Page 1

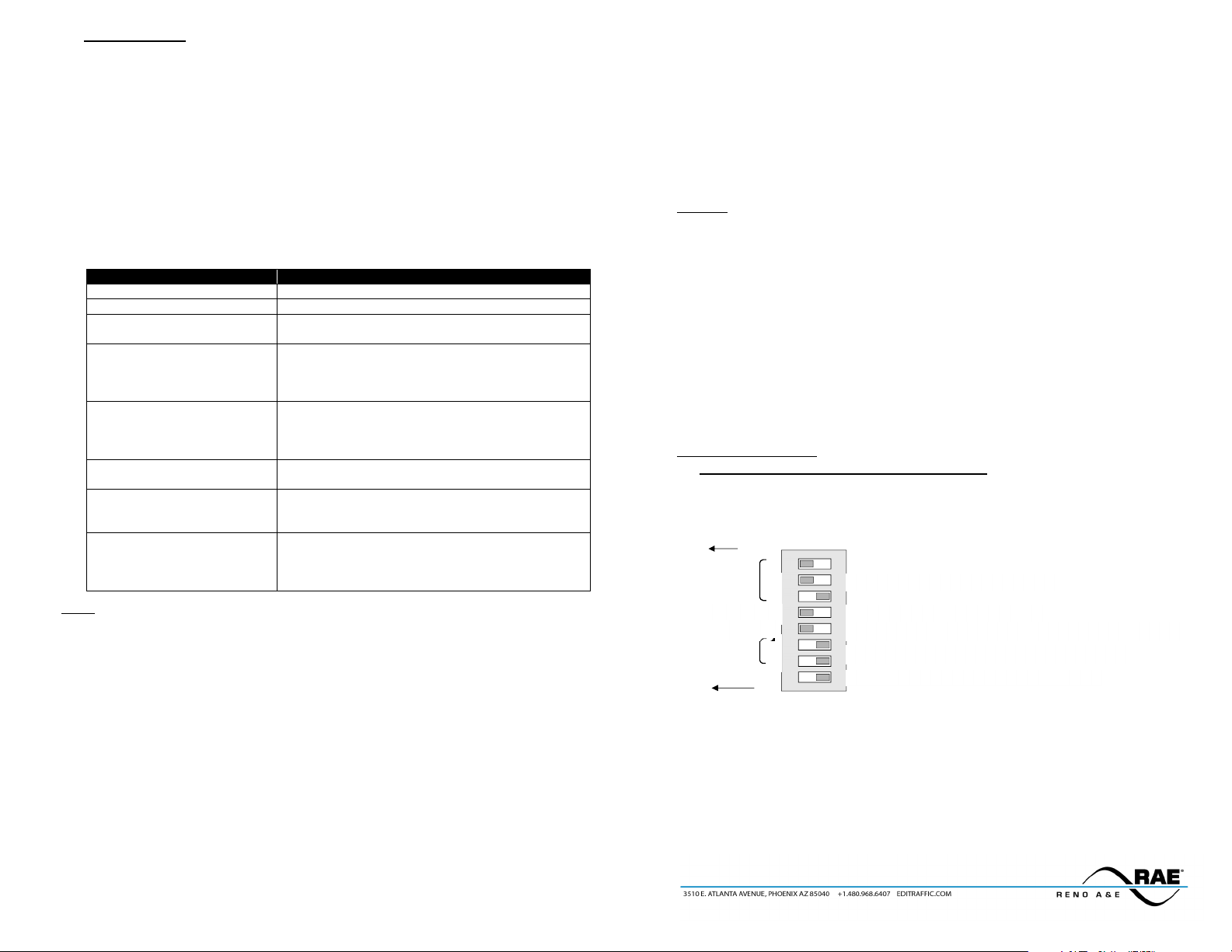

iv. Detect / Fail LEDs:

)

8

7

6

5

4

3

2

The Model G-200 detector has a single two color (green / red) light emitting diode (LED) per

channel to indicate a Call output and/or the status of any current or prior loop failure conditions. A

green indication signifies a Call output (detect state). A red indication signifies a loop failure

condition. A continuous ON (green) state indicates a Call output. A continuous ON (red) state

indicates that a current open loop failure condition or an inductance change condition of greater than

+25% exists. When operating in Fail-Safe mode, this indication also generates a Call output. When

operating in Fail-Secure mode, no Call output is generated. A one Hz (red) flash rate indicates that a

current shorted loop failure condition or an inductance change condition of greater than -25% exists.

