EdilKamin H2 Oceano 15, H2 Oceano 23, H2 Oceano 28 Installation, Use And Maintenance Manual

H

OCEANO 15-23-28

2

I Installazione, uso e manutenzione pag. 2

UK Installation, use and maintenance pag. 20

F Installation, usage et maintenance pag. 38

E Instalación, uso y mantenimiento pag. 56

D Installations-, Betriebs- und Wartungsanleitung pag. 74

NL Installatie, gebruik en onderhoud pag. 92

SL Vgradnja, uporaba in vzdrževanje str . 110

- 1 -

Dear Sir/Madam

Congratulations and thank you for choosing our product.

Please read this document carefully before you use this product in order to obtain the best performance in complete safety.

For further details or assistance, please contact the DEALER where you purchased the product or visit our website

www.edilkamin.com. and click on DEALERS.

Please note that a quali¿ ed dealer MUST install the ¿ replace as is stipulated in the Italian Ministerial Decree No. 37 ex Italian

Law No. 46/90.

For installations implemented outside Italy, please refer to the local regulations in the country of use.

ENGLISH

NOTE

- After having unpacked the boiler-¿ replace, ensure that its contents are complete and intact (“cold hand” handle, guarantee

booklet, glove, technical data sheet/CD).

In case of anomalies please contact the dealer where you purchased the product immediately.

You will need to present a copy of the warranty booklet and valid proof of purchase.

- Commissioning/ testing

Commissioning and testing must be performed by the DEALER. Failure to do so will void the warranty.

Commissioning, as speci¿ ed in standard UNI 10683 Rev. 2005 (section “3.21”) consists in a series inspections to be

performed with the boiler-¿ replace installed in order to ascertain the correct operation of the system and its compliance to

applicable regulations.

- Incorrect installation, incorrect maintenance, or improper use of the product, shall relieve the manufacturer from any damage

resulting from the use of this product.

- the proof of purchase tag, necessary for identifying the boiler-¿ replace, is located:

- on the top of the package

- in the warranty booklet found inside the ¿ rebox

- on the nameplate af¿ xed on the right side of the device;

This documentation must be saved for identi¿ cation together with the valid proof of purchase receipt. The data contained

therein must be reported when requesting information and made available should servicing be required;

- All images are for illustration purposes only; actual products may vary.

The undersigned EDILKAMIN S.p.a. with head of¿ ce headquarters at Via Vincenzo Monti 47 - 20122 Milano - Italy - VAT 0192220192

Declares under its own responsability as follows:

The wood Thermo Fireplaces illustrated below conforms to Regulation EU 305/2011 (CPR) and to the harmonised European

Standard EN 13229:2001 - A1:2003 - A2:2004 - AC:2006 - AC:2007

THE WOOD THERMO FIREPLACES, trademark EDILKAMIN, called H

2OCEANO 15-23-28

YEAR OF MANUFACTURE: Ref. Data nameplate Declaration of performance (DoP - EK 078-079-080) Ref. Data nameplate

EDILKAMIN S.p.a. will decline all responsability of malfunctioning or damage to the equipment in case of unauthorized substitution, assembly or modi¿ cations of any sort on the said equipment on the part of non-EDILKAMIN personnel.

- 20 -

TECHNICALAND HEATING SPECIFICATIONS

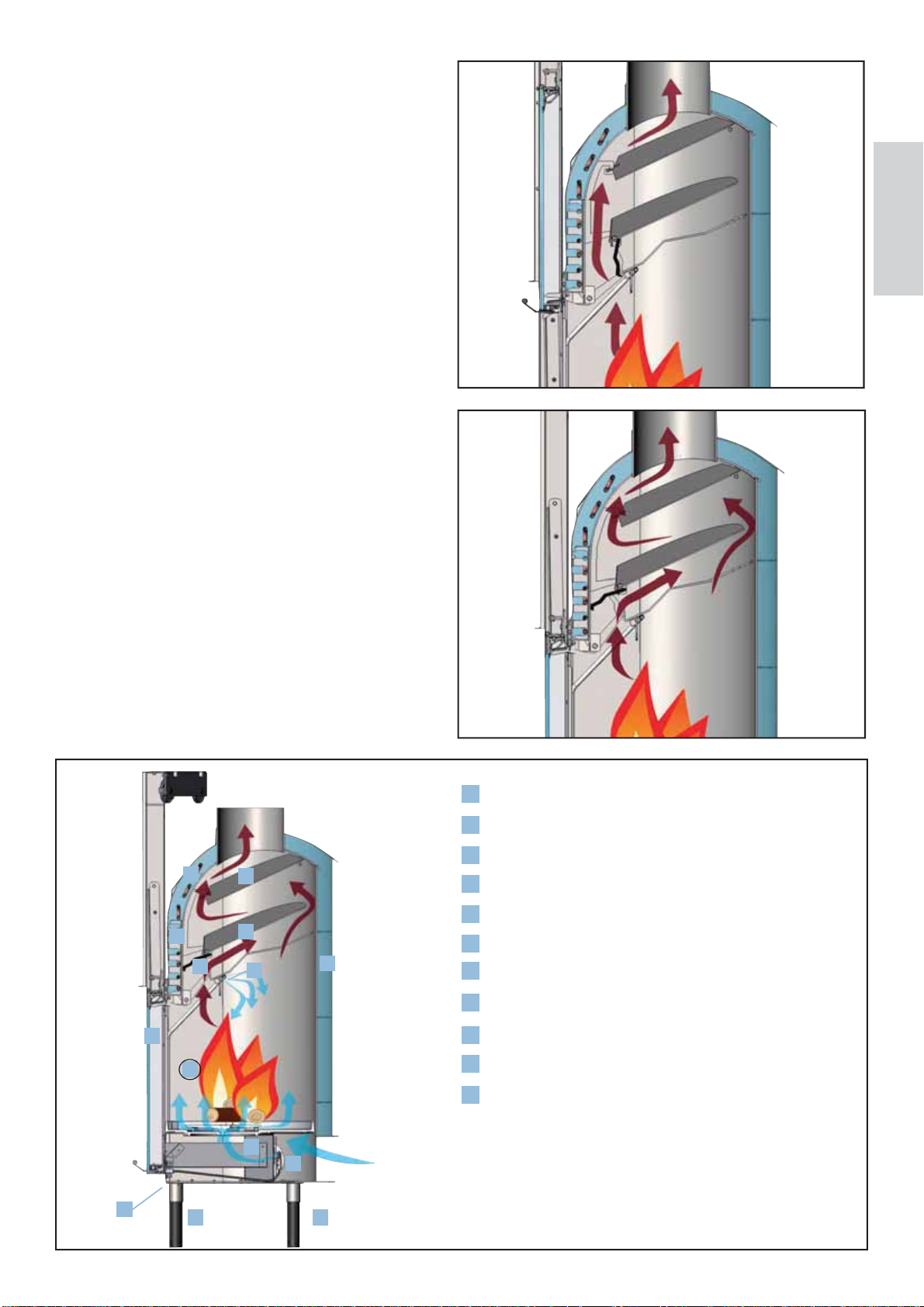

When turning on with the frame open, to facilitate combustion

start-up, the smoke damper (

) remains in the opening position

so that smoke can directly and easily reach the chimney ŏ ue.

When combustion has been started up, the smoke damper

also closes automatically when the door is closed (

- Ŏ g. b

In this mode, before reaching the chimney ŏ ue, the smoke

deviates in such a way to lap and give off heat to the water in

an efŎ cient manner.

The by-pass is automatically controlled by the door’s movement.

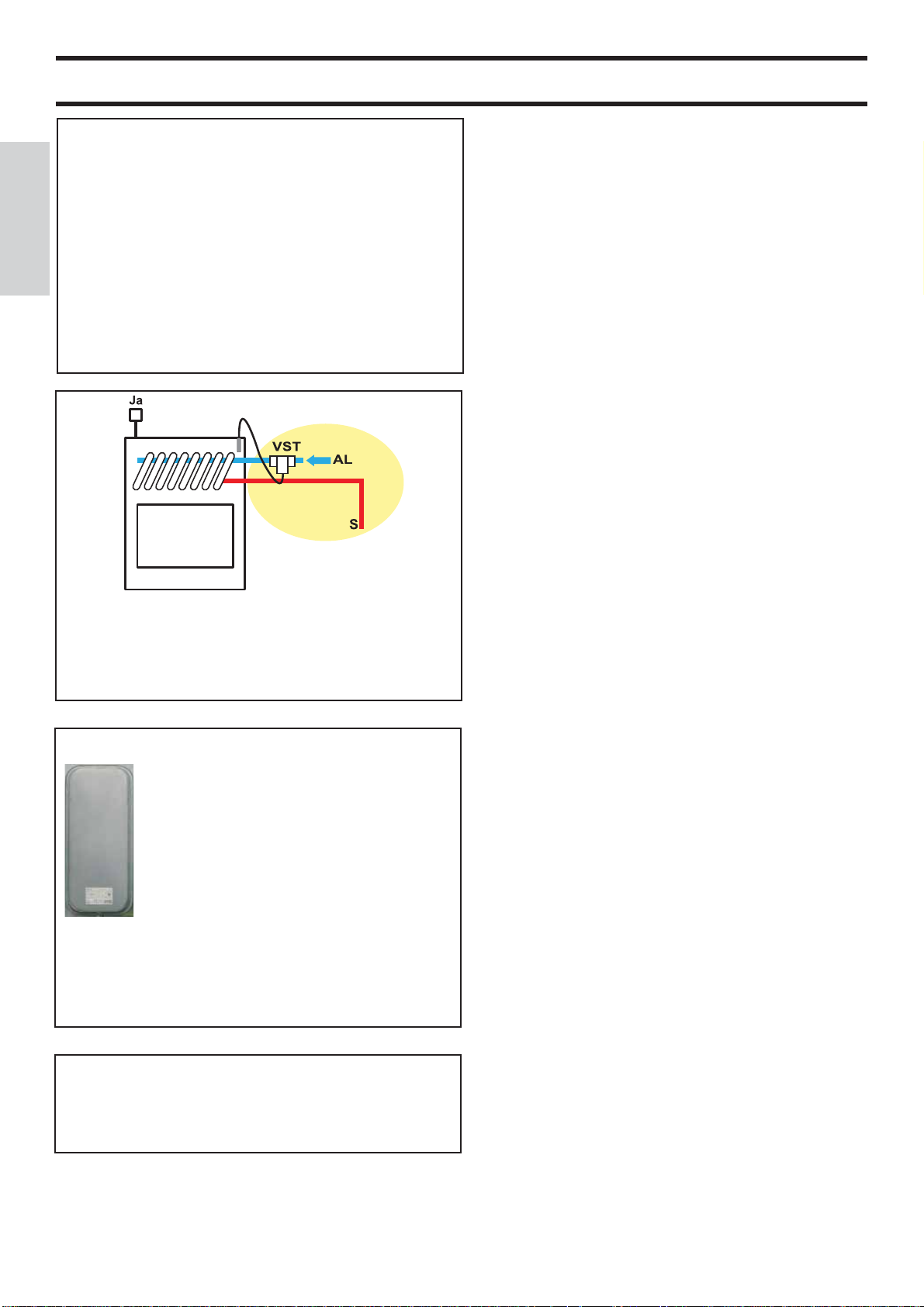

H2OCEANO is designed to heat water by the combustion of

wood in the hearth.

The water contained in the thermo Ŏ replace is heated and sent

into the heating system (radiators, heated towel rails, underŏ o-

or heating panels) and also heats the room in which it is located

via natural convection radiation.

The thermo Ŏ replace MUST NEVER FUNCTION WITHOUT

WATER IN THE SYSTEM.

