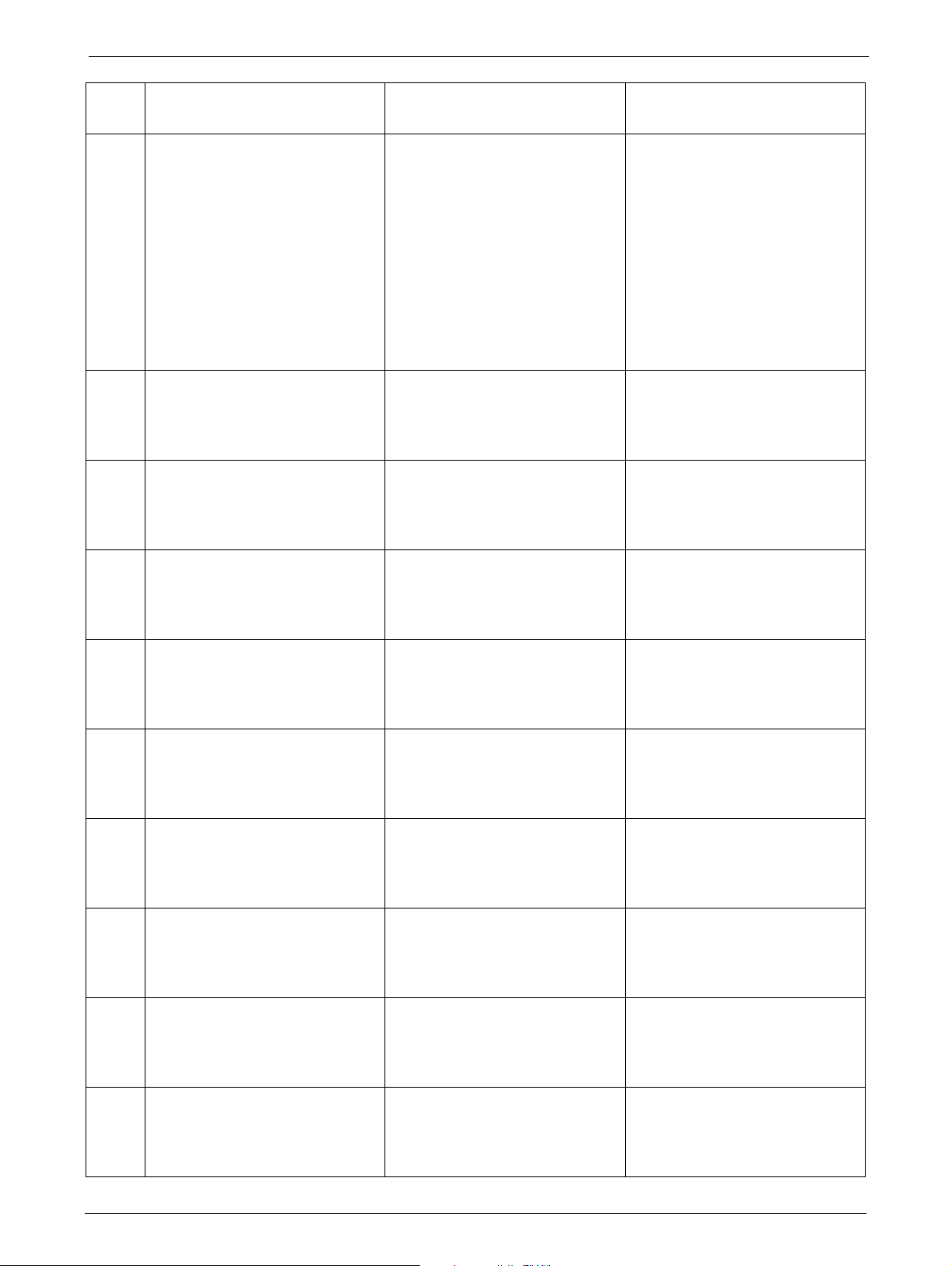

Supported speeds by drive generation are listed in the following table:

LTO G en er a ti on Supported Speeds

LTO - 5 2 Gb/s, 4 Gb/s, 8 Gb/s

LTO - 6 2 Gb/s, 4 Gb/s, 8 Gb/s

LTO - 7 2 Gb/s, 4 Gb/s, 8 Gb/s

LTO - 8 2 Gb/s, 4 Gb/s, 8 Gb/s

TP-00347-01 19

hased from Editshare will be configured with a compatible FC

Unpacking

STEPS

Unpacking the Library

Chapter 2: Installation

If the temperature in the room where the library is to be installed varies by 15°C

(30°F) or more from the room where the libra

acclimatize to the surrounding environment for at least 12 hours before

unpacking it from the shipping container.

ry was stored, allow the library to

Do not place the library on either the end or sides as this

Before unpacking the library, clear a work surface on

the library is to be installed in a rack, select an open rack location allowing easy access to the host

server and an easily accessible power outlet.

1. Before opening and removing the tape library from the box, inspect the container for

shipping damage. If you notice any damage, report it to the shipping company immediately.

2. Open the box.

3. Carefully remove the shipping materials from the top of

4. Remove the accessory package and set a

5. Remove the two rack rails and set a

6. Lift the library out of the carton and remove the bag from the loader. Save the packaging

materials for future use.

Identifying Product Components

Confirm that you received the following:

may damage the unit.

which to place the unpacked components. If

the library.

side (if included).

side (if included).

1) 24Q/48Q Ark Tape Library, including:

• 1 x Power Supply,

• 1 or more half-height T

• 1 x Library controller

• 2 x Tape magazines for the 24Q - or:

4 x Tape magazines for the 48Q

2) Rack mount kit comprising:

• 2 x Rack Mount Rails

• 1 x Bag of eight M6 screws for the rack m

column)

• 1 x Bag of eight M6 screws for rack mounting

column)

3) Power cord

4) Library documentation

Optional components, depending on the purchased configuration:

• Cables - Fibre Channel or

20 TP-00347-01

SAS cables

pe drives (as ordered)

a

o

unting (9.5 mm square holes in the rack

(6.85 mm round holes in the rack

Unpacking

STEPS

24Q

48Q

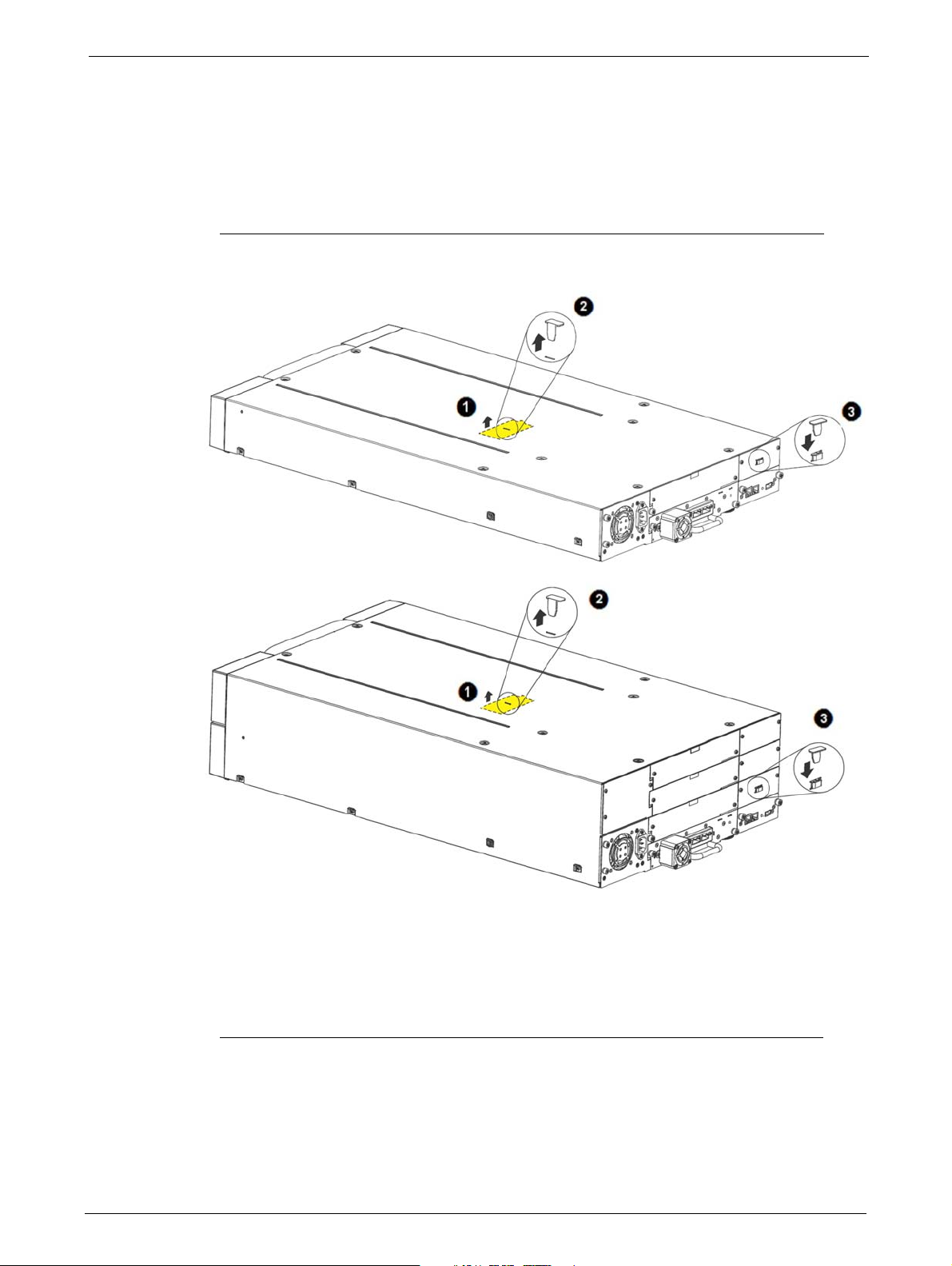

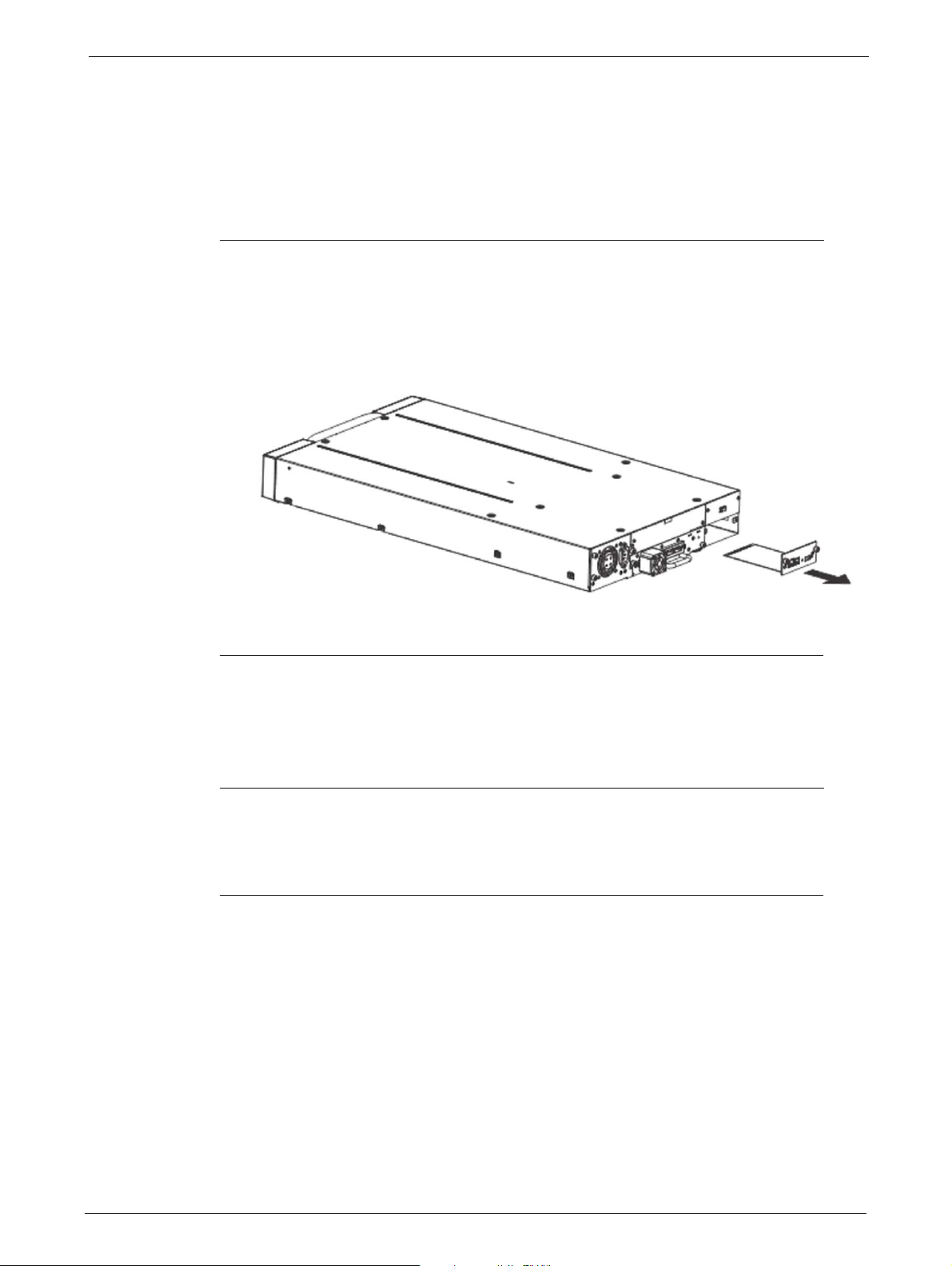

Removing the Shipping Lock

The Shipping Lock, which prevents the media changer transport mechanism from moving

during shipment, must be removed before the library is powered on.

To remove and store the shipping lock:

1. Remove the yellow label that is securing the shipping lock on the top of the

library.

2. Remove the shipping lock.

3. Store the shipping lock in the slot provide

library is to be returned or transported to a new location at some future time.

