Page 1

Copyright © 2018 by Eding CNC

Hardware Manual

CNC310

Revision 1 30 July, 2018

Released

Page 2

Hardware Manual – CNC310

Page | 2

History:

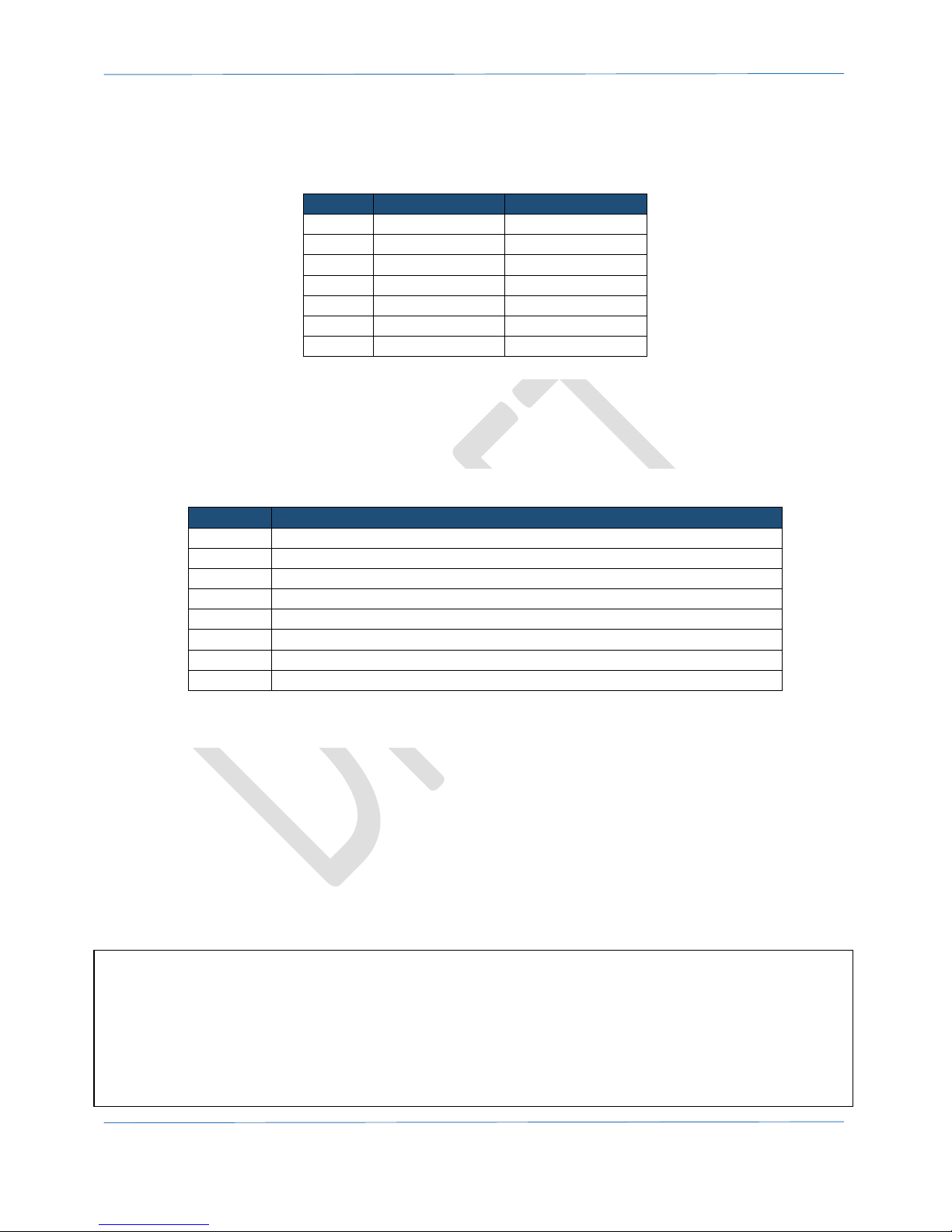

Revision overview:

Revision

Date

Author

1

29-3-2018

AB

Revision

Remarks

1

Initial version

The information contained herein is believed to be reliable. Eding CNC makes no warranties regarding the information contain herein.

Eding CNC assumes no responsibility or liability whatsoever for any of the information contained herein. Eding CNC assumes no

responsibility or liability whatsoever for the use of the information contained herein. The information contained herein is provided "AS IS,

WHERE IS" and with all faults, and the entire risk associated with such information is entirely with the user. All information contained

herein is subject to change without notice. Customers should obtain and verify the latest relevant information before placing orders for

Eding CNC products. The information contained herein or any use of such information does not grant, explicitly or implicitly, to any party

any patent rights, licenses, or any other intellectual property rights, whether with regard to such information itself or anything described

by such information. Eding CNC products are not warranted or authorized for use as critical components in medical, life-saving, or lifesustaining applications, or other applications where a failure would reasonably be expected to cause severe personal injury or death.

Page 3

Hardware Manual – CNC310

Page | 3

Table of contents

1 Introduction .................................................................................................................................... 4

1.1 Purpose ................................................................................................................................... 4

2 Board overview ............................................................................................................................... 5

3 Board jumpers and indicators ......................................................................................................... 6

3.1 Jumper USBPWR ..................................................................................................................... 6

3.2 Jumper PRG ............................................................................................................................. 6

3.3 Jumper RDY/PLS ...................................................................................................................... 7

3.4 Jumper JP1 .............................................................................................................................. 8

3.5 Power LED ............................................................................................................................... 9

3.6 Status LED 1-4 ......................................................................................................................... 9

3.7 Network LEDs (optional) ....................................................................................................... 10

3.8 SYSRDY led ............................................................................................................................ 11

4 I/O pinning .................................................................................................................................... 12

4.1 Pinning functions overview ................................................................................................... 12

5 OUTPUTS ....................................................................................................................................... 14

5.1 TOOL output .......................................................................................................................... 14

5.2 COOLANT output ................................................................................................................... 16

5.3 STEP/DIRx output .................................................................................................................. 16

5.4 AMP-ENABLE output ............................................................................................................. 16

5.5 WATCHDOG/SYSRDY output ................................................................................................. 17

6 Inputs ............................................................................................................................................ 18

6.1 PROBE input .......................................................................................................................... 18

6.2 E-STOP input ......................................................................................................................... 19

6.3 HOME1 input ......................................................................................................................... 20

6.4 HOME4 input ......................................................................................................................... 21

7 MPG/Pendant ............................................................................................................................... 23

8 Getting started .............................................................................................................................. 24

9 Example of connecting CNC310 to Leadshine DM422C. .............................................................. 26

10 Mechanical dimensions ................................................................................................................ 27

Page 4

Hardware Manual – CNC310

Page | 4

1 Introduction

1.1 Purpose

This manual describes the hardware of the CNC310.

The CNC310 is a basic 3-axis CNC controller the specification is:

The starter software has basic operations and is able to operate 2.5D.

SW upgradable features:

- 4th Axis + home input

- Ethernet interface

- Full software support (full 3D)

3x Axis controller interface

(optional 4th axis)

Puls/Direction

5V (f

step,max

= 125Khz)

Enable

5V

1x digital HOME inputs

(optional 2nd input)

Max. 5V

1x cooling output

5V

1x toolsetter/tool length input

Max. 5V

Interface

USB

(optional Ethernet)

Power Supply

Via USB or externally 5VDC

Dimension

54.5x67.5mm

Others

- Firmware upgradable through USB connection

- Connector pitch 2.54mm/0.1”

