EdilKamin Tally, Tally UP, Tally UP S, Tally F, Tally S Installation, Use And Maintenance Handbook

WOOD stOve

TALLY - TALLY UP

TALLY S - TALLY UP S

TALLY F

UK Installation, use and maintenance

CONTENTS

Introduction 3

Safety information 4

Dimensions 5

Technical data 10

Optionals 11

Packaging 12

Installation of components and claddings

ducting kit (optional) 15

wood drawer (optional) 16

Tally and Tally Up steel cladding 18

Tally and Tally Up stone cladding 22

food warmer kit for Tally F 26

S kit and storage for Tally S 28

ENGLISH

2

Tally S, F and UP S steel cladding 30

Tally S, F and UP S stone cladding 34

orientation of combustion gas outlet 38

Installation 39

Instructions for use 41

Adjusting the self-closing door 43

Maintenance 44

In the event of any problems 45

The undersigned EDILKAMIN S.p.a. with head office

headquarters at Via Vincenzo Monti 47 - 20123 Milan Italy - VAT IT00192220192

Declares under its own responsability as follows:

The below listed wood burning stoves comply with EU

Regulation 305/2011 and the harmonized European

Standard EN 13240:2001 + A2:2004 + AC:2006 +

AC:2007

WOOD STOVES, trademark EDILKAMIN,

called TALLY / TALLY S / TALLY F/ TALLY UP /TALLY

UP S

Year of manufacture: Ref. Data nameplate

Declaration of Performance (DoP EK n° 133):

Ref. Data nameplate

The liability of Edilkamin is limited to the product supply

only.

Dear Sir/Madam

Congratulations and thank you for choosing our product.

Please read this document carefully before you use this

product in order to obtain the best performance in complete

safety.

This manual is an integral part of the product, therefore we

ask you to keep it for the entire duration of the life cycle of

the product.

If lost, ask the retailer for a copy or download it from the

download area on the website www.edilkamin.com.

- After having unpacked the stove, ensure that its contents

are complete and intact.

In case of anomalies please contact the dealer where you

purchased the product immediately.

You will need to present a copy of the warranty booklet and

valid proof of purchase.

All local and national laws and European Standards must be

met for installation and use of the appliance. For installation

and any other further information not expressly outlined, refer

to the local laws in place for each country.

The product is clearly identified by a seven-digit number, the

“quality control label”.

Keep:

• the guarantee certificate found with the productthe

• the fiscal receipt issued by the retailer

• the Declaration of Conformity issued by the installation

technician.

ONLY FOR U.K.

Under the Clean Air Act local authorities may declare the

whole or part of the district of the authority to be a smoke

control area. It is an offence to emit smoke from a chimney

of a building, from a furnace or from any fixed boiler if loca-

ted in a designated smoke control area. It is also an offence

to acquire an “unauthorised fuel” for use within a smoke

control area unless it is used in an “exempt” appliance

(“exempted” from the controls which generally apply in the

smoke control area).

In England appliances are exempted by publication on a list

by the Secretary of State in accordance with changes made

to sections 20 and 21 of the Clean Air Act 1993 by section

15 of the Deregulation Act 2015. Similarly in Scotland ap-

pliances are exempted by publication on a list by Scottish

Ministers under section 50 of the Regulatory Reform (Scot-

land) Act 2014.

In Wales and Northern Ireland these are authorised by regu-

lations made by Welsh Ministers and by the Department of

the Environment respectively.

Further information on the requirements of the Clean Air Act

can be found here: https://www.gov.uk/smoke-control-area-

rules

Your local authority is responsible for implementing the

Clean Air Act 1993 including designation and supervision of

smoke control areas and you can contact them for details

of Clean Air Act requirements”

The Tally, Tally S, Tally F and Tally UP stoves in steel and

soapstone have been recommended as suitable for use in

smoke control areas when burning wood logs

TALLY UP is Tally with round glass.

For UK the product is supplied with a block for air combustion.

ENGLISH

3

All these documents will be requested by the retailer or the

Support Centre in the event of requests for information,

maintenance or otherwise.

The content of this manual is the property of Edilkamin.

No part must be reproduced or changed without the

authorisation of Edilkamin.

All images are for illustration purposes only; actual products

may vary.

SYMBOLS

Some parts of the manual use the following symbols:

CAUTION:

Read carefully the message to which this

refers, as failure to do so may result in

serious damage to the product and may

endanger the safety of people using it.

INFORMATION:

Failure to follow these instructions could

compromise correct product use.

SAFETY INFORMATION

• Incorrect installations or improper maintenance

causes safety risks,for which Edilkamin cannot be

held liable.

• The stove was not designed for use by people, including children, whose physical, sensory or mental capacities are reduced.

• The stove was not designed for cooking.

• The stove was designed to burn dry wood in the

quantities and methods described in this manual

• The stove was designed for internal use and in

premises with normal humidity

• For the legal and standard guarantee, refer to the

Certificate of Guarantee found with the stove

• The stove must be installed in premises where there is no danger of fire.

• In the event of fire, call the competent authorities

• Do not extinguish the fire with water jets

• The stove must be kept in dry places and not ex-

posed to bad weather.

The safety risks can be caused, among other things,

by:

• contact with the fire and hot parts (e.g. glass and

piping). DO NOT TOUCH HOT PARTS and, with

ENGLISH

the stove off but hot, always use the glove sup-

4

plied. Otherwise you risk getting burnt

• use of unsuitable products for lighting (e.g. alcohol). DO NOT LIGHT OR RE-LIGHT THE FLAME WITH LIQUID SPRAY PRODUCTS OR FLAMETHROWERS. You risk getting seriously burned

and causing damage to property and people.

• use of fuel other than dry wood. DO NOT BURN

RUBBISH, PLASTIC OR ANYTHING OTHER THAN

DRY WOOD IN THE FIREPLACE. You risk dirtying

the product, fires in the chimney flue and causing

damage to the environment.

• use of fuel different from the recommended fuel.

DO NOT OVERLOAD THE FIREPLACE. There is

a risk of deformation with risks for people in the

event of attempted

• fixing up and irreversible changes to the colour of

the paint on the metal parts. Edilkamin or the retai-

ler cannot be held liable.

• cleaning the hot fireplace. DO NOT EXTRACT

HOT. You risk compromising the extractor and,

possibly, smoke in the environment

• cleaning of the smoke channel with various substances. DO NOT CLEAN WITH FLAMMABLE

PRODUCTS. There is a risk of fires, back draft.

• cleaning of the hot glass with unsuitable products.

DO NOT CLEAN THE HOT GLASS WITH WATER

OR SUBSTANCES OTHER THAN GLASS CLEANERS RECOMMENDED OR DRY CLOTHES. There is a risk of cracks in the glass as well as permanent, irreversible damage to the glass

• deposit of inflammable materials under the safety

distance indicated on this manual. DO NOT REST

LINEN ON THE STOVE DO NOT POSITION THE

CLOTHES HORSE AT DISTANCES UNDER THOSE CONSIDERED SAFE. Keep any form of inflammable liquid far from the appliance in use. There

is a risk of fire.

• blocked opening of the air vents in the premises

or air input. DO NOT BLOCK THE AIR VENT OPENINGS OR BLOCK THE CHIMNEY FLUE. There is

a risk of a back draft in the room which could damage property and people.

• use of the stove as a support or ladder (DO NOT

CLIMB ON THE PRODUCT OR USE IT AS A SUPPORT). You risk damaging property and people.

• use of the stove with the fireplace open. DO NOT

USE THE STOVE WITH THE DOOR OPEN. For

greater protection of the stove, there is a spring

that allows the product to close automatically.

• addition of fuel and door opening approaching the

fire with flammable and loose clothing. Do NOT

open the door or approach the glass with flammable, wide clothing whose ends could catch fire

• open the door with incandescent material exiting.

Do NOT throw incandescent material out of the

stove. You risk a fire

Lastly, you are advised to take all normal precautions

in relation to home heatingIf in doubt, do not act on

your own initiative, but contact the retailer or installation technician.