4. Replace the yellow label on the top of the library.

TP-00347-01 21

d on the rear panel - The Lock is required if the

Installing the Library

STEPS

Tools Required

The following tools are required to install the library:

•No. 3 Phillips screwdriver

• T10 Torx screwdriver

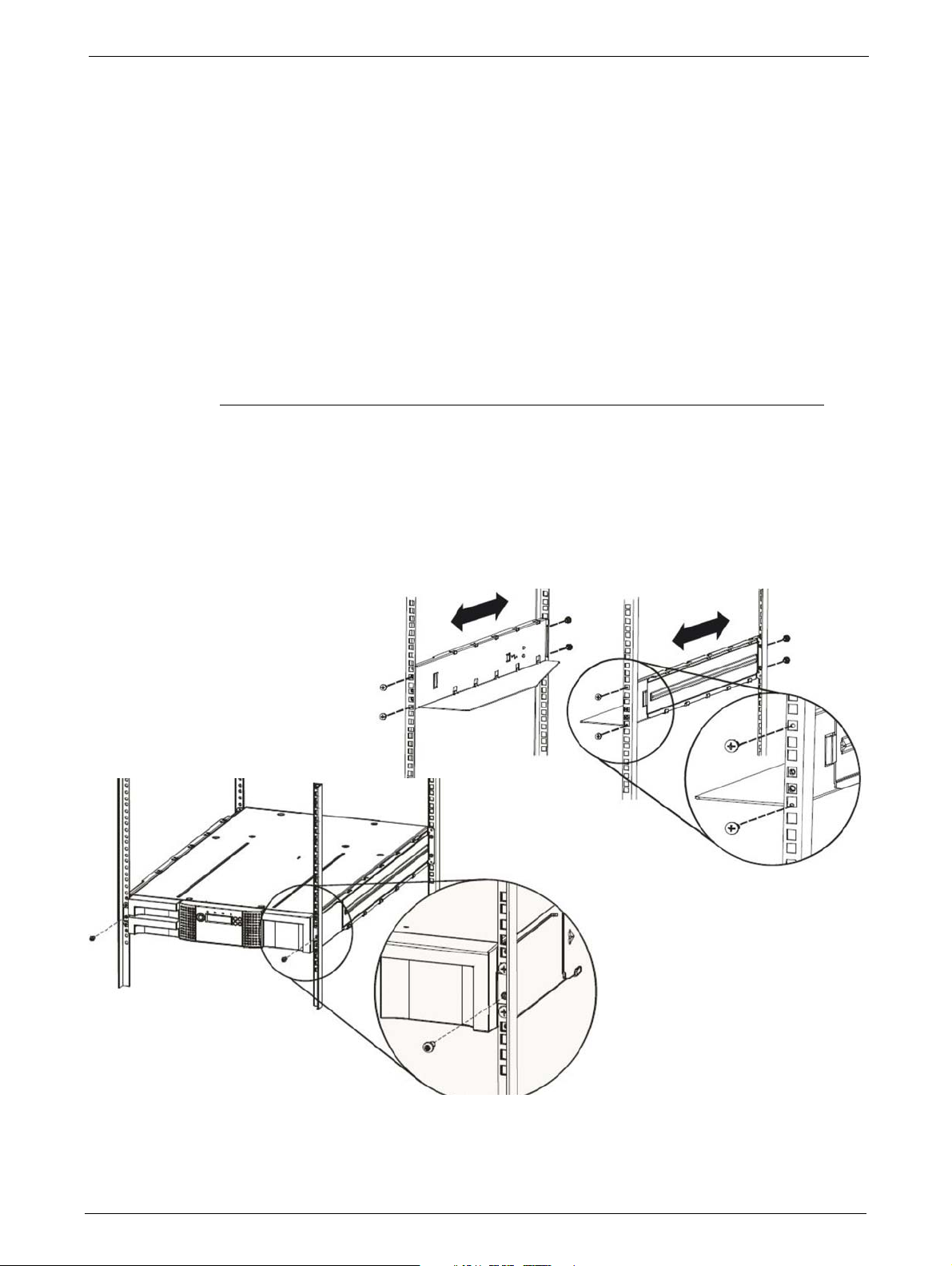

Rack-Mounting the Library

To rack mount the library:

1. Determine the location in which the library rack is to be installed.

2. Use a pencil to mark the location on each vertical rail in the rack.

Chapter 2: Installation

3. In the rack mount kit are two sets of eight M6 sc

choose the appropriate type of M6 screws.

4. Secure one rail to each side of the rack in your chosen rack location with a #3 Phillips

screwdriver. I

nsure the rails are mounted level and at the same rack height on each

rews. Determine the type of rack then

side.

5. Secure both the front and back of each

22 TP-00347-01

rack rail to the rack.

Installing Tape Drives

STEPS

6. Slide the library onto the rack rails.

7. Secure the library to the rack using a No 3 Phillips screwdriver placed through the small

holes in the mounting bracket to tighten the M5 screw(s) on each side of the library.

Installing Tape Drives

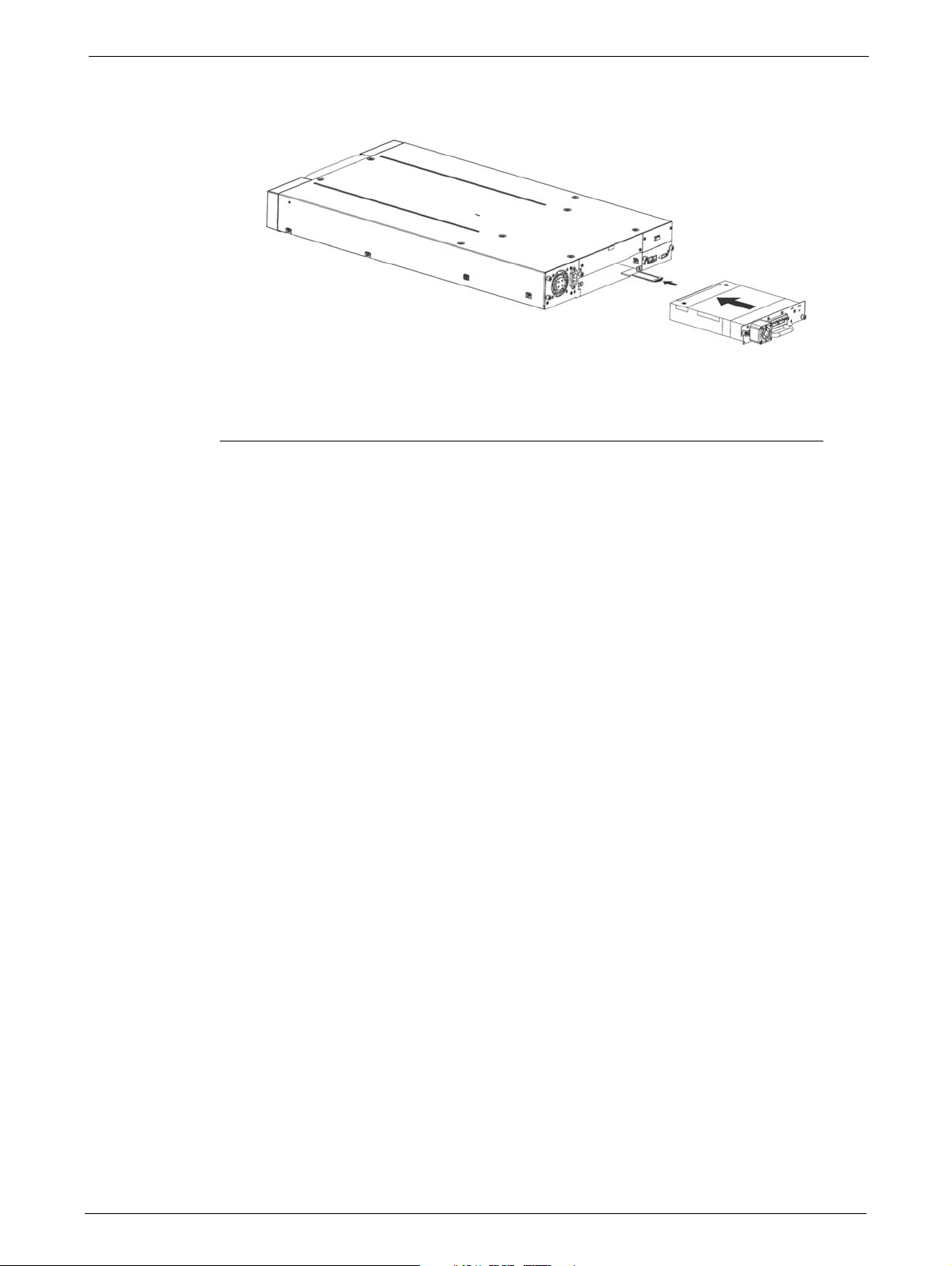

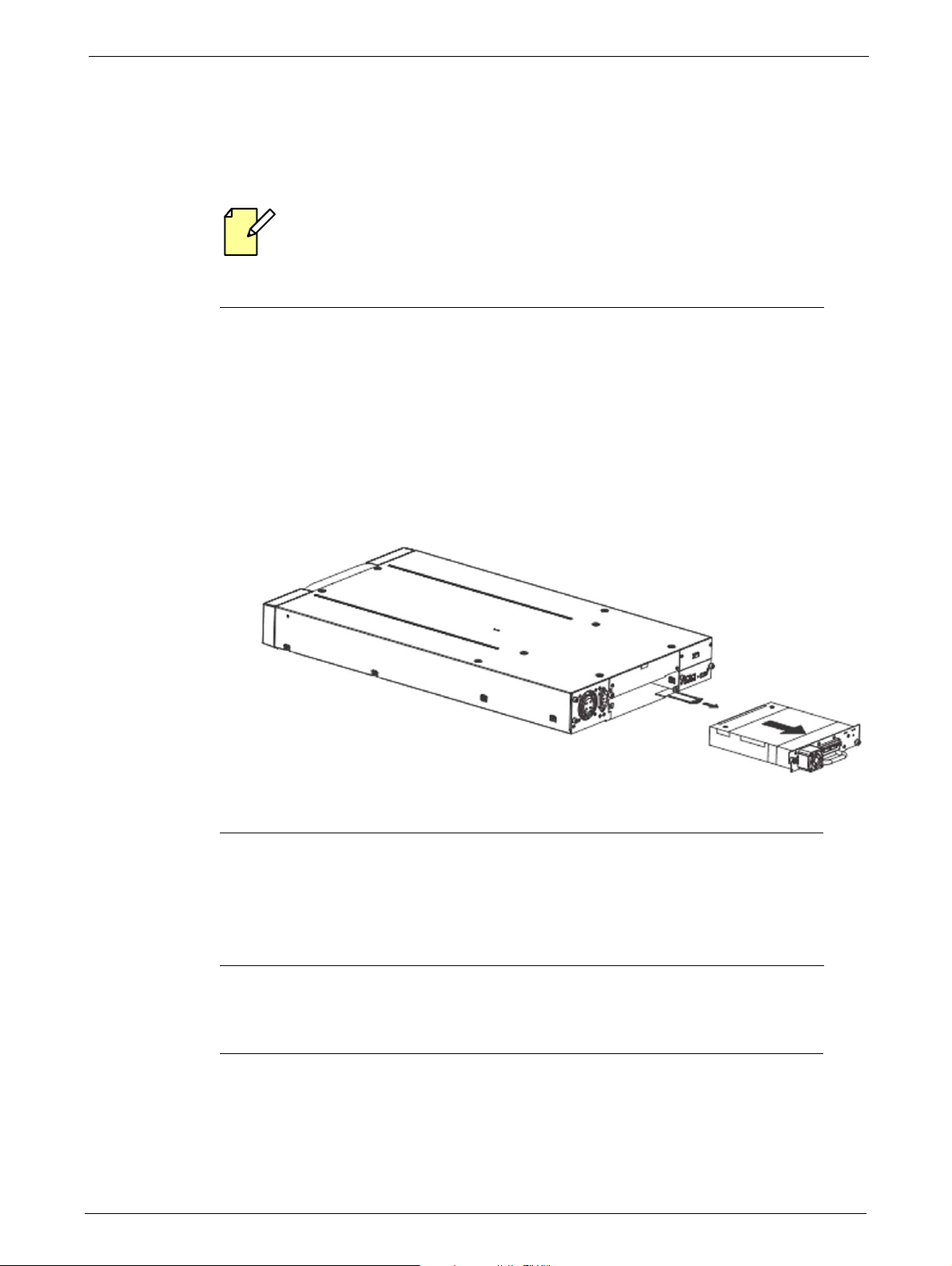

Tape drives are installed from the rear of the library. If the library does not already have a tape drive

installed, install it now. If the library already has one tape drive installed, additional tape drives may

be added now or after installation of the library is complete.

Tools Required

The following tool is required:

•No 2 Phillips screwdriver

Installation Procedure

To install tape drives:

1. The 24Q has space for two half-height tape drives, and the 48Q has space for four half-height

tape drives. Always install the first tape drive in the bottom of the drive bay. A drive bay

cover must be installed over any empty drive positions.

2. If a drive cover is present, loosen the screws and remove the cover to install one half-height

tape drive.

3. When installing the bottom drive, slightly pull out the tab of the product ID label so it does

not interfere with the inse

rtion or removal of the

tape drive.

4. Before installing the drive, inspect th

intact, free of any foreign objects, and have no cracks, or deformed or bent contacts.

TP-00347-01 23

e connectors on it. Ensure that the connectors are

Chapter 2: Installation

5. Insert the tape drive into the drive bay, and align the connectors on the library while

supporting the

drive.

6. Push the tape drive into the drive bay until the tape

library. If extended, push the tab for the product ID label back into the library.