Page 5

Hardware Manual – CNC310

Page | 5

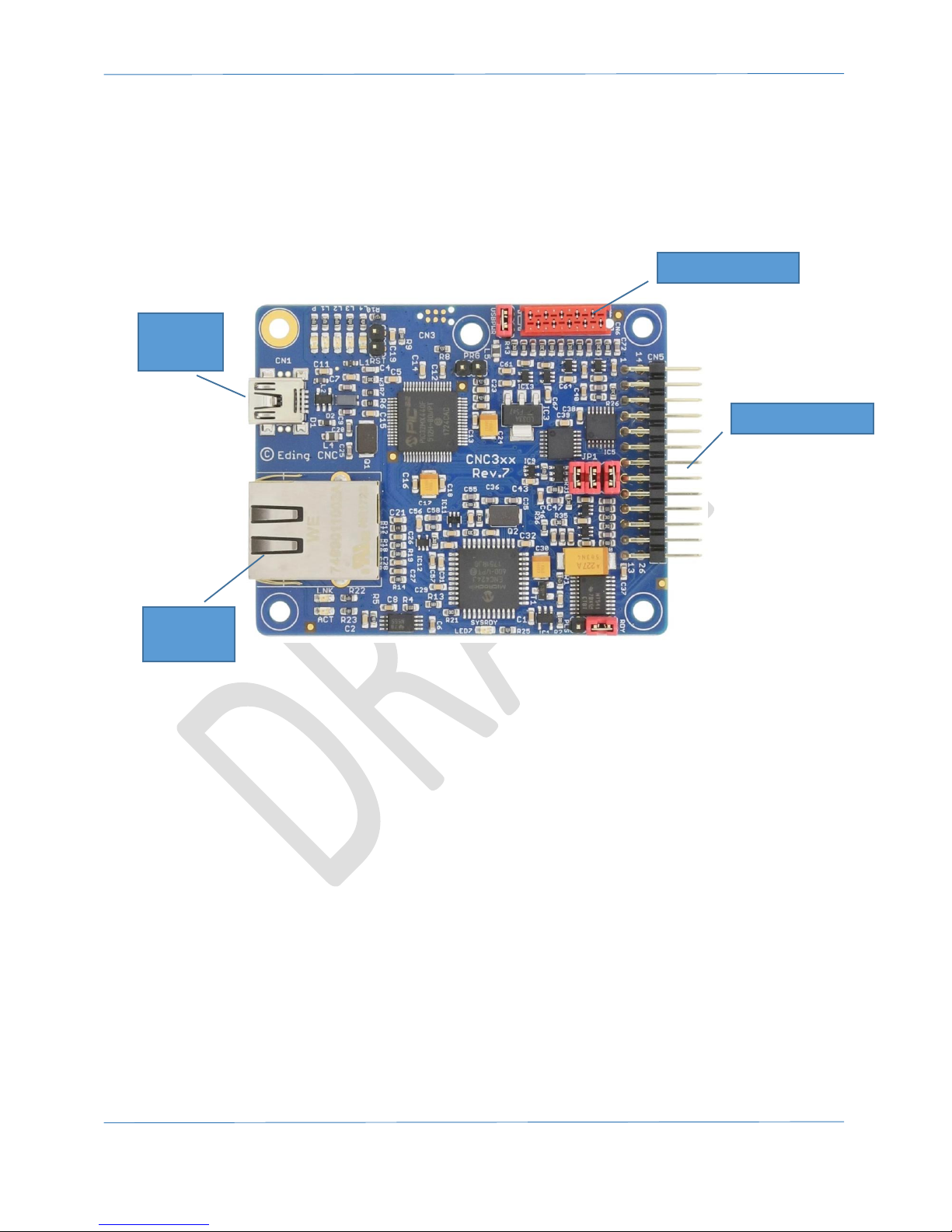

2 Board overview

The CNC310 is a CNC controller with USB interface, and is intended for 3 axes. However, the user can

upgrade the board through separate licenses with a 4th axis and activate the ethernet interface.

The image below shows an overview of the CNC310.

The purpose of the board is to offer a simple controller that can be used for operating small CNC

machines that need only limited I/O.

This document focusses on the hardware interface of this board, and how to use it to get a simple

CNC set up, up and running. This manual will only focus on the hardware part. For more information

about the software please check the software manual that can be downloaded from the website.

I/O Connector

USB

Interface

Ethernet

Interface

Wired Pendant

Page 6

Hardware Manual – CNC310

Page | 6

3 Board jumpers and indicators

This chapter describes the jumpers and indicators that are present on the controller board.

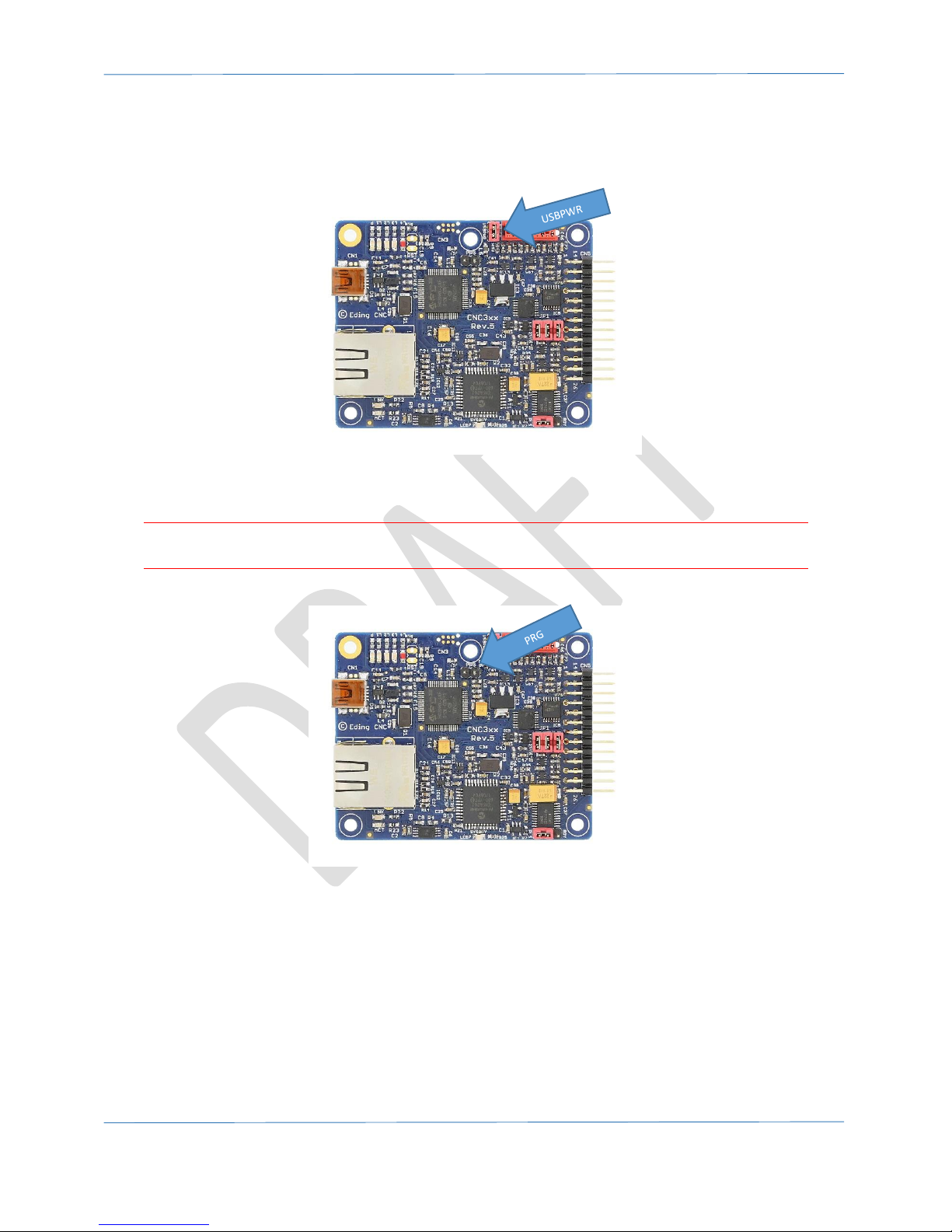

3.1 Jumper USBPWR

This jumper is used to power the board via the USB interface. The board can also be powered

through an external pin.

WARNING: If the board is powered externally make sure that the USBPWR jumper is removed

because else the USB interface will get externally powered which can damage the USB port.

3.2 Jumper PRG

If this jumper is place the board will skip the bootloader mode and will go directly to starting the

firmware.

Page 7

Hardware Manual – CNC310

Page | 7

3.3 Jumper RDY/PLS

This jumper is used to set the output signal that is present on the I/O pin ‘WATCHDOG/SYSRDY‘.

For more info see chapter 5.5 WATCHDOG/SYSRDY output

Page 8

Hardware Manual – CNC310

Page | 8

WATCHDOG/SYSRDY output.