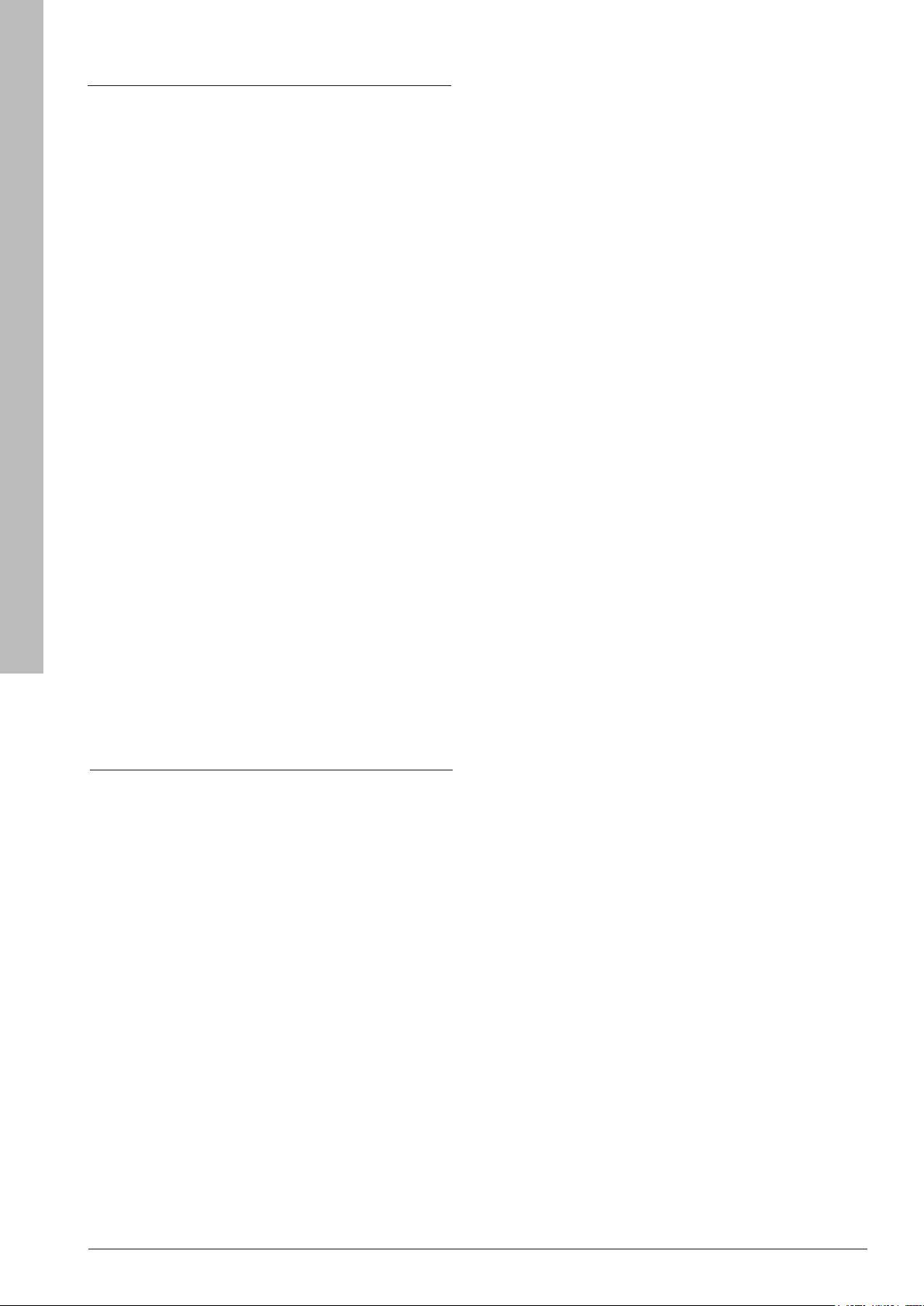

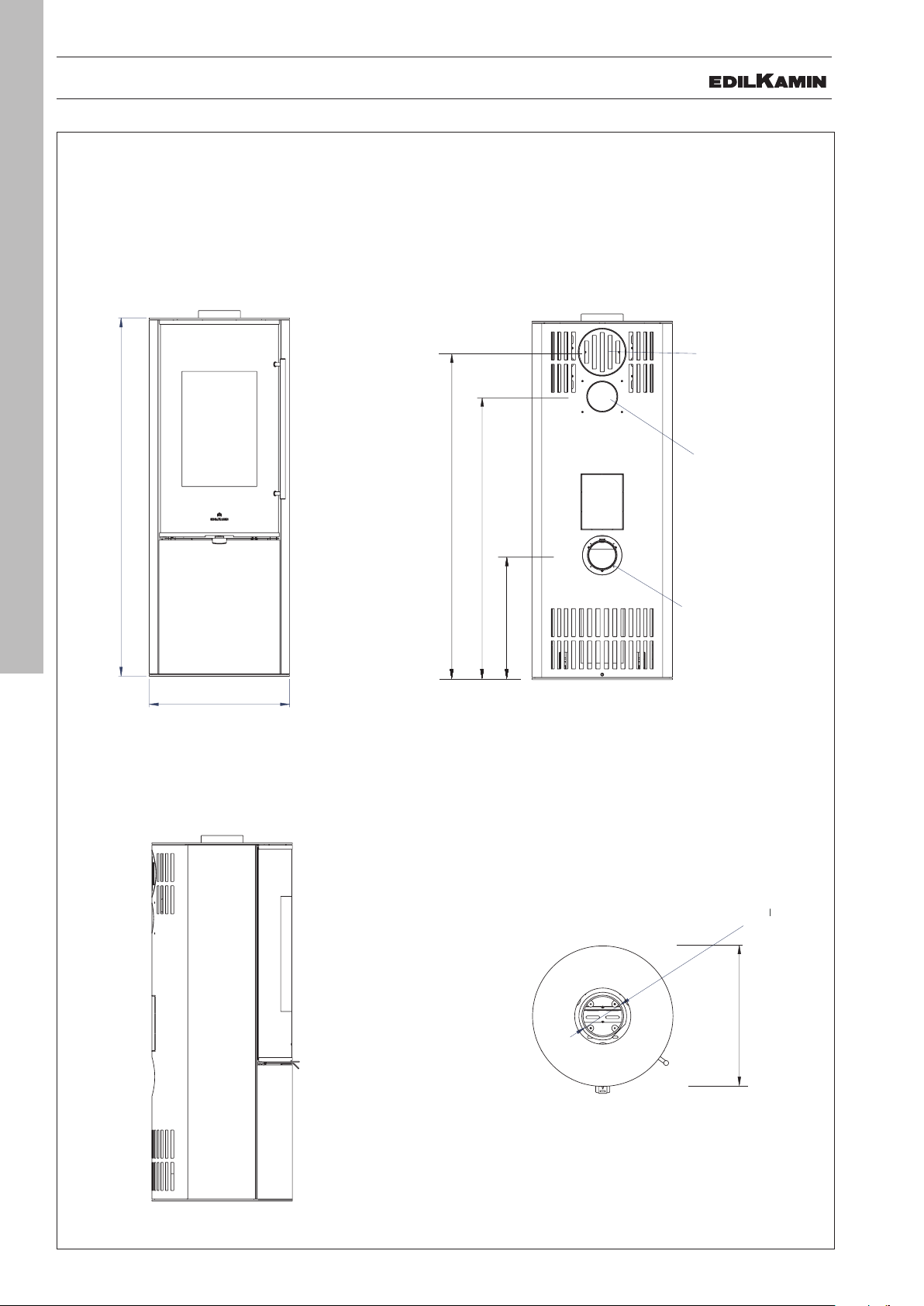

DIMENSIONS

38

38

Ø 15 cm

uscita fumi

Ø 8 cm aria

combustione

116,5

44

i

Ø 50

110

Ø 10 cm

uscita aria calda

31

44

38

131

pietra ollare

TALLY

- fireplace inner dimensions cm 29 (L) x 23 (P) x 38.5 (H)

Smoke outlet

Ø 15 cm

Ø 15 cm

uscita fumi

acciaio

steel

pietra ollare

soapstone

128

131

116,5

110

101

Ø 10 cm

Ø 10 cm

takes warm air for

uscita aria calda

ducting *

Combustion air

Ø 8 cm aria

Ø 10 cm

31

44

44

combustione

Ø 50

* use the specific kit (the

assembly instructions are

in the kit inside)