7. Tighten the blue captive screws with your fingers to secure the tape drive to the library.

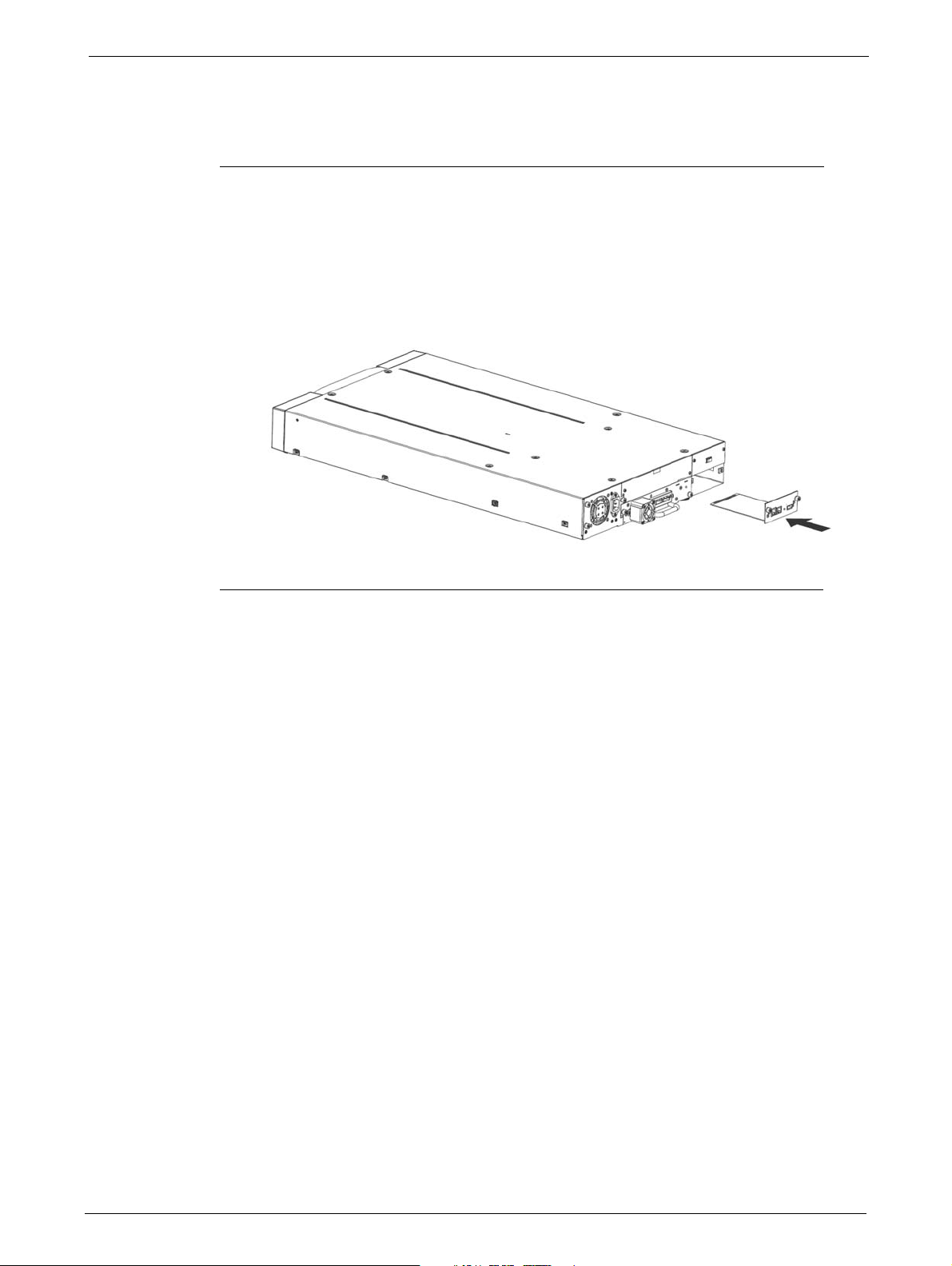

Installing the Library Controller

The library controller is installed from the rear of the library. If the library does not already have a

library controller installed, install it now.

Tools Required

The following tool is required:

•No 2 Phillips screwdriver

drive seats itself against the back of the

24 TP-00347-01

Power Supply Installation

STEPS

Installation Procedure

To install tape drives:

1. Locate the vacant library controller bay on the lower right side of the rear panel.

2. If present, loosen the screws and remove the library controller bay cover.

3. Before installing the library controller, inspect its connectors. Ensure that the connectors are

intact,

free of any foreign objects, and have no cracks or deformed or bent contacts.

4. Insert the library controller on the alignment rails and push it into the

against the back of the

5. Tighten the blue captive screws with your fingers to secure the library controller.

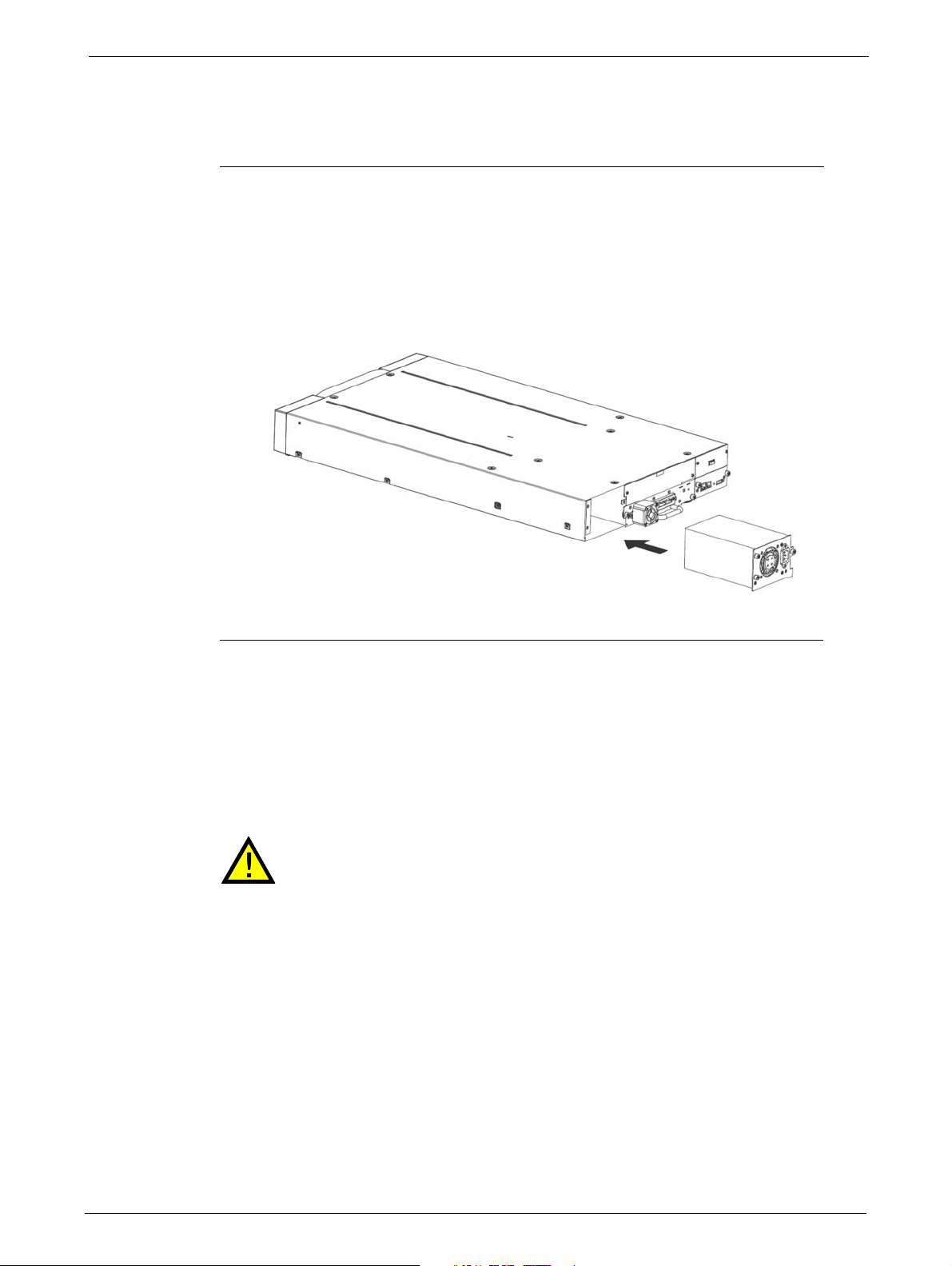

Power Supply Installation

The power supply is installed from the rear of the library. If the library does not have a power supply

installed, install it in the left power supply bay now.

bay until it seats itself

library.

Tools Required

The following tool is required:

•No 2 Phillips screwdriver

TP-00347-01 25

Installation Procedure

STEPS

To install a power supply:

1. Locate the power supply bay on the lower left side of the rear panel of the library.

2. If present, loosen the screws and remove the power supply bay cover.

3. Before installing the power supply, inspect its connectors. Ensure that the connectors are

intact,

Chapter 2: Installation

free of any foreign objects, and have no cracks or deformed or bent contacts.

4. Insert the power supply on the alignment rails and push it into the

against the back of the

5. Tighten the blue captive screws with your fingers to secure the power supply to the library.

Cable Connections

bay until it seats itself

library.

Power Cord Connections

Mains voltages are present on this equipment. Before connecting a power cord

to the library:

Ensure that the power cord meets safety standards for

equipment is installed.

Use cable rated at 13A to avoid overheating the cord.

Always observe the Safety Warnings and

To connect the powe

26 TP-00347-01

r cord to the library:

Cautions described on page 3.

the country where the

Cable Connections

STEPS

STEPS

STEPS

1. Plug the female connector of the power cord into the power connector (AC connector) on

the rear panel of the power supply.

• For 24Q power supplies, refer to the diagram "24Q Library" on page 14.

• For 48Q power supplies, refer to the diagram "48Q Library" on page 14.

2. Plug the male connector into an appropriate electrical socket.

Connecting Fibre Channel Cables

To connect the fibre channels:

1. Remove the FC port caps if necessary. Attach one end of the FC cable to port A on the tape

drive.

2. Attach the other end of the FC cable to the HBA installed in your EditShare Ark Tape server.

Refer to the EditShare Ark Setup and User’s Guide for additional information.

Connecting SAS Cables

SAS signal rates require clean connections between the HBA and tape drive. Do not use

adapters or converters between the HB

maximum SAS cable length of six meters.

To connect the SAS cables:

1. Attach the HBA end of the SAS cable into the connector on the HBA. If you are using a SAS

fanout

the HBA.

A and the tape drive. For reliable operation, use a

/ Hydra cable, the end of the cable with only one connector should be plugged into

TP-00347-01 27

2. Connect the drive end of the cable:

Chapter 2: Installation

• If you are using a cable with a single connector on each end, attach the

connector on the

• If you are using a SAS fanout/Hydra cable, attach one mini-SAS connector into the

nnector on each tape drive. Coil and secure any unused fanout cables to the rack to

co

minimize stress on the cables and connectors.

Connecting an Ethernet Cable

The connection to the Ethernet network is via an industry standard RJ45 copper interface on the

rear panel of the library. The Ethernet connection is used to access the library RMU over a network.

To connect the library to the Ethernet network,

the library. When the plug is in the correct position, a click should be heard.

other end into the

tape drive.

insert the Ethernet cable into the Ethernet port of

Connecting a USB device

The USB port is on the rear of the library. It can be used for firmware upgrades/skin file updates

initiated via the Operator Control Panel (OCP).

28 TP-00347-01

Chapter 3: Cartridges and Magazines

This chapter explains which media to use with your library, and how to label and write-protect your

tape cartridges. Careful labeling and handling of the tape cartridges prolongs the life of tape

cartridges and the library.

See the following sections:

• "Use and Care of Tape Cartridges" on page 29

• "Supported Cartridge Types" on page 30

• "Labeling Tape Cartridges" on page 30

• "Write Protecting Tape Cartridges" on page 31

• "Read/Write Compatibility" on page 32

• "Magazines" on page 32

Use and Care of Tape Cartridges

DO NOT degauss LTO data cartridges. These data cartridges are prerecorded with

a magnetic servo signal. This sign

tape drive. Keep magnetically charged objects away from the cartridge.

al is required to use the cartridge with the LTO

Do not place data cartridges near sources of electro

magnetic fields such as computer monitors, electric motors, speakers, or X-ray

equipment. Exposure to electromagnetic energy or magnetic fields can destroy

data and the embedded servo code written on the media by the cartridge

manufacturer, which can render the cartridge unusable.

Clean drives with Ultrium Universal cl

To ensure the longest possible life for your data cartridges, follow these guidelines:

• Use only the data cartridges designated for your device.

• Clean the tape drive when the Clean drive LED is illuminated.

Do not drop a cartridge. Excessive shock can damage the internal contents of the

cartridge or the cartridge case itself

Do not expose data cartridges to direct sunlight

portable heaters and heating ducts.

The operating temperature range for data cartridges is

temperature range is +40°C to 60°C in a dust-free environment in which relative

humidity is always between 20% and 80% (non-condensing).

If the data cartridge has been exposed to temperatur

ranges, stabilize the cartridge at room temperature for the same length of time it

was exposed to extreme temperatures or 24 hours, whichever is less.

eaning cartridges only.

, making the cartridge unusable.

magnetic energy or strong

or sources of heat, including

10 to 35º C. The storage

es outside the specified

Place identification labels only

TP-00347-01 29

in the designated area on the cartridge.

Supported Cartridge Types

Use the Ultrium data and cleaning tape cartridges designed for the tape drive formats present in

your library.

Tape Drive Cartridge Type

LTO - 5 LTO -5 U ltr i um D ata C art rid g e

LTO - 6 LTO -6 U ltr i um D ata C art rid g e

LTO - 7 LTO -7 U ltr i um D ata C art rid g e

LTO - 8 LTO-8 and LTO-7 Type M Ultrium Data Cartridge

- Ultrium Universal Cleaning Cartridge

Chapter 3: Cartridges and Magazines

Labeling Tape Cartridges

Neither the EditShare Ark Tape application nor the tape library support unlabeled media.

Make sure every cartridge has a barcode label in place.

Misusing and misunderstanding bar code technology can result in backup and

failures. Use only high quality labels. Self-printed labels are not recommended as they are

often a source of barcode reading issues.

The device contains a bar code reader that reads the tape labels and stores the inventory data in

memory. The device then provides the inventory information to the host application, OCP, and

RMI. LTO tape cartridges must have barcode labels in order for the EditShare Ark Tape application

to work as designed.

A proper bar code label includes the media ID in the last two characters of the bar code. The library

will not load an incompatible cartridge, based on the

example, the library will not load a cartridge labeled as LTO-3 into an LTO-6 tape drive. This saves

the time needed to load the cartridge and have the tape drive reject it.