When operating in Fail-Safe mode, this indication also generates a Call output. When operating in

Fail-Secure mode, no Call output is generated. A flash rate of three 50 millisecond (red) flashes per

second indicates a prior loop failure condition. A flash rate of three 50 millisecond (red) flashes per

second followed by a single 750 millisecond (green) flash indicates a prior loop failure condition and

a current Call output (detect state).

If either channel has the audible detect feature activated, that channel’s Detect / Fail LED will be

illuminated in an orange state for any Call output condition.

Detect / Fail LED Meaning

OFF

Solid ON (Green)

Solid ON (Orange)

Solid ON (Red)

One Hz flash rate (Red)

(50% Duty Cycle)

Three 50 ms (Red) flashes per

second

Three 50 ms (Red) flashes per

second followed by a single 750

ms (Green) flash

Three 50 ms (Red) flashes per

second followed by a single 750

ms (Orange) flash

III. Reset:

Changing the position of any of an individual channel’s front panel mounted DIP switches (except the

Frequency switches) resets the channel. When the detector is installed and operating, the most

convenient method for resetting a channel is to momentarily change the position of the Presence / Pulse

DIP switch and then return it to its original position. The detector can be reset by reapplying power after

a power loss. Both detector channels will also be reset when Pin C is momentarily connected to DC

Common.

Loop Failure condition occurred but no longer exists

Loop Failure condition occurred but no longer exists

Loop Failure condition occurred but no longer exists

No Detect (No Call Output)

Detect (Call Output)

Audible Detect Signal Activated

Detect (Call Output)

Open Loop Failure

or

Inductance change condition of

greater than +25% exists

Shorted Loop Failure

or

Inductance change condition of

greater than -25% exists

and

Detect (Call Output)

Audible Detect Signal Activated

and

Detect (Call Output)

Operating Instructions

Model G-200 Series

Fir mware Vers ion GT 2.1

TWO C H A N NEL, TS 2-1 9 9 8 TYPE A

DIP SW I T CH PROGRAMM A BLE

LOOP D E T ECTORS

I. General:

The Model G-200 is a scanning, two channel, card rack mounted loop detector. Once the detector

is plugged into an appropriately wired card rack with 10.8 to 30 VDC present, the detector will

begin to operate. The detector automatically tunes itself and is operational within two seconds

after application of power or after being reset. Full sensitivity and hold time require approximately

30 seconds of operation. The detector is fully self-compensating for environmental changes and

loop drift over the full temperature range and the entire loop inductance range. The Model G-200

is available with solid state or relay outputs.

The operation of each channel is independent and is programmed using two front panel mounted

eight-position DIP switch modules. Each channel has a single, dual color (green / red) Detect /

Fail LED indicator. The LED provides an indication of the channel’s output state and loop failure

conditions. Output state conditions are indicated when the Detect / Fail LED is illuminated in a

green state. Loop Failure conditions are indicated when the Detect / Fail LED is illuminated in a

red state. The Model G-200 also has a Test Mode that verifies proper operation of the LED

indicators, DIP switches, and loop oscillator circuitry.

II. Controls and Indicators:

i. Front Panel Mounted Programming DIP Switches:

The two, eight-position DIP switch modules located on the front panel that are labeled 1 and 2

affect each channel independently. To turn one of these DIP switches ON, push the switch to

the left.

SW ON

SENSE

LEVEL

PRES PULS

FAIL SAFE

FREQ

DISABLE

(

4

2

8 Sensitivity Levels: 0 to 7

1

Presence or Pulse Mode

1

2

Front Panel Eight-position DIP Switch

(Factory Default Settings Shown)

Selects Call or No Call state during a loop failure condition

4 Frequency Selections: 0 to 3

Disable or Enable Channel

P/N 889-0700-02 Rev: June 2020 4 Model G-200 Operating Instructions

Page 2

Channel Disable (DISABLE) (DIP Switch 1):

HI

6 *

When the DISABLE DIP switch is turned ON, the channel’s output is continuously in the No Call

state regardless of the presence or absence of vehicles over the loop. The loop oscillator is not

activated when the channel is in the disabled state. The factory default setting of this switch is OFF.

NOTE: Changing the Channel Disable switch setting will reset the detector channel.

Frequency (FREQ) (DIP Switches 2 and 3):

Each channel of the Model G-200 detector has four (4) frequency selections that allow altering the

resonant frequency of the loop circuit. DIP switches 2 and 3 are used to select the frequency for a

given channel. The value (1 or 2) to the left of the DIP switch is assigned to the switch when the

switch is ON. If the switch is OFF, the switch has a value of zero (0). By adding the switch ON

and OFF values, the two switches will combine for values from 0 to 3 that indicate one of the four

frequency selections. The following table is a reference for the switch settings and associated

frequency selections.