ENGLISH

5

Smoke outlet

Ø 15 cm

Ø 15 cm

uscita fum

Ø 50

38

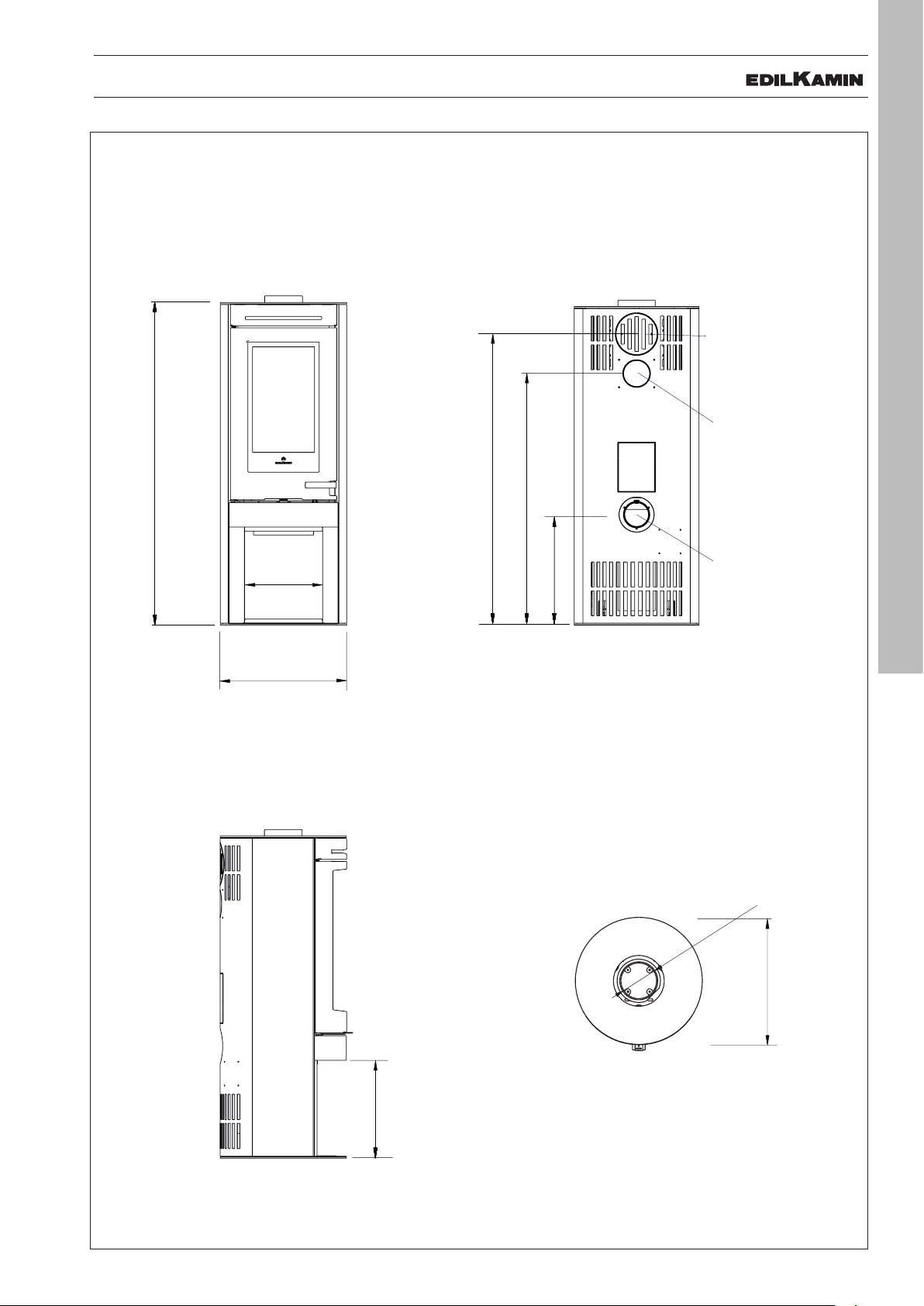

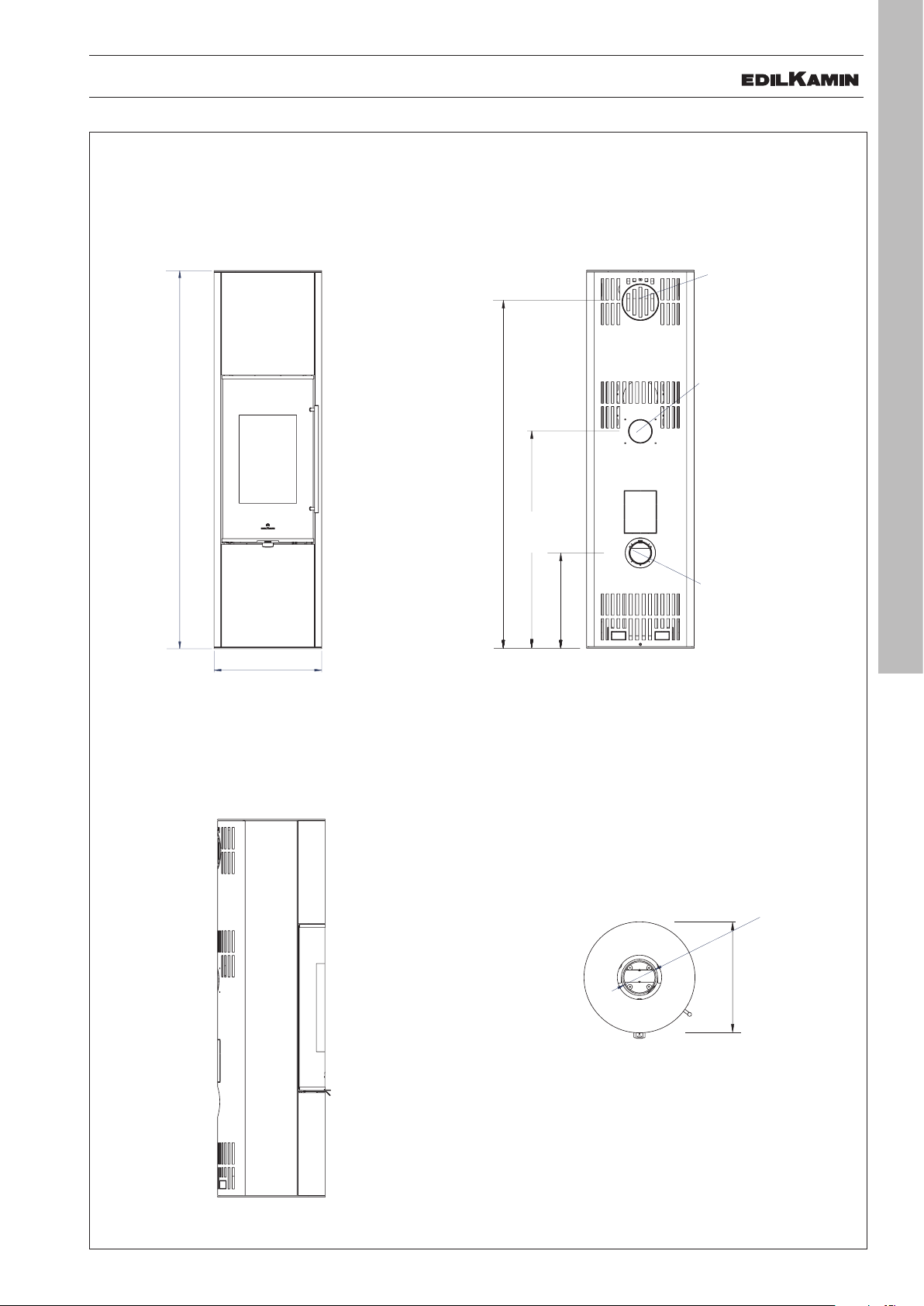

DIMENSIONS

161

44

110

Ø 15 cm

uscita fumi

Ø 10 cm aria

combustione

Ø 10 cm

uscita aria

calda

Ø 15 cm

uscita fumi

Ø 8 cm aria

combustione

116,5

44

i

Ø 50

110

Ø 10 cm

uscita aria calda

31

44

38

131

pietra ollare

161

44

Ø 15 cm

uscita fumi

Ø 50

110

Ø 50

Ø 15 cm

uscita fumi

Ø 10 cm aria

combustione

Ø 10 cm

uscita aria

calda

31

176

179

acciaio

pietra ollare

TALLY S

- fireplace inner dimensions cm 29 (L) x 23 (P) x 38.5 (H)

Smoke outlet

Ø 15 cm

uscita fumi

Ø 15 cm

Ø 10 cm

Ø 10 cm

uscita aria

takes warm air for

calda

steel

acciaio

pietra ollare

soapstone

161

176

179

ducting *

ENGLISH

6

31

Ø 50

110

101

Combustion air

Ø 10 cm aria

combustione

Ø 10 cm

44

* use the specific kit (the

assembly instructions are

in the kit inside)

Smoke outlet

Ø 15 cm

Ø 15 cm

uscita fum

Ø 50

38

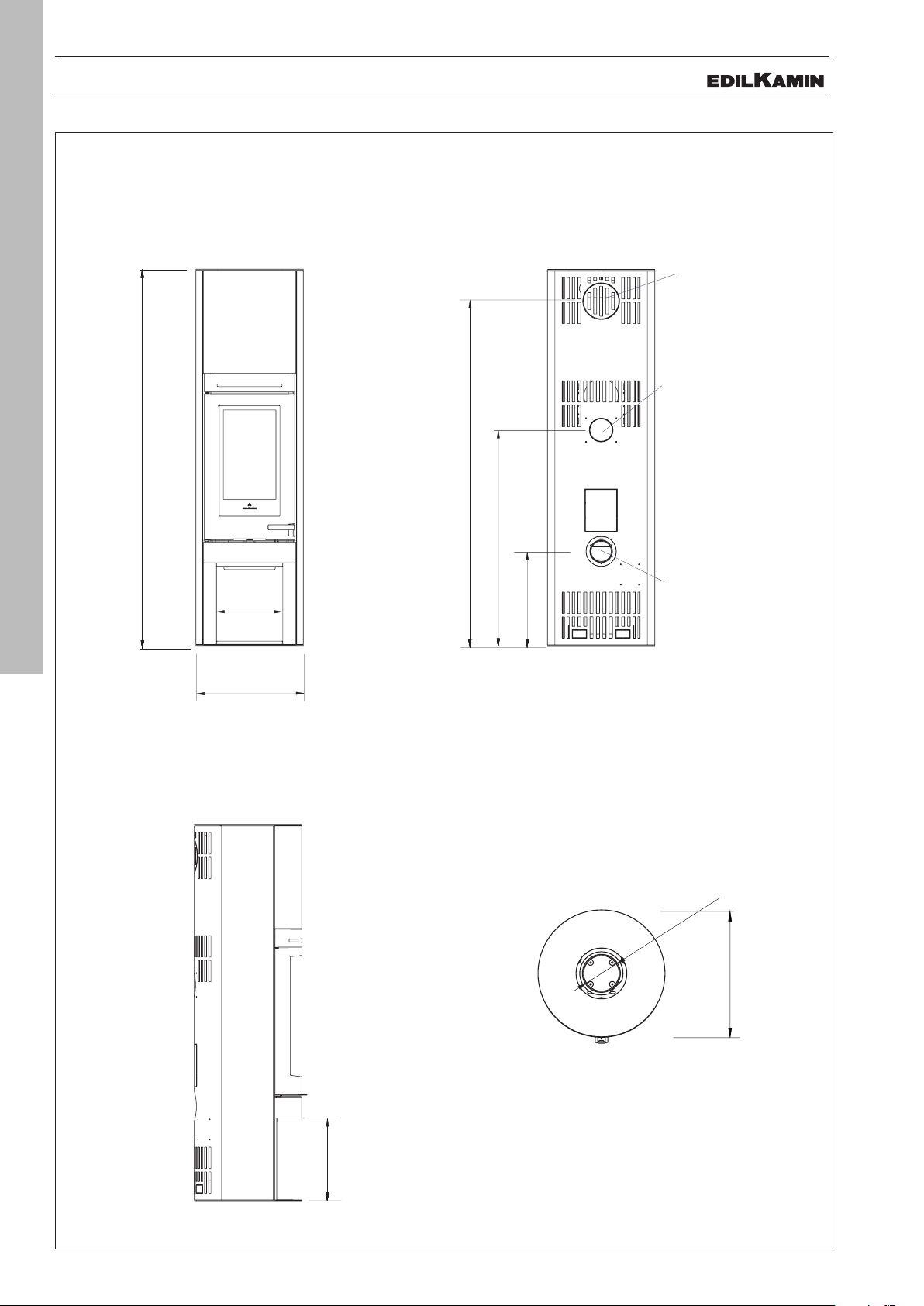

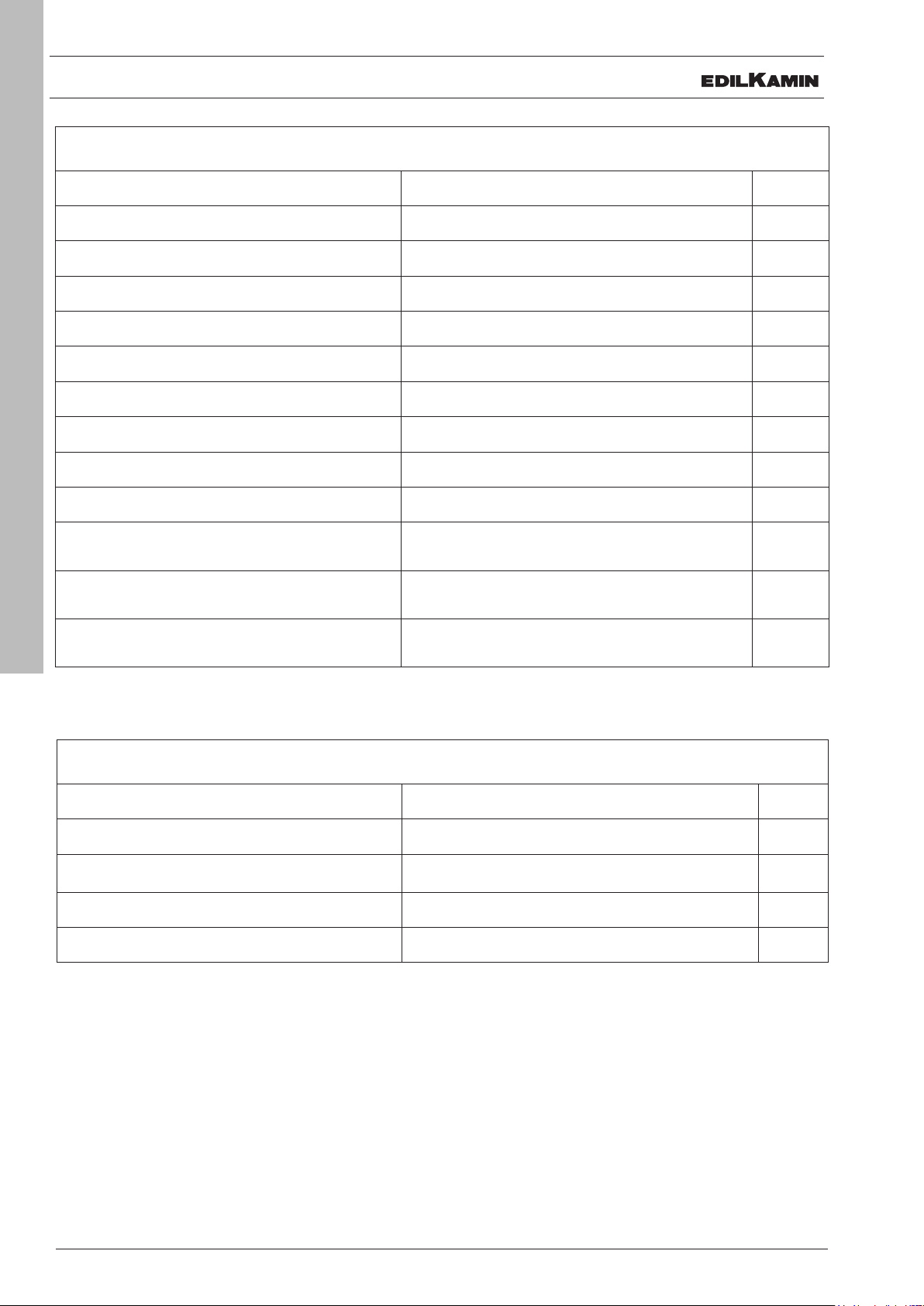

DIMENSIONS

161

44

Ø 15 cm

uscita fumi

Ø 10 cm aria

combustione

110

Ø 10 cm

uscita aria

calda

Ø 15 cm

uscita fumi

Ø 8 cm aria

combustione

116,5

44

i

Ø 50

110

Ø 10 cm

uscita aria calda

31

44

38

131

pietra ollare

161

44

Ø 15 cm

uscita fumi

Ø 10 cm aria

combustione

Ø 15 cm

uscita fumi

Ø 50

110

Ø 50

Ø 10 cm

uscita aria

calda

31

176

179

acciaio

pietra ollare

TALLY F

- fireplace inner dimensions cm 29 (L) x 23 (P) x 38.5 (H)