EditShare Ark Tape keeps track of the

• Date of format or initialization

• Media pool to which the tape belongs

•

Data residing on the tape

restore

barcode media ID, into a tape drive. For

following information via the associated bar code:

•Age of the backup

• Errors encountered while using

30 TP-00347-01

the tape (to determi

ne if the tape is faulty)

Write Protecting Tape Cartridges

STEPS

LTO tape cartridges have a recessed area located on the face of the cartridge next to the

write-protect switch. Use this area for attaching the adhesive-backed bar code label. Only apply

labels as

shown:

The bar code label should only be

of the tape cartridge. Never apply multiple labels onto a cartridge because extra labels can cause the

cartridge to jam in a tape drive.

applied as shown, with the alphanumeric portion facing the hub side

Write Protecting Tape Cartridges

All rewriteable data cartridges have a write-protect switch to prevent accidental erasure or

overwriting of data. Before loading a cartridge into the device, make sure the write-protect switch

on the front of the cartridge is in the desired position.

1 Insertion Arrow

2 Barcode Label

3 Write-Protect Switch

4 Write-Protected

5 Write-Enabled

1. Slide the switch (3) to the left to allow the device to write data to the cartridge.

2. Slide the switch to the right to write-protect the cartridge. An indicator, such as a red mark

or small padlock, is visible showing that the cartridge is write-protected.

TP-00347-01 31

Chapter 3: Cartridges and Magazines

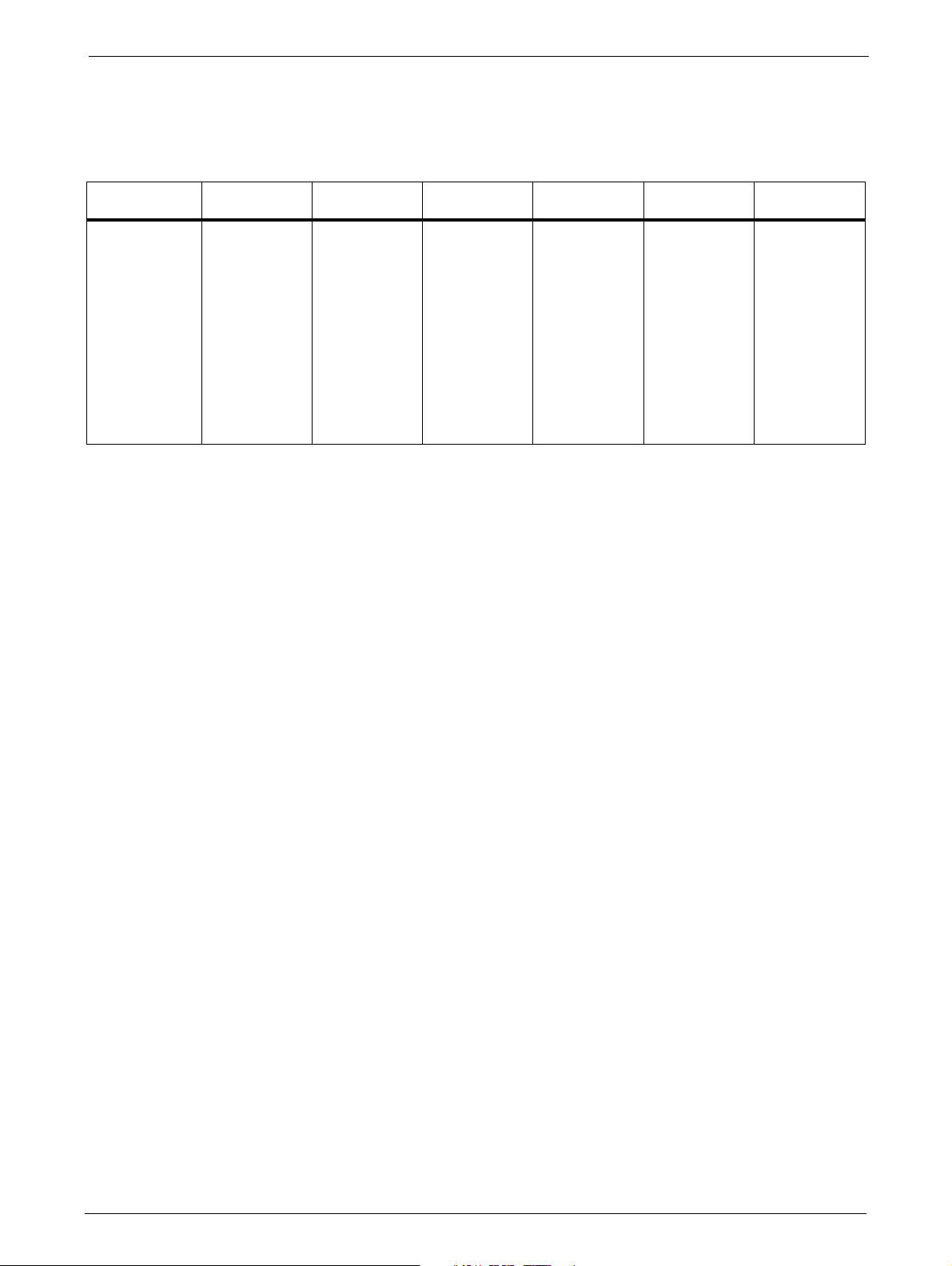

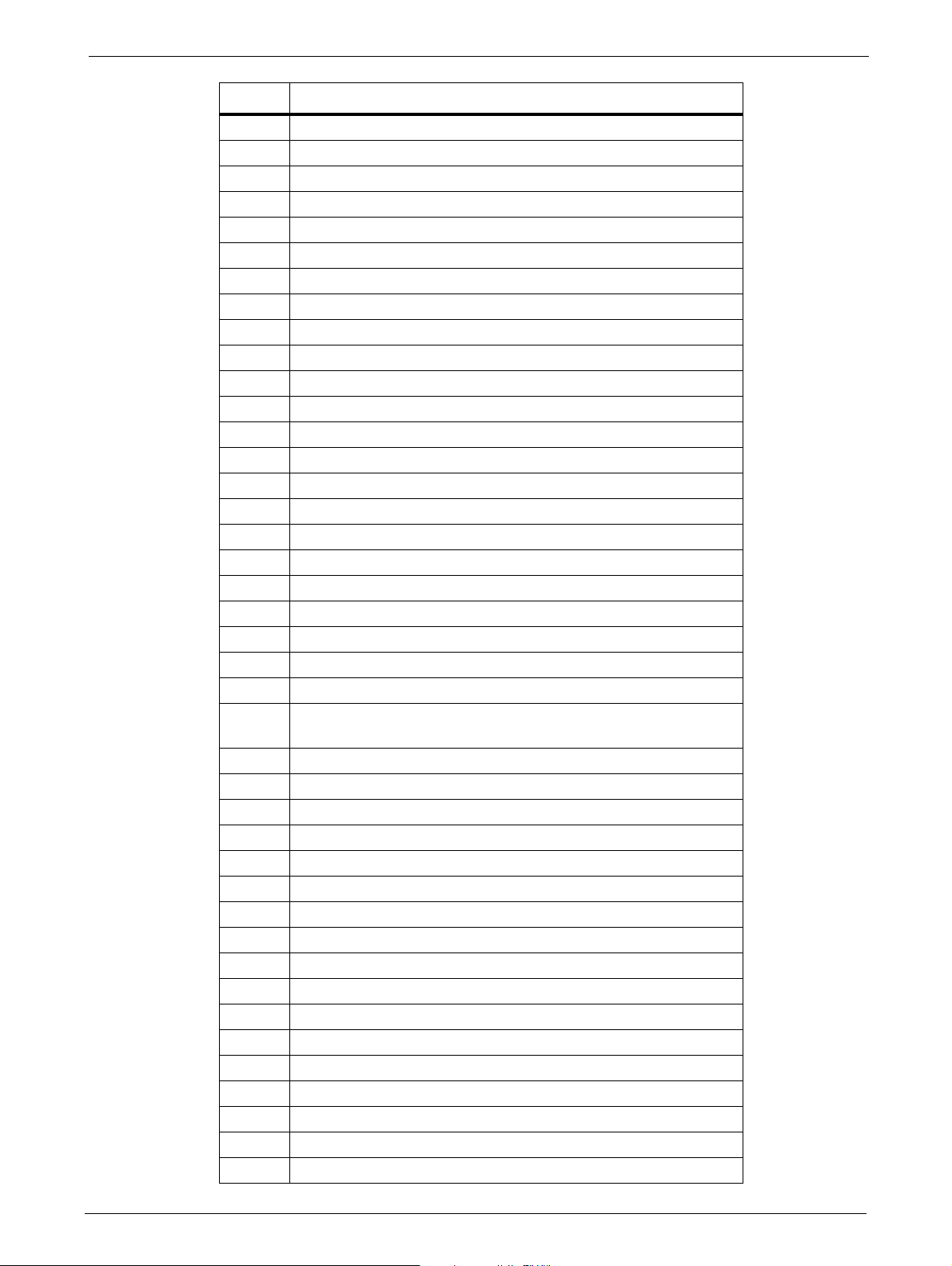

Read/Write Compatibility

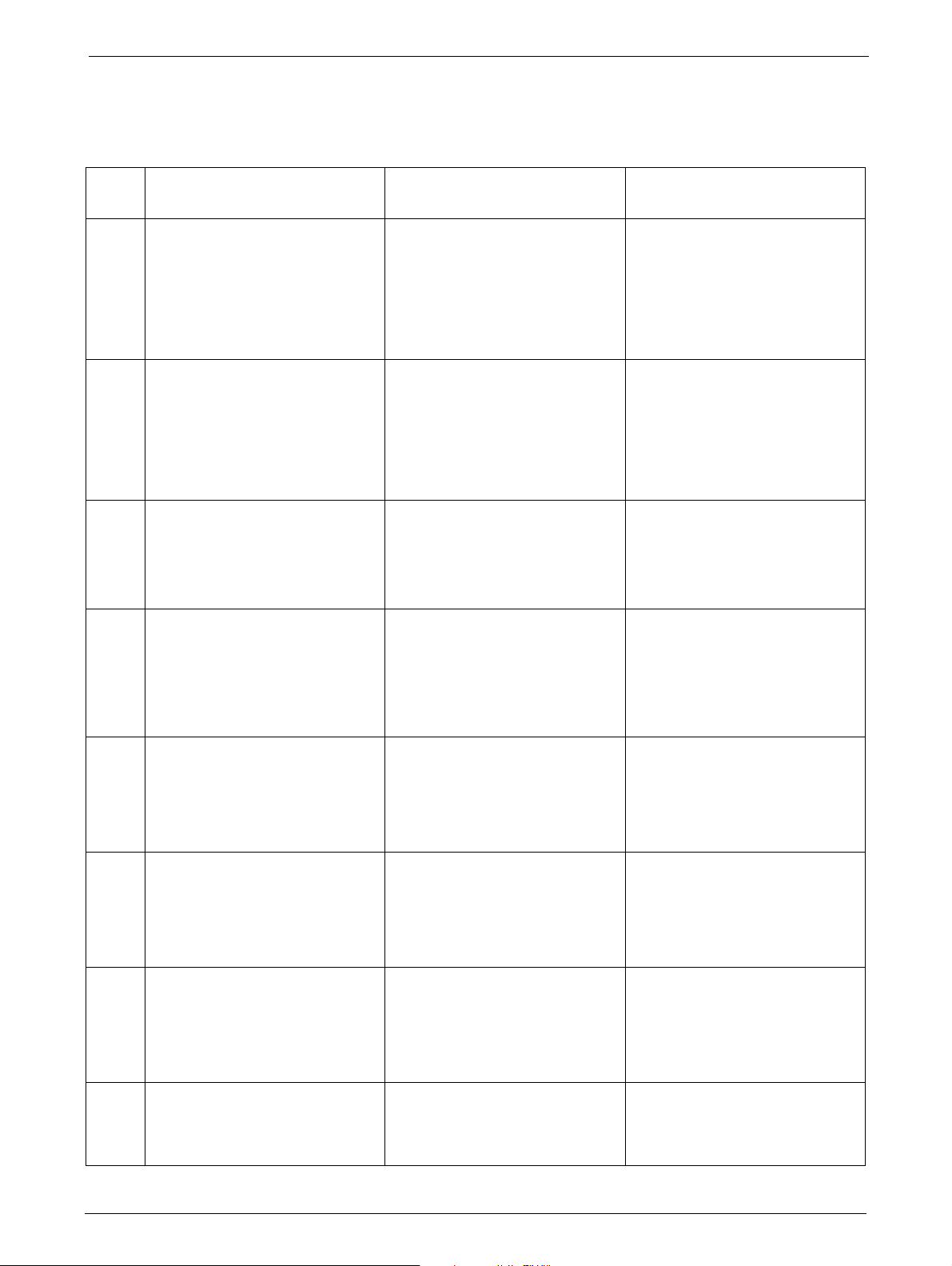

The following table summarizes the Read/Write compatibility of the Ultrium LTO drives:

LTO - 3 D riv e LT O -4 D riv e LT O -5 D ri ve LTO -6 Dr iv e LT O -7 D ri ve LTO -8 Dri ve

LTO -3 M edi a Read/Write Read/Write Read-Only Incompatible Incompatible Incompatible

LTO -4 M edi a Incompatible Read/Write Read/Write Read-Only Incompatible Incompatible

LTO - 5 Me d i a Incompatible Incompatible Read/Write Read/Write Read-Only Incompatible

LTO -6 M edi a Incompatible Incompatible Incompatible Read/Write Read/Write Incompatible

LTO -7 M edi a Incompatible Incompatible Incompatible Incompatible Read/Write Read/Write

LTO -8 M edi a Incompatible Incompatible Incompatible Incompatible Incompatible Read/Write

LTO -7M Med ia Incompatible Incompatible Incompatible Incompatible Incompatible Read/Write