NOTE: After changing any Frequency switch setting(s), it is necessary to reset the detector channel

by momentarily changing one of the other switch positions.

Frequency Switch 3 Switch 2 Effective Value

* OFF * OFF * 0 + 0 = 0 *

MED HI

MED LO

LO

* Factory default setting.

Fail Safe / Fail Secure Mode (FAIL SAFE) (DIP Switch 4):

DIP switch 4 is used to select the Call state of each channel’s output when a loop failure condition

exists on the loop network to the channel.

When DIP switch 4 is turned ON, the channel’s output maintains a Call state during a loop failure

condition. This is the factory default setting and the most common setting for intersection control.

When DIP switch 4 is turned OFF, the channel’s output maintains a No Call state during a loop

failure condition. This setting is typically used in incident detection systems for freeway

management.

NOTE: Changing the Fail-Safe / Fail-Secure switch setting will reset the detector channel.

Presence / Pulse Mode (PRES PULS) (DIP Switch 5):

DIP switch 5 controls the output mode of each channel.

PRESENCE (PRES): When the switch is in the ON position, Presence Mode is selected.

Presence Mode will hold the smallest vehicle for four minutes minimum and either a small truck

or a car typically for one to three hours. This is the factory default setting and the most common

setting.

PULSE (PULS): When the switch is in the OFF position, Pulse Mode is selected. Pulse Mode

will generate a single 125 millisecond pulse output for each vehicle entering the loop detection

area. Any vehicle remaining in the loop longer than two seconds will be tuned out providing full

sensitivity for the vacant portion of the loop detection zone. Full sensitivity for the entire loop

detection zone is recovered within one second following the departure of any vehicle, which has

occupied the loop for longer than two seconds.

NOTE: Changing the Presence / Pulse switch setting will reset the detector channel.