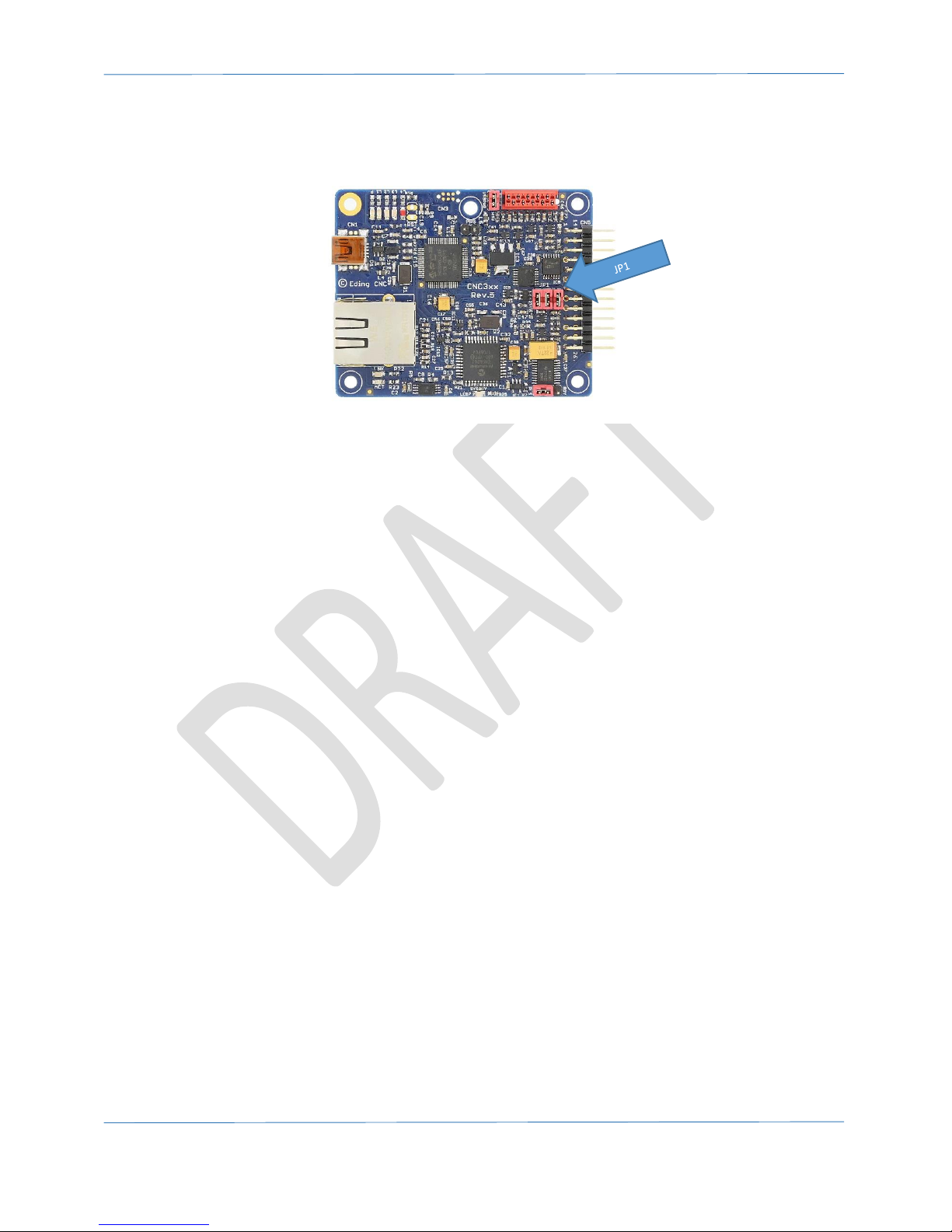

3.4 Jumper JP1

This jumper can be used to deactivate the signals on some I/O pins. Currently make sure that all

jumpers are mounted.