Magazines

Slot Usage

All listed media is incompatible with LTO-1 and

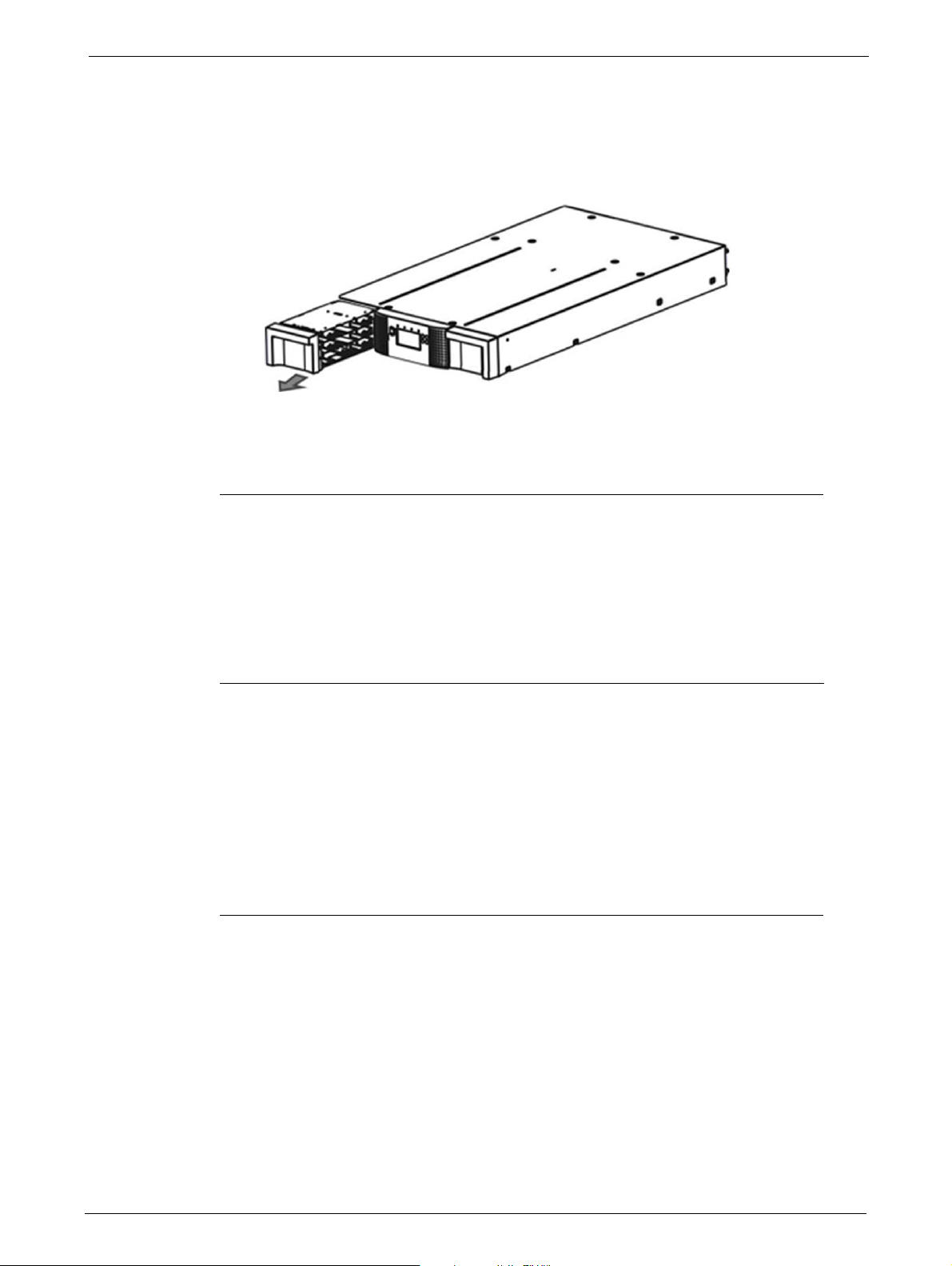

The Ark Tape Libraries make use of removable magazines. Tape cartridges are stored in the

magazines. Each magazine can be individually removed, or inserted. Each magazine inserted in the

library, is locked into position, to prevent unauthorized removal. Access to unlock the magazines

can be password protected. For safety reasons, removal of a tape magazine disables media

changer motion.

The magazines can be unlocked via the Operator Control Panel (OCP) or the Remote Management

Unit (RMU).

•OCP, see "Operator Control Panel (OCP)" on page 33

•RMU, see "Servicing a Magazine" on page 75

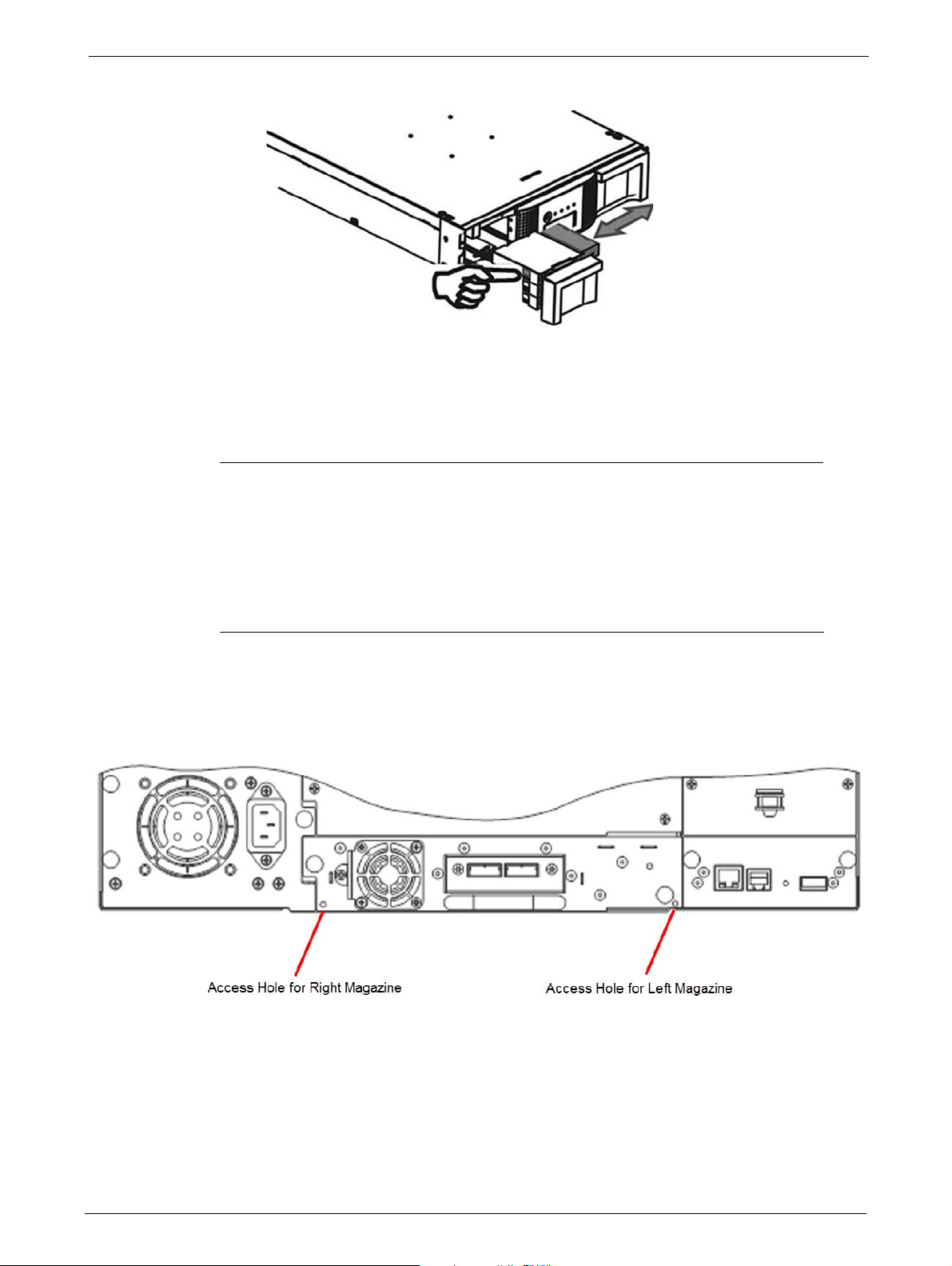

In case the OCP or RMU initiated process fails or

emergency release is available, see "Emergency Release" on page 84.

TO-2 drives.

L

the library no longer has power, a manual

Each magazine contains four slots for tape cartridge storage. However, the front slot in the

left-hand magazine can function as a ‘mailslot’.

The mailslot is used to import/export individual ta

operation. The command to open the mailslot may be denied if the media changer is busy with

some operation. In that case, "Busy" is displayed on the OCP and the command has to be repeated

once the media changer operation is finished.

32 TP-00347-01

pe cartridges without interrupting the library

Chapter 4: Operation

STEPS

See the following sections:

• "Powering the Library Up or Down" on page 33

• "Operator Control Panel (OCP)" on page 33

• "Remote Management Unit (RMU)" on page 44

• "Operations" on page 61

• "Partitioning the Library" on page 66

• "Default Settings" on page 69

Powering the Library Up or Down

To power the library up or down:

1. Press the power button on the front panel of the 24Q or 48Q Tape Library.

2. Powering up can take a few minutes because it includes scanning the inventory and

configuration (for example, how many and what type of drives are installed).

Operator Control Panel (OCP)

Operating Modes

The OCP operates in two basic modes:

• User interaction mode: This mode is employed wh

operating panel.

• System driven mode: This is the nor

status associated with the actions that were caused from commands issued from the EditShare

Ark Tape application. Actions like loading, rewinding or moving tape cartridges will be

displayed.

Whenever an operating button is pressed and released, the operating panel automatically

tions to user interaction mode. The user interaction mode will be active until 3 minutes after

transi

the user stops pushing buttons, or the requested media changer activity stops - whichever is

longer. At this time, the operating panel will return to the system driven mode.

en a user is pushing buttons on the

mal mode of operation. In this mode, the OCP displays

In the event that the administrator-programed user security feature is

mode is restricted to the information and login menu screens, until a login with correct PIN is

entered.

TP-00347-01 33

in use, the user interaction

OCP Rules

Chapter 4: Operation

OCP commands obey the following basic rules:

1) Any operational conflict between commands received from the host interface or RMU and

th

ose entered via the front panel will be avoided with a reservation mechanism on a

'first-come, first-served' basis.

Any reservation by OCP is cancelled by an OCP logout or timeout, which cancels the User

eraction Mode.

Int

2) The library firmware will not allow a user to select an impossible request. Those situations

include, but are

• Moving a tape cartridge from any source to a full magazine slot

not limited to:

3) Any error detected by the library or drive controller and not recoverable through predeter-

4) Numeric error codes are only used for unrecoverable, fatal errors (see "Main Error Codes" on

Power-Up Display

When the library powers up or resets, it goes through internal processes that initialize and prepare

the unit for normal operation. These processes are called Power-On-Self-Test (POST). While the

POST is in process, the OCP will display appropriate information to keep the user informed. When

the library finishes POST, it displays the current library status for a defined time or until a front panel

key is pressed.

After this initial status screen, the

screen shows the overall health of the library, indicating the status of the media changer and the

connected drives.

• Moving a tape cartridge from an empty magazine

• Loading a tape cartridge from any so

• Unloading a tape cartridge from an empty tape drive

mined firmware algorithms will be considered as fatal. An error code displays on the OCP

an

d the error LED illuminates. The error code remains on the OCP until a button is pressed,

which causes the OCP to return to the home screen.

page 89), otherwise text status messages are provided.

home screen will be displayed until any key is pressed. The home

urce to a full tape drive

slot

LEDs

All LEDs are updated during power up and reset sequences. Upon power up or software reset, the

library illuminates all LEDs at some point during the POST process. This helps the user to verify

whether all LEDs are functional. When initialization starts, all LEDs are extinguished and the

ready/activity LED flashes at approximately two-second intervals. When the mechanical

initialization is complete, the ready/activity LED stops flashing and remains constantly illuminated.

If a library failure occurs, the ready/activity LED is turned off and the error LED illumina

also displays a specific error code to help identify the failure.

The following are additional operational details regarding the LEDs:

• The <Ready/Activity> LED illuminates any time the unit is powered

successfully completed the POST). The LED blinks whenever there is any tape library or drive

activity. The LED also blinks when the unit is offline.

34 TP-00347-01

on and functional (i.e.

ted. The OCP

Operator Control Panel (OCP)

• The <Clean> LED is only lit when a 'cleaning required' has been issued by one of the drives. The

LED is turned off after a successful drive cleaning operation is performed to the requesting

drive.

Input Modes

Selectable Predefined Values

Toggle Values

• The <Media Attention> LED indicates that there is a piec

or invalid. The LED clears when all such cartridges have been exported from the tape library.

• The <Error> LED illuminates when t

failure. This occurs simultaneously with the hard error message displayed on the screen - the

LED remains illuminated until the error state is resolved.

There are several modes for entering values in the different menu items. These values may be

selectable predefined values, toggle values (e.g. on/off) or numerical values like network

addresses.

After navigating to the menu item, the various predefined values can be selected with the

<DOWN> and <UP> buttons. As soon as the display shows the desired value, it may be confirmed

by pressing the <ENTER> button.

here is an unrecoverable (i.e. hard) drive or tape library

e of LTO media which is bad, marginal

Toggle values are used to switch between two different states like 'on' and 'off'. After navigating to

the menu item the display shows its current state. Pressing the <ENTER> button will select the

item, whose value may then be toggled using the <UP> and <DOWN> buttons. Pressing <ENTER>

again sets the item to the displayed value.

Numerical Values

Numerical values are needed for network addresses, PIN entries, and other configuration entries.

After navigating to the menu item to be changed, the actual value will be displayed and the cursor

stays on the first digit. The value may be incremented / decremented with the <DOWN> and <UP>

buttons. After pressing the <ENTER> button to select the displayed value, the cursor moves to the

next editable digit. Each digit can be changed in the same way. After pressing the <ENTER> button

at the last digit, the complete entry will be stored. Pressing the <CANCEL> button will cancel the

whole edit process and the old value will be restored.

TP-00347-01 35

Power-Down

Chapter 4: Operation

The shutdown process may be aborted by pressing the Cancel button within the first three

seconds.

Pressing the Power button on the library while it is operational will initiate a controlled power

down.

The following operations will take place before the unit shuts down completely:

• The display indicates with an appr

• The library controller finishes all ongoing loader an

• The media changer is moved to its home position.

• The library controller switches off the power supply's secondary side.