The water heats up, circulating in the cavity that runs around

the entire semi-circular wall and dome of the hearth.

The hollow space is constructed in thick steel sheet.

The hearth is closed in the front by a door that slides up and

down and side to side for cleaning the glass.

INNOVATIVE PATENTED ASH GRILLE

This allows for the distribution of primary combustion air not

only from the bottom up, but also horizontally to achieve high

oxygenation of the ŏ ame, better combustion and increased power.

“GASKET-SAVING” DOOR

During sliding, the door remains slightly ajar from thermo Ŏ re-

place inlet in order to protect the gaskets. In the closed position

the door is perfectly ŏ anked against the thermo Ŏ replace to en-

sure maximum sealing and therefore optimal performance. The

handle is removable or it can be Ŏ xed to the door (see pg. 29)

(a)

(b)

s

ENGLISH

AUTOMATIC SMOKE BY-PASS

When turning on with the frame open, to facilitate combustion

start-up, the smoke damper (SS

so that smoke can directly and easily reach the chimney ŏ ue.

When combustion has been started up, the smoke damper

also closes automatically when the door is closed (SS

In this mode, before reaching the chimney ŏ ue, the smoke

deviates in such a way to lap and give off heat to the water in

an efŎ cient manner.

The by-pass is automatically controlled by the door’s movement.

) remains in the opening position

- Ŏ g. b))..

H

I

S

A

A

C

H

s

Deŏ ectors/Ceilings

A

Grill motor housing

B

Post-Combustion

C

Automatic external air inlet adjustment valve (optional)

D

Possibility of applying adjustable feet (optional)

E

Calibration for automatic adjustment of combustion air

F

G

Up/down sliding door

H

Enveloping cavity for water containment

Safety coil for thermal relief (CS version)

G

B

L

D

F

E

E

I

L

Primary combustion air distribution ash grille

Smoke diversion damper

S

- 21 -

SAFETY INFORMATION

IMPORTANT: ONLY THERMO FIREPLACES WITH

COILS DRIVEN BY A THERMAL RELIEF VALVE

SHOULD BE INSTALLED ON CLOSED TANK SY-

STEMS (version marked with the abbreviation CS).

• The installer is responsible for the correct installation of the

system, which is to be compliant with UNI standards 10683 –

ENGLISH

9615/90 – 10412:2

• All must be performed by qualiŎ ed personnel according to

Ministerial Decree 37 ex Law 46/90

H2OCEANO MUST NEVER BE MADE TO OPERATE WITHOUT WATER IN THE SYSTEM.

MUST BE MADE WITH A PRESSURE OF ABOUT 1.5 BAR.

IT CAN BE DAMAGED IF IT IS IGNITED WITH NO WATER IN THE SYSTEM.

• The thermo Ŏ replace is designed to heat water by means of

wood combustion in the hearth.

• The only hazards that can derive from using the thermo Ŏ re-

place pertain to non-compliance with the installation instructions, direct contact with live electrical parts (inside), contact

made with the Ŏ re and hot parts or foreign substances being put

in the Ŏ replace.

• For the thermo Ŏ replace to function properly installation

must be carried out according to the instructions given in this

booklet and the door must only be opened to reŎ ll the hearth

with wood.

• Never put foreign substances in the hearth.

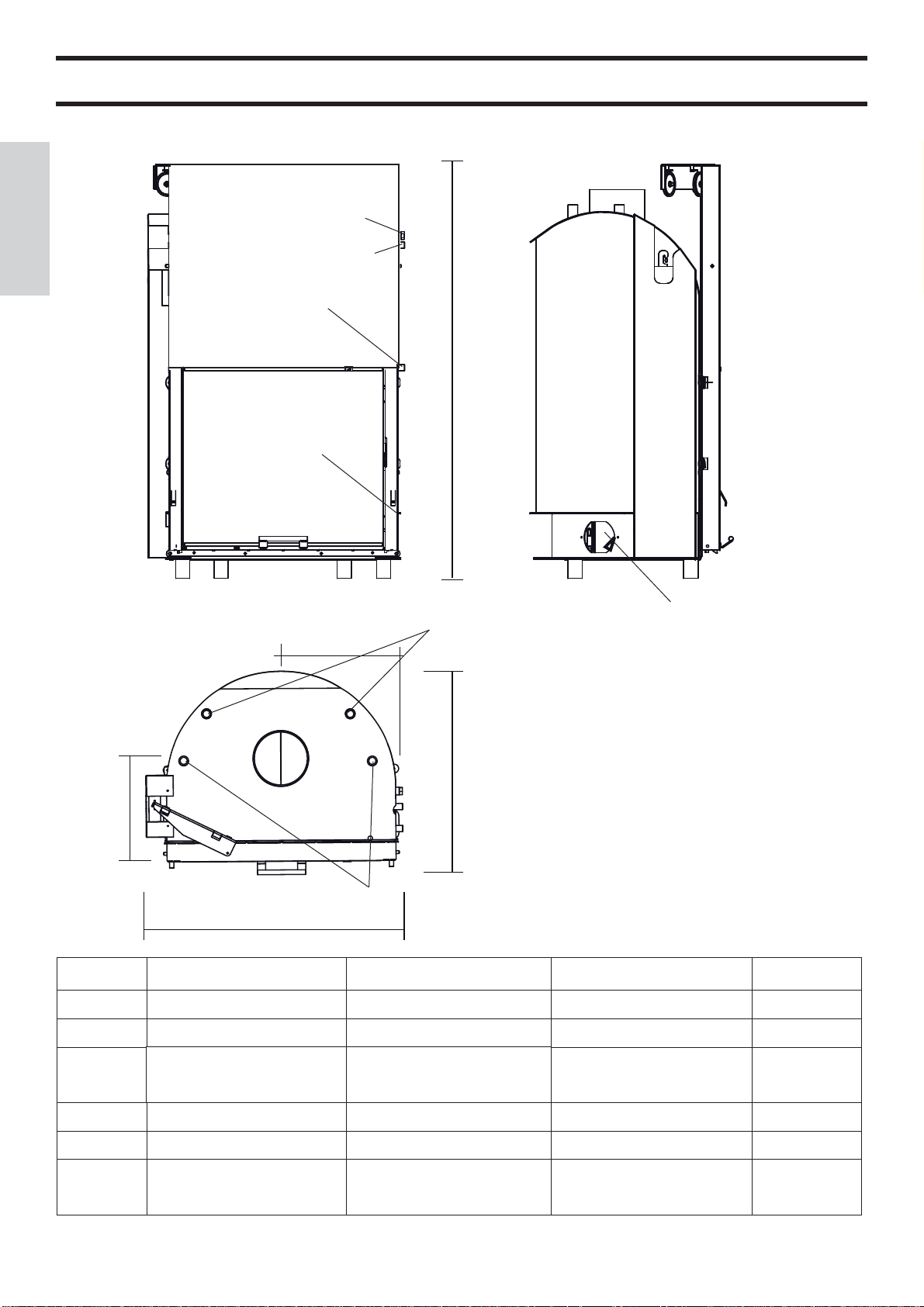

The thermal relief valve (TRV - provided by Edilkamin) must

be connected to the cooling circuit (AL) with a minimum

pressure of 1.5 bar.

JA = automatic relief valve

S = drain

Litres ?

• The heating system must include an expansion tank dedicated

only to the thermo Ŏ replace, evaluated based on the volume of

water present in the system itself (an expansion tank shared with

other generators is not allowed).

• Whilst functioning, the door must never be opened. In fact,

combustion is fully automatic and requires no manual interven-

tion.

• Do not use ŏ ammable products to clean the smoke channel

(the ŏ ue section connecting the boiler-Ŏ replace smoke outlet to

the chimney ŏ ue).

• The glass can be cleaned when COLD with a suitable product

(e.g. GlassKamin) and a cloth. Do not clean when hot.

• The exhaust pipes and the door become very hot when the

thermo Ŏ replace is used.

• Do not place anything that is not heat resistant close to the

thermo Ŏ replace.

• NEVER use liquid fuel to ignite the thermo Ŏ replace or to

rekindle the embers.

• Do not obstruct the external air inlets in the room where the

Ŏ replace is installed or the air inlets of the thermo Ŏ replace

itself.

• Do not wet the thermo Ŏ replace and do not go near the elec-

trical parts of the system with wet hands.

1 Year

• The safety and thermal relief valves must be checked at least

once a year by qualiŎ ed personnel according to Ministerial De-

cree 37 ex Law 46/90.

• Do not use reducers on the smoke exhaust pipes.

• The thermo Ŏ replace must be installed in a place that is sui-

table against Ŏ re hazards and equipped with all that is required

(power and air inlets/outlets) for it to function properly and

safely.

- 22 -

GENERAL SAFETY REGULATIONS

IN CASE OF INSTALLATION ON OPEN

TANK SYSTEMS

The connections, commissioning and veriŎ cation of proper

operation of the thermo Ŏ replace must be carried out by quali-

Ŏ ed personnel, who can implement all connections in accordance with the laws in force, particularly with Italian D.M 37

Law No. 46/90, apart from complying with these instructions.

For installations implemented outside Italy, please refer to the

local regulations in the country of use.

The thermo Ŏ replace and the system are Ŏ lled with water that

ŏ ows from the water inlet pipe (the diameter must not be less

than 18 mm) to the open expansion tank.

All the vents of the radiators must be opened during this

phase so as to prevent air pockets from forming in the system,

which would obstruct the circulation of water.

NB:

• The open tank should be positioned at a height greater than

3 m higher than the highest component of the primary circuit

and less than 15 m from the edge of the thermo Ŏ replace.

IN CASE OF INSTALLATION ON CLOSED

TANK SYSTEMS

(provisions in addition to those provided for open tank

systems)

• Be careful not to exceed 1.5 bar when Ŏ lling the system.

• Only if a thermal relief valve actuates the coil can the

Ŏ replace be installed on a CLOSED TANK system (version

marked with the abbreviation CS).

• When connecting a thermo Ŏ replace to an existing system,

an assessment must be made regarding a need for another

CLOSED TANK on the system.

- The upstream pressure of the cooling circuit must be at least

1.5 bar (UNI 10412/2 point 6.2).

ENGLISH

• In any case, the tank must be high enough to create a greater

pressure than that produced by the pump (circulator).

• The system must never be Ŏ lled directly from the water

mains as the pressure may be greater than that stipulated on

the data plate of the thermo Ŏ replace, with resulting damage

to the thermo Ŏ replace itself.

• The safety pipe to the expansion tank must allow the water

to ŏ ow freely without shut-off valves and be appropriately

insulated to prevent the water inside from freezing, which

would compromise the connection.

• The water inlet pipe must not have taps nor curves.

• The maximum operating pressure must not exceed 1.5 bar

• The testing pressure is 3 bar.

• It is a good idea to add an anti-freeze liquid to the water

contained in the system or to observe standard UNI 8065.

• Never ignite the Ŏ re in the thermo Ŏ replace (not even as a

test) unless the system is Ŏ lled with water as this could cause

irreparable damage.

• Connect the drains of the thermal relief valve (TRV) and

the safety valve (SV) (diagrams are found on the following

pages).

• The ŏ ow test of the system must be carried out with the

expansion tank open.

• It is recommended to install a 6 bar safety valve on the hot

sanitary water circuit so as to drain any excessive increase in

the volume of the water in the heat exchanger.

• Place all the components of the system (circulator, heat

exchanger, valves, etc.) in easily accessible points for routine

and special maintenance procedures.

WATER TREATMENT

If need be, antifreeze, descaling and anticorrosive solutions

are to be added to the water.

A softener must be used if the hardness of the water used to

reŎ ll and top-up the system exceeds 35°f (French degrees).