Page 9

Hardware Manual – CNC310

Page | 9

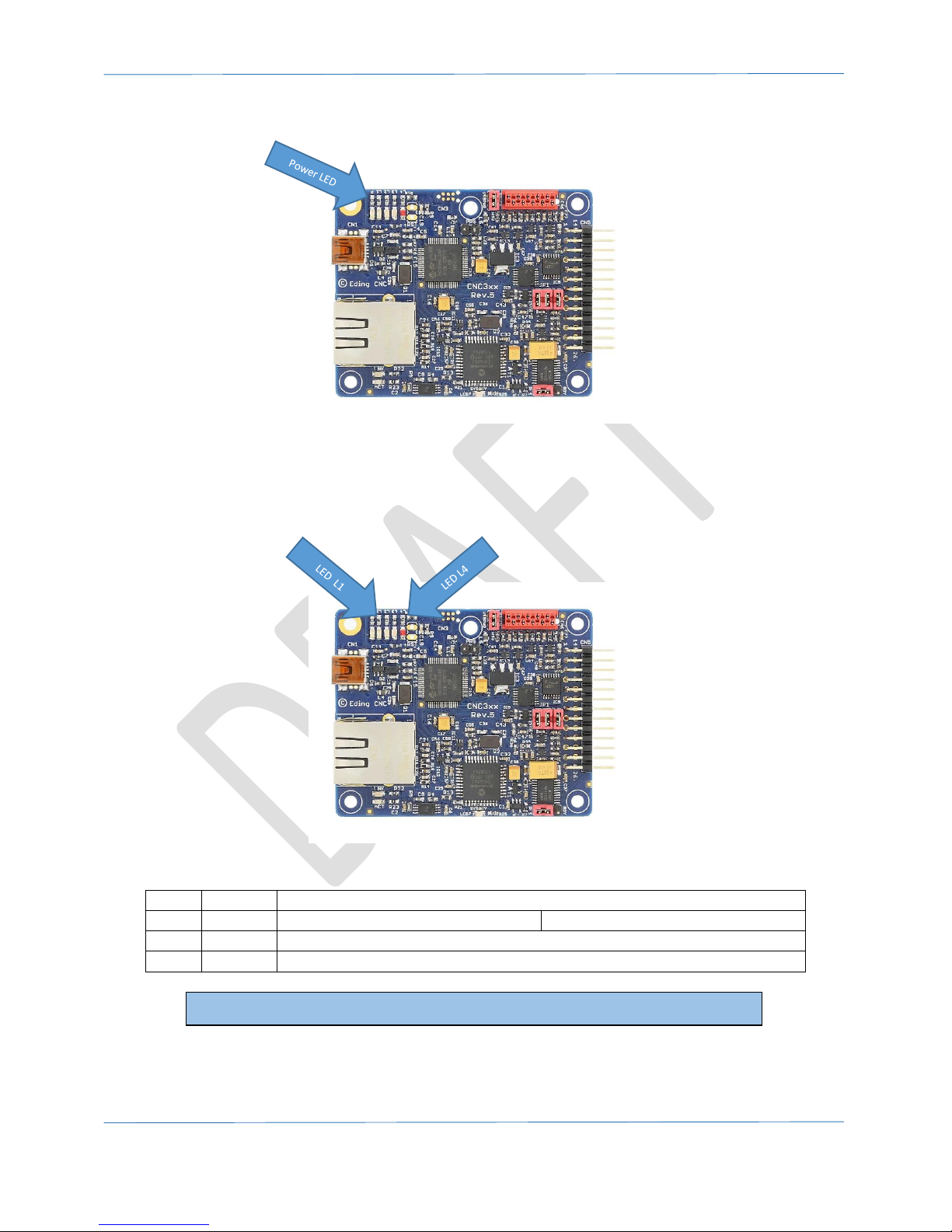

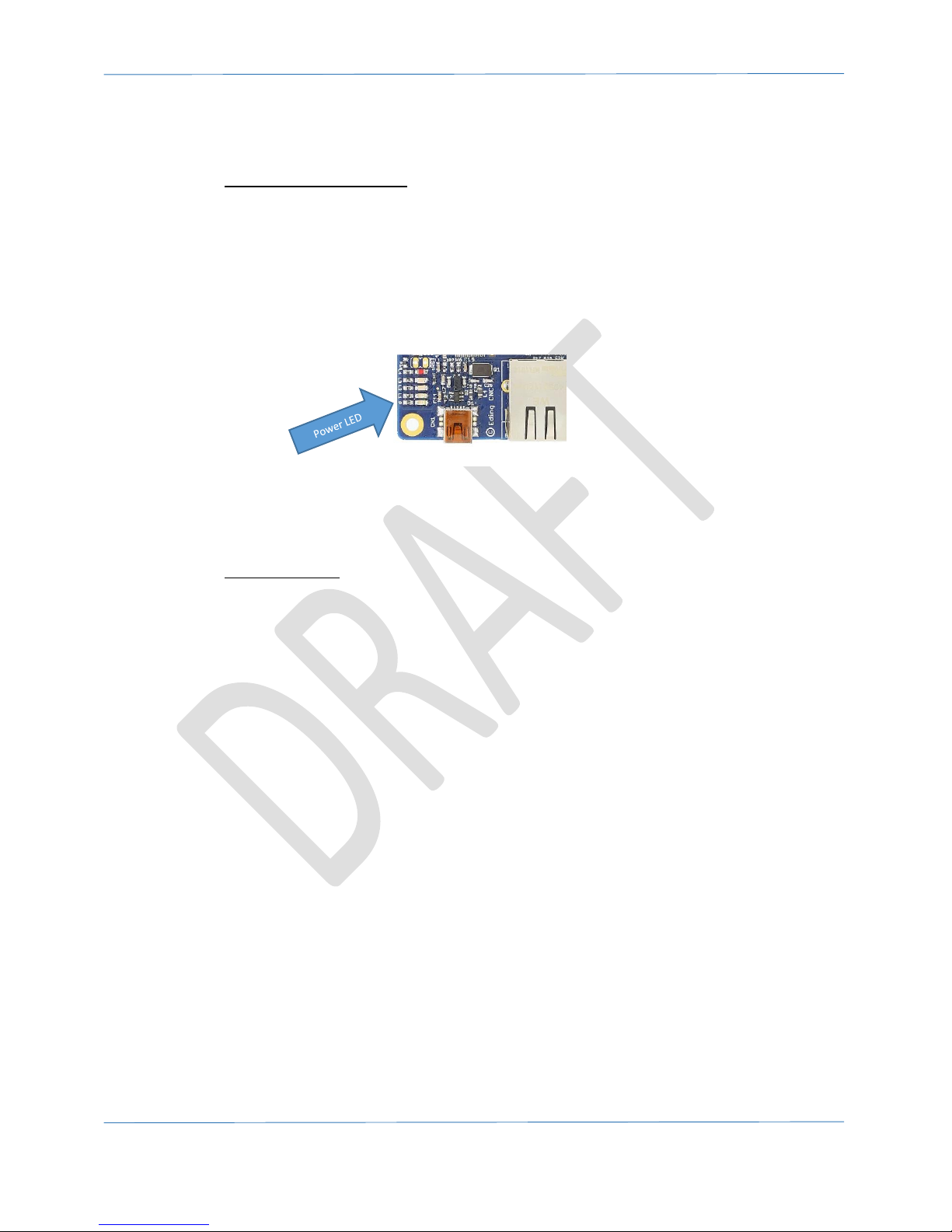

3.5 Power LED

This blue power led indicates when power is applied to the board.

3.6 Status LED 1-4

The status LEDs indicate the current mode of the controller. The status LEDs are indicated by L1

through L4.

L1

ORANGE

BLINKING = Board is starting

L2

GREEN

ON = System is active

OFF = System if inactive

L3

GREEN

BLINKING = Board is active

L4

RED

BLINKING = Watchdog is active

Please note,

when in bootloader mode L2 and L3 will toggle to indicate this.

Page 10

Hardware Manual – CNC310

Page | 10

3.7 Network LEDs (optional)

The network LEDs will only be active if the license has been activated for the network and new

firmware has been downloaded.

The LINK LED indicates if a network cable is connected. The ACTIVITY LED will blink if there is

network communication.

Page 11

Hardware Manual – CNC310

Page | 11

3.8 SYSRDY led

The LED indicates that status of the SYSRDY output. If it is ON, it indicates that the signal on the

WATCHDOG/SYSRDY output also is active.

Page 12

Hardware Manual – CNC310

Page | 12

4 I/O pinning

4.1 Pinning functions overview

The board can be connected through a 26-pole header. The pitch of the connector is 2.54mm or

0.1”. The images below show the pin numbering and the functions on each pin.

Figure 1. Pin numbering on connector.

Figure 2. Functions on connector overview.

Page 13

Hardware Manual – CNC310

Page | 13

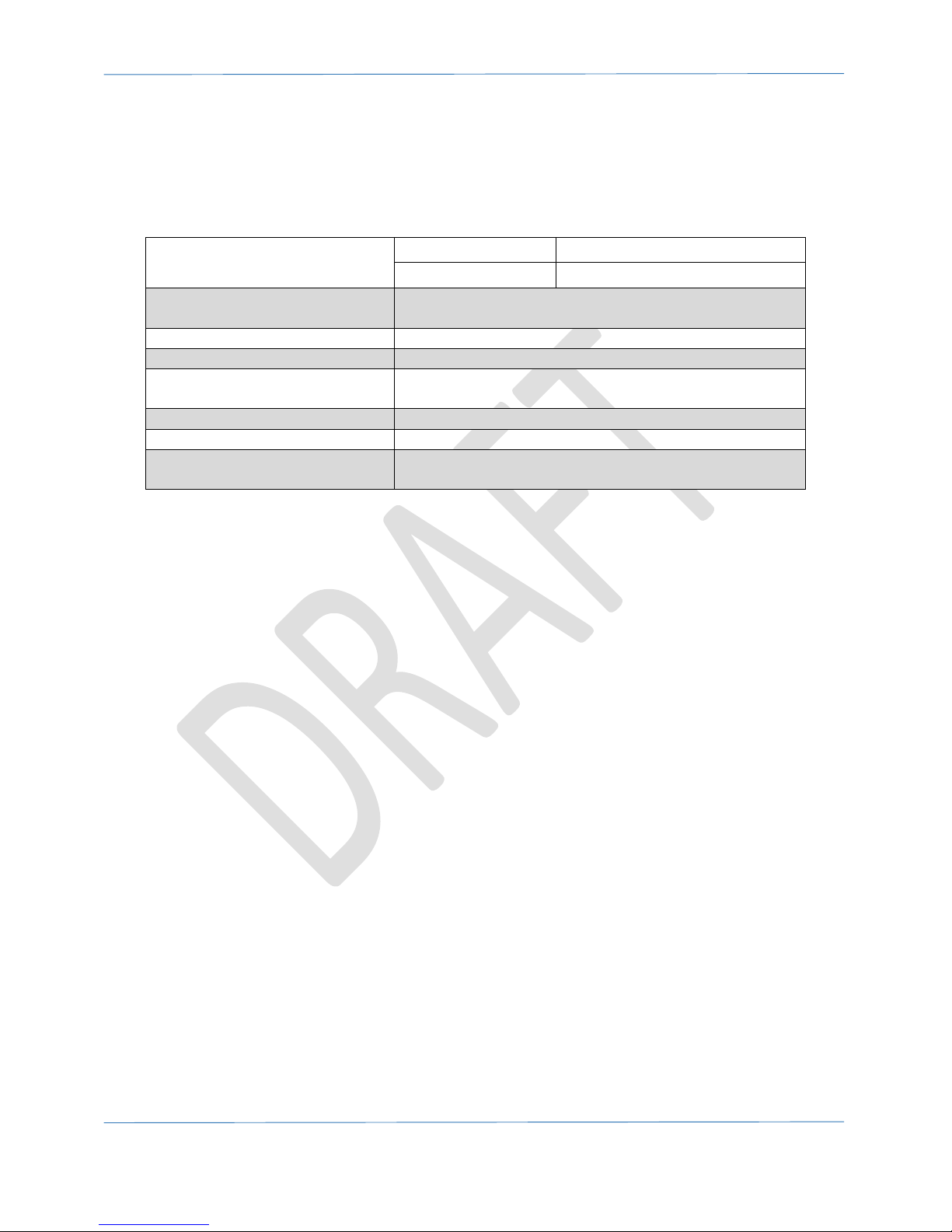

In “Figure 3. Overview of functions.” all signals that are present are discussed in more detail.

Make sure that the maximum in or output limitations are not exceeded.

Figure 3. Overview of functions.

Pin

#

Name

Direction

Type

Function

Electrical Spec.