ON OFF 1 + 0 = 1

OFF ON 0 + 2 = 2

ON ON 1 + 2 = 3

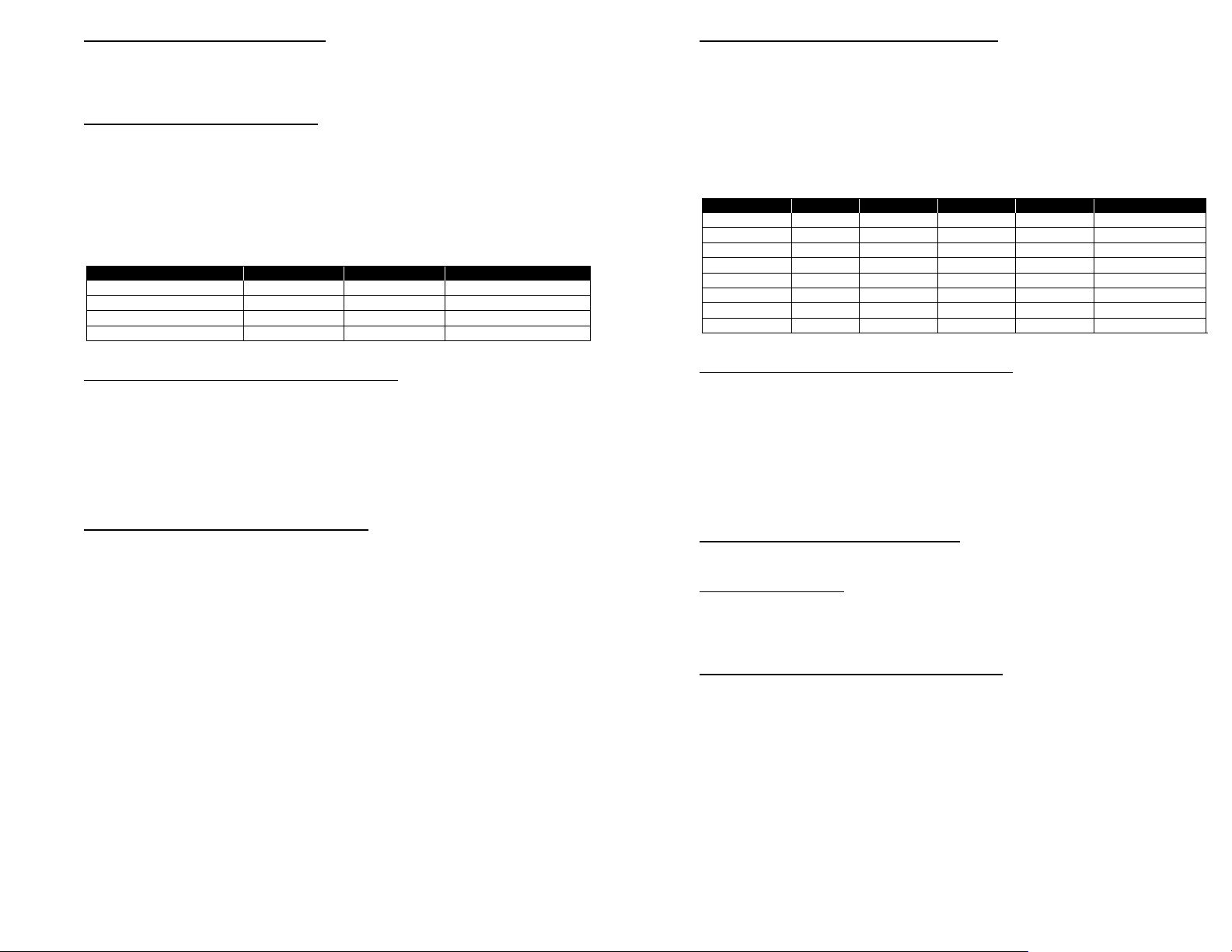

Sensitivity (SENSE LEVEL) (DIP Switches 6, 7, and 8):

There are eight (8) selectable sensitivity levels for each channel. The eight sensitivity levels are

selected via DIP switches 6, 7, and 8 on each of the two front panel mounted eight-position DIP

switch modules. The value (1, 2, or 4) to the left of the DIP switch is assigned to the switch when

the switch is ON. If the switch is OFF, the switch has a value of zero (0). By adding the switch ON

and OFF values, the three switches will combine for values from 0 to 7 that indicate one of the eight

sensitivity level selections. Choose the lowest sensitivity level that will consistently detect the

smallest vehicle that must be detected. Do not use a sensitivity level higher than necessary. The

factory default setting is Sensitivity Level 6: -∆L/L = 0.02% for detection. The following table is a

reference for the switch settings and associated sensitivity selections.

NOTE: Changing the Sensitivity Level setting will reset the detector channel.

Sense Level -ΔL/L Switch 6 Switch 7 Switch 8 Effective Value

0

1

2

3

4

5

6 *

7

* Factory default setting.

ii. Front Panel Mounted Pushbutton - Audible Detect Buzzer:

A front panel mounted pushbutton labeled BUZZER is used to enable an audible detect signal that is

emitted any time a given channel’s detection zone is occupied. To activate this feature, press the

pushbutton. Only one channel can have this feature active at any given time. The first time the

pushbutton is pressed, a short (50 millisecond) audible signal confirms the activation of the feature

for Channel 1. The second time the pushbutton is pressed, two short (50 millisecond) audible signals

confirm the activation of the feature for Channel 2. To deactivate this feature, press and hold the

pushbutton for one second. A long (250 millisecond) audible signal confirms the deactivation of the

feature. This feature will automatically turn off 15 minutes after activation.

NOTE: When operating in Pulse mode, the audible detect signal will cease if a vehicle occupies the

detection zone for more than two seconds.

iii. PC Board Mounted Programming DIP Switches:

The two-position DIP switch module labeled S3 located on the printed circuit board affects both

channels. To turn one of these DIP switches ON, push the switch up.

Test Mode (DIP Switch 1):

When DIP switch 1 is turned ON, Test Mode is activated. For more information on Test Mode, refer

to the Model G-200 Operation Manual. The factory default setting of this switch is OFF (Test

Mode Off).

NOTE: The Test Mode DIP switch must be OFF for normal detector operation.

100 Millisecond Minimum Output Mode (DIP Switch 2):

Two modes of operation are available for the Call outputs of the detector when operating in Presence

Mode. Normal Mode or 100 Millisecond Minimum Output Mode is selected by means of DIP

switch 2. When this switch is in the OFF position, the Call outputs stay on only as long as the

detection zone is occupied. When this switch is in the ON position, every Call output will have a

minimum duration of 100 milliseconds. This feature forces all detection events less than 100

milliseconds long to be 100 milliseconds long. The factory default setting of this feature is OFF

(100 Millisecond Minimum Output Off).

1.28% OFF OFF OFF 0 + 0 + 0 = 0

0.64% ON OFF OFF 1 + 0 + 0 = 1

0.32% OFF ON OFF 0 + 2 + 0 = 2

0.16% ON ON OFF 1 + 2 + 0 = 3

0.08% OFF OFF ON 0 + 0 + 4 = 4

0.04% ON OFF ON 1 + 0 + 4 = 5

0.02% * OFF * ON * ON * 0 + 2 + 4 =

0.01% ON ON ON 1 + 2 + 4 = 7

2

3

Loading...

Loading...