- food warmer dimensions cm 25 (L) x 31 (P) x 28 (H)

Not used

Ø 15 cm

uscita fumi

Ø 10 cm

Ø 10 cm

takes warm air for

uscita aria

calda

ducting *

161

110

44

Combustion air

Ø 10 cm aria

Ø 10 cm

combustione

* use the specific kit (the

assembly instructions are

in the kit inside)

Smoke outlet

Ø 15 cm

Ø 15 cm

uscita fum

ENGLISH

7

steel

acciaio

176

pietra ollare

soapstone

179

101

31

Ø 50

Ø 50

38

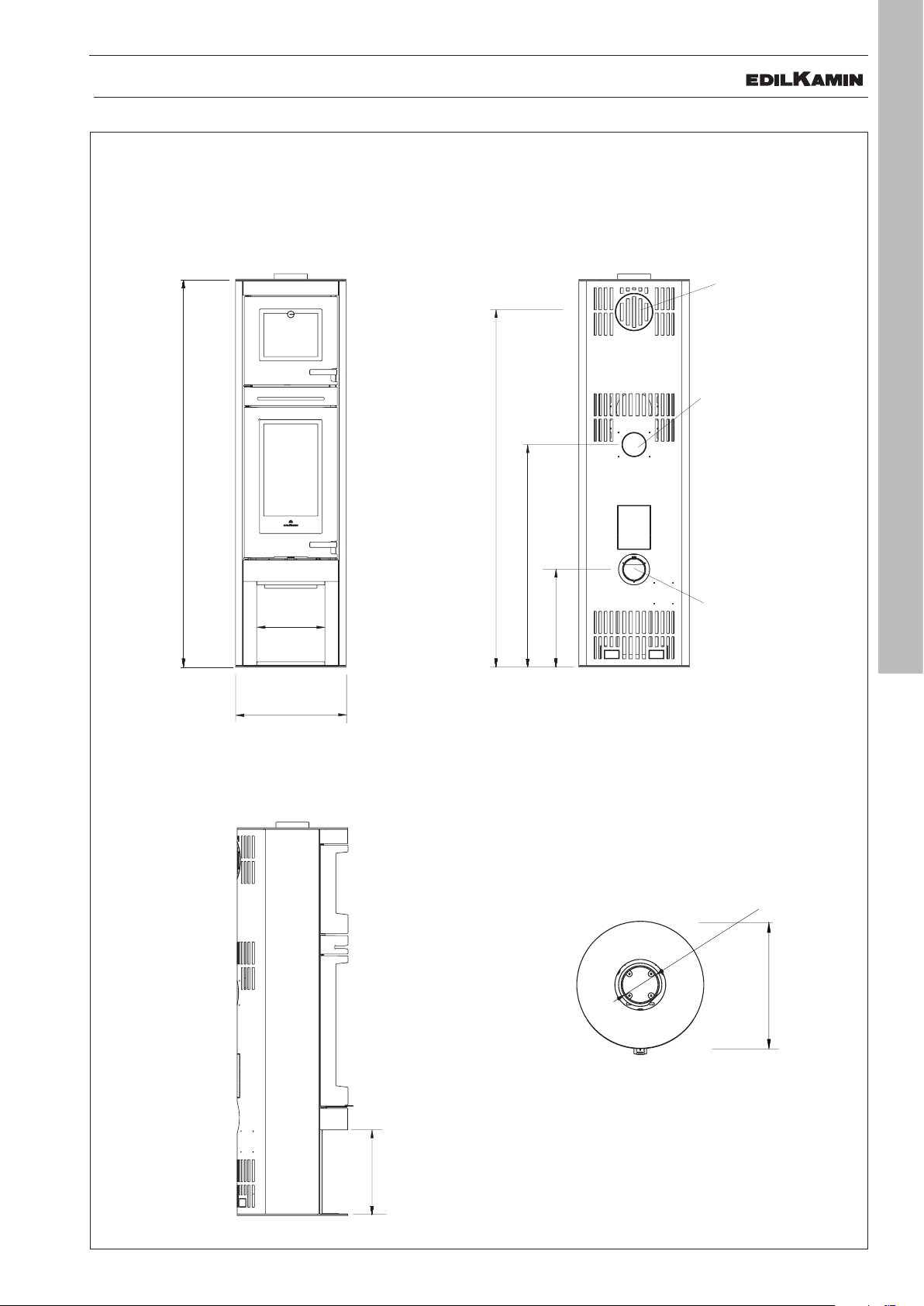

DIMENSIONS

116,5

128

Ø 15 cm

uscita fumi

Ø 10 cm aria

116,5

uscita fumi

Ø 50

110

Ø 10 cm

uscita aria

calda

131

acciaio

pietra ollare

TALLY UP

- fireplace inner dimensions cm 29 (L) x 23 (P) x 38.5 (H)

acciaio

pietra ollare

Smoke outlet

Ø 15 cm

uscita fumi

Ø 15 cm

Ø 10 cm

Ø 10 cm

uscita aria

takes warm air for

calda

ducting *

8

ENGLISH

128

131

110

101

Ø 10 cm aria

Combustion air

combustione

44

44

Ø 10 cm

Ø 50

* use the specific kit (the

assembly instructions are

in the kit inside)

Smoke outlet

Ø 15 cm

Ø 15 cm

Ø 50

DIMENSIONS

161

44

110

Ø 15 cm

uscita fumi

Ø 10 cm aria

combustione

Ø 10 cm

uscita aria

calda

161

44

uscita fumi

Ø 50

110

Ø 15 cm

uscita fumi

Ø 10 cm aria

combustione

Ø 10 cm

uscita aria

calda

176

179

acciaio

pietra ollare

161

44

110

Ø 15 cm

uscita fumi

Ø 10 cm aria

combustione

Ø 10 cm

uscita aria

calda

TALLY UP S

- fireplace inner dimensions cm 29 (L) x 23 (P) x 38.5 (H)

acciaio

pietra ollare

176

179

161

Smoke outlet

Ø 15 cm

uscita fumi

Ø 15 cm

Ø 10 cm

Ø 10 cm

uscita aria

takes warm air for

calda

ducting *

101

Ø 50

110

44

Combustion air

Ø 10 cm aria

Ø 10 cm

combustione

ENGLISH

9

* use the specific kit (the

assembly instructions are

in the kit inside)

Smoke outlet

Ø 15 cm

Ø 15 cm

Ø 50

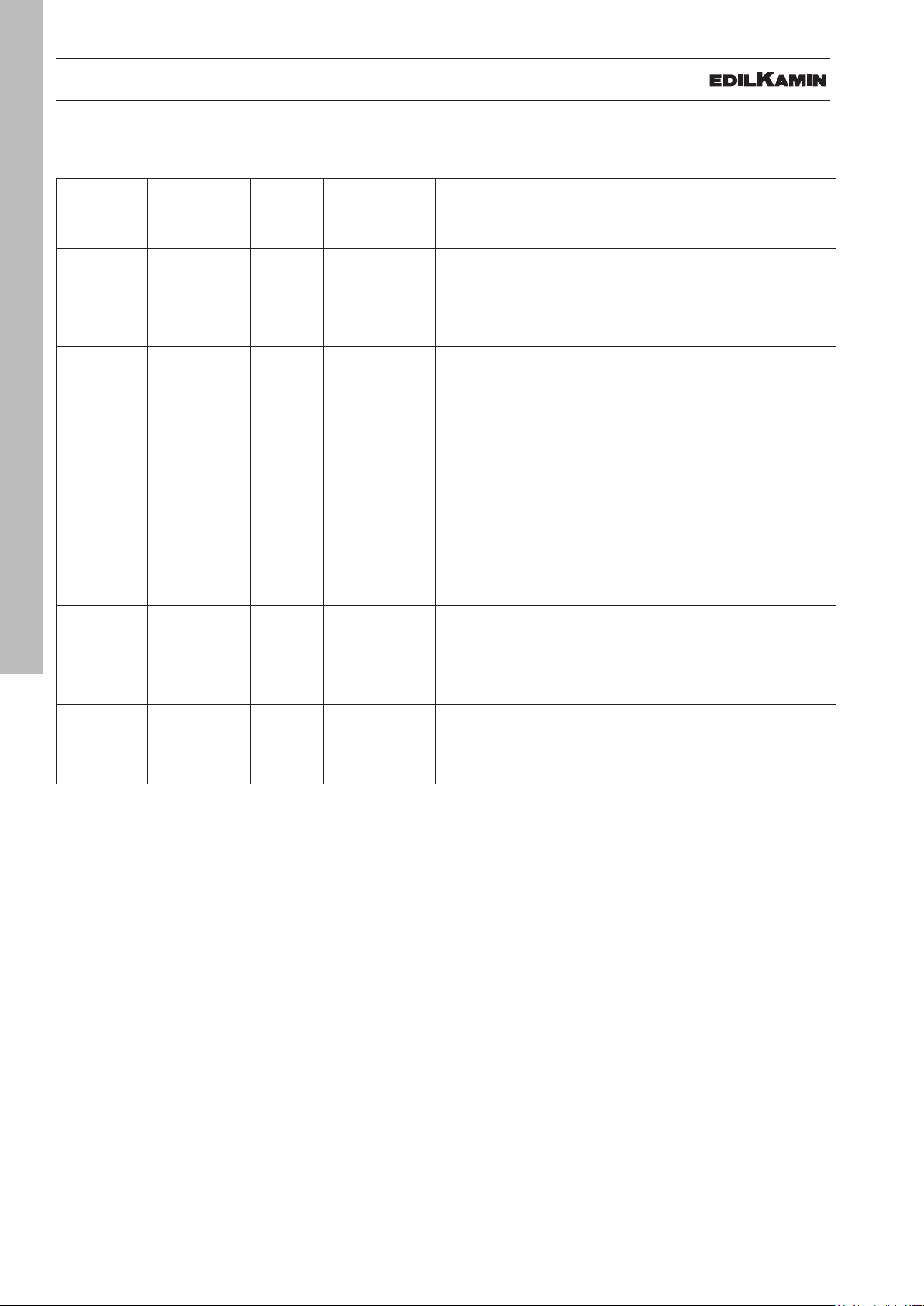

TECHNICAL DATA

TECHNICAL CHARACTERISTICS according to EN 13240

The given data are indicative and taken during the certification stage at a notified Body under regulation conditions

Nominal power

Power output 6

Yield 85,6

Emissions CO 13% O

2

0,095

Fume temperature 160

Minimum draught 12

Fuel consumption 1,5

Heatable volume * 155

Smoke outlet pipe diameter (male) 150

Air intake pipe diameter (male) 100

Weight including packaging

Weight including packaging

(Tally - Tally/S - Tally/F) steel 150/200/200 soapstone 220/300/300

(Tally UP - Tally UP S) steel 150/200 soapstone 220/300

Refractory storage Kit (OPTIONAL) 40 kg

ENGLISH

kW

%

%

°C

Pa

kg/h

m

mm

mm

kg

kg

3

10

* The heating volume is calculated with the heat request of 33 Kcal/m³ hour

TECHNICAL DATA FOR THE DIMENSIONING OF THE FLUE

Nominal power

Power output 6 kW

Temperature of fumes on exit from the discharge pipe

192 °C

Minimum draught 5 Pa

Fume flow capacity 6 g/s

EDILKAMIN s.p.a. reserves the right to change the products at its discretion without notice.