Remarks

1

TOOL

OUT

DIGITAL

Switching of tool

TTL 5V/20mA

2

DIR1

OUT

DIGITAL

Direction signal X axis

TTL 5V/20mA

3

STEP1

OUT

DIGITAL

Step signal X axis

TTL 5V/20mA

Max. 125kHz

4

DIR2

OUT

DIGITAL

Direction signal Y axis

TTL 5V/20mA

5

STEP2

OUT

DIGITAL

Step signal Y axis

TTL 5V/20mA

Max. 125kHz

6

DIR3

OUT

DIGITAL

Direction signal Z axis

TTL 5V/20mA

7 STEP3

OUT

DIGITAL

Step signal Z axis

TTL 5V/20mA

Max. 125kHz

8

DIR4*1

OUT

DIGITAL

Optional: Direction signal A axis

TTL 5V/20mA

9 STEP4*1

OUT

DIGITAL

Optional: Step signal A axis

TTL 5V/20mA

Max. 125kHz

10

PROBE

IN

DIGITAL

Probe input

Max. 5V

11

E-STOP

IN

DIGITAL

Emergency stop signal input

Max. 5V

12

HOME1

IN

DIGITAL

Input for homing switches

Max. 5V

13

HOME4*1

IN

DIGITAL

Optional: input home switch A axis

Max. 5V

14

reserved

Do not connect

15

reserved

Do not connect

16

COOLANT

OUT

DIGITAL

Controlling the coolant.

TTL 5V/20mA

17

reserved

Do not connect

18

GND

GROUND

19

reserved

Do not connect

20

reserved

Do not connect

21

reserved

Do not connect

22

WATCHDOG/SYSRDY

OUT

DIGITAL

Indication if system is active

TTL 5V/20mA

23

AMP-ENABLE

OUT

DIGITAL

Enabling motor drivers

TTL 5V/150mA

24

GND

GROUND

25

GND

GROUND

26

+5V*2

IN/OUT

POWER

Power supply, can be in and output.

Max. 5V

Page 14

Hardware Manual – CNC310

Page | 14

5 OUTPUTS

5.1 TOOL output

The TOOL output is used for switching ON and OFF the tool of your machine. The TOOL output is not

cable of switching large loads. Therefor it will need a relay to switch large loads.

Standard relays cause a lot of EMI noise. EMI noise can disturb the USB communication.

We therefor recommend using a solid-state relay.

Figure 4. Example of solid-state relay.

A solid-state relay can be often connected directly to the TOOL output. Please check the current that

the solid-state relay input needs do not exceed the maximum current that the port can supply.

The biggest difference between a ‘normal’ relay and a solid-state relay is that the lather does not

have moving parts and in and output are also separated through a optocoupler. It should cause

much less EMI problems.

Connecting a solid-state relay is shown in the image below:

Figure 5. Connecting a solid-state relay.

TOOL output

Page 15

Hardware Manual – CNC310

Page | 15

If you want to use a ‘normal’ relay it’s important to check the current that a relay needs to switch.

This can be improved by adding a transistor to the output of the board as shown in the image below.

Figure 6. How to switch a power relay.

This image shows how you can control a 5V or 24V (or almost any) relay with the output of the

CNC310. It might be easier to find a board that has all logic already included on one board, and

which can readily be found in the internet. Some will even include optocouplers.

Figure 7. Example of finished relay interface.

We recommended to use standard relays only for low power.

However, our advices remains to use solid state relay.

Please note to always use an anti-parallel diode of 100-200v / 1-2 Amp. Without this

diode the controller may be damaged.

Page 16

Hardware Manual – CNC310

Page | 16

5.2 COOLANT output

The coolant output can be used to control any form of coolant that might be used during the

operation of the machine. Its output is electrically identical to the TOOL output. For information

about how to use this please refer to that part of the document.

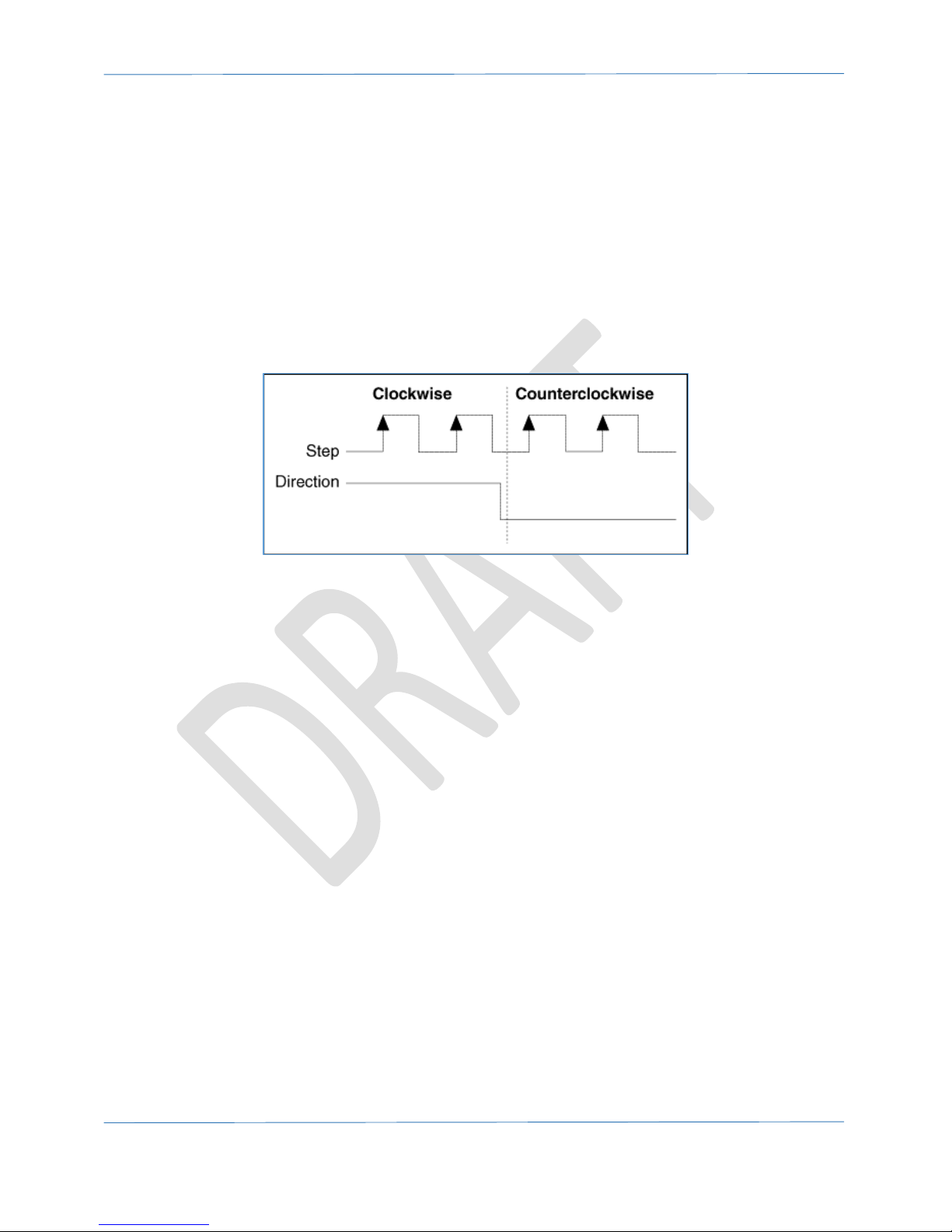

5.3 STEP/DIRx output

The controller board features 3, optional 4, outputs for controlling the driver of a stepper motor. The

signals generated are the common signals STEP and DIRECTION, as used by many drivers.

The DIRECTION signal indicates to the driver whether it has the move clockwise (CW) of counterclockwise (CCW). The STEP signal indicates when a step is to be made. Figure 8 illustrates this.

Figure 8. Example of STEP/DIRECTION signal.

Whether the DIRECTION signal means CW or CCW depends on the stepper driver and how you wire

it or configure it. Also, whether the low/high or high/low signal indicates a step depends on the way

it is connected and used by the driver.

Please refer to you motor driver’s manual to find more information about how to connect the

controller to it.

5.4 AMP-ENABLE output

The AMP-ENABLE output is used for enabling the motor drivers. This output can supply more output

current than the other digital outputs.

See also chapter 9 Example of connecting CNC310 to Leadshine DM422C.

Page 17

Hardware Manual – CNC310

Page | 17

5.5 WATCHDOG/SYSRDY output

The WATCHDOG/SYSRDY can be used to indicate when the system is active. This can be either with a

HIGH (active) / LOW (not active) signal or by outputting a square wave of 12 kHz. Often that signal is

used as a kind of watchdog signal by for example stepper drivers.

Figure 9. Output is HIGH if SYSREADY is active

Figure 10. Output is square wave if SYSREADY is active.