Please refer to UNI 8065-1989 standard (water treatment in

domestic heating systems).

- 23 -

DIMENSIONS

FRONT SIDE

well for probe

ENGLISH

SYSTEM

thermal relief coil ŏ ow 1/2” M

(closed tank version)

thermal relief coil return 1/2” M

(closed tank version)

H

drain

combustion air

water return to system 1” M

X

P

Y

water ŏ ow to system 1” M

L

H2OCEANO 15 - 15/CS H2OCEANO 23 - 23/CS H2OCEANO 28 - 28/CS

L 74 88 106 cm

P62 68 83cm

H

X34 34 51cm

Y36 37 50cm

internal

hearth

dimensions

135 without feet

(with feet + 14 cm)

50x38 60x50 78x60 cm

147 without feet

(with feet + 14 cm)

147 without feet

(with feet + 14 cm)

cm

THE INLET AND OUTLET PIPES MUST BE CROSSED FOR THIS TO FUNCTION PROPERLY

- 24 -

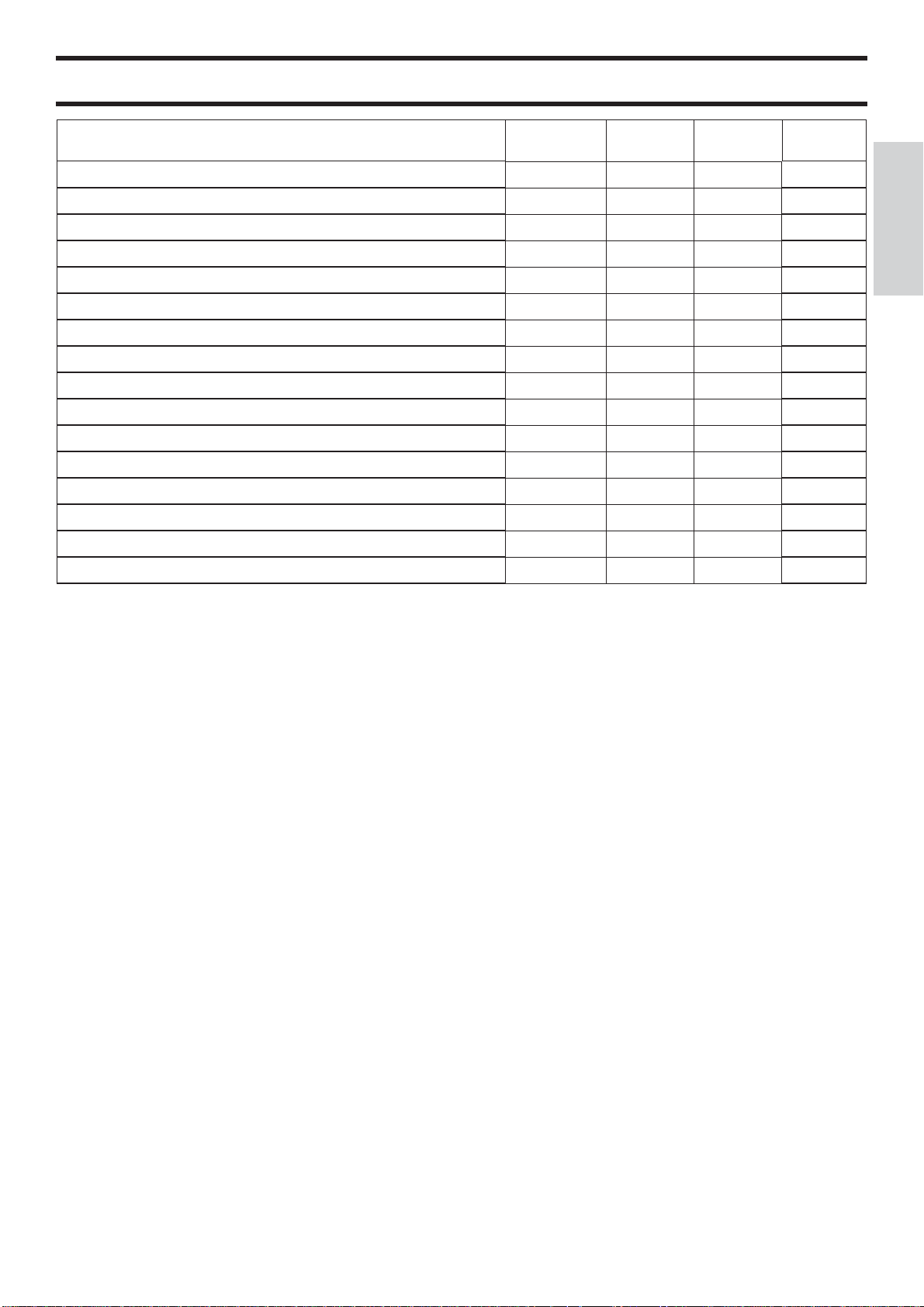

TECHNICALAND HEATING SPECIFICATIONS

15-15/CS 23-23/CS 28-28/CS

Thermal output (burnt) 18,5 27,8 34,8 kW

Rated power 14,8 22,2 27,8 kW

Water heating power 12,1 18,2 22,8 kW

Approx. overall efŎ ciency 80 80 80 %

Approx. water efŎ ciency 82 82 82 %

Class efŎ ciency (EN 303-5) > 3 > 3 > 3 -

ø female smoke outlet 18 22 25 cm

Maximum operating pressure 1,5 1,5 1,5 bar

Fuel consumption 4,5 7 8,5 kg/h

Water capacity 50 100 130 litres

Heating capacity * 355 535 670 m³

Weight including packing 240 285 325 kg

Hot sanitary water production (kit 1- 3 - N3 - N3bis)** 13-14 13-14 13-14 litres/min

ø external air inlet 12,5 12,5 12,5 cm

ENGLISH

System return (male) 1” 1” 1” inches

System ŏ ow (male) 1” 1” 1” inches

N.B.: DATA PROJECT (Refer to standard EN 13229)

* The heatable room dimensions are calculated on the basis home insulation in compliance with Italian law 10/91, and subsequent

changes together with an expected heat output of 33 Kcal/m³ per hour.

* It is also important to consider the position of the boiler-Ŏ replace in the room to be heated.

* * boiler temperature is 70° - (ðT=25K)

THE DIAMETER OF THE CHIMNEY FLUE TO BE USED MUST BE ASSESSED BY THE INSTALLER ACCORDING TO THE HEIGHT OF THE CHIMNEY FLUE ITSELF.

THE INLET AND OUTLET PIPES MUST BE CROSSED FOR THIS TO FUNCTION PROPERLY

The data shown above is purely indicative.

EDILKAMIN s.p.a. reserves the right to change the products at its discretion without notice.

- 25 -

INSTALLATION

NO

IMPORTANT ADVICE REGARDING THE

INSTALLATION

Other than that described in this documentation, you are also

asked to note the following UNI standards:

- No. 10683 - Ŏ rewood heat generators:

installation requirements

- No. 9615/90 - calculating the internal dimensions of Ŏ replaces

- No. 10412:2 - hot water heating systems.

ENGLISH

SpeciŎ c safety requirements for systems provi

ded with residential solid fuel burning applian

ces and combined boiler, not exceeding a total

nominal heat input of 35 kW.

Particularly:

- Before carrying out any assembly it is important to verify

compatibility of the appliance, as stipulated in UNI 10683

standard, paragraphs 4.1 / 4.1.1 / 4.1.2.

- When assembly is completed, the installer must implement

“start-up operations” and issue documentation as required

by UNI 10683 standard in paragraphs 4.6 and 5, respectively.

- The connections, commissioning and veriŎ cation of pro-

per operation of the thermo Ŏ replace must be carried out

by qualiŎ ed personnel, who can implement the electrical and

plumbing connections as required by UNI standards 10683,

paragraph 4.5 and 10412:2, apart from complying with these

assembly instructions.

- VeriŎ cation must be carried out with the Ŏ replace on and

after having been on for a couple of hours, before covering the

thermo Ŏ replace, so that you can intervene if need be.

After which, the Ŏ nishing operations such as:

- setting-up the Ŏ replace mantel

- mounting the Ŏ replace covering

- pilasters, painting, etc.

are carried out, once the tests are completed successfully.

Consequently, EDILKAMIN does not accept responsibility for

expenses deriving from demolition as well as construction even

if either occurs as a result, after having replaced any damaged

parts of the thermo Ŏ replace.

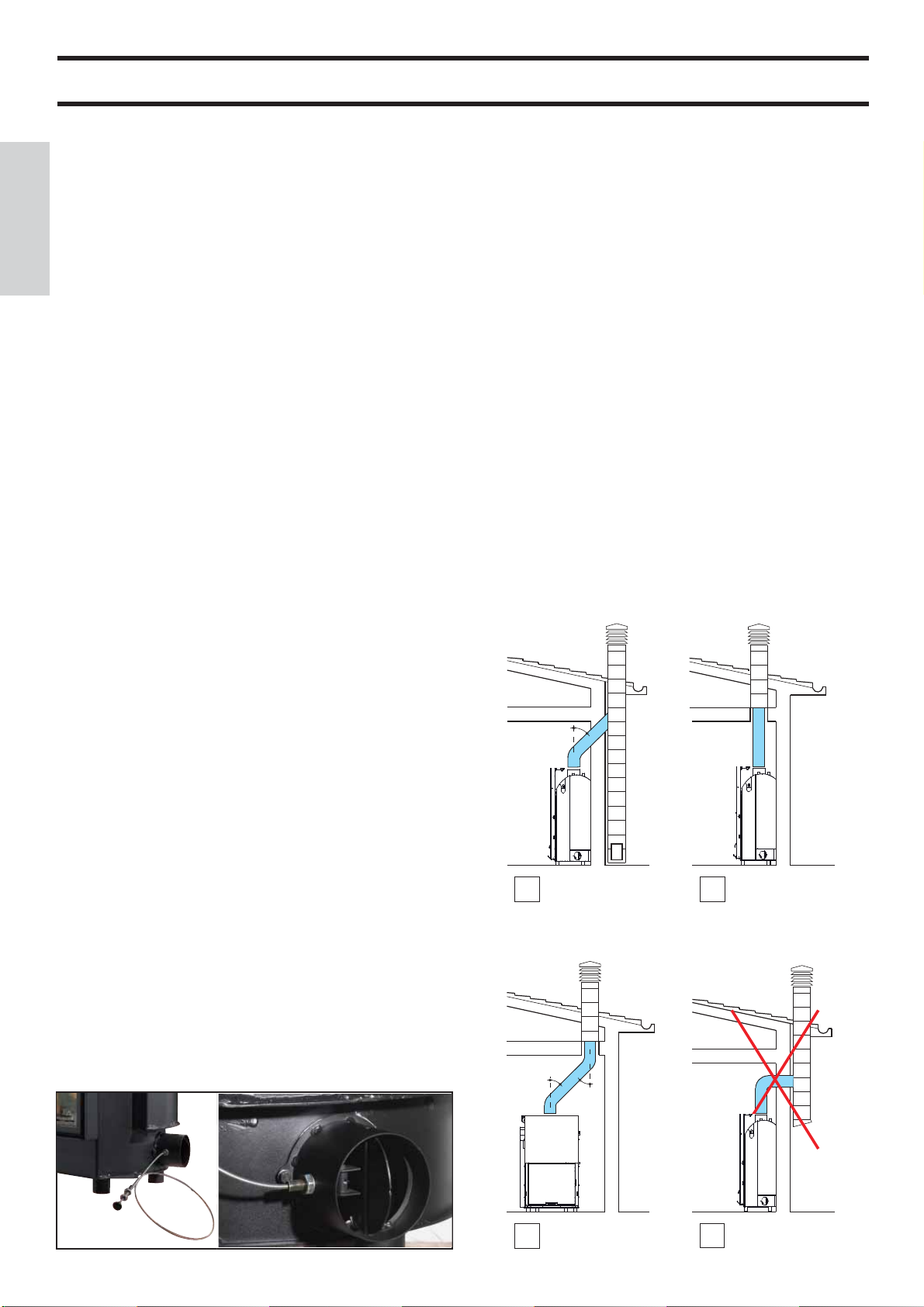

CHIMNEY FLUES AND CHIMNEYPOT

The thermo Ŏ replace smoke outlet has a circular crosssection

so that stainless steel pipes can be used. If the chimney ŏ ue

inlet is not vertically above the thermo Ŏ replace, the connection

from the Ŏ replace to the ŏ ue must not have a narrowing

section or inclinations greater than 45° (Ŏ g. 1-2-3-4).