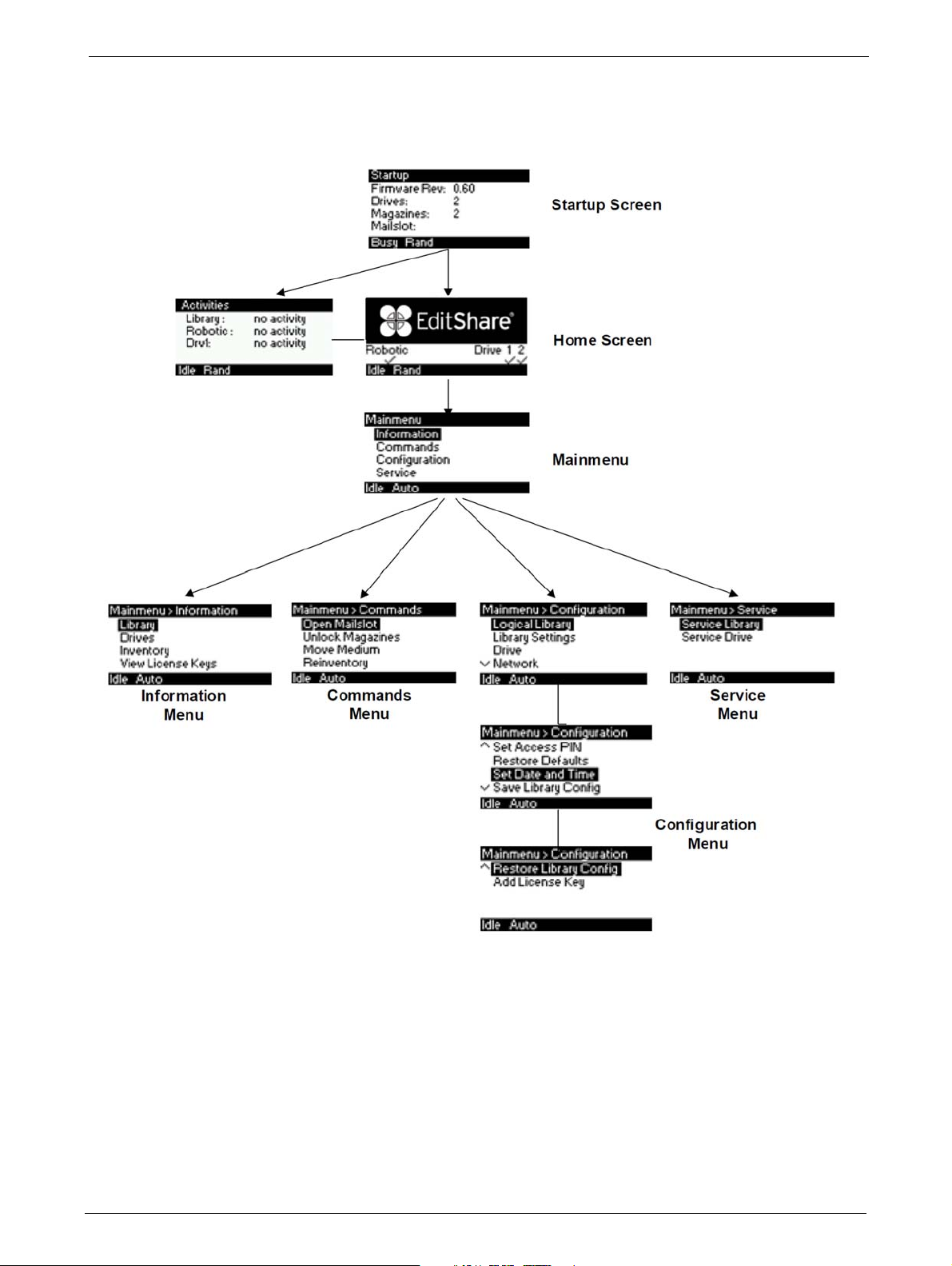

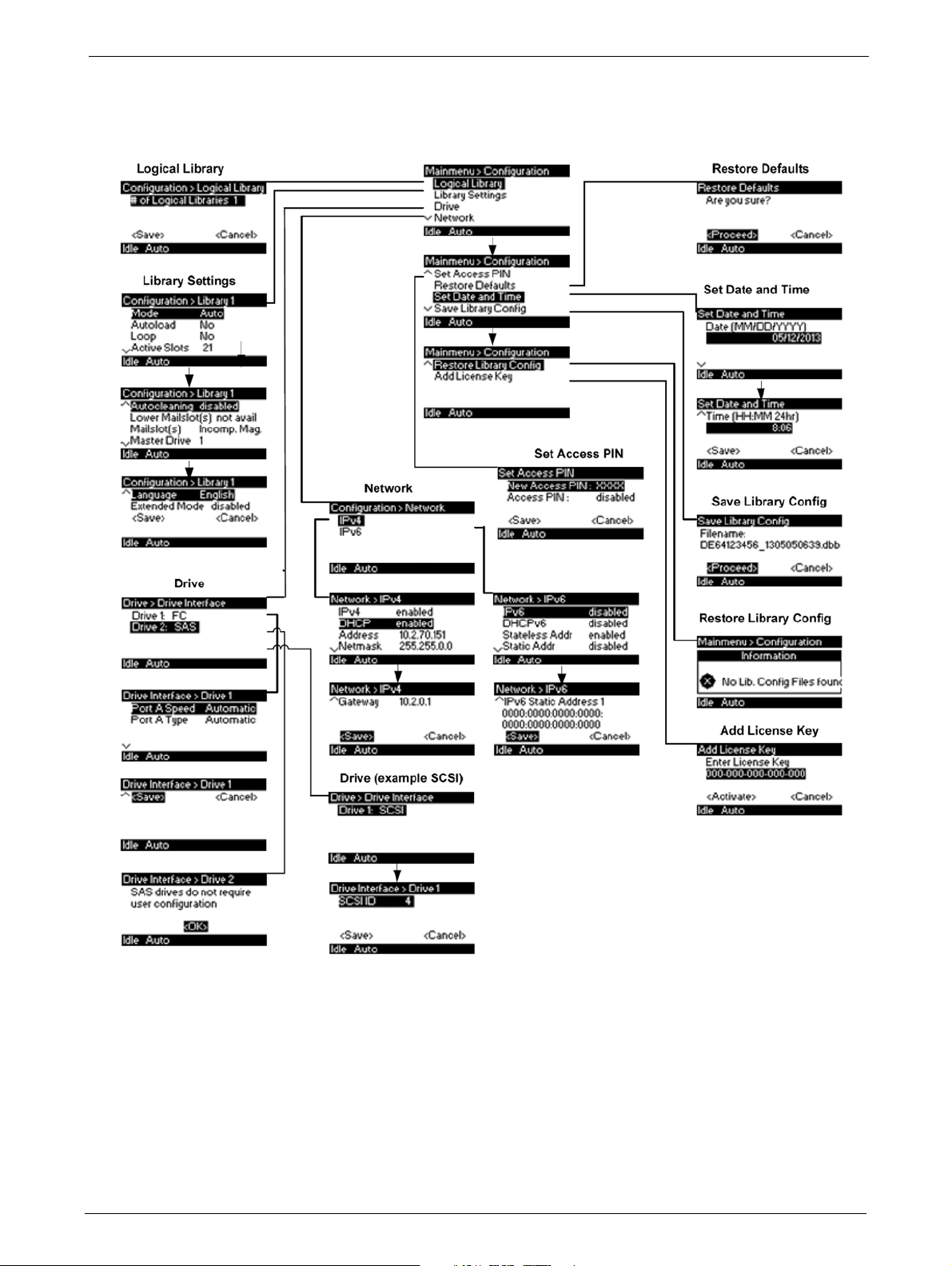

Menu Flow Charts (OCP)

See the following sections:

• "Main Menu" on page 37

• "Information Menu" on page 38

• "Commands Menu" on page 40

• "Configuration Menu" on page 41

• "Service Menu" on page 42

opriate message that the shutdown is in progress.

d drive activities.

36 TP-00347-01

Operator Control Panel (OCP)

Main Menu

Main Menu

TP-00347-01 37

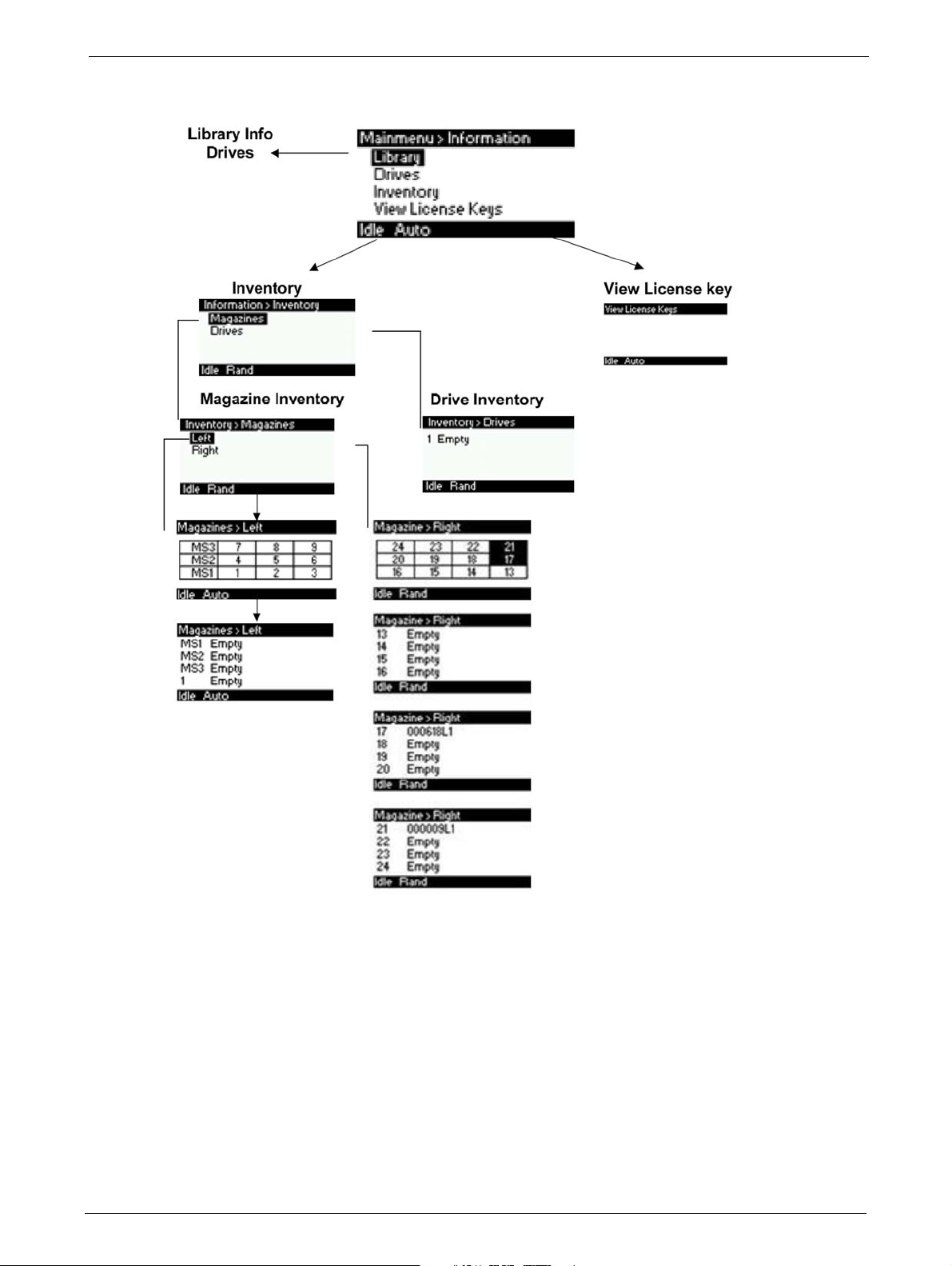

Information Menu

Chapter 4: Operation

Information Menu (1 of 2)

38 TP-00347-01

Operator Control Panel (OCP)

Information Menu (2 of 2)

TP-00347-01 39

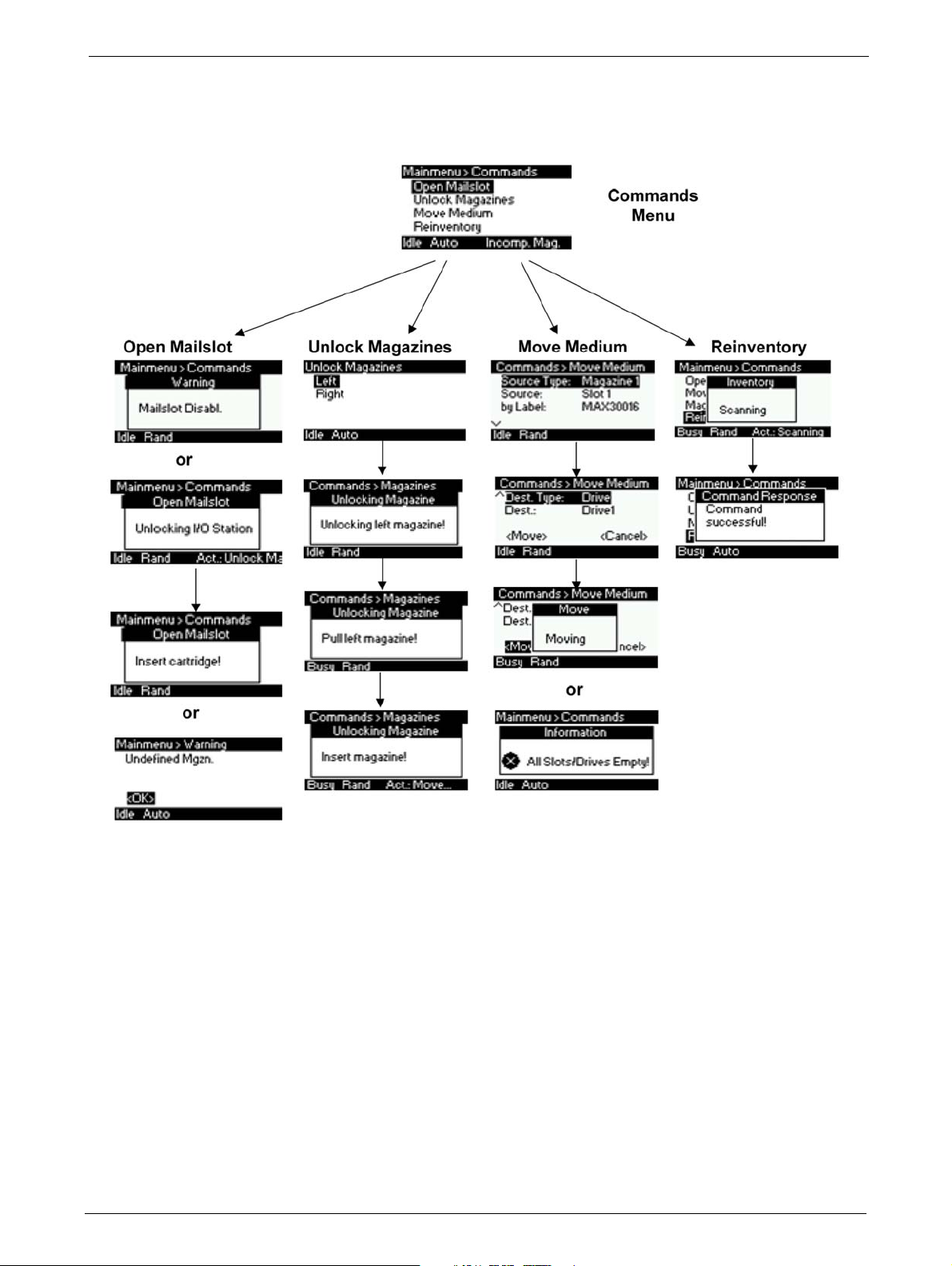

Commands Menu

Chapter 4: Operation

Commands Menu

40 TP-00347-01

Operator Control Panel (OCP)

Configuration Menu

Configuration Menu

TP-00347-01 41

Service Menu

Chapter 4: Operation

Service Menu (1 of 2)

42 TP-00347-01

Operator Control Panel (OCP)

Service Menu (2 of 2)

TP-00347-01 43

Remote Management Unit (RMU)

Overview

Many of the same operations performed locally from the operator control panel (OCP) can also be

performed remotely using the network connected Remote Management Unit (RMU).