OPTIONAL

OPTIONALS AVAILABLE FOR EACH MODEL

Optional Use Stove

Wood drawer storing wood Tally

Tally S

Tally F

Tally UP have wood drawer

Storage kit in refractory

material

Air Diffuser Kit ducting with hot air fan Tally

Connection Kit for the Air

Diffuser Kit ducting

Automatic ignition kit to light the wood automatically Tally

maintaining heat for as long as possible Tally S

Tally UP S

Tally UP

Tally S

Tally S UP

Tally F

to connect the ducting pipes to the rear of the

stove. In combination with the Air Diffuser Kit.

Tally

Tally UP

Tally S

Tally S UP

Tally F

Tally UP

Tally S

Tally S UP

Tally F

ENGLISH

11

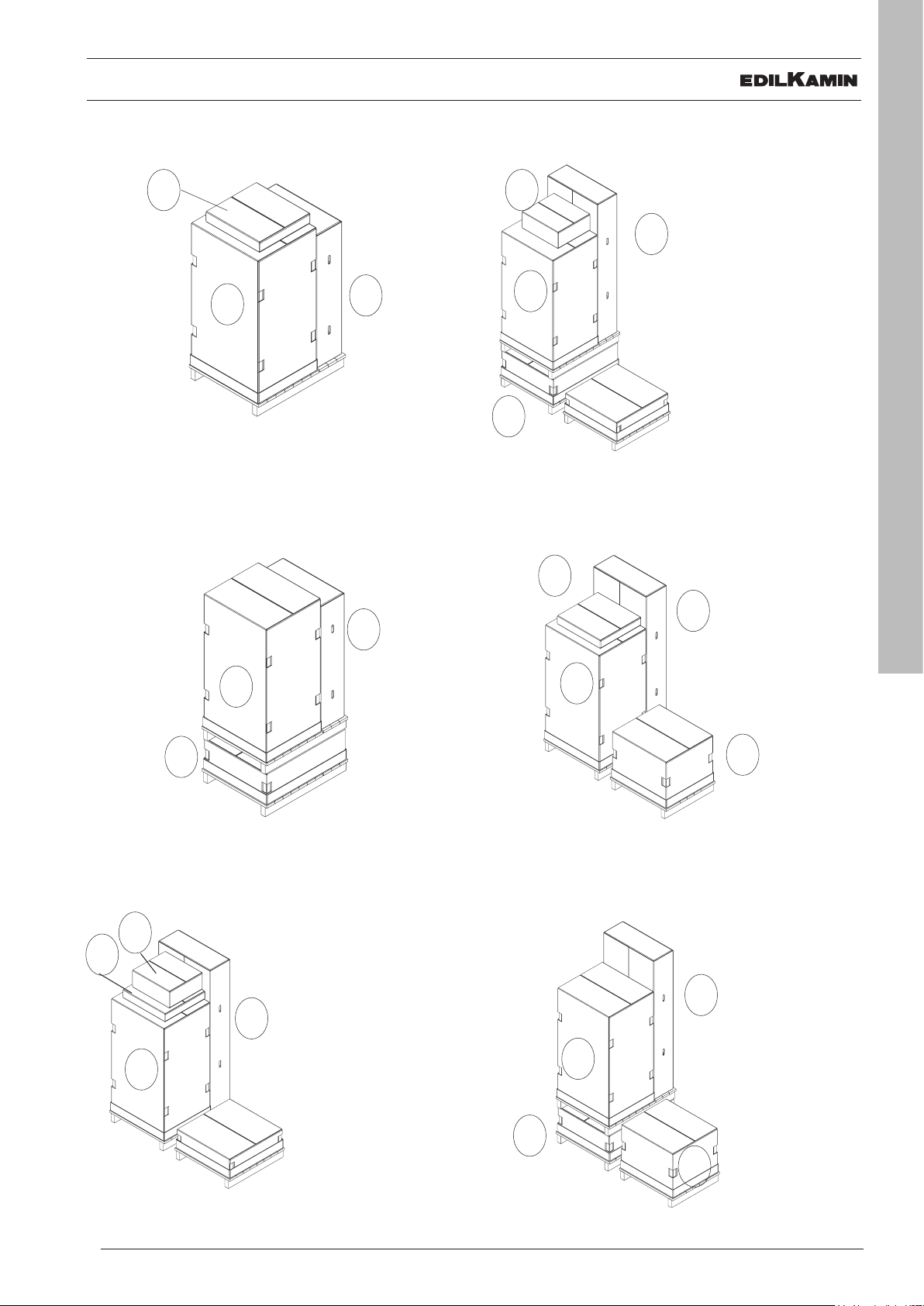

PACKAGING

PACKAGING

Model Version Figure No. of

packs

TALLY

TALLY UP

TALLY

TALLY UP

TALLY S

TALLY UP S

TALLY S

TALLY UP S

TALLY F STEEL: Fig. 5 4 • Structure (1)

ENGLISH

12

TALLY F POTSTONE Fig. 6 4 • Structure (1)

STEEL: Fig. 1 3 • Structure (1)

POTSTONE Fig. 2 3 • Structure (1)

STEEL: Fig. 3 4 • Structure (1)

POTSTONE Fig. 4 4 • Structure (1)

Components in packs

• Side panels, rear protection casing, top front panel

• Top (3)

• Rear protective casing (2)

• Series of stones (3)

• Side panels, rear protection casing, top front panel

• Top (3)

• S Kit, top part (4). The storage rings are optionals.

• Rear protective casing (2)

• Series of Stones (3)

• S Kit, top part (4). The storage rings are optionals.

• Side panels and rear protection casing and (only with

• Top (3)

• Food Warmer Kit

• Rear protective casing (2)

• Series of Stones (3)

• Food Warmer Kit (4)

and (only with Tally UP) bottom front panel for the

drawer (2)

and (only with Tally UP) bottom front panel for the

drawer (2)

TALLY UP) bottom front panel (2)

PACKAGING

TALLY e TALLY UP steel (fig. 1)

3

1

TALLY e TALLY UP stone (fig. 2)

TALLY S e TALLY UP S stone(fig. 4)

4

2

2

1

Prepared for

accumulation

OPTIONAL

3

TALLY F steel (fig. 5)

3

1

3

TALLY S e TALLY UP S steel (fig. 3)

4

3

2

2

2

ENGLISH

1

13

4

TALLY F stone(fig. 6)

2

1

Prepared for

accumulation

OPTIONAL

3

1

4

PACKAGING

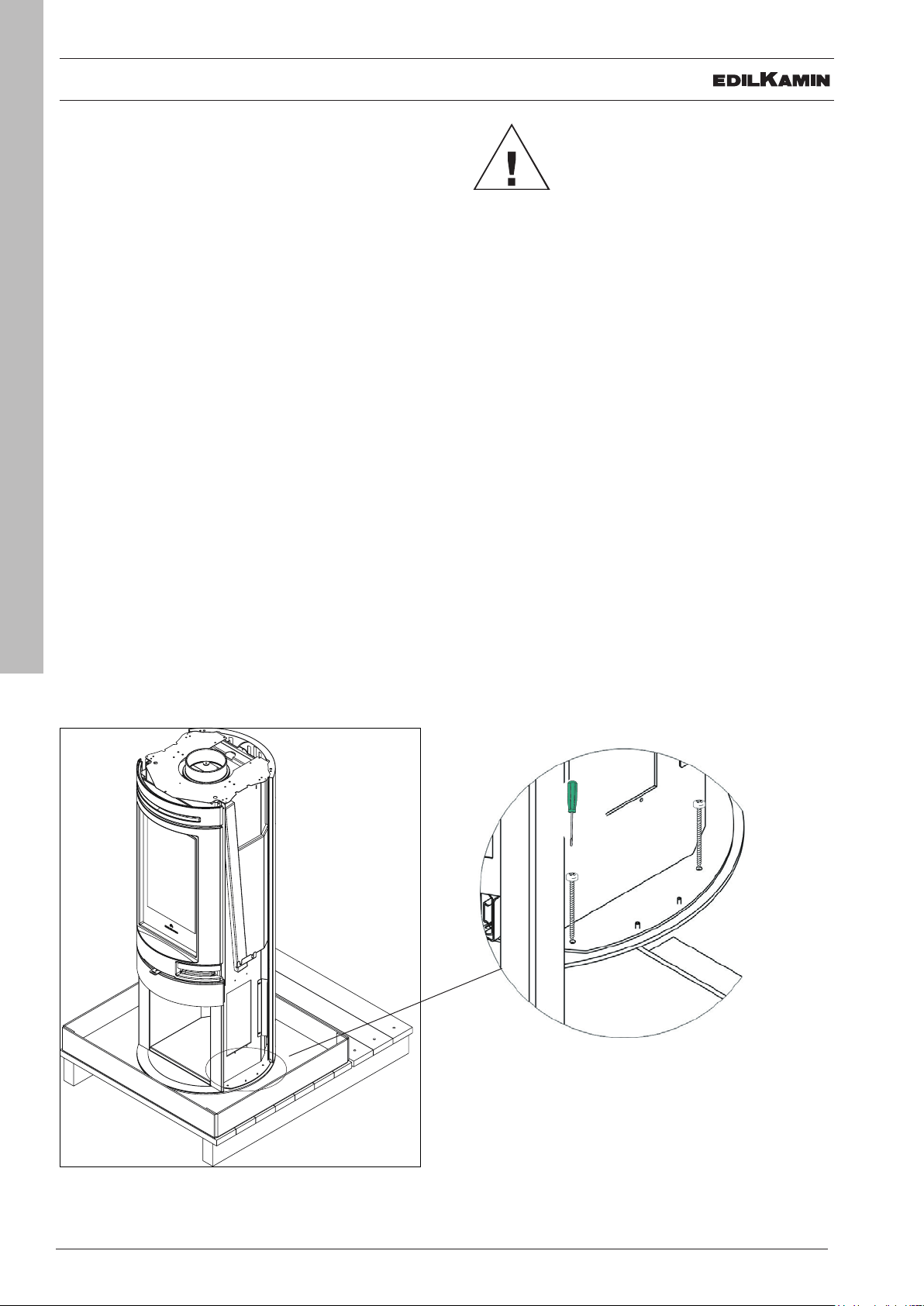

PREPARATION AND UNPACKING

The materials composing the packaging are not toxic

or harmful, therefore no particular disposal processes

are required.