If the chimney ŏ ue is not brand new or too big, it is recommen-

ded to Ŏ t in stainless tubes of an appropriate diameter and with

suitable insulation.

If the chimney ŏ ue is installed outside, it is recommended to

use an insulated, double walled, stainless steel ŏ ue.

The characteristics of the construction must be suitable to

withstand a smoke temperature of at least 450° C, with particular reference to the mechanical resistance, insulation and the

gas tight sealing.

The junction of the steel ŏ ue inlet and the smoke outlet of the

Ŏ replace must be sealed with high temperature mastic.

The fundamental characteristics of the chimneypot are:

- an internal cross-section at the base, which is the same as that

of the chimney ŏ ue.

- an outlet cross-section which is no smaller than twice that of

the chimney ŏ ue.

- its position must be high enough to catch the wind and avoid

downdraft areas in turbulent wind.

In addition to that mentioned above, please consider the

indications stipulated in UNI 10683/2005 standard, paragraph 4.2: “connection to the smoke outlet system” and its

subsections.

max.45°

EXTERNAL AIR INLET

An external connection with a 12,5 cm diameter crosssection throughout (refer to the technical table) is absolutely

necessary for the thermo Ŏ replace to function properly and

is therefore imperative for this to be implemented.

This connection must link the air adjustment mechanism (E),

delivered separately. The mechanism, delivered separately,

can be assembled either right or left of the thermo Ŏ repla-

ce. Connection can be made with a ŏ exible aluminium pipe.

Ensure that the points where there may be dispersion of air are

sealed well. The air adjustment mechanism (E) can be removed and mounted on the right side of the thermo Ŏ replace. It is

recommended to place a protection grille on the outer part of

the air inlet channel, however, ensure that this does not reduce

the cross-section. For distances longer than 3 m or with bends,

increase the given cross-section by a minimum of 10% to a maximum of 20%. The intake of external air must enter at ŏ oor

level (it cannot enter from above).

E

E

- 26 -

3

1

45°

45°

2

4

INSTALLATION

If combining with a pre-fabricated Edilkamin covering, to deŎ -

ne the exact positioning of the thermo Ŏ replace, it is important

to take the chosen covering model into consideration.

The positioning is implemented according to the model chosen

(refer to the installation instructions found inside the packaging

of each thermo Ŏ replace covering).

Always ensure the thermo Ŏ replace is level during the installa-

tion process.

- Drill a hole into the wall or the ŏ ooring for the external air

intake and connect the air adjustment mechanism to the hole as

described in the chapter called “external air inlet”.

- Use a stainless steel ŏ ue to connect the thermo Ŏ replace to the

chimney ŏ ue, adhering with the diameters indicated in the spe-

ciŎ cations table and the guidelines given in the chapter called

“chimney ŏ ues”.

- Verify that all moving parts function properly before setting

the thermo Ŏ replace covering in place.

- This system must be tested and ignited for the Ŏ rst time

before the covering is set in place.

INSTALLATION COVERING, FIREPLACE MANTEL AND VENTILATION OUTLETS

The base of the thermo Ŏ replace covering must allow the

internal air to be recycled. Therefore, suitable slots or apertures

must be made for the air to pass through. Parts of the thermo

Ŏ replace covering that are made of marble, stone and bricks

must be mounted with a small gap between them and the Ŏ re-

place so as to prevent possible breakage due to expansion and

excessive overheating.

Wooden parts must be protected by Ŏ re resistant panels and

no part must touch the thermo Ŏ replace, on the contrary, there

must be an appropriate distance of at least 1 cm to allow the

air to ŏ ow, preventing heat accumulation. The Ŏ replace mantel

can be made of Ŏ reproof plasterboard panels or gypsum board

and, however, of completely Ŏ reproof material. Air should be

allowed to ŏ ow inside the Ŏ replace mantel (through the gap

between the door and the beam). Through convective motion,

the air will ŏ ow out from the grille installed at the top, resulting

in heat recovery and preventing excessive overheating.

The Ŏ replace mantel must have appropriate openings to carry

out maintenance on the Ŏ ttings.

In addition to that mentioned above, please consider the indications stipulated in the UNI 10683 standard, paragraphs

4.4 and 4.7: “insulation, Ŏ nishing, Ŏ replace covering and

safety recommendations”.

Insulating mats must be applied when using an installation

KIT so as to protect it from the heat radiation emitted by

the thermo Ŏ replace.

INLET FRAME (OPTIONAL)

To facilitate coupling with the covering’s components, the thermo Ŏ replace can be Ŏ tted with a frame (A) to be applied on the

front of the inlet.

Plasterboard

A

ENGLISH

INSTRUCTIONS FOR USE

Practical advice

It is recommended to keep the radiators closed in the room

where the thermo Ŏ replace is installed; The heat emitted from

the outlet may be sufŎ cient to heat.

- An incomplete combustion process causes excessive fouling

on the heat exchanger pipe.

To prevent this you must:

- burn dry wood.

- ensure the hearth contains a bed of embers and burning carbon before adding more wood.

- place larger logs together with smaller ones.

- make sure the temperature of the return water is at least 50 °C

(use temperature control valve).

Igniting the Ŏ replace

- Ensure that at least one radiator is always open.

- Actuate the switches of the electronic regulator.

- Place a pile of medium-thin dry wood in the thermo Ŏ replace

and ignite the Ŏ re.

- Wait a few minutes until it reaches sufŎ cient combustion.

- Close the door

- Set the thermostat on the electronic regulator (*) at a temperature between 50 and 70° C.

NOTE: There may be a slight smell of paint the Ŏ rst few times

it is ignited, however, this will disappear quickly.

A

3-way valve

- During ignition the 3-way valve (*) diverts the ŏ ow of water,

forcing it to return directly to the thermo Ŏ replace;

when the set temperature is reached, the 3- way valve (*)

diverts the ŏ ow to the system (does not depend on the kit

installed).

By-pass damper

- When the door is closed, the by-pass damper automatically

diverts smoke, thus improving efŎ ciency.

- When the door is opened, the damper bypass opens automatically, allowing the smoke to reach the smoke ŏ ue directly,

preventing it from coming out of the inlet.

Thermal Relief Valve

If the water temperature exceeds 90° C (e.g. because of too

much wood being placed in the hearth) the thermal relief valve

will be activated and the acoustic signal triggered.

In this case you must proceed as follows:

Do not load additional fuel and wait for the temperature to fall

below 80°C checking the warning lights on the electronic regulator. The hot water tap can be opened to speed up the cooling

process if the thermo Ŏ replace is equipped with a hot sanitary

water production KIT.

(*) these components of the system are to be provided by the installer.

- 27 -

INSTRUCTIONS FOR USE

E

ENGLISH

Ŏ g. 1

External air regulation

The control, via the dedicated damper (E- Ŏ g. 1) located on the

external air intake, regulates the quantity of primary air necessary for combustion.

Push the knob to close the external air intake; pull the knob to

open the external air intake.

OPTIONAL THERMOSTATIC VALVE (FIG. 2)

Manual adjustment of combustion air (to be carried out

during installation)

To obtain the desired water temperature, manually calibrate the

thermostatic valve.

Using the Allen supplied (X - Ŏ g. 3) it is possible to regulate

the thermostatic valve using the screw located just below the

ash pan (Y - Ŏ g. 3).

• Screw on RT: combustion air on minimum

• Screw all the way to the LT: combustion air on maximum

• obviously, all intermediate settings are possible

NOTE: If a thermostatic valve must be installed, you must remove the manual air intake damper by removing the valve and

the cable with the knob (E- Ŏ g. 1).

Automatic adjustment of combustion air

The combustion air is captured by the external air intake via the

outlet (E - Ŏ g. 1) and reaches the hearth through the ash grille.

This is adjusted using valve V (Ŏ g. 2).

If the temperature inside the hearth is low,compared to that set

during calibration, the valve automatically positions itself in

the open position and vice versa, it closes when the temperature

is high.

This allows the right quantity of wood to be consumed for the

set thermal comfort to be reached and unnecessary waste is

avoided.

NOTE: when the thermostatic valve fully closes the combustion air inlet completely (the temperature in the hearth is very

high), limited but sufŎ cient access is allowed for the air to

enter and keep the glass clean.

Installation of thermostatic valve “V” is optional.

All operations must be performed with the thermo Ŏ re-

place off and fully cooled.

The mains power must also be disconnected.

Proceed as follows:

- Open the door and block it in the open position in order

to easily work inside the hearth (Ŏ g. 4).

- Remove the following components (Ŏ g. 5):

• ash pan

• cast iron grille

• hearth base

Note: The hearth base is only on rested on the gasket,

therefore to remove it simply lift it up (keep in mind that

if the thermo Ŏ replace has been used for a long period of

time there may be signiŎ cant adhesion between hearth

base and hearth).

- Install the pre-assembled thermostatic valve on the

Ŏ xing pate (Ŏ g. 6 - pg. 29).

- Secure the plate with the three screws supplied (S) to

the bottom of the hearth (Ŏ g. 7 - pg. 29).

Before Ŏ xing, make sure to pass the adjustment cable and

the probe wire through the prepared slots.

- The adjustment cable must be inserted into the front

hole under the ash pan (Ŏ g. 8 - pg. 29), and secured in

position using the elastic ring supplied.

- The probe wire must be unwound along the right side of

the ash pan proceeding then to the outside of the thermo

Ŏ replace (Ŏ g. 9 - pg. 29) via the hole on the right side.

- At this point insert the probe in the well on the thermo

Ŏ replace (pg. 24).

- Before putting back the hearth base check the wear condition of the gasket (if necessary replace it) and insert the

gasket on the perimeter of the Ŏ xing plate of the thermo-

static valve (Ŏ g. 8 - pg. 29).

Ŏ g. 2

Ŏ g. 3

V

Ŏ g. 4

Y

X

Ŏ g. 5

- 28 -

REAR VIEW

INSTRUCTIONS FOR USE

Probe positioning for OPEN TANK version

probe wire

ENGLISH

S

Ŏ g. 6

Ŏ g. 7

S

adjustment cable

S

adjustment cable

S

gasket

S

Ŏ g. 10

Probe positioning for CLOSED TANK version

First insert the probe for the temperature relief valve, then the

probe for the thermostatic valve.

S

Ŏ g. 12

Ŏ g. 11

Ŏ g. 13

Ŏ g. 8

Ŏ g. 9

adjustment cable

probe wire

probe wire

Ŏ g. 14

Ŏ g. 15

- 29 -

INSTRUCTIONS FOR USE

Door opening

- Use the provided removable handle to open the door (Ŏ g. 16).

- The same handle can be Ŏ xed to the door using the 2 grub

screws supplied.

ENGLISH

Ŏ g. 16

Installing counterbalances

The latch door is equipped with counterbalances which ensure

smooth movements as well as closure of the door.