The RMU lets you monitor and control the library from any computer connected to your network

or

through the World Wide Web (WWW). The RMU hosts a dedicated, protected Internet site that

displays a graphical representation of the library.

Chapter 4: Operation

After establishing a network connection to the libr

address of the library. To allow access from the RMU, you must first set the desired static IP address

at the OCP or configure to use DHCP.

Operation Modes

The following operations are available through the remote management unit as explained below:

1) Identity

2) Status

3) Configuration

ary, open any HTML browser and enter the IP

• Viewing the static library identity

• Viewing the static drive identity

• Viewing the network identity

• Viewing the dynamic library status

• Viewing the dynamic drive status

• Viewing the tape cartridge inventory

• Changing the system configuration

• Changing the logical library configuration

• Setting the license key

• Changing the drive configuration

• Changing the network configuration

• Changing the SNMP configuration

• Changing the user password

• Setting date/time

• Setting error log mode

• Setting event for email no

• Restoring factory defaults

4) Operations

• Move media within the library

• Rescanning the media inventory

44 TP-00347-01

tification parameters

Overview

Model NameAction Bar

Object Bar

Details

Login

• Releasing magazines for removal

5) Service

• Performing a general diagnosis of the library

• Determining and updating firmware

• Reboot of the library

• Viewing library logs

• Cleaning tape drive(s)

•Cartridge memory

Some options of the RMU take the library offline. This inactive mode can interfere with

EditShare Ark Tape, causing data loss. Make sure the library is idle before attempting to

perform any remote operations that will take the library offline.

To login, select the access type and enter the correct password. There are three levels of access:

• Guest - (standard user level - default password

std001).

• Admin - (administrator user level - default password

adm001).

• Service - (service user level; for access by service

personnel only - default password ser001).

Each level affects the areas to which you have access and

what actions you can initiate in those areas.

RMU Screen Layout

Once logged in, the general layout of all RMU screens is similar:

Menu items in the Action bar and Object bar are selectable, and the currently selected item is

displayed in bold italics. The items listed in the Action bar are fixed, but the items in the Object bar

vary according to the action selected (see "Operating Modes" on page 33). Similarly, the contents

of the detailed information area shown below the two bars depend on the selected action and

object.

TP-00347-01 45

Chapter 4: Operation

At the right side of every screen, a summary of the

system status is displayed and continually updated:

The status icons that may be displayed are as

follows:

The information displayed is as follows:

Date/Time

Status: Overall library status

Drive Status: Individual drive status (there will be one entry for each installed drive).

Slots (Free/Total): Total library slot capacity

Mailslot: Open/Closed

Library Time: Time stamp displayed in 24 hour format

Auto Clean Status: If Auto Clean Option is configured, its status displays here

Identity

Viewing Static Library Identity

This page provides access to the static information about the system. No changes can be made

from this page.

46 TP-00347-01

Overview

The following information displays:

1) Library Information

• Serial Number

•Product ID

• Currently installed library firmware

• Boot code firmware revision

•Barcode Reader

• Library Mode

• World Wide Node Name

2) Extended logical library information: If the unit has more than one partition, the properties

of each logical library display as above.

Viewing Static Drive Identity

This page provides access to the static information about the drive(s). No changes can be made

from this page.

If two tape drives are installed in the library, the information will be shown by selecting the

appropriate drive from the pull down menu.

The following information is displayed:

1) Drive information:

• Vendor ID = Drive manufacturer

• Product ID = Model identification of the drive

• Serial Number = Serial number of the drive

• Firmware Revision = Operating firmware level of the drive

• Physical Drive Number = Number indicating drive's physical position within the library

• Element Address = Number indicating the logical identification of the drive

• Library Master Drive = Indicates if library's logical interface is hosted by this drive

• Data Compression = Indicates if drive hardware data compression is enabled

• Interface Type (SAS or FC) = Indicates drive's physical interface connection type

2) Additional drive information (up to 4 x half-height tape drives for the Q48)

TP-00347-01 47

Chapter 4: Operation

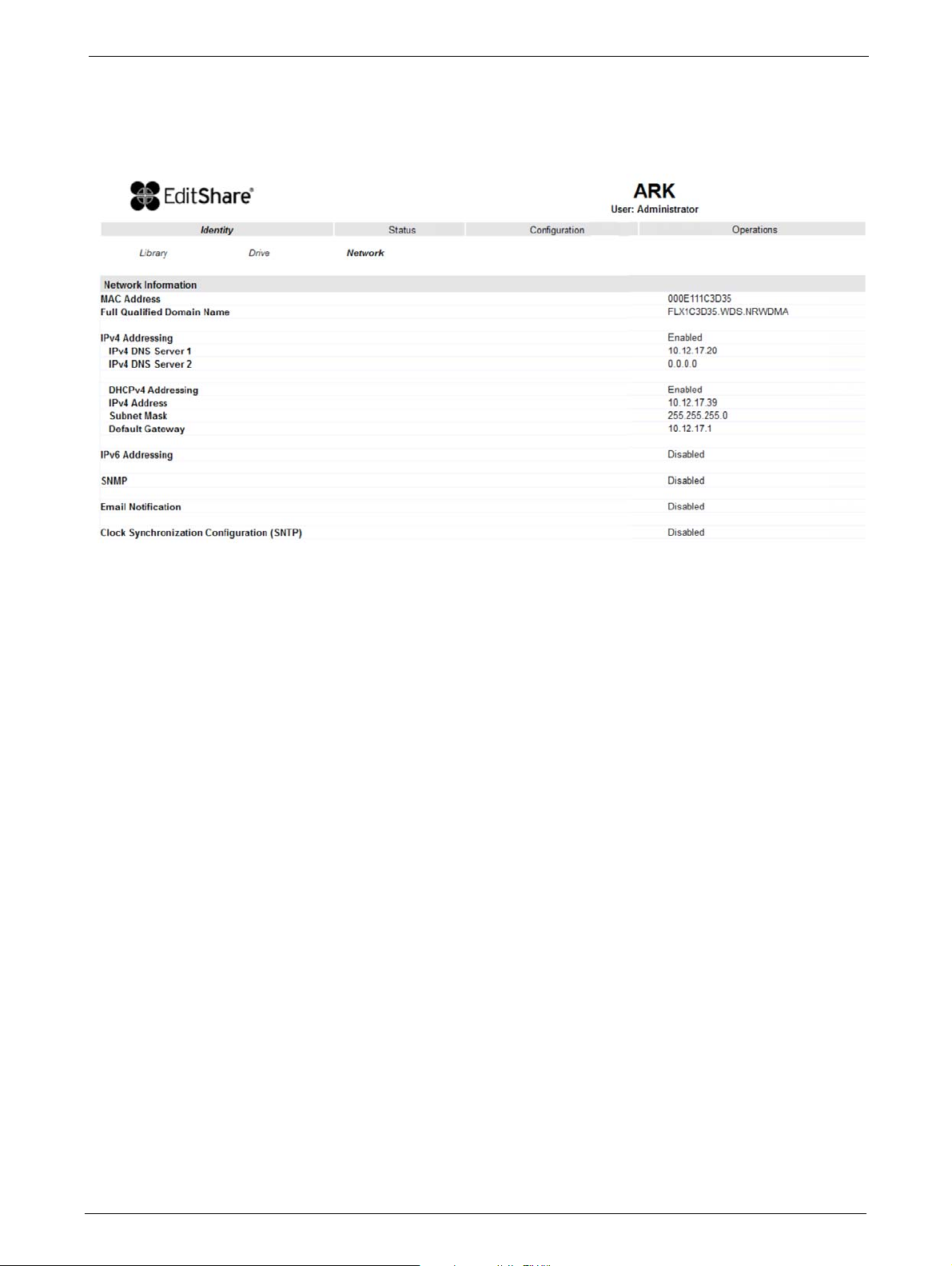

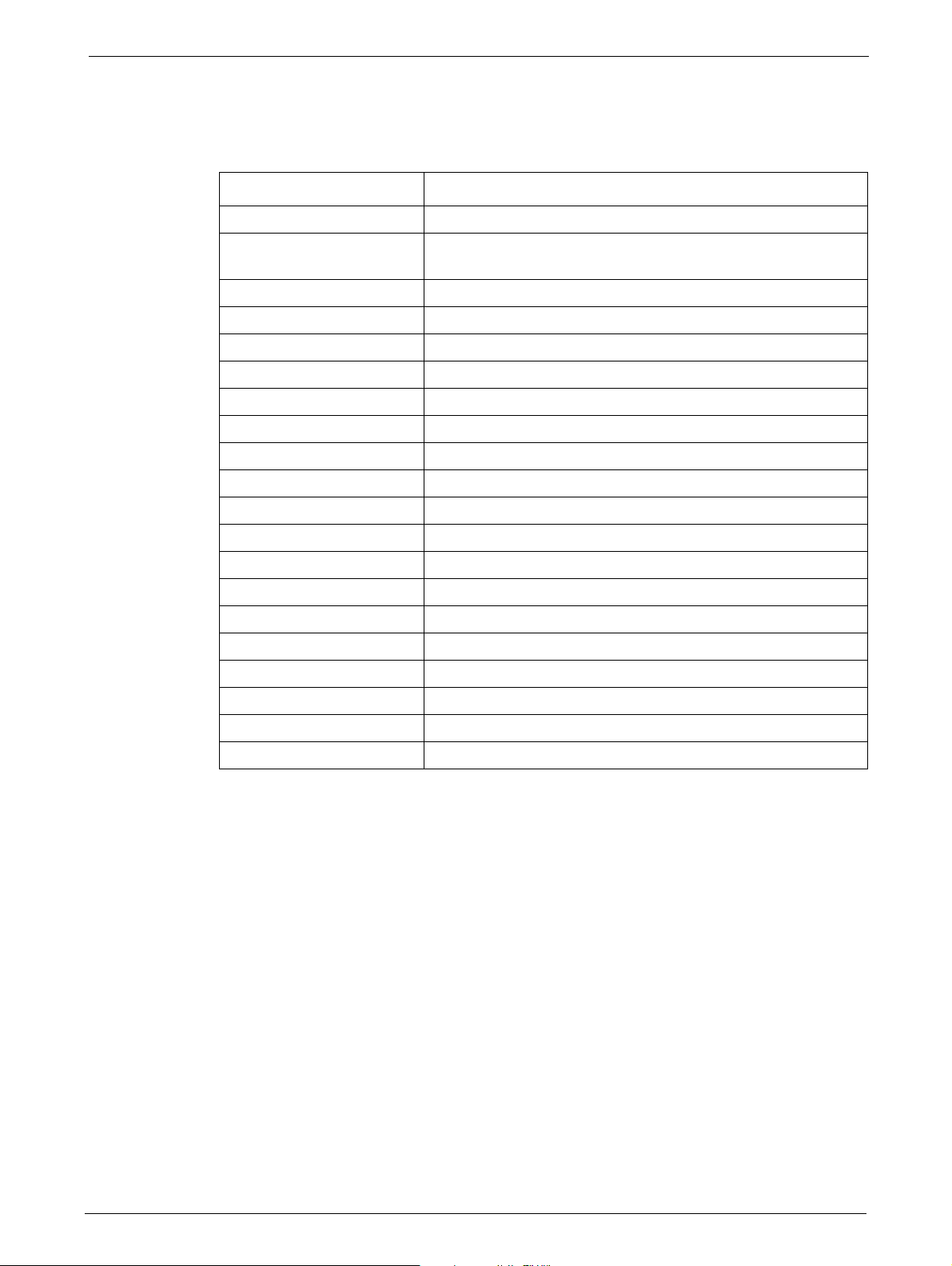

Viewing Network Identity

This page provides access to the network information about the connections of the library. No

changes can be made from this

page.