Storage, disposal and any recycling is the responsibility

of the end user in compliance with the laws in force on

the matter.

TO REMOVE THE PRODUCT FROM THE PALLET:

- remove the fastening screws on the pallet on both sides

of the stove

- remove the stove from the pallet and pay particular attention so the door and the glass are protected from mechanical knocks that could damage them.

ENGLISH

You are recommended to make each

movement in a vertical position with suitable

devices, paying attention to the safety

standards in force.

Do not overturn the packaging and be

cautious when assembling parts.

The packaging includes a useful inspection

hatch to check the status of the product.

On receipt, check and immediately notify

the retailer of any anomalies.

14

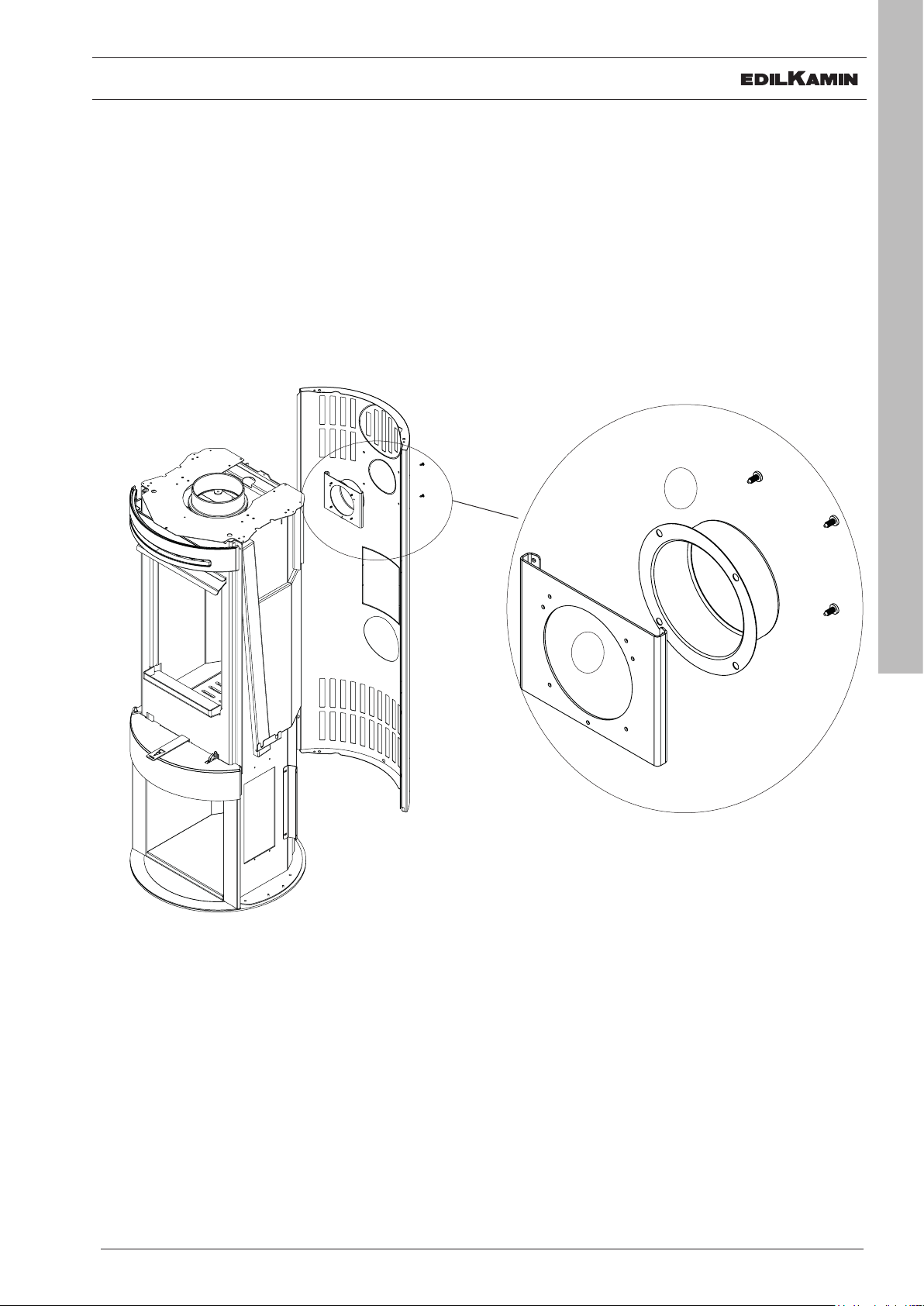

AIR DUCTING KIT

AIR DUCTING KIT (optional)

The stove is equipped for connecting the Air Diffuser

Kit, which allows warm air to be ducted to another

room using a fan.

To connect the Air Diffuser Kit (instructions with the kit),

you first need to mount the kit with the bracket (A) and

the flange (B) in order to fit the ducting pipe.

Fasten the bracket and the flange of the kit to the back

of the rear protective casing.

B

A

ENGLISH

15

OPTIONAL WOOD DRAWER

The pack for the optional drawer contains:

• 1 fitted drawer (A)

• 1 top cover (B);

• 4 self-tapping screws

WOODEN DRAWER KIT

B

A

FITTING THE OPTIONAL DRAWER

In order to fit the drawer, you need to prepare the

structure and then install the optional accessory

Preparing the structure:

ENGLISH

remove the wood box by unscrewing the three screws

(one per side and one at the back). The wood box is

16

replaced by the drawer.

Unscrew the CE marking plate from the

wood box and then fit it onto the drawer so

that the sign remains with the product

Once the wood box has been removed, the stove

appears as in the adjacent picture

1 per

side

FITTING THE OPTIONAL DRAWER

WOODEN DRAWER KIT

Preparing the optional drawer:

• slide the rails off

• insert the drawer into the prepared structure and

screw the rails onto the structure (2 screws per

side)

Optional drawer (A)

ENGLISH

17

CLADDING

FITTING THE TALLY AND TALLY UP STEEL CLADDING

The cladding is in two packs.

One contains:

• 1 rear protective casing (1)

• 2 side panels (2) and 1 front panel for the drawer, on the Tally UP model

• 1 hardware bag with:

- 10 self-tapping screws for the side panels and rear protective casing (and 4 additional screws for the UP version)

- 6 M 4x9 grub screws: 4 to be fixed to the sides of the base for the side panels; 2 for the top

- 2 M 5 grub screws (normally not used)

- 2 M 5 nuts and 1 dome bolt to make the door self-closing (see specific paragraph)

The other pack contains:

- 1 top (3)

- 1 top closure cap if the outlet is at the rear (4)

1

2

ENGLISH

18

SUMMARY OF OPERATIONS FOR FITTING THE CLADDING (description in the gures below)

4

3

1. Loosen the two screws on the bracket fixed to the

structure so as to be able to adjust the rear protective

casing;

2. insert the rear protective casing

1.

2.

1

CLADDING

3a. fasten it with 2 screws on the top part

3b. fasten it with 4 screws (2 per side) on the bottom

part, on the bracket referred to in point 1. Tighten the

screws that had previously been loosened under point

1.

4. screw the M 4x9 grub screws to the base (two per

side), onto which the side panels will be inserted

3a.

3b.

Grani

4.

5. fit the side panels (2) and fasten them (on all sides)

with 2 screws on the top part. Make sure that you insert

them at the bottom onto the previously-attached grub

screws

Insert the side panels with the profile facing

forwards.

ENGLISH

19

5.

2

CLADDING

6. prepare the top by screwing two M 4x9 grub screws

underneath.

7. then position the top, on top, centring the grub

screws in the holes on the U-shaped plate, which can

be adjusted if necessary with screw A.

6.

7.

vite A

screw A

3

U-shaped

plate

ENGLISH

20

CLADDING

ONLY FOR TALLY UP

In addition to what is mentioned in the previous pages

for the Steel Tally Base, the Tally UP has a wood drawer

with a steel front that needs fitting.

A

B

FITTING THE DRAWER CLADDING

• unscrew handle A from the drawer (figure below)

• insert the front panel in steel B

• screw on the front panel B using four screws (two

per side)

ENGLISH

21

CLADDING

FITTING THE TALLY AND TALLY UP STONE CLADDING

The cladding is in two packs.

The protective casing pack contains:

• 1 rear protective casing (1)

• 1 hardware bag with:

- 2 M 5 nuts and 1 dome bolt to make the door self-closing (see specific paragraph)

- 6 self-tapping screws to fasten the protective casing

The stone piece pack contains:

• 4 elements in stone: four are 48 cm long (2a) and two 78 cm long (2b), and, only for the UP version, another two

stone elements (38 cm long) for the drawer

• 1 top (3)

• 1 top closure cap if the outlet is at the rear (4)

• 6 lateral stone brackets (5)

• 2 stone block brackets (6)

• 1 hardware bag with:

- 16 screws in total: 12 for fastening the brackets (2 per bracket) and 4 for fastening the stone block brackets (2 per

bracket)

- 16 (spacer) pins to be screwed onto the stone pieces (4 for each stone piece)

- 2 pins to be placed under the top

- 8 M 6x8 screws for the UP version

ENGLISH

22

4

3

1

2a

2b

CLADDING

SUMMARY OF OPERATIONS FOR FITTING THE CLADDING (description in the gures below)

1. loosen the screws on the bracket fixed to the structure

so as to be able to adjust the protective casing;

2. insert the rear protective casing

3. fasten it with 2 screws on the top part and with 4

screws (2 per side) on the bottom part

3.

1.

2.

1

ENGLISH

23

4. Prepare the side elements in stone (2a and 2b),

by screwing the pins into the threaded inserts on the

stone.

Tighten or loosen the pins as required to

improve the alignment of the stones. In

case use the thickness too.

4.

CLADDING

5. fasten the metal brackets (5 - three per side) with

the self-tapping screws in line with the holes on the

structure.

6. starting at the bottom, insert the side panels onto

the metal brackets (5).

7. block the side panels using the Z-shaped bracket

(6).

Z-shaped

bracket (6)

5.

6.

7.

6

5

2b

5

2a

lateral stone

bracket (5)

ENGLISH

24

8. Position the top, on top, centring the locator pins in

the holes on the U-shaped plate.

fixed to the

structure

CLADDING

ONLY FOR TALLY UP IN STONE

In addition to what is mentioned in the previous pages

for the Tally Base, the Tally UP has a wood drawer

including a front with stone pieces that need to be

fitted and screwed on.

A

B

FITTING THE DRAWER CLADDING

• unscrew the handle (A) from the drawer. See figure

below;

• unscrew the bottom front wall (B);

• fasten the stones (C) by screwing them on from

the back

C

ENGLISH

25

B

FOOD WARMER KIT

FITTING THE TALLY F FOOD WARMER KIT

(to be done by the installation technician)

The food warmer kit pack contains:

• food warmer system

• internal elements of the food warmer (fixed tray to be fitted onto the stove after installation and the removable

tray)

• hardware:

- 10 self-tapping screws;

- 4 thread-forming screws;

- gasket

To remove it from the pallet open the

door and undo the screws (V) used to fix the food

warmer kit to the pallet.