The counterbalances can be regulated by adding platte/s

(additional counterbalances) that are supplied with the thermo

Ŏ replace (P - Ŏ g. 17).

P

Ŏ g. 17

MAINTENANCE

Cleaning the hearth

- The soot deposits that tend to accumulate on the internal walls

of the hearth decrease the efŎ ciency of heat transfer.

- It is therefore necessary to clean the Ŏ replace regularly, by

bringing the water temperature to 80 / 85° C to soften the fouling and then remove this with a steel spatula.

Glass cleaning

- Use an appropriate spray for ceramic glass to clean the glass

(Glasskamin - Edilakmin)..

- The glass must be cleaned when cold.

- For the opening swing of the door it is necessary to bring it in

the closed position.

- Insert the “cold handle” door handle on the latch between the

structure and the door and turn to open (Ŏ g. 18).

Ŏ g. 18

- 30 -

SYSTEM FOR AN OPEN TANK INSTALLATION

AN EXAMPLE OF A HYDRAULIC SYSTEM FOR A THERMO FIREPLACE WITH HOT SANITARY WATER PRODUCTION USING

Electricity

Mains

KIT 1

Safety pipe Ø> 28mm

Inlet pipe Ø> 18mm

Collector

ACS: Hot Sanitary Water

AF: Cold Water

EV: 3-way Solenoid Valve

F: Flow Switch

MI: System Flow

NA: Normally Open

NC: Normally Closed

P: Pump (circulator)

RA: Radiators

RE: Electronic Regulator

RI: System Return

S: Drain

Sc 20: 20-plate Heat Exchanger

ST: Temperature Sensor

TC: Thermo Fireplace

V: Valve

VE: Open Expansion Tank

VSP: 1.5 bar Pressurized Safety Valve

VST: Thermal Relief Valve

Ja: Automatic Relief Valve

Kit 1 is designed to facilitate the work carried out by the installers. In fact, it consists of all the necessary components for the

product to be properly installed.

NB: insulating mats must be applied so that the components of the kit are well-protected from the heat radiation emitted

by the thermo-Ŏ replace.

1. 1” Male-Female Brass Collector

2. 1” Ball Valve

3. Circulator with 1½” Fasteners (219660)

4. 1” Check Valve (261910)

5. 1” Male-Female 3-way Solenoid Valve

(143330)

6. Copper Fittings

7. 30-plate Heat Exchanger for heat transfer

with the gas boiler circuit (216620)

8. 20-plate Heat Exchanger for hot sanitary

water production (205270)

9. ¾” Thermal Relief Valve (72940)

10. ¾” 1.5 bar Safety Valve (143260)

11. Flussostato (220830)

12. ½” Thermometer Well + Sensor (175960)

13. Electronic Regulator (220780)

A ¾” System Return

B ¾” System Flow

C ¾” Fireplace Return

D 1” Fireplace Flow

E ½” Cold Sanitary Water

F ½” Hot Sanitary Water

20-plate heat

exchanger

Regulator

(included in the kit)

ENGLISH

Electrical Connections

Power Supply

230 Vac

Fuse

Circulator enabled

Overheating alarm

3-way valve

Display

20 - 80° C

Valve Setting

20 - 80° C

Circulator Setting

OFF

ON

Enable

Disable

Acoustic

Alarm

Sensor (insert in the

appropriate well)

SELECTOR FUNCTIONS

Selector: OFF Everything is switched off

Selector: MAN Driven Circulator

Valve is set

Selector: AUTO Circulator is set

Valve is set

Alarm selection No acoustic signal in the

OFF position

Circulator

Flow Switch

Attention: Connect the normally

3-way valve

closed contact

KIT 1 code 261880

THE INLET AND OUTLET PIPES MUST BE CROSSED FOR THIS TO FUNCTION PROPERLY

- 31 -

SYSTEM FOR AN OPEN TANK INSTALLATION

AN EXAMPLE OF A HYDRAULIC SYSTEM FOR A THERMO FIREPLACE THAT DOES NOT PRODUCE HOT

SANITARY WATER BUT HAS A WALL MOUNTED BOILER USING

ENGLISH

Electricity

Mains

Safety pipe Ø> 28mm

Inlet pipe Ø> 18mm

KIT 2

AF: Cold Water

CA: Wall Mounted Boiler

MI: System Flow

P: Pump (circulator)

RA: Radiators

RE: Electronic Regulator

RI: System Return

S: Drain

Ja: Automatic Relief Valve

Sc 30: 30-plate Heat Exchanger

ST: Temperature Sensor

TC: Thermo Fireplace

V: Valve

VE: Open Expansion Tank

VR: Check Valve

VSP: 1.5 bar Pressurized Safety Valve

VST: Thermal Relief Valve

Collector

Kit 2 is designed to facilitate the work carried out by the installers. In fact, it consists of all the necessary components for the

product to be properly installed.

NB: insulating mats must be applied so that the components of the kit are well-protected from the heat radiation emitted

by the thermo-Ŏ replace.

1. 1” Male-Female Brass Collector

2. 1” Ball Valve

3. Circulator with 1½” Fasteners (219660)

4. 1” Check Valve (261910)

5. 1” Male-Female 3-way Solenoid Valve

(143330)

6. Copper Fittings

7. 30-plate Heat Exchanger for heat transfer

with the gas boiler circuit (216620)

8. 20-plate Heat Exchanger for hot sanitary

water production (205270)

9. ¾” Thermal Relief Valve (72940)

10. ¾” 1.5 bar Safety Valve (143260)

11. Flow Switch (220830)

12. ½” Thermometer Well + Sensor (175960)

13. Electronic Regulator (220780)

A ¾” System Return

B ¾” System Flow

C ¾” Fireplace Return

D 1” Fireplace Flow

E ½” Cold Sanitary Water

F ½” Hot Sanitary Water”

30-plate heat

exchanger

Regulator

(included in the kit)

Electrical Connections

Power Supply

230 Vac

Fuse

Circulator enabled

Overheating alarm

3-way valve

Display

20 - 80° C

Valve Setting

Minimum temperature

setting for circulators to

be actuated 20 – 80° C

OFF

ON

Enable

Disable

Acoustic

Alarm

Sensor (insert in the

SELECTOR FUNCTIONS

Selector: OFF Everything is switched off

Selector: MAN Driven Circulator

Valve is set

Selector: AUTO Circulator is set

Valve is set

Alarm selection No acoustic signal in the

OFF position

appropriate well)

Circulator A

Circulator B

KIT 2 code 261890

THE INLET AND OUTLET PIPES MUST BE CROSSED FOR THIS TO FUNCTION PROPERLY

- 32 -

SYSTEM FOR AN OPEN TANK INSTALLATION

AN EXAMPLE OF A HYDRAULIC SYSTEM FOR A THERMO FIREPLACEITH HOT SANITARY WATER PRODUCTION AND A WALL MOUNTED BOILER USING

Electricity

Mains

Safety pipe Ø> 28mm

Inlet pipe Ø> 18mm

KIT 3

Collector

ACS: Hot Sanitary Water

AF: Cold Water

CA: Wall Mounted Boiler

EV: 3-way Solenoid Valve

F: Flow Switch

MI: System Flow

NA: Normally Open

NC: Normally Closed

P: Pump (circulator)

RA: Radiators

RE: Electronic Regulator

RI: System Return

S: Drain

Sc 20: 20-plate Heat Exchanger

Sc 30: 30-plate Heat Exchanger

TC: Thermo Fireplace

V: Valve

VE: Open Expansion Tank

VR: Check Valve

VSP: 1.5 bar Pressurized Safety Valve

VST: Thermal Relief Valve

Ja: Automatic Relief Valve

Kit 3 is designed to facilitate the work carried out by the installers. In fact, it consists of all the necessary components for the

product to be properly installed.

NB: insulating mats must be applied so that the components of the kit are well-protected from the heat radiation emitted

by the thermo-Ŏ replace.

1. 1” Male-Female Brass Collector

2. 1” Ball Valve

3. Circulator with 1½” Fasteners (219660)

4. 1” Check Valve (261910)

5. 1” Male-Female 3-way Solenoid Valve

(143330)

6. Copper Fittings

7. 30-plate Heat Exchanger for heat transfer

with the gas boiler circuit (216620)

8. 20-plate Heat Exchanger for hot sanitary

water production (205270)

9. ¾” Thermal Relief Valve (72940)

10. ¾” 1.5 bar Safety Valve (143260)

11. Flow Switch (220830)

12. ½” Thermometer Well + Sensor (175960)

13. Electronic Regulator (220780)

A ¾” System Return

B ¾” System Flow

C ¾” Fireplace Return

D 1” Fireplace Flow

E ½” Cold Sanitary Water

F ½” Hot Sanitary Water

30-plate heat

exchanger

20-plate heat

exchanger

Regulator

(included in the kit)

ENGLISH

Electrical Connections

Power Supply

230 Vac

Fuse

Circulator enabled

Overheating alarm

3-way valve

Flow Switch

Attention: Connect the

normally closed contact

Display

20 - 80° C

Valve Setting

Circulator Setting

20 - 80° C

OFF

ON

Enable

Disable

Acoustic

Alarm

Sensor (insert in the

appropriate well)

SELECTOR FUNCTIONS

Selector: OFF Everything is switched off

Selector: MAN Driven Circulator

Valve is set

Selector: AUTO Circulator is set

Valve is set

Alarm selection No acoustic signal in the

OFF position

3-way valve

Circulator A

Circulator B

KIT 3 code 261900

THE INLET AND OUTLET PIPES MUST BE CROSSED FOR THIS TO FUNCTION PROPERLY

- 33 -

SYSTEM FOR AN OPEN TANK INSTALLATION

AN EXAMPLE OF A HYDRAULIC SYSTEM FOR A THERMO FIREPLACEITH HOT SANITARY WATER PRO-

TA

V

VR

ACS

KIT N3

AF

V

VR

Collector

COLLETTORE

VR

V

RI

MI

V

CA: Wall Mounted Boiler

PR: Pump (circulator)

P1: Primary circuit pump

RE: Electronic regulator

TA: Room thermostat

VE: Expansion Tank

Ja: Air reŎ ef Valve

V: Intercept valve

Water

RETE

IDRICA

V

Mains

VR: Retaining valve

ST: Temperature Sensor

F: Flow switch

Sc: Heat plate exchanger

EV: 3-way solenoid valve

V

RI: Heating system return

RA: Radiators

MI: Heating system ŏ ow

AF: Cold water

RA

V

ACS: Hot sanitary water

S: Drain

DUCTION AND A WALL MOUNTED BOILER USING

RETE

ELETTRICA

AF

Sc

F

INT

CA

VR

ACS

RE

P1

V

Vs

circuit connected

Circuito collegabile al

to the room

termostato ambiente

(a discrezione del cliente)

thermostat

(implemented by

the client)

must be connected

Da collegare necessariamente

al circolatore dell’impianto

to the heating system

di riscaldamento

PR

circulator

PR

V

V

ENGLISH

Tubo di sicurezza Ø> 28 mm

Safety pipe Ø> 28mm

ST

S

TCN

VE

Ja

S

Electricity

Mains

V

Tubo di carico Ø> 18 mm

Inlet pipe Ø> 18mm

V

VR

Kit N3 is designed to facilitate the work carried out by the installers. In fact, it consists of all the necessary components for the

product to be properly installed.

NB: insulating mats must be applied so that the components of the kit are well-protected from the heat radiation emitted

by the thermo-Ŏ replace.