This HIGH/LOW signal is selected by setting the jumper on the ‘RDY’ position, the square wave is

selected by selecting the ‘PLS’ position.

Page 18

Hardware Manual – CNC310

Page | 18

6 Inputs

This chapter describes how to use the inputs of the controller board. Make sure that the input

signals do not exceed the maximum values of the input.

6.1 PROBE input

The PROBE input has multiple functions, it can be used for:

- Determining the height of the material

- Determining the length of a tool

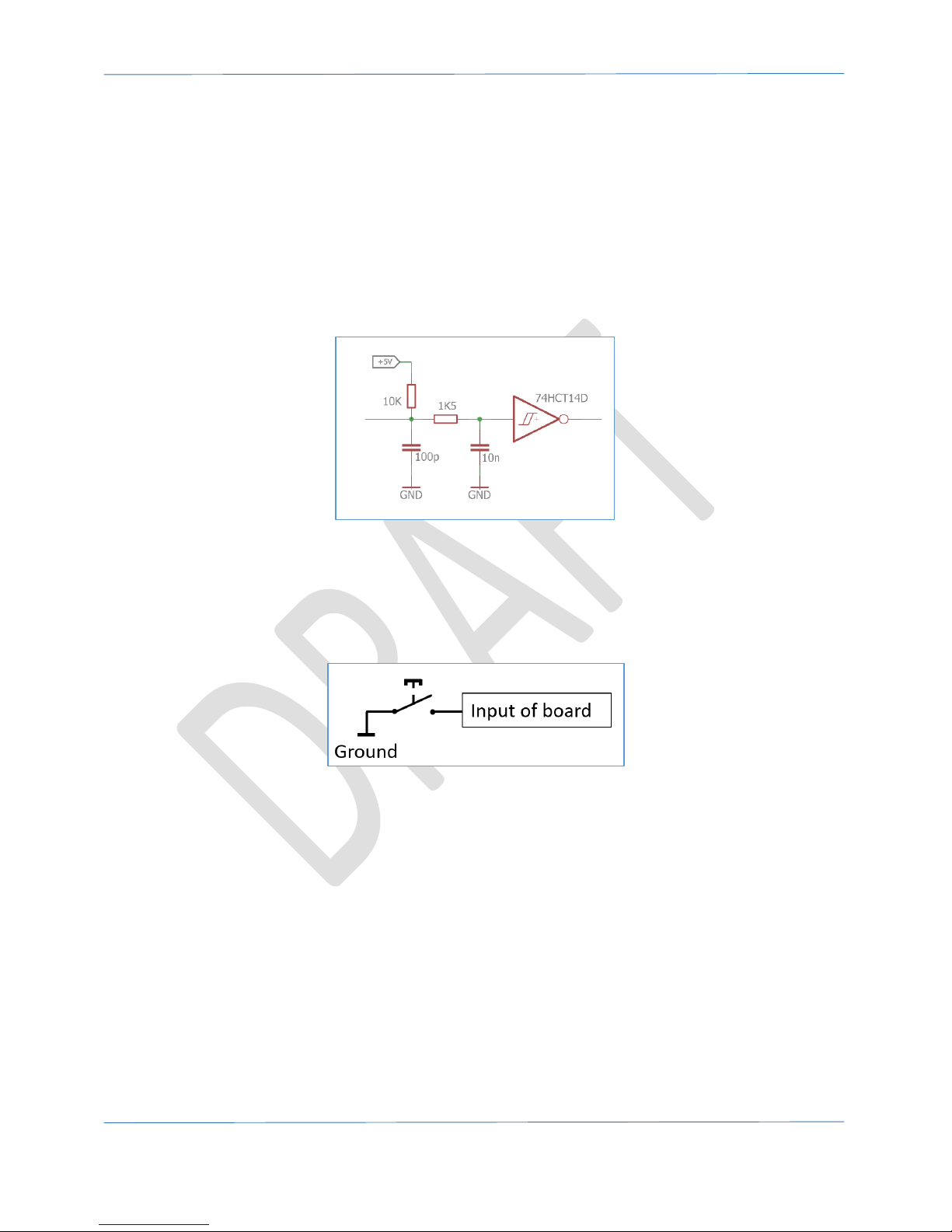

The figure below, it shows how the input circuit is designed.

Figure 11. Probe input circuit.

This image shows that on the input a 10k resistor is used as a pull-up. This means that IF you would

measure on this input you will measure 5V. Please note, that this is not the ‘real’ 5V but just a pullupped value. The image also shows, in order to activate this input you need to connect it to ground.

In the image below this is illustrated.

Figure 12. Connecting switch to probe input.

Page 19

Hardware Manual – CNC310

Page | 19

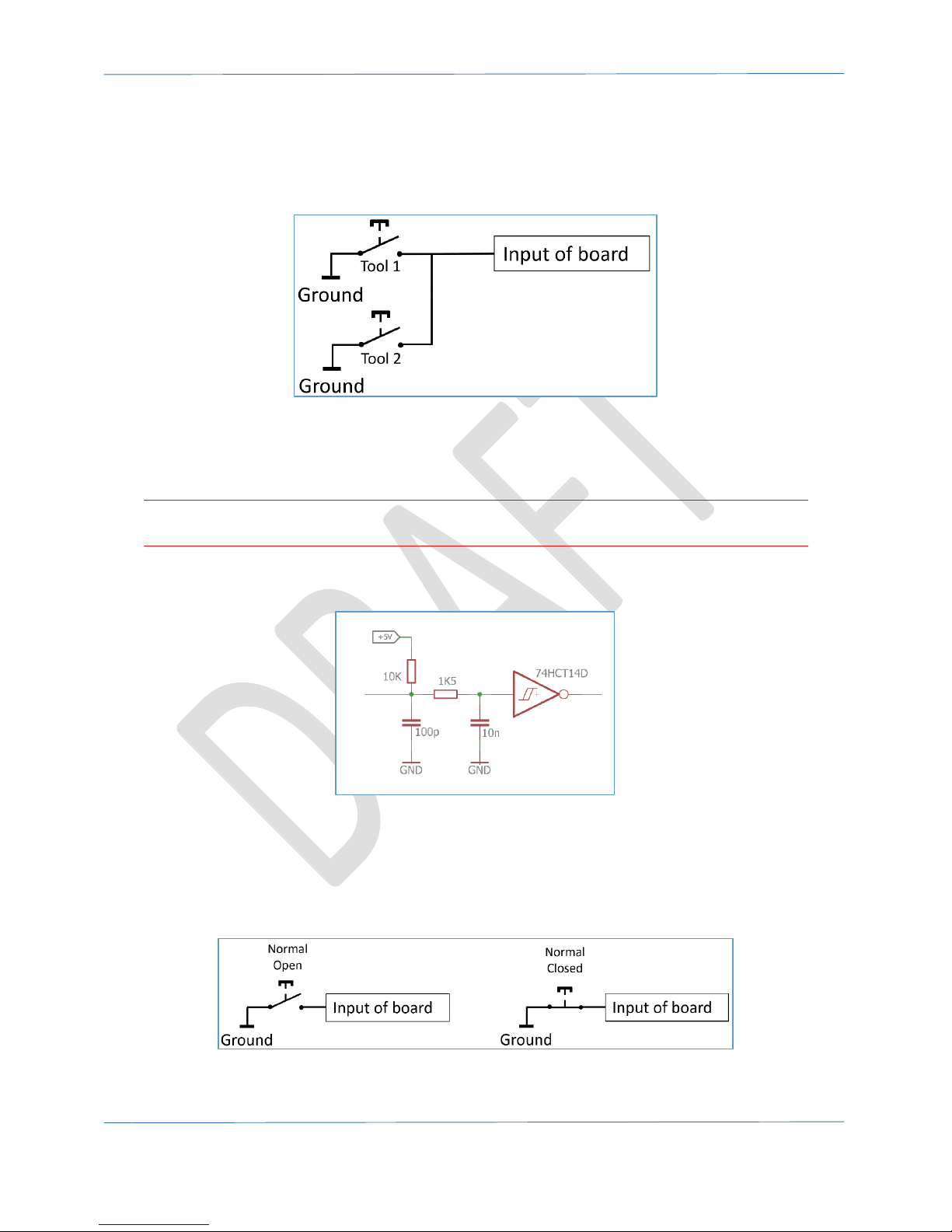

If you need to connect multiple devices to this input, you can simply connect them in parallel, as

shown in the image below. The system will know when to consider this an actual probe or when it is

a toolsetter.