V

x n° 4

ENGLISH

26

SUMMARY OF OPERATIONS FOR FITTING THE FOOD WARMER KIT (description in the gures

below)

1. remove the U-shaped plate and the combustion gas

collar.

1.

U-shaped plate

combustion

gas collar

FOOD WARMER KIT

2. dismantle the top front panel of the structure, by

unscrewing the side screws

3. also with the food warmer kit on the floor, loosen

the screws of the front plate and the two rear brackets

so as to allow the four central screws to be positioned

correctly later

2.

3.

If presente,check the condition of the

adhesive gasket under the food warmer.

If required, apply a new one. IF NOT

PRESENT APPLY A NEW ONE

4. place the food warmer kit on the structure. Open the

door, tighten the four internal thread-forming screws

(without over-tightening) to block it with the structure,

the two front self-tapping screws (Figure 4a) and the

screws on the rear brackets. Then tighten the screws

further, starting with the rear ones and re-tighten the

previously-loosened screws.

4a.

ENGLISH

27

4.

internal threadforming screws x 4

bracket

screws,

one per side

5. re-position the U-shaped plate and the combustion

gas collar on top of the food warmer kit and re-position

the top front panel of the structure, removed in points 1

and 2, and screw the fixed tray inside the food warmer.

KIT S

ASSEMBLING THE TALLY S (STORAGE) S KIT (to be done by the installation technician)

THE RINGS IN REFRACTORY MATERIAL (3) ARE OPTIONAL

The S Kit pack contains:

• 3 containment walls of the S Kit (1)

• 2 L-shaped brackets for fixing the protective casing (2)

• 18 self-tapping screws to screw the containment walls of the S Kit

2

ENGLISH

28

1

(3) Rings

OPTIONAL

KIT S

SUMMARY OF OPERATIONS FOR ASSEMBLING THE STORAGE KIT (description in the gures

below)

1. remove the U-shaped plate from the structure

2. join together the side containment walls of the S Kit

(1) and screw them onto the structure.

Fix the front section last of all (mounting the cladding),

because the potstone front piece is screwed onto

this.

3. install the two L-shaped brackets (2) for fixing the

rear protective casing.

1.

U-shaped plate

2.

3.

2

4.

1

*

*

3

1

ENGLISH

29

4. IF PURCHASED AS AN OPTIONAL, fit the stone

discs of the storage unit (3) inserting them one on

top of the other

In case of exit rear, dontt use the two

upper discs*

5. re-position the previously-removed U-shaped plate

onto the storage kit.

6. then fit the rear protective casing and proceed with

fitting the cladding in steel or potstone (at which time

the front panel of the S Kit will also be fitted)

5.

6.

1

2

CLADDING

FITTING THE TALLY F, TALLY S AND TALLY UP S STEEL CLADDING

The cladding is in two packs.

One contains:

• 1 rear protective casing (1)

• 2 side panels (2)

• 1 top front panel (3) and, for the Tally UP S model, the front panel for the drawer

• 1 bag of hardware with:

- 22 self-tapping screws in total: for the side panels (4 = 2 per side), for the rear protective casing (10 = 2 for the top

and 4 per side on the brackets), 4 for the top front panel and 4 for the U-shaped plate and 4 additional screws for the

UP version;

- 6 M 4x9 grub screws: 4 to be fixed to the sides of the base for the side panels; 2 for the top

- 2 M 5 grub screws (normally not used)

- 2 M 5 nuts and 1 dome bolt to make the door self-closing (see specific paragraph)

The other pack contains:

- 1 top (4)

- 1 closure cap (5) if the outlet is at the rear

ENGLISH

30

1

5

3

2

4

CLADDING

SUMMARY OF OPERATIONS FOR FITTING THE CLADDING (description in the gures below)

1. Loosen the screws on the bracket fixed to the

structure so as to be able to adjust the protective

casing;

2. insert the rear protective casing

3a. fasten it with 2 screws on the top part

1.

3a.

2.

1

3b. fasten it with 4 screws (2 per side) on the top part

on the bracket fitted with the S Kit

3c. fasten it with 4 screws (2 per side) on the bottom

part of the bracket referred to in point 1.

4. screw the M 4x9 grub screws to the base (two per

side), onto which the side panels will be inserted

3b.

3c.

4.

ENGLISH

31

grub screws

CLADDING

5. insert the front panel (3) from above and screw it on

6. fit the side panels (2) and fasten them with 2 screws

on the top part. Make sure that you insert them at the

bottom onto the previously-attached grub screws

5.

6.

top front panel

food warmer version

3

top front panel storage unit version

3

ENGLISH

32

7. prepare with the grub screws and position the top as

with the base version

Then position the top, on top, centring the grub

8.

screws in the holes on the U-shaped plate. If required,

any alignments can be made with the screw fastened to

the U-shaped plate.

2

7.

Grub screws

CLADDING

ONLY FOR TALLY UP

In addition to what is mentioned in the previous pages

for the Steel Tally Base, the Tally UP has a wood drawer

with a steel front that needs fitting.

A

B

FITTING THE DRAWER CLADDING

• unscrew handle A from the drawer (figure below)

• insert the front panel in steel B

• screw on the front panel B using four screws (two

per side)

ENGLISH

33

CLADDING

FITTING THE TALLY F and S or TALLY UP S STONE CLADDING

The cladding is in two packs:

The protective casing pack contains:

- 1 rear protective casing (1)

1 hardware bag with:

- 2 M 5 nuts and 1 dome bolt to make the door self-closing (see specific paragraph)

- 10 self-tapping screws to fasten the protective casing

The stone piece pack contains:

• 6 lateral elements in stone: four are 48 cm long (2a) and two 78 cm long (2b), and, only for the UP version, an-

other two stone elements (38 cm long) for the drawer

• 2 elements in stone for the front piece (2a)

• 1 top (3)

• 1 top closure cap (4) if the outlet is at the rear

• - 10 brackets for the lateral stone (5)

• 2 Z-shaped stone block brackets (6)

1 hardware bag with:

- 24 screws: 20 for fastening the brackets (2 per bracket) and 4 for fastening the stone block brackets (2 per bracket)

- 24 (spacer) pins to be screwed onto the stone pieces (4 for each stone piece)

- 2 pins to be placed under the top

- 8/4 M 6x8 screws (depending on if it is an S or F model) for the stones of the top front panel

- 8 M 6x8 screws for the UP version

ENGLISH

34

1

4

3

2a

2b

CLADDING

SUMMARY OF OPERATIONS FOR FITTING THE CLADDING (description in the gures below)

1. Loosen the screws on the bracket fixed to the

structure so as to be able to adjust the protective

casing;

2. insert the rear protective casing

1.

2.

1

3a. fasten it with 2 screws on the top part

3b. fasten it with 4 screws (2 per side) on the top part

on the bracket fitted with the S Kit

3c. fasten it with 4 screws (2 per side) on the bottom

part of the bracket referred to in point 1.

3a.

3b.

3c.

ENGLISH

35

4. Prepare the side elements in stone (2a and 2b),

by screwing the pins into the threaded inserts on the

stone.

Tighten or loosen the pins as required to

improve the alignment of the stones. n

case use the thickness too.

4.

CLADDING

5. fit the two parts of the top front panel in stone (the

large one for the S version and small one for the F

version) by screwing the stones to the front wall of the

S Kit

After fitting, it may be necessary to reposition some stones in order to improve

overall alignment.

6. fasten the metal brackets (5 - five per side) with

the self-tapping screws in line with the holes on the

structure.

7. starting at the bottom, insert the side panels onto

the metal brackets (5).

8. block the side panels using the Z-shaped bracket

(6).

5.

6.

7.

8.

(small) top front panel

potstone version food

warmer F

ENGLISH

36

Z-shaped

bracket (6)

lateral stone

bracket (5)

fixed to the

structure

walls of the S Kit

front panel in stone

6

5

5

5

5

5

9. Position the top, on top, centring the locator pins in

the holes on the U-shaped plate.

CLADDING

ONLY FOR TALLY UP IN POTSTONE

In addition to what is mentioned in the previous pages

for the Tally Base, the Tally UP has a wood drawer

including a front with stone pieces that need to be

fitted and screwed on.

A

B

FITTING THE DRAWER CLADDING

• unscrew the handle (A) from the drawer. See figure

below;

• unscrew the bottom front wall (B);

• fasten the stones (C) by screwing them on from

the back

C

ENGLISH

37

B

INSTALLATION

1

2

4

1

SMOKE OUTLET

The stove is prepared for connection of the smoke

outlet tube from the top and back.

The stove is delivered configured for the smoke outlet

pipe from the top.

For smoke outlet from the rear:

- remove the pre-cut diaphragm to the rear (1)

- unscrew the two screws from the smoke coupling

collar on the top of the stove (2) and the two screws

fastening the plug on the rear of the stove (3)

- invert the two parts (smoke coupling collar 2 and plug

3) and screw them back in, paying attention to the seal

- inside the stove packaging there is a metal cover

supplied which should be used to close the smoke

outlet hole on the top (4).

POSITIONING ON THE FLOOR

The stove is not fitted with feet.

You can decide whether to add felt pads to ensure

easier movement of the stove.

Place the stove on a perfectly-flat surface.

ENGLISH

38

In case of exit rear, dontt use the two

upper discs*

4

3

1

INSTALLATION

INTRODUCTION ON INSTALLATION

Remember that:

• the stove must be installed by qualified staff who

can issue a Declaration of Conformity

• all the local and national laws and the European

Standards must be met for installation and use of

the product.

• In the event of installation in apartment blocks, ask

the administrator’s opinion beforehand.

The general instructions are provided below, taking

the Italian standard UNI 10683 as an example and

guideline.

Checking the suitability of the installation

premises

• The volume of the room must be over 15 m

3

• Installation is not permitted in bedrooms,

bathrooms or premises with other products that

take in air for combustion of the same premises

or in premises with an explosive atmosphere. Any

extractor fans, if working in the same environment

or space in which the product is installed, can

cause draft problems.

• In Italy, check compatibility pursuant to UNI 10683

and UNI 7129 in the presence of gas products.

• The floor must be able to support the weight of the

stove and the accessories.

Protection from heat and safe distances

All the surfaces of the building adjacent to the stove

must be protected against heating.The insulation

measurements to implement depend on the type of

surface present.

Distance from flammable materials must be:

- 25 cm from the sides ;

- 20 cm from the back

CHIMNEY SYSTEM

(Smoke channel, chimney ue and chimney

stack)

This chapter is drafted according to the European

Standards EN 13384, EN 1443, EN 1856, EN 1457. The

installation technicians must take into consideration

these and any other local standards. The manual

should in no way be considered a replacement for the

laws in force.

The stove must be connected to a suitable smoke

discharge that guarantees completely safe evacuation

of the smoke produced by combustion.

Before positioning the stove, you need to check the

chimney flue is suitable.