9

9

11

10

13

9

7

12

4

6

14

8

7

Cable duct

Passacavi

2

1

5

3

4

6

18

17

16

15

1

5

3

2

1. Heating system ŏ ow G 3/4”

2. EDILKAMIN generator ŏ ow G 3/4”

3. EDILKAMIN generator return G 3/4”

4. Heating system return G 3/4”

5. Cold sanitary water inlet G 1/2”

6. Hot water return to the sanitary system G 1/2”

7. Safety valve - temperature and pressure (90

°C - 3bar)

8. Flow Switch

9. Air relief valve G 3/8”

10. EDILKAMIN generator circuit circulator

11. 3-way heat exchanger

12. Intercept valve G 1”

13. Electronic regulator with wiring

14. Appropriate aperture for the cable duct to pass

through

15. Power cable

16. Cables for the heating system circulator (phase,

neutral, earth)

17. Temperature sensor

18. Room thermostat circuit

Electrical Connections

OFF

ON

Electricity

Mains 230 Vac

50 Hz +/- 10%

Sanitary-heating enabled

setting

40-80°C

Enabled

alarm

Primary circulator

enabled setting

30-40°C

Primary circuit pump

Heating pump

Room

thermostat

sensor

Flow sensor

EV

KIT N3 code 627690

THE INLET AND OUTLET PIPES MUST BE CROSSED FOR THIS TO FUNCTION PROPERLY

- 34 -

SYSTEM FOR AN OPEN TANK INSTALLATION

AN EXAMPLE OF A HYDRAULIC SYSTEM FOR A THERMO FIREPLACE WITH HOT SANITARY WATER PRODUCTION AND A WALL MOUNTED BOILER USING

INT

Water

RETE

ELETTRICA

Mains

VE

S

Tubo di sicurezza Ø> 28 mm

Safety pipe Ø> 28mm

bo di carico Ø> 18 mm

Tu

TCN

ST

Inlet pipe Ø> 18mm

Ja

S

V

AF

V

circuit connected

Circuito collegabile al

RE

P1

Vs

termostato ambiente

(a discrezione del cliente)

to the room

thermostat

(implemented by

the client)

V

ACS

Sc

Sc

V

P2

F

EV

CA

VR

V

V

By-pass

V

KIT N3 BIS

TA

AF

VR

Collector

COLLETTORE

V

V

RI

VR

ACS

CA Wall Mounted Boiler

P2 Pump (circulator)

P1 Primary circuit pump

RE Electronic regulator

TA Room Thermostat

VE Expansion Tank

Ja Air Relief Valve

v Intercept valve

Water

RETE

Mains

IDRICA

V

VR

VR Retaining valve

ST Temperature Sensor

F Flow switch

Sc Heat Plate Exchanger

EV 3-way Solenoid Valve

V

V

MI

V

RI Heating system return

RA Radiators

MI Heating system ŏ ow

AF Cold Water

ACS Hot Sanitary Water

RA

S Drain

INT Main switch

V

TCN Contact Thermostat

Kit N3BIS is designed to facilitate the work carried out by the installers. In fact, it consists of all the necessary components for the

product to be properly installed.

NB: insulating mats must be applied so that the components of the kit are well-protected from the heat radiation emitted

by the thermo-Ŏ replace.

1111

1111

17

13

2

1

15

14

12

9

14

5

4

3

11

11

16

Cable duct

Passacavi

8

6

10

19

18

7

4

2

1

20

7

8

17

6

5

3

1. Heating system ŏ ow G 3/4”

2. EDILKAMIN generator ŏ ow G 3/4”

3. EDILKAMIN generator return G 3/4”

4. Heating system return G 3/4”

5. Cold sanitary water inlet G 1/2”

6. Hot water return to the sanitary system G 1/2”

7. Sanitary hot water inlet to the gas boiler G 1/2”

8. Safety valve - temperature and pressure (90 °C 3bar)

9. Flow Switch

10. 3-way deviation solenoid valve

11. Air relief valve G 3/8”

12. EDILKAMIN generator circuit circulator

13. Heating system circuit circulator

14. Intercept valve G 1”

15. 3-way heat exchanger

16. Electronic regulator with wiring

17. Appropriate aperture for the cable duct to pass

through

18. Power cable

19. Temperature sensor

20. Room thermostat circuit

ENGLISH

Electrical Connections

OFF ON

Sanitary-heating enabled

setting

40-80°C

Enabled

alarm

Primary circulator

enabled setting

30-40°C

Room

thermostat

sensor

Flow sensor

Electricity

Mains 230 Vac

50 Hz +/- 10%

Primary circuit pump

EV

Heating pump

KIT N3 BIS code 627860

THE INLET AND OUTLET PIPES MUST BE CROSSED FOR THIS TO FUNCTION PROPERLY

- 35 -

ELECTRONIC REGULATOR

IMPORTANT ADVICE REGARDING THE INSTALLATION

The connections, commissioning and veriŎ cation of proper

operation of the Ŏ replace must be carried out by qualiŎ ed per-

sonnel, who can implement all connections in accordance with

the laws in force, particularly with Italian Law No. 46/90, apart

from complying with these instructions.

Compliance with regulations regarding the earth connection is fundamental for the safety of people.

ENGLISH

It is obligatory to install a differential circuit breaker switch

before the device and the entire electrical circuit of the thermo

Ŏ replace.

It is also obligatory to connect the pump, valve and metal parts

of the thermo Ŏ replace to an earthing system.

LEGEND

AA acoustic alarm switch

R way valve opening setting (KITS 1-3)

R circulators operation setting (KIT 2)

RIC internal pump setting

S MAN-OFF-AUTO selector

SP pump light

SS overheating light

ST temperature scale

SV 3-way valves light (KITS 1-3)

SV circulators setting (KIT 2)

OPERATION

- Control device:

• Thermometer

- Protection device (acoustic alarm system):

• Acoustic alarm (AA)

• Overheating alarm (SS)

This system intervenes when the water temperature exceeds

90° C and warns the user to stop adding fuel.

The acoustic alarm can be disabled from the switch (AA).

However, the alarm remains enabled by means of the overheating light (SS). To restore the initial settings, the switch (AA)

must be enabled after the water temperature in the thermo

Ŏ replace has cooled down.

Power supply device (circulation system):

• MAN-OFF-AUTO selector (S)

• Pump light (SP)

The pump remains on when in manual mode and off when in

OFF mode. When in AUTO mode, the pump is activated by the

system when the desired temperature is reached, by means of

the internal setting (RIC), which ranges from 20 to 80° C (this

is pre-set at 20° C).

- Operation device (setting system):

• 3-way valve opening setting (R)

• 3-way valve operating light (SV)

When the ŏ uid reaches the temperature set through the regu-

lator, the 3-way valve diverts the ŏ uid to the radiators and the

operating light (SV) goes on.

When the temperature of the ŏ uid drops below the set value,

the system opens the electrical circuit and the 3-way valve

bypasses the ŏ uid directly to the thermo Ŏ replace.

Attention: During normal operation check that the warning

lights (SV) and (SP) are lit.

TECHNICAL DATA

Power Supply (+15 – 10%) Vac 230

Degree of protection IP 40

Min/Max Room Temperature °C 0÷+50

Sensor range mt 1,2

Thermometer °C 30÷90

Maximum contact rating of the circulator W 400

Maximum contact rating of the 3-way valve W 250

Fuse mA 500

The electric control regulator allows you to monitor the operating conditions and is equipped with:

- MAN-OFF-AUTO selector (S)

- temperature scale (ST)

- acoustic alarm (AA)

- 3-way valve opening setting (R) (KIT1-3)

- circulators operation setting (R) (KIT2)

- internal pump setting (RIC)

- 3-way valve light (SV) (KIT1-KIT3)

- circulators setting light (SV) (KIT2)

- overheating pump (SS)

- pump light (SP)

POSITIONING

The electronic regulator must be installed close to the thermo

Ŏ replace. The sensor of the operation, protection and control

devices must be placed directly on the thermo Ŏ replace or at

most on the ŏ ow pipe, no more than 5 cm away from the ther-

mo Ŏ replace and in any case before any intercepting device.

The sensor must be immersed in the well.

INSTALLATION

The power supply must be disconnected from the mains

and the AUTO-OFF-MAN selector (S) must be in the OFF

position when all these operations are carried out.

Follow this procedure to install the electronic regulator correctly: loosen the fastening screw, remove the cover and fasten

it in place against the wall with the dowels supplied.

Then make the connections, paying utmost attention to the

wiring diagram and pass the wires through ducts that are in

conformity with the regulations in force. Put the cover back in

place and tighten the screw.

Connect the brown wire (phase) and blue wire (neutral) of the

3-way Valve, respectively, to terminals 5 and 6 of the regulator. Connect the yellow/green wire to the earth.

Follow the assembly instructions contained in the package to

connect the regulator to the system properly.

- 36 -

OPTIONAL ACCESSORIES

ELECTRONIC REGULATOR (Optional)

This lets you monitor the operating conditions and is equipped

with:

- MAN-OFF-AUTO selector

- temperature scale

- acoustic alarm

- 3-way valve opening setting

- internal pump setting

- pump light

- 3-way valve light

- overheating light

Electronic Regulator (220780)

The electronic regulator is part of various types of installation

kits (supplied as optionals)

HEAT EXCHANGER 20-PLATE FOR SANITARY

WATER (Optional)

This is a very simple and inexpensive device with guaranteed

performance that produces 13-14 litres of hot water per minute

according to the power plant. It is easily installed on the ŏ ow

pipe to the radiators, in the most suitable position according to

the layout of the system. This has the great advantage of being

removed for maintenance or replacement without affecting the

thermo Ŏ replace.

hot sanitary

cold water

from the mains

water

Valves Kit (421600) consisting

of: automatic air relief valve,

1.5 bar safety valve,

90 ° C thermal relief valve

H2OCEANO 15 - RISER FEET KIT raises the

Ŏ replace unit from 14 to 19 cm from the ŏ oor

OCEANO 23 - RISER FEET KIT raises the

H

2

Ŏ replace unit from 12 to 17 cm from the ŏ oor

OCEANO 28 - RISER FEET KIT raises the

H

2

Ŏ replace unit from 12 to 17 cm from the ŏ oor

Circulator

UPS 25-50 code 219660

UPS 25-60 code 238270

1 ” 3-way valve (143330) to

set the water

ŏ ow to the system

Exchanger 3-way

code 627780

20-plate Heat

Exchanger for

sanitary water

(262570)

Flow Switch

(220830)

ENGLISH

30-plate Heat

Exchanger for

sanitary water

(216620)

hot water from the

return water to

thermo Ŏ replace

the thermo Ŏ replace

The 20-plate heat exchanger is part of various types of

installation kits (supplied as optionals)

EXCHANGER 3-WAY (optional)

It produces hot water for a domestic circuit and a secondary

circuit (radiators), excluding, with respect to KIT 3, use of

3-way valve and a plate heat exchanger.

cold water

system

hot water from the

thermo Ŏ replace

cold

sanitary water

Thermostatic valve

H2OCEANO 15 code 739460

H

OCEANO 23 code 739440

2

H

OCEANO 28 code 739450

2

Roaster

H2OCEANO 15 code 750820

H

OCEANO 23 code 234560

2

H

OCEANO 28 code 236710

2

Hydraulic kit V for OPEN TANK

versions code 743430 (installation on

right)

- 37 -

Inlet frame

H2OCEANO 15 code 739390 - dim. 63x63 cm

H

OCEANO 23 code 739370 - dim. 77x68 cm

2

OCEANO 28 code 739380 - dim. 95x68 cm

H

2

Support for hydraulic kits A1-A2-B-C-D

(installation on right)

OCEANO 15 code 739510

H

2

H

OCEANO 23 code 739470

2

H

OCEANO 28 code 739490

2

Remote dispaly

741180

code

H2OCEANO 15

96

94

95

93

61

60

84

80

92

91

76

82

79

69

86

83

85

71

74

81

72

73

73

75

74

86

70

85

81

78

77

4

31

39

14

38

32

68

64

14

54

9

50

6

21

6

40

21

10

15

13

5

15

52

7

56

22

12

51

5

55

11

53

8

Optionals

89

87

90

88

42

36

67

16

17

37

3

41

35

59

34

19

65

33

22

45

43

47

46

44

48

29

49

60

61

27

57

1

30

28

2

24

25

26

66

23

58

- 128 -

63

18

20

62

H2Oceano 15KW

1

1

M14 x 20

* Ketelstructuur gesloten vat 1

* Heizkesselkörper geschlossenes ausdehnungsgefäss

Deur met katrollen 1

Einheit Tür Riemenscheiben

Bus schroefdraad bevestiging bev. 3

Gewindehülse Befestigung Sicherheitseinrichtungen

Stelpen M10

Einstellstift M10

Rook keerschot boven 1

Abnehmbarer Türgriff Afneembaar handvat deurtje 1

Oberes Rauchleitblech

Manija puerta pequeña extraíble

DeÀ ector superior humo

Schroef T.E.