The following information is displayed:

1)

Network information:

• MAC Address

• Full Qualified Domain Name

• IPv4 Addressing = Enabled/Disabled

• IPv4 DNS Server 1 = IP address of domain name server 1

• Pv4 DNS Server 2 = IP address of domain name server 2

• DHCPv4 Addressing = En

• IPv4 Address = IP address assigned by DHCP

•

Subnet Mask

•Default Gateway = IP address of def

• Ipv6 Addressing = Enabled/Disabled

2) SNMP Information:

•SNMP = Enabled/Disabled

• Email Notification = Enabled/Disabled

• Clock Synchronization Configurat

ab

led/Disabled

on (SNTP) = Enabled/Disabled

i

ault gateway

48 TP-00347-01

Overview

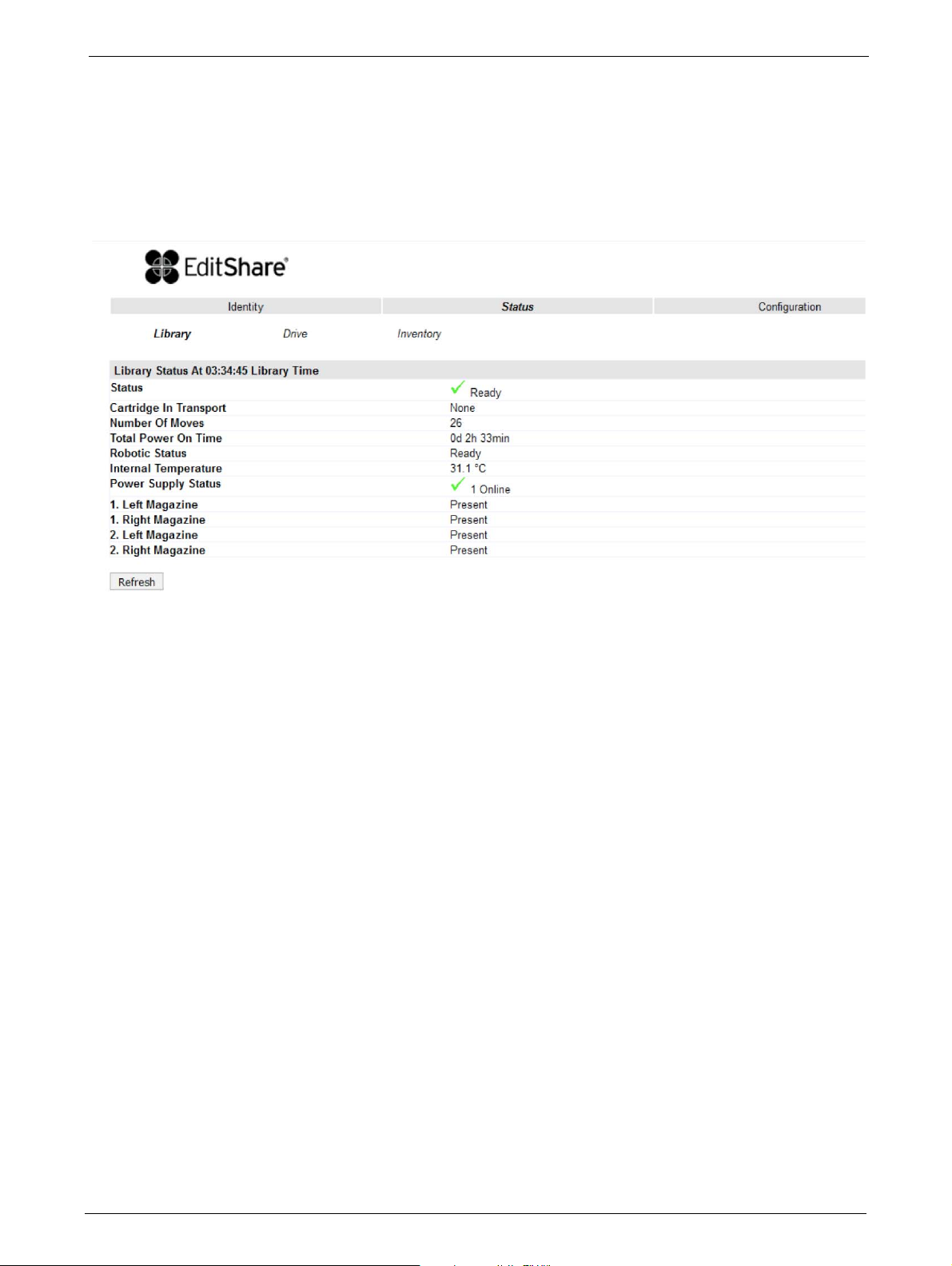

Status

Viewing Dynamic Library Status

This page displays the dynamic information about the library, such as the current status of the

components.

The following information is displayed:

Status Indicates whether library is ready to accept commands

Cartridge in Transport Indicates whether the media changer contains a cartridge

Number Of Moves

(O

ometer)

d

Total Power On Time Indicates total library power-on time

Robotic Status Indicates whether the media changer is ready to accept commands

Internal Temperature Indicates internal unit temperature in degrees centigrade

Left/Right Magazine Indicates presence or absenc

Indicates total number of moves made by the media changer

e of tape magazines

TP-00347-01 49

Viewing Dynamic Drive Status

This page provides detailed information about all drives that are present in the library.

Chapter 4: Operation

If multiple tape drives are installed in the library, the info

the pull down menu.

rmation can be shown by selecting it from

The following information is displayed:

1) Drive Status

Status Indicates whether drive is ready for use

Cartridge in Drive Indicates whether the drive contains a tape cartridge

Drive Error Code

Drive Temperature

Cooling Fan Active

Drive Activity

Drive Port Information relevant to the specific drive interface (FC or SAS)

2) Additional drive information (up to 4

f-height tape drives for a 48Q)

hal

50 TP-00347-01

Overview

STEPS

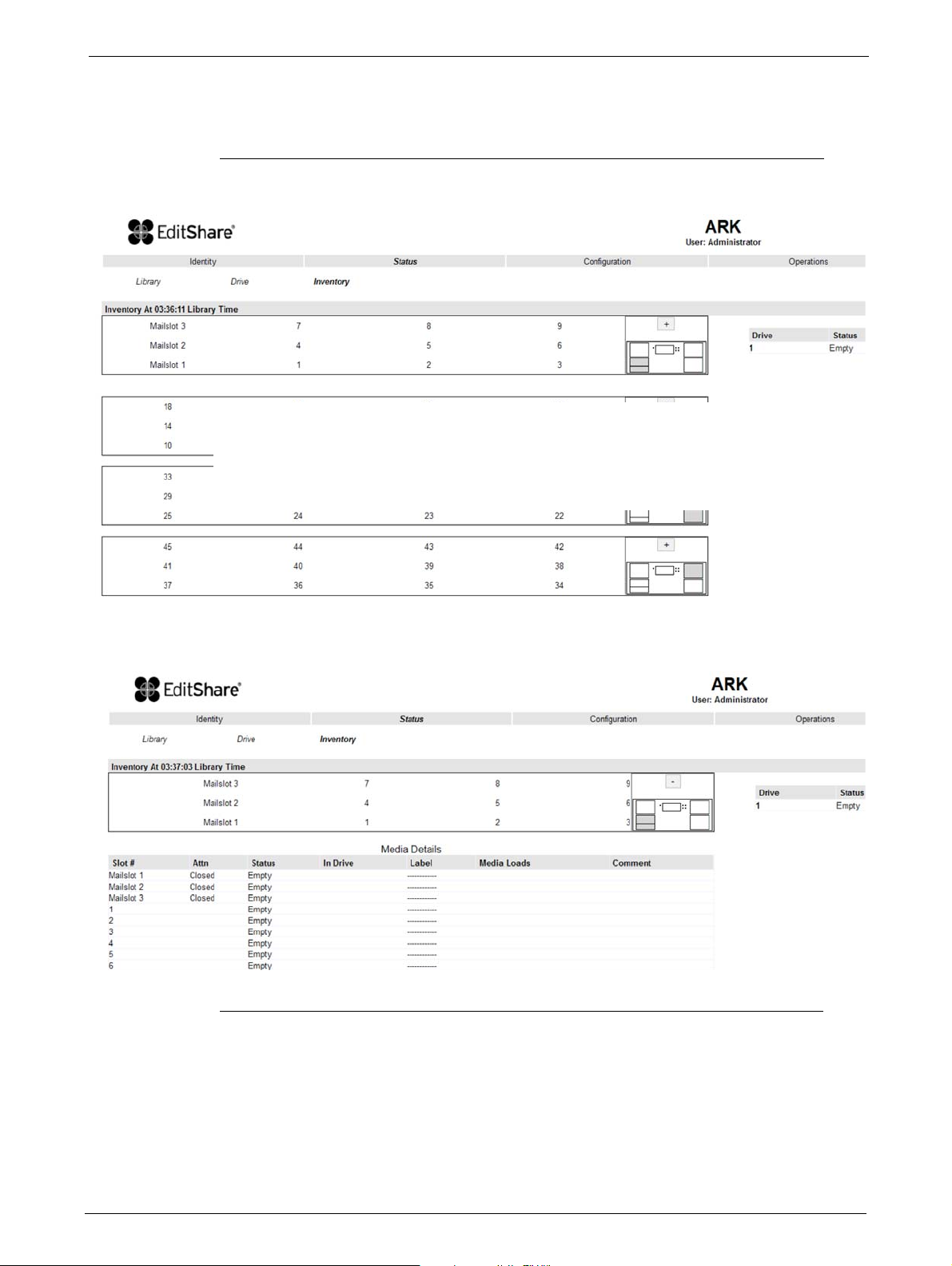

Viewing Tape Cartridge Inventory

This page provides detailed information about the tape inventory in the library.

1. A summary of each magazine displays.

2. To show detailed informat

3. The display expands for the specified

4. Detailed cartridge information displays below the summary panel.

ion, click on the + button.

magazine.

TP-00347-01 51

Configuration

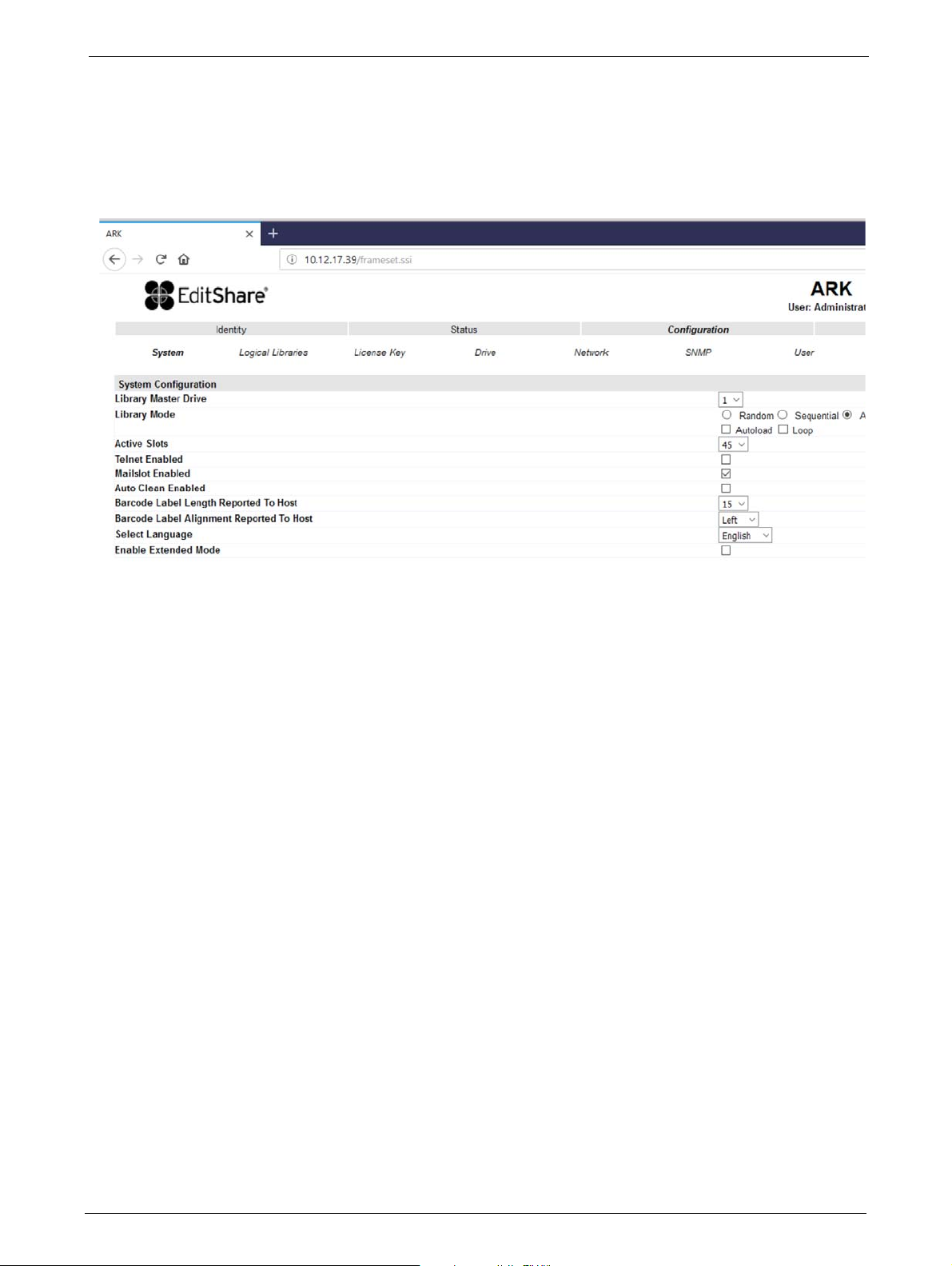

Changing the System Configuration

Chapter 4: Operation

This page allows the user to change the system configuration.

The following information displays:

1) Library Master Drive: - The drive number that will host the library's logical unit number (LUN)

2) Library Mode: - One of three

• <Random> In random mode, the library does not automatically load tapes into the tape

dr

ives. The random mode is used with a full featured or a media changer-aware backup

application and is the most common mode of operation.

• <Sequential > In sequential mode, th

from the tape drive. The sequential mode is used when the backup software is not

media changer-aware or was designed for standalone drives only.

• <Automatic> This is the defa

sequential mode into random mode when it receives library SCSI commands through

its unique LUN.

In sequential mode, the user can set the <Loo

load mode, the library automatically loads the tapes from the lowest-numbered full slot

into the tape drive. In loop mode, the original first tape in the sequence is reloaded after

the library has cycled through all available tapes.

3) Active Slots: - In this field the user can select the number of slots in the library that are available to the backup software.

4) Mailslot Enabled: - Enabling the mailslot in the library reduces the total number of available

storage slots to the library's max