SMOKE CHANNEL, CHIMNEY FLUE

The smoke channel (pipe that connects the smoke

outlet of the fireplace with the chimney flue inlet) and the

chimney flue must, along with other legal provisions:

• receive the discharge for a single product (multiple

product discharges are not permitted together)

• have a mainly vertical development

• no section should have a reserve slope

• have an inner section preferably circular and

however with a ratio between sides lower than 1.5

• complete the roof with the appropriate chimney

stack: direct discharge is forbidden on walls or

towards closed spaces, even if outdoors

• be created with materials with a fire reaction class

A1 pursuant to UNI EN 13501 or similar national

standard

• be appropriately certified, with an appropriate

fireplace plate, if metal

• keep the initial section or change it only immediately

above the stove output and not along the chimney

stack

ENGLISH

39

In the event of installation on a floor with inflammable

material and/or combustible material or with insufficient

capacity, you are advised to position the stove on a

steel or glass plate to distribute the load.Ask the retailer

about the optionals.

INSTALLATION

THE SMOKE CHANNEL

•ifinmetalmusthavea CEmarking(EN1856-2)or

similar national law;

•cannotbeinflexiblemetalmaterial

•

to check the flow, a shutter is advised for draft over

25 Pa

THE CHIMNEY FLUE:

• must have a draft capable of creating negative

pressure ideally around 12 Pa. Lower drafts can

cause leaking smoke if the door is open; higher

values tend to generate fast combustion by

reducing the yield

• must be correctly sized to meet smoke evacuation

(EN 13384-1)

• must preferably be insulated, in steel with a circular

inner section. If rectangular, the inner edges must

have a radius under 20 mm and a ratio between

between the inner dimensions <1.5

• normally have a minimum height of 3.5-4 metres

• maintain a constant section

• be waterproof and thermally insulated to guarantee

draft.

• preferably create a collection chamber for

unburned fuel and any condensate

ENGLISH

• be at least category T400, with an adequate

40

resistance to soot fireIf pre-existing, it must be

cleaned to avoid risk of fire.

EXTERNAL AIR INTAKE

To re-integrate burnt oxygen during stove functioning,

you need to have an installation premises suitable for

the external air intake.The intake must preferably be

installed at floor level and must have a passing surface

of at least 200 cm² (Ø 16).Alternatively, you can take

the air for combustion directly from outside.Connect a

Ø 10 cm tube directly on the back of the stove (1), by

applying a protection grid which must not reduce the

passing useful section.You are advised not to exceed

3 metres in length based on the chimney flue draft.

THE CHIMNEY STACK

• must be wind-proof

• have an internal section equivalent to that of the

chimney flue and passage section outlet equal to

at least double the inner passage of the chimney

flue

• for paired chimney flues (which should be at least

2 m apart) the chimney stack of the chimney flue

receiving the product discharge with solid fuel or

that of the highest floor must be at least 50 cm

taller

• must go beyond the reflux zone

• must enable chimney maintenance

1

ISTRUCTIONS FOR USE

FUEL

The stove was designed to burn wooden logs or

sawdust briquettes.

Use dry wood logs (max. humidity 20%)Use logs with

a maximum length around 33 cm vertically and 25 cm

horizontally and a maximum diameter of 20-30 cm The

use of damp wood would cause the product and the

flue to get dirty, the risk of smoke and a lower yield

than that declared.Each type of wood has different

characteristics that also influence combustion yield.

The data outlined on this manual are with wood used

during certification.

In general wood can have a heat of combustion up to

4.5 kWh/kg while cut fresh it has heat of combustion

around 2 kWh/kg

In general, beech or elm is recommended, or however

class A1 wood according to UNI EN ISO 17225-5

Attention to prolonged use of wood with aromatic oils

(e.g. eucalyptus). Cast iron parts can deteriorate

Use the recommended quantities of wood:

Overloading causes overheating, resulting in damage:

• possible deformation of the inner parts;

• possible irreversible changes to the colour of the

paint on the metal parts

for which Edilkamin or the retailer cannot be held liable.

AIR ADJUSTMENT

Move the air adjustment lever forward or back to allow

more or less combustion air in the combustion chamber.

- “Brazier Maintenance” position (Fig. 1)

Air valve command withdrawn.

This position is used to extend combustion (for example at

night, or when you are not at home) so the product goes to

the minimum, saving fuel and maintaining the flame.

FIG. 1

- Intermediate position (Fig. 2)

Command in intermediate position.

This position allows combustion completion.

ENGLISH

To respect the environment and safety, do NOT burn,

among other things: plastic, varnished wood, coal and

bark waste.

Do not use the stove as an incinerator.

Use of these fuels also nullifies the guarantee.

41

FIG. 2

- “Switch on”/max power position (Fig. 3)

Air valve command totally extracted.It has the purpose of

bringing a large quantity of air in the fireplace to enable

quick and efficient lighting of the fire. Useful to switch on a

cold stove and give maximum power in the fireplace.

FIG. 3

ISTRUCTIONS FOR USE

First switch on phases

• Ensure you have read and understood the content

of this manual

• Remove all the inflammable parts from the product

(manuals, labels, etc.). In particular remove any

labels from the glass. If they melt, they would

irreversibly damage the glass.

For initial switch on of the fireplace, always use the

smallest logs. Use larger wooden logs to raise the fire.

Always locate the wood deep in the fireplace, almost in

contact with the rear wall, so that even if they slide they

won’t come in contact with the glass.

There may be a slight smell of paint the first few times it

is ignited, however, this will disappear quickly.

Lighting a cold replace

1. Check the existing ash bed is not too high. If the

ash bed is too high, there is a danger of opening the

door of the fireplace to add wood and possible brazier

fragments fall out of the fireplace.

2. Position the adjustment lever of the valve in the “total

opening” position. The air for combustion will flow

intensely to the wood in the fireplace, to quickly reach

ENGLISH

good combustion.

42

3. place the wood in the fireplace without excessively

squashing it in. Position a firelighter between the wood

logs and light. Never user materials such as petrol,

alcohol and similar to switch on.

4. At this point, close the door and monitor it for a few

minutes. If the fire should extinguish, slowly open the

door, re-position another firelighter between the logs

and light again.

Lighting a hot replace

When should wood be added? When the fuel is

almost completely consumed to embers. With the

glove supplied, slowly open (to avoid formation of

vortexes that can cause smoke to exit) the door. Add

the desired wood to the fireplace, locating it on the

existing embers (within the quality limits indicated in

the technical table).

Stove functioning changes with the chimney flue draft

and adjustment of the air valve in combustion.

Functioning with initial low draft

To extract air for combustion and discharge the

smoke, the fireplace needs a draft to be exerted on the

chimney flue.

If the draft is weak, initially light a “starter” fire using

small sized lighting material.

Once the correct draft is restored, you can add the fuel.

As with all the products, the wood stove heats and

cools during the various phases. This would lead to

normal dilation. Such dilation can cause slight settling

noise, which is not a reason for dispute.

The hot air reaches the premises with natural motion

(natural convection) without the help of a fan.The

retailer also offers an Air Diffuser kit with fans to

distribute the hot air in the premises.

NOTE FOR UK

Refuelling on to a low fire bed

If there is insufficient burning material in the firebed to

light a new fuel charge, excessive smoke emission can

occur. Refuelling must be carried out onto a sufficient

quantity of glowing embers and ash that the new fuel

charge will ignite in a reasonable period. If there are

too few embers in the fire bed, add suitable kindling to

prevent excessive smoke

Fuel overloading

The maximum amount of fuel specified in this manual

should not be exceeded, overloading can cause

excess smoke.

ISTRUCTIONS FOR USE

Tally is equipped with a piston to enable door closure

return, if opened up to little under 90 °.

Opening over the 90 °, the door will not close.

The Tally stove can be made fully self-closing by

applying a screw in the threaded hole in the figure

below.

SPECIAL FEATURES OF TALLY S AND

TALLY F

The food warmer was designed not as an oven for

baking but simply to heat food.

Ordinary maintenance is recommended with tray

removal.

Tally S accumulation was designed to maintain heat

and diffuse it even when the stove is off.

Accumulation in refractory material absorbs the heat

produced by the stove and gradually releases it in the

premises.

This means you can keep the premises warm for hours

without loading it.

The heat released naturally depends on the previous

loads and the overall installation and use situation.

ENGLISH

43

MAINTENANCE

ATTENTION!

All the cleaning operations of all the parts

should be carried out with the stove completely cooled.

Removing ash

The ash pan is located under the fireplace.It must

absolutely be emptied before the ash reaches the hip.

It should be removed when the stove is cold, for

example each morning before switch on.

Cleaning the glass

You can use specific products to clean the glass (see

our Glasskamin pricelist).

Do not spray the product on painted parts or the seals of the door. An alternative to the product is a rag

soaked in a bit of white ash and a piece of newspaper. Attention, ensure there are no abrasive elements

in the ash that could scratch the glass.

Ceramic glass installed on the products can

resist heat up to approx. 750°C and is tested

and controlled before and after assembly to

check for the presence of cracks, bubbles

ENGLISH

44

and blowing.

The glass, despite its high resistance to temperature, is however a fragile element and

therefore you are advised to move the door

cautiously without banging or forcing it.

Glass, since it is not flexible, can break.

Cleaning the external parts

The covering must be clean without using aggressive

detergents. Do not wet with cold water when the

covering is hot because the thermal shock could

cause damage.

Cleaning the chimney ue

This should be carried out before the use season and

each time you note a layer of soot and tar has formed

inside, a substance that is easily flammable.

Scale, in the presence of high temperatures and

sparks, can catch fire with serious consequences

both for the chimney flue and for the home. You are

therefore advised to clean at least once a year.

IN THE EVENT OF PROBLEMS

IN THE EVENT OF PROBLEMS

1) In case of smoke leaking from the

replace hearth, check if:

Installation is correct (smoke channel, chimney flue,

stack, air intake). The wood used is dry.the door was

opened too quickly

2) In the event of uncontrolled combustion,

check if:

The seals of the fireplace are intact:

The door of the fireplace is closed properly.

3) If the glass gets dirty quickly, check if:

The wood used is dry.

However, consider that after a few hours of work, it is

normal for a light layer of soot to form on the glass.

4) If the chimney flue catches fire or you need to

suddenly extinguish the fire lighting in the fireplace:

• if possible, in safe conditions, remove the ash and

brazier using tools and only touch metal containers

with fireproof gloves.

• in the event of a fire, ask the authorities for help

NOTES ON REFRACTORY MATERIAL

The inner refractory material was designed to resist

normal use.

Its cleaning is ensured by good combustion.The main

damage to refractory material comes from:

• accidental knocks

• use of firelighters which are not ecologicalloading

• wood beyond the recommended amount (1.5

kg/h)

• use of fuel other than that recommended

Edilkamin or the retailer cannot be held liable for

damage caused as described above

DISPOSAL

At the end of its service life, dispose of the product as

required by regulations.

5) In case of odours, check if:

If first switch on: in this case a paint smell is normal.

If the product is dirty or dusty

If you cannot solve the problem, contact

the retailer or, in countries where present,

the authorised Technical Support Centre.

The guarantee is only valid if the product

defect is proven.

ENGLISH

45

*941291-GB*

www.edilkamin.com

cod. 941291-GB 10.16/L

Loading...

Loading...