M14 x 20

Schraube T.E.

M14 x 20

Tornillo T.E.

ITALIANO ENGLISH FRANÇAIS ESPAÑOL DEUTSCH NEDERLANDS pz.

2 Piano fuoco in ghisa Hearth made of cast iron Plan feu en fonte Plano del fuego en hierro fundido Brennraumboden aus Gusseisen Vuuroppervlak in gietijzer 1

3 Assieme frontale Front assembly Ensemble frontal Grupo frontal Frontale Einheit Voorkant 1

1 Struttura saldata VA Bolier structure open tank Structure chaudière vase ouvert Estructura de la caldera vaso abierto Heizkesselkörper offene sausdehnungsgefäss Ketelstructuur open vat 1

1 * Struttura saldata VC * Bolier structure closed tank * Structure chaudière vase fermé * Estructura de la caldera vaso cerrado

4 Assieme anta montata Mounted door assembly Ensemble porte montée Grupo puerta montada Baugruppe montierter TürÀ ügel Gemonteerde deur 1

M14 x 20

Poignée porte amovible

DéÀ ecteur supérieur fumée

Removable door handle

Upper smoke deÀ ector

5 Assieme scorrimento Sx Left slider Coulisse gauche Desplazamiento izqdo. Knagge Afvoer links 1

6 Guide scorrimento Slider guide Guides de coulissage Guías de desplazamiento Wärmeschutzgriff zur Türöffnung Geleiders afvoer 1

7 Cuscinetto Bearing Coussinet Cojinete Lager Dempertje 2

8 Assieme porta scorrevole sx LT sliding door assembly Ensemble porte coulissante gauche Grupo puerta corredera izq. Baugruppe Schiebetür links Schuifdeur l 1

9 Molla spinta anta Door push spring Ressort de poussée porte Muelle empuje puerta Druckfeder TürÀ ügel Duwveer deur 2

11 Gommino Pad Bouchon Tapón de goma Gummi Pakking 2

10 Pro¿ lo giunizione scorrimenti Slide coupling pro¿ le Pro¿ l de jonction coulissements Per¿ l unión deslizamientos Verbindungspro¿ l Gleitlauf Pro¿ el verbinding schuiven 1

12 Leva sicurezza per chiusura Safety lever for closure Levier sécurité pour fermeture Palanca de seguridad para cierre Sicherheitshebel für Verriegelung Veiligheidshendel voor afsluiting 2

13 Assieme scorrimento Dx Right slider Coulisse droite Desplazamiento dcho Stift für Türaufhängung Afvoer rechts 1

14 Assieme porta scorrevole dx RT sliding door assembly Ensemble porte coulissante droite Grupo puerta corredera dch. Baugruppe Schiebetür rechts Schuifdeur r 1

15 Assieme perno serratura Lock pin assembly Ensemble goujon serrure Grupo perno cerradura Baugruppe Verriegelungsstift Pen slot 2

16 Assieme porta puleggie Pulley holder assembly Ensemble porte poulies Grupo porta poleas

17 Puleggia con boccola Pulley with bushing Poulie avec douille Polea con casquillo Seilscheibe mit Lager Katrol met bus 2

18 Assieme contrappeso Counterbalance Contrepoids Contrapeso Gegengewicht Contragewicht 1

19 Fune L.1000 mm Counterbalance rope L.1000 mm Câble contrepoids L.1000 mm Cable contrapeso L.1000 mm Gegengewicht-Seil L.1000 mm Kabel contragewicht L.1000 mm 1

20 Carter contrappeso Interchangeable counterbalance casing Carter contrepoids Cárter contrapeso Beidseitiges Gegengewicht-Gehäuse Bekleding contragewicht 1

21 Fermo silicone D15 Silicone stop D15 Crochet silicone D15 Tope silicona D15 Silikonsicherung D15 Siliconen pal D15 2

22 Bussola ¿ lettata ¿ ssaggio sicurezze Threaded safety device ¿ xing bush Douille ¿ letée ¿ xation sécurités Casquillo roscado ¿ jación protecciones

23 Lamiera base Base sheet Tôle base Chapa base Sockelblech Basisplaat 1

24 Assieme cassetto cenere Ash pan assembly Ensemble tiroir cendres Grupo cajón cenizas Aschenladen-Einheit Aslade 1

25 Supporto cassetto cenere destro RT Ash pan support Support tiroir à cendres droite Soporte cajón cenizas dch. Halterung Aschenlade rechts Steun aslade rechts 1

26 Supporto cassetto cenere sinistro LT Ash pan support Support tiroir à cendres gauche Soporte cajón cenizas izq. Halterung Aschenlade links Steun aslade links 1

27 Griglia cenere Ash grill Grille cendres Parrilla cenizas Aschenbehälter Asla 1

28 Lamierino chiusura passaggio sonda Probe passage closure plate Tôle ¿ ne pour fermeture du passage sonde Chapa de cierre paso sonda Verriegelungsblech für Sondendurchgang Sluitplaatje doorgang meter 1

29 Tubo post-combustione dx RT post-combustion tube Tuyau post-combustion droit Tubo post-combustión dch. Nachverbrennungsrohr rechts Leiding post-verbranding r 1

30 Copertura entrata aria Air inlet covering Revêtement entrée air Cubierta entrada de aire Abdeckung Lufteinlass Afdekplaat luchtinvoer 1

33 Tubo post-combustione sx LT post-combustion tube Tuyau post-combustion gauche Tubo post-combustión izq. Nachverbrennungsrohr links Leiding post-verbranding l 1

31 Manofredda Cold hand Main froide Manofría Kalthandgriff Koude 1

34 Manicotto giunzione tubo post-comb. Post-combustion connection sleeve Manchon joint tuyau post-comb. Manguito unión tubo post-comb. Verbindungsstutzen Nachverbrennungsrohr Verbindingsmof leiding post-verb. 1

32 Perno regolazione M10 M10 adjustment pin Axe de réglage M10 Perno regulación M10

35 Cielino basso Low ceiling Plafond bas Parte superior baja Niedrige Decke Lage bovenkant 1

36 Controcielino Drop ceiling Faux-plafond Contra parte superior Zwischendecke Bovenkant 1

37 Assieme cielino con valvola Ceiling assembly with valve Ensemble plafond avec vanne Grupo parte superior con válvula Baugruppe Decke mit Ventil Bovenkant met klep 1

38 Maniglia antina asportabile

40 Molla di ritegno Retaining spring Ressort de retenue Muelle de retención Haltefeder Terugslagveer 1

41 Perno bloccaggio Locking pin Goujon de blocage Perno bloqueo Blockierstift Vergrendelpal 1

39 DeÀ ettore superiore fumo

42 Carter frontale Front casing Carter frontal Cárter frontal Frontabdeckung Bekleding voorkant 1

Vis T.E.

M14 x 20

Screws T.E.

Vite T.E. M14 x 20

46 Dado M10 Nut M10 Écrou M10 Tuerca M10 Mutter M10 Moer M10 2

47 Vite T.E. M10x40 Screws T.E. M10x40 Vis T.E. M10x40 Tornillo T.E. M10x40 Schraube T.E. M10x40 Schroef T.E. M10x40 1

44 Eccentrico by pass By-pass eccentric Came by-pass Excéntrico by pass Exzenter Bypass Excentrische bypass 1

45

43 Leva comando farfalla fumi Smoke butterÀ y valve control lever Levier commande papillon des fumées Palanca de mando de mariposa para humos Bedienungshebel Rauchdrossel Bedieningshendel rookklep 1

48 Vite T.E. M4X8 Screws T.E. M4X8 Vis T.E. M4X8 Tornillo T.E. M4X8 Schraube T.E. M4X8 Schroef T.E. M4X8 2

- 129 -

1

2

1

1

8

1

-

D4

TCL-TCR 4,2x6,5 2

Platte ring

Schroef

5x8 SchroefT.T.B zesk. intern M8x25 2

D4

Flache Unterlegscheibe

Schraube mitRundkopf undInnensechskant M

D4

Arandela plana

C.C. M5x8 4

Schroef T.E.

D5

Ring

D5

5 Unterlegscheibe

D

M6.3x25 1

D5

*Afvoerklep thermische veiligheid met put

Überhitzungsschutzventil mit Schacht

Holzschutzleiste Houtscherm

*

*Válvula de descarga de seguridad térmica con pozo

Schroef T.E.

Ring

D5

5 Unterlegscheibe

D

Poot 4

Aufbaufuß

Gelaste deur

Rooster rookafvoer beschermlaag (optie) 1

* Uitsluitend in het geval van de versie met spi-

raal (installatie met gesloten expansievat)

Luftauslassgitter Rauchfangabdeckung (auf Wunsch)

* nur für Ausführung mit Rohrschlange (Installation

mit geschlossenem Ausdehnungsgefäß)

* solo para versión con serpentín

(instalación con vaso cerrado

5x8 TornilloT.T.B hexag interno M5x8

D4

Rondelle plate

Vis tête ronde bombée hexagonale intérieur M

D4

Flat washer

5 Arandela

D

Rondelle

D5

5 Arandela

D

Soupape décharge sécurité thermique avec logem

*

Safety thermal relief valve with well

Rondelle

D5

Ensemble porte soudée Grupo puerta soldada Baugruppe geschweißter TürÀ ügel

Welded door assembly

* seulement pour version avec serpentin

(installation à vase fermé)

* only for versions with a coil

(closed Tank installation)

ITALIANO ENGLISH FRANÇAIS ESPAÑOL DEUTSCH NEDERLANDS pz.49Rondella piana D4

50 Vite zinc nera t.t.bomb.ei int. M5x8 T.T.B internal hexag screw M5x8

52 Dado basso M10 M10 low nut Écrou bas M10 Tuerca baja M10 Mutter niedrig M10 Lage moer M10 4

51 Vite aut-tcl-tcr s/pu 4,2x6,5 Screws TCL-TCR 4,2x6,5 Vis TCL-TCR 4,2x6,5 Tornillo TCL-TCR 4,2x6,5 Schraube TCL-TCR 4,2x6,5

53 Vite tsp -cava esag. M6X12 TSP allen head screw M6X12 Vis TSP tête cylindrique pans M6X12 Tornillo TSP cab hexágono M6X12 Zyl.-Kopf-Inbusschraube TSP M6X12 Schroef TSP cav zeskant M6X12 2

54 Vite T.E. C.C. M5x8 ScrewsT.E. C.C. M5x8 VisT.E. C.C. M5x8 TornilloT.E. C.C. M5x8 SchraubeT.E. C.C. M5x8

55 Vite TSP cava es M10x30 TSP allen head screw M10x30 Vis TSP tête cylindrique pans M10x30 Tornillo TSP cab hexágono M10x30 Zyl.-Kopf-Inbusschraube TSP M10x30 Schroef TSP cav zeskant M10x30 2