Figure 13. Connecting multiple tools to probe input.

6.2 E-STOP input

The E-STOP input signals that the systems needs to stop immediately.

Warning: The E-STOP does not replace a proper external E-STOP switch, the user is responsible for

having an external hardware E-STOP switch to switch off the machine in case of emergency.

The figure below shows how the input circuit is designed.

Figure 14.E-STOP input circuit.

This image shows that on the input a 10k resistor is used as a pull-up. This means that IF you would

measure on this input you will measure 5V. Please note, that this is not the ‘real’ 5V but just a pull-

upped value. The image also shows that in order to activate this input you need to connect it to

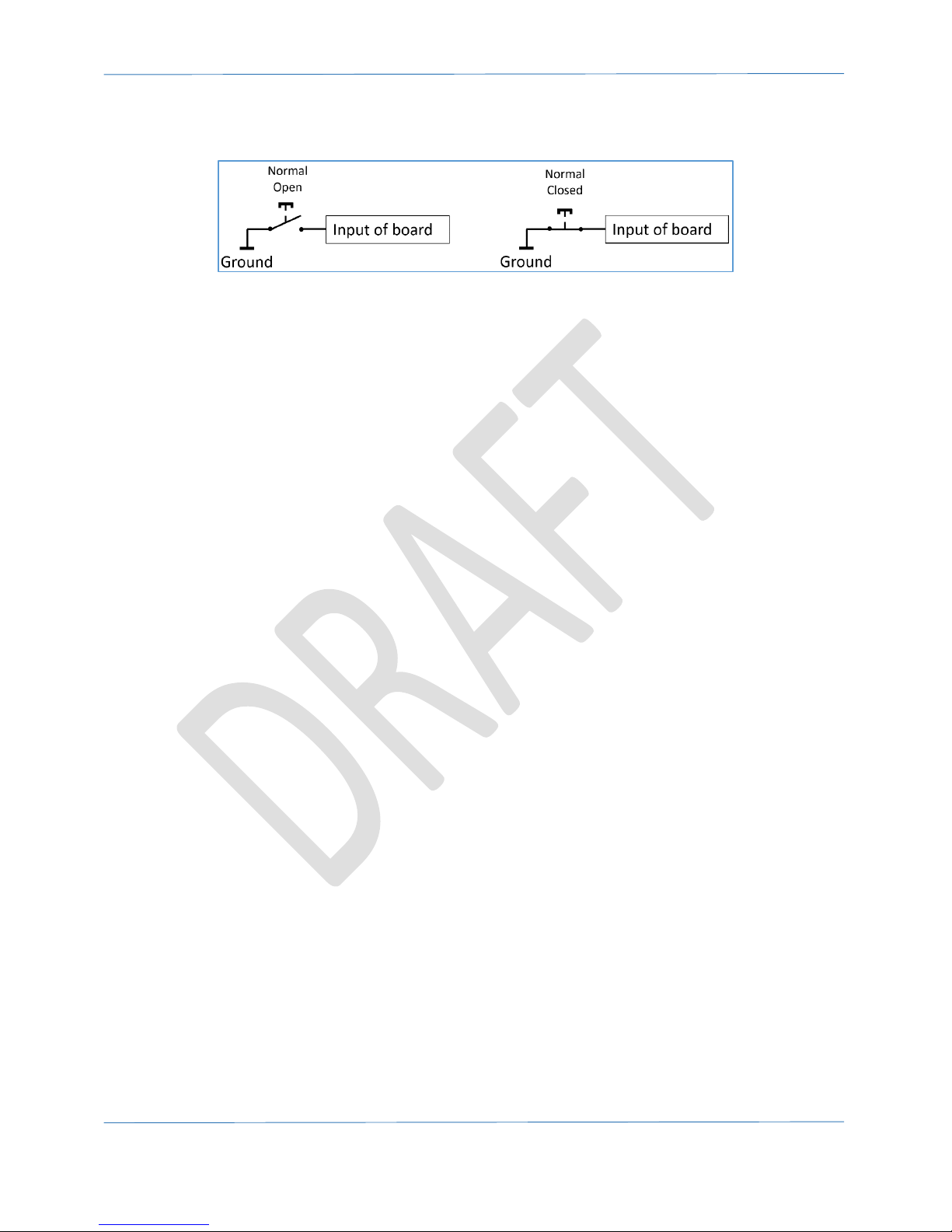

ground. In the image below this is illustrated for a Normal-Open and Normal-Closed switch.

Figure 15. Connecting switch to E-STOP input.

Page 20

Hardware Manual – CNC310

Page | 20

In the software it must be indicated whether a switch is either Normal-Open (NO) or Normal-Closed

(NC). This is set via ‘Homing and E-Stop’ part of the setup screen. A message will appear onscreen to

show that an E-STOP condition has occurred.

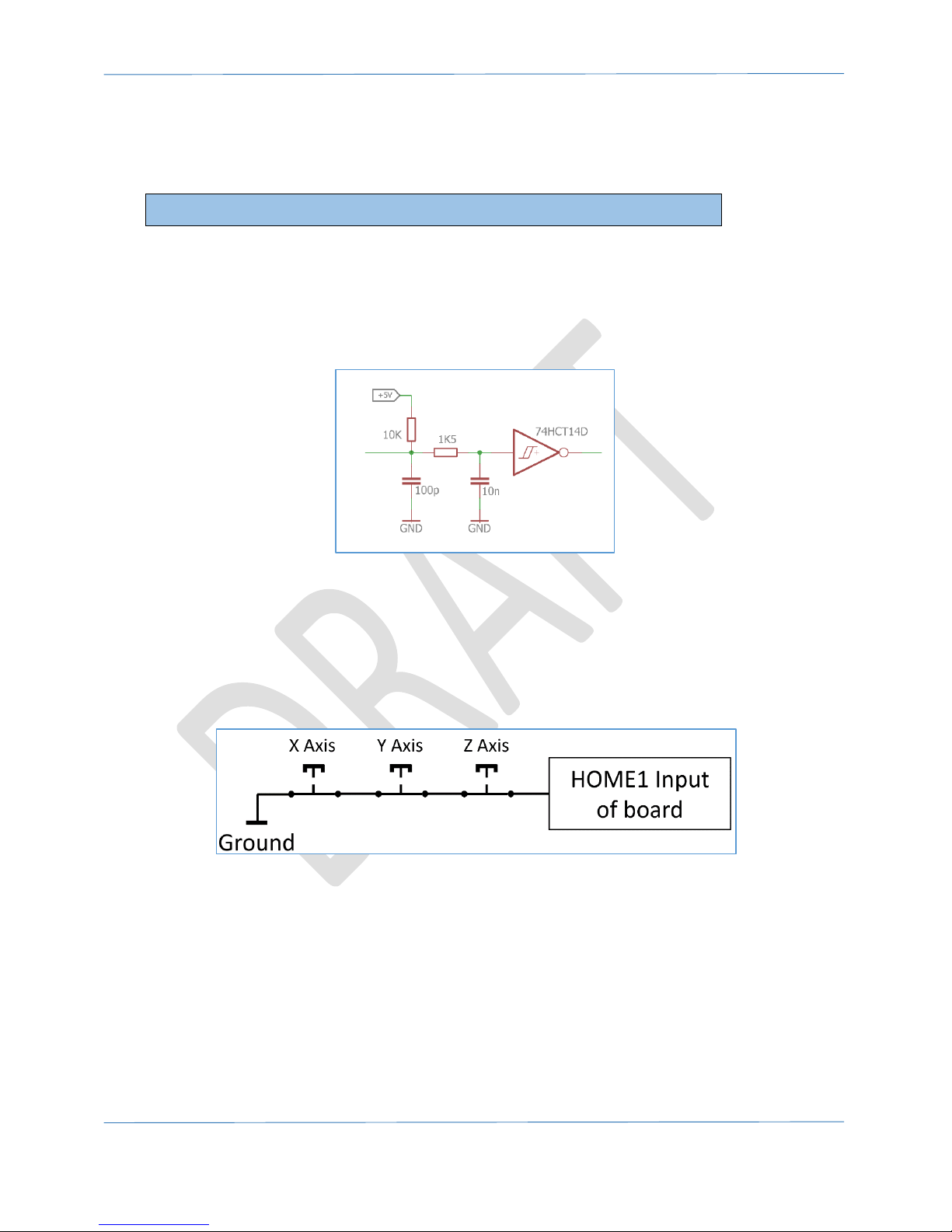

6.3 HOME1 input

The HOME1 input is used for connecting the X, Y and Z home switches for the machine so it knows

where it is.