57 Paralegna Log retainer Pare-buche Protección leña

56 Rondella D5 Washer

*Valvola scarico sicurezza termica con pozzetto *

58 Lamiera aumento contrappeso Balance sheet growth Croissance du bilan Balance de crecimiento de la hoja Bilanzentwicklung Balans groei 1

59

60 Guarnizione carta ceramica girrarosto Rotisserie ceramic paper gasket Joint papier céramique pour tournebroche Empaquetadura papel cerámica rustidor Keramikpapierdichtung Bratspieß Papieren pakking keramiek spit 1

61 Supporto girarrosto Rotisserie support Support tournebroche Soporte rustidor Halter für Bratspieß Steun spit 1

62 Meccanismo presa aria External air inlet mechanism Mécanisme prise d’air externe Mecanismo toma de aire externo Außenlufteinlassmechanismus Mechanisme externe luchtinlaat 1

63 Vite aut t.e.brun 6.3x25 ScrewsT.E. M 6.3x25 VisT.E. M6.3x25 TornilloT.E. M6.3x25 SchraubeT.E. M6.3x25

65 Ruota battuta su by pass Stop wheel on by-pass Roue butée sur by-pass Rueda tope en by pass Anschlagrad auf Bypass Wieltje op bypass 1

64 Rondella D5 Washer

66 Piede di riporto Return foot Pied de soutien Pie de recubrimiento

67 Ogiva per sonde Ogive for probes Ogive pour sonde Caperuza para sondas Dichtkegel für Sonde Meterhouder 1

70 Vetro Glass Vitre Vidrio Scheiibe Glas 1

68 Guanto Glove Gant Guante Schutzhandschuh Handschoen 1

69 Assieme anta saldata

71 Chiavistello Bolt Verrou Pestillo Riegel Slot 1

72 Comando chiavistello Bolt control Commande verrou Mando pestillo Riegel Bedienelement Bediening klik 1

73 Busoola serratura Lock bushing Douille serrure Casquillo cerradura Verriegelungsbuchse Bus slot 2

74 Bussola guida serratura Lock guide bushing Douille guide serrure Casquillo guía cerradura Führungsbuchse Verriegelung Bus geleider slot 2

75 Copertura com.do chiavistello Bolt control cover Couverture commande verrou Cubierta mando pestillo Abdeckung Riegel Bedienelement Afdekking bediening slot 1

76 Fermavetro superiore Holder glass holders Pare-closes supèrieur Sujeta vidrios superior Obere Glashalteleisten Glashouder onderste 1

77 Fermavetro inferiore Lower glass holders Pare-closes infèrieur Sujeta vidrios inferior Linke Glashalteleisten Glashouder bonveste 1

78 Fermaguarnizione iinferiore Lower gasket stop Arrêt joint inférieur Tope empaquetadura inferior Befestigung für untere Dichtung Pal pakking onder 1

79 Fermaguarnizione superiore Lower gasket stop Arrêt joint inférieur Tope empaquetadura inferior Befestigung für untere Dichtung Pal pakking onder 1

80 Serranda aria Air damper Trappe air Compuerta de aire Luftklappe Luchtklep 1

81 Fermaguarnizione laterale Side gasket stop Bloc-joint latéral Protección empaquetadura lateral Seitliche Dichtungssperrung Klem pakking zijkant 2

82 Convogliatore aria anta Door air conveyor Convoyeur air porte Transportador aire puerta Luftableitblech TürÀ ügel Rookgeleider deur 1

83 Guarnizione Gasket Garniture Junta Dichtun Afsluiting 1

84 Attuatore by pass fumi Smoke by-pass actuator Actionneur by-pass fumées Actuador by pass de humos Stellantrieb Rauch-Bypass Actuator bypass rook 1

85 Piastra battuta vetro Plate glass joke Blague Verre plat Placa de vidrio de broma Flachglas Witz Spiegelglas grap 2

86 Piastrina dx fermavetro Right bead plate Droit plaque de talon Placa de cordón derecho Rechts Wulstplatte Rechts kraal plaat 2

87 Assieme cornice rastremata Tapered frame assembly Ensemble cadre fuselé Grupo marco ahusado Baugruppe verjüngter Rahmen Gelaste deur 1

88 Kit idraulico supporto Support hydraulic kit Kit hydraulique support Kit hidráulico soporte Halterung Hydraulik-Kit Conische steun 1

89 Kit regolazione aria automatica Automatic air regulation kit Kit de réglage air automatique Kit regulación de aire automática Kit für automatischen Luftregler Automatische regeling lucht 1

90 Piede rialzo KIT Kit lifting foot Pied de réhaussement KIT Pie elevación KIT KIT Fußerhöhung Pootje KIT 1

91 Asta girarrosto (optional) Spit rod (optional) Tige broche (optional) Varilla espetón (opcional) Bratspieß (optional) Spitstaaf (optioneel) 1

92 Prolunga asta girarrosto (optional) Roaster rod extension (optional) Rallonge tige tournebroche (optional) Extensión varilla rustidor (opcional) Bratspießverlängerung (optional) Verlenging spitstaaf (optioneel) 1

93 Motorino elettrico girarrosto (optional) Roaster electric motor (optional) Moteur électrique tournebroche (optional) Extensión varilla rustidor (opcional) Elektromotor Bratspieß (optional) Elektromotortje spit (optioneel) 1

94 Regolatore elettronico (optional) Electronic regulator (optional) Régulateur électronique (optional) Regulador electrónico (opcional) Elektronischer Regler (optional) Elektronische regelaar (optioneel) 1

(installazione a Vaso Chiuso)

- * solo per versione con serpentina

95 Griglia uscita aria interna controcappa (optional) Mantel air outlet grille (optional) Grille sortie air contre-hotte (en option) Rejilla salida del aire contra campana (opcional)

96 Griglia presa aria esterna (optional) External air inlet grille (optional) Grille prise d’air externe (optional) Rejilla toma aire externa (opcional) Gitter für Außenlufteinlass (optional) Rooster externe luchtinlaat (optioneel) 1

- 130 -

SLOVENŠýINA pz.

1 Zavarjeno ogrodje VA 1

1 * Zavarjeno ogrodje VC 1

2 Ognjišþe iz litoželeza 1

3 Sklop sprednjih delov 1

4 Sklop vgrajenih delov 1

5 Levi drsnik 1

6 Vodila drsnika 1

7 Ležaj 2

8 Sklop levih drsnih vrat 1

9 Vzmet za potisk vrat 2

10 Pro¿ l sklopa drsnikov 1

11 Gumijasti zamašek 2

12 Varnostni zapiralni roþaj 2

13 Desni drsnik 1

14 Desna drsna vrata 1

15 Zapiralni zatiþ 2

16 Nosilec škripcev 1

17 Škripec s pestnico 2

18 Protiutež 1

19 Kabel 1000 mm dolž. 1

20 Ohišje protiuteži 1

21 Zaustavitveni silikon D15 2

22 Navojni vložek za pritrditev varnostnih

elementov

23 Temeljna ploþevina 1

24 Sklop predala za pepel 1

25 Nosilec desnega predala za pepel 1

26 Nosilec levega predala za pepel 1

27 Rešetka za pepel 1

28 Zapiralna ploþevina za prehod tipala 1

29 Desna cev po izgorevanju 1

30 Pokrivalo zraþnega pretoka 1

31 "Mrzla" roþica 1

32 Regulacijski zatiþ M 10 1

33 Leva cev po izgorevanju 1

34 Sklopni roþaj cevi 1

35 Spodnja medkrovje 1

36 Medkrovje 1

37 Sklop medkrovja z ventilom 1

38 Roþica snemljivih vrat 1

39 Zgornja dimna loputa 1

40 Varnostna vzmet 1

41 Zaustavljalni klin 1

42 Sprednje ohišje 1

43 Krmilna roþica za dimno loputo 1

44 By pass ekscentra 1

45

Vijak T.E. M14 x 20

46 Matica M 10 2

47 Vijak T.E. M 10x40 1

48 Vijak T.E. M4X8 2

SLOVENŠýINA pz.

49

Plošþata podložka D4

50 Pocink.þrni vijak t.t. bomb. ei int. M5x8 2

51 Vijak aut-tct-tcr s/pu 4,2x6,5 2

52 Kratka matica M10 4

53 Vijak tsp - vdolb. šest. M6 X 12 2

54 Vijak T.E. C.C. M5x8 4

55 Vijak TSP vdolb. šest. M10x30 2

56 Podložka D5 2

57 Varovalo lesa 1

58 Ploþevina pospešitev protiuteži 1

59 Izpustni ventil termiþnega stikala z jaškom 1

60 Tesnilo keramiþnega ražnja 1

61 Nosilec ražnja 1

62 Sistem zraþnika 1

63 Vijak aut t. e. brun. 6.3x25 1

64 Podložke D5 8

65 By pass kolesce 1

66 Podstavek 4

67 Tesnilni stožec 1

68 Rokavica 1

69 Sklop zavarjenih vrat 1

70 Steklo 1

3

1

71 Kljuþavnica 1

72 Krmilo kljuþavnice 1

73 Nastavek kljuþavnice 2

74 Nastavek vodila za kljuþavnico 2

75 Pokrivalo krm. kljuþavnice 1

76 Zgornji nosilec stekla 1

77 Spodnji nosilec stekla 1

78 Spodnji nosilec tesnila 1

79 Zgornji nosilec tesnila 1

80 Loputa za zrak 1

81 Boþni nosilec tesnila 2

82 Usmerjevalec zraka 1

83 Tesnilo 1

84 Element dimnih plinov 1

85 Plošþa za steklo 2

86 Des. plošþica za steklo 2

87 Sklop okvirja 1

88 Hidravliþni nosilni kit 1

89 Kit za samodejno reguliranje zraka 1

90 Nastavek za dvig KITA 1

91 Drog ražnja (opcija) 1

92 Dodatni rog ražnja (opcija) 1

93 Elektriþni motor za raženj (opcija) 1

94 Elektronski regulator (opcija) 1

95 Rešetka za izhod zraka iz dimnike kape 1

96 Rešetka za zraþnik (vhod zraka) opcija 1

- * le za model z vijaþno cevjo (montaža z

zaprto eksp. posodo)

1

-

- 131 -

96

95

81

79

78

82

84

73

77

75

76

75

73

74

69

84

72

70

62

63

H2OCEANO 23

65

64

66

61

58

59

94

93

90

14

89

15

92

91

80

71

68

83

69

18

37

67

57

40

60

56

39

83

41

42

41

43

46

45

46

44

50

49

48

47

54

53

52

55

51

39

38

28

23

27

27

28

19

20

30

22

21

31

33

29

36

32

35

34

24

25

26

15

17

12

86

2

14

13

16

10

Optionals

87

88

6

4

3

11

5

4

7

1

9

85

- 132 -

8

H2Oceano 23KW

96

94

95

93

35

34

83

108

92

91

109

109

107

111

105

104

80

101

110

77

106

78

110

73

84

106

112

79

75

103

74

102

113

66

H2OCEANO 28

36

112

12

15

6

16

15

7

62

6

14

11

13

54

13

37

24

21

38

9

10

55

53

4

17

8

62

5

8

53

60

12

62

61

54

10

9

17

25

55

382138

90

89

88

40

42

23

39

67

44

43

10

45

35

46

49

50

34

51

30

28

64

19

20

68

41

71

2

1

26

33

69

29

32

27

31

72

Optionals

87

22

70

63

48

18

- 136 -

www.edilkamin.com

- 140 -

cod. 941000 11.13/D

Loading...

Loading...