The figure below shows how the input circuit is designed.

Figure 16. Home1 input circuit.

This image shows that on the input a 10k resistor is used as a pull-up. This means that IF you would

measure on this input you will measure 5V. Please note, that this is not the ‘real’ 5V but just a pull-

upped value. This input is used for the X, Y and Z axis. Depending on the type of switch, Normal

Open or Normal Closed, the switched need to be connected differently.

Figure 17. Connecting Normal-Closed home switches in series.

Please note, by default the E-STOP input is disabled.

Page 21

Hardware Manual – CNC310

Page | 21

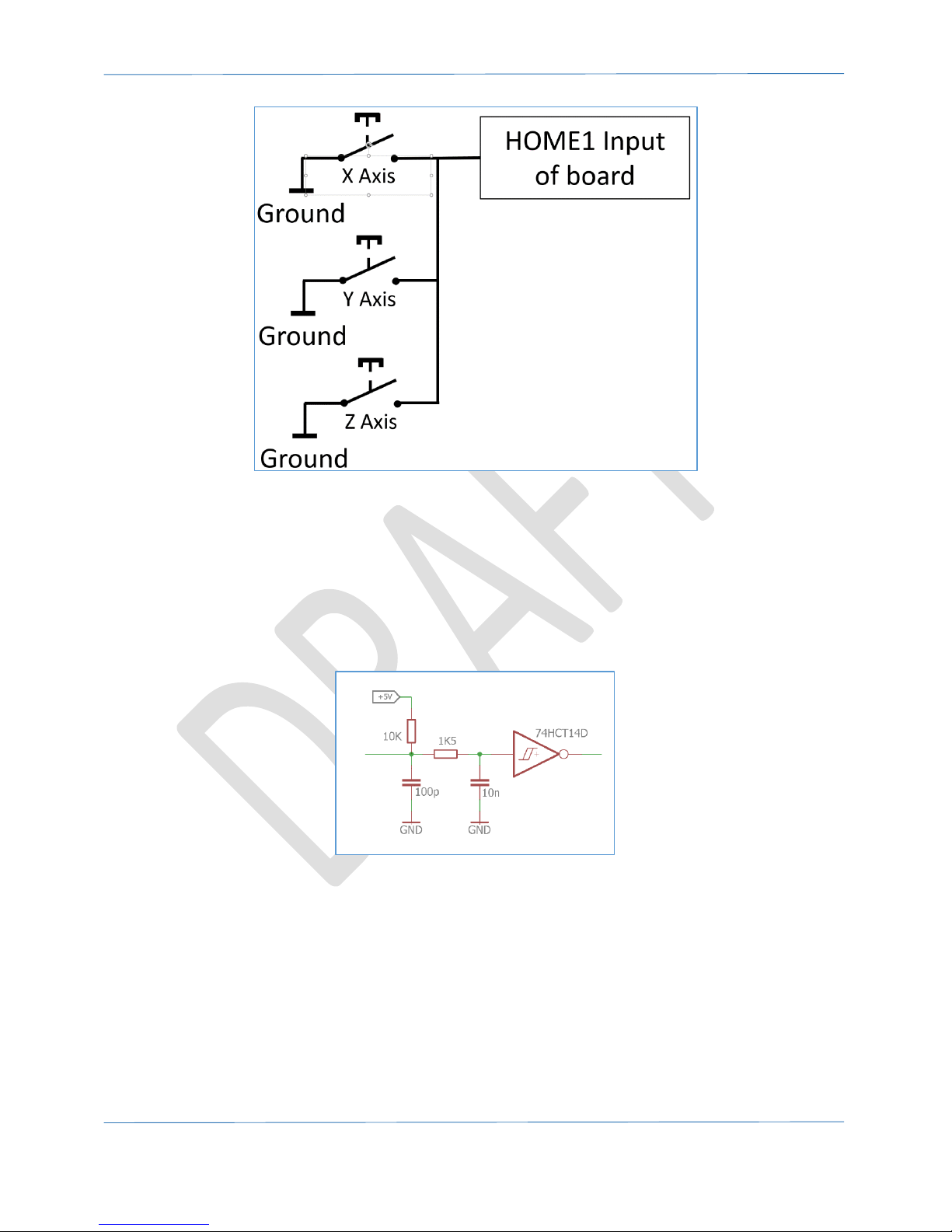

Figure 18. Connecting Normal-Open home switches in parallel.

In the software it must be indicated whether a switch is either Normal-Open (NO) or Normal-Closed

(NC). This is set via ‘Homing and E-Stop’ part of the setup screen.

6.4 HOME4 input

The HOME4 input is used if a 4th axis is activated. This input takes only a single home switch.

The figure below it shows how the input circuit is designed.

Figure 19. Home1 input circuit.

This image shows that on the input a 10k resistor is used as a pull-up. This means that IF you would

measure on this input you will measure 5V. Please note, that this is not the ‘real’ 5V but just a pullupped value.

Page 22

Hardware Manual – CNC310

Page | 22

Please note, that all home switches need to be the same with respect to Normal-Open or NormalClose.

Figure 20. Connecting switch to HOME4 input.

In the software it must be indicated whether a switch is either Normal-Open (NO) or Normal-Closed

(NC). This is set via ‘Homing and E-Stop’ part of the setup screen.

Page 23

Hardware Manual – CNC310

Page | 23

7 MPG/Pendant

The MPG connectors makes it possible to directly connect a pendant to the controller.

This option is only available if the full software is used.

<TO BE ADDED>

Page 24

Hardware Manual – CNC310

Page | 24

8 Getting started

Before installing the board it’s a good idea to validate that the board is operational.

A. Validate the board is active

Step 1. The first step is to validate the board is operational. Connect the USB.

Step 2. As a result the blue power led should turn on. Also, observe that the status LEDs indicates

that the board is active, indicated by the ‘heart beat’. See also “3.6 Status LED 1-4”.

Step 3. The board is now able to communicate with the application software. If you startup the

software the board should be found. This is indicated by the controller type ‘CNC310’ appearing in

the top-left of the window. If the board is not found it will show ‘SIMULATION’.

B. Check for motion

Now the board is operational the next step is to check whether the machine and home switches

work correctly. We start with the homing switches. Make sure that the power is off.

Step 1. Connect the home-switches

Step 2. Power up the board and connect with it with the software.

Step 3. By using the I/O screen of the application validate that the switches are correctly detected;

make sure not to forget to setup the switches in the setup screen of the software. This is

determined by the HomeInputSenseLevel, at default it is Normal Open.

Step 4. First, check there is no power connected. Next, connect the driver(s) to the board, you can

choose to connect all motors at once or just one at a time. Please check the manual of the

driver on how to connect it to the controllers, also check that the enable is correctly

connected. Some drivers will automatically be enabled when this input is not connected, and

they are powered up.

Step 5. DOUBLE check all connections.

Step 6. Power up the board and driver(s) and re-connect with it.

Step 7. Normally with the default settings of the software you should be able to get some motion. If

not please check the following:

- Are all signals correctly connected?

- Do some signals need to be inverted (e.g. enable)?

Page 25

Hardware Manual – CNC310

Page | 25

TIP: By using the software I/O screen you can manually control enabling the drivers. When the drive

is not enabled you will be able to move the axis by hand, if it is enabled this should not be possible.

If all checks went ok, your machine has now a basic setup. From here you can continue to connect

more I/O (eg. E-STOP) to the board, please check all I/O via the software; also check whether

inversion is necessary.

Please note that the system will need to be tuned to each specific machine. This means that machine

parameters as speed/acceleration etc. will need to be changed to get optimum performance. Please

make sure you know how to do this, and if not request support.

Page 26

Hardware Manual – CNC310

Page | 26

9 Example of connecting CNC310 to Leadshine DM422C.

In the image below is drawing of how to simple the CN310 can be connected to a DM422C.

Figure 21. Connecting CNC310 to Leadshine DM422C.

Page 27

Hardware Manual – CNC310

Page | 27

10 Mechanical dimensions

The controller can simply be connected by using standard connector (2x13 pole), pitch 2.54mm/0.1”:

For example:

Wurth WR-PHD 613026243121

Loading...

Loading...