EDILGRAPPA MU 22N Use And Maintenance Instructions

MACHINE BODY

WITH INTERCHANGEABLE HEADS

USE AND MAINTENANCE

INSTRUCTIONS

MANUAL

2

MU22N

MU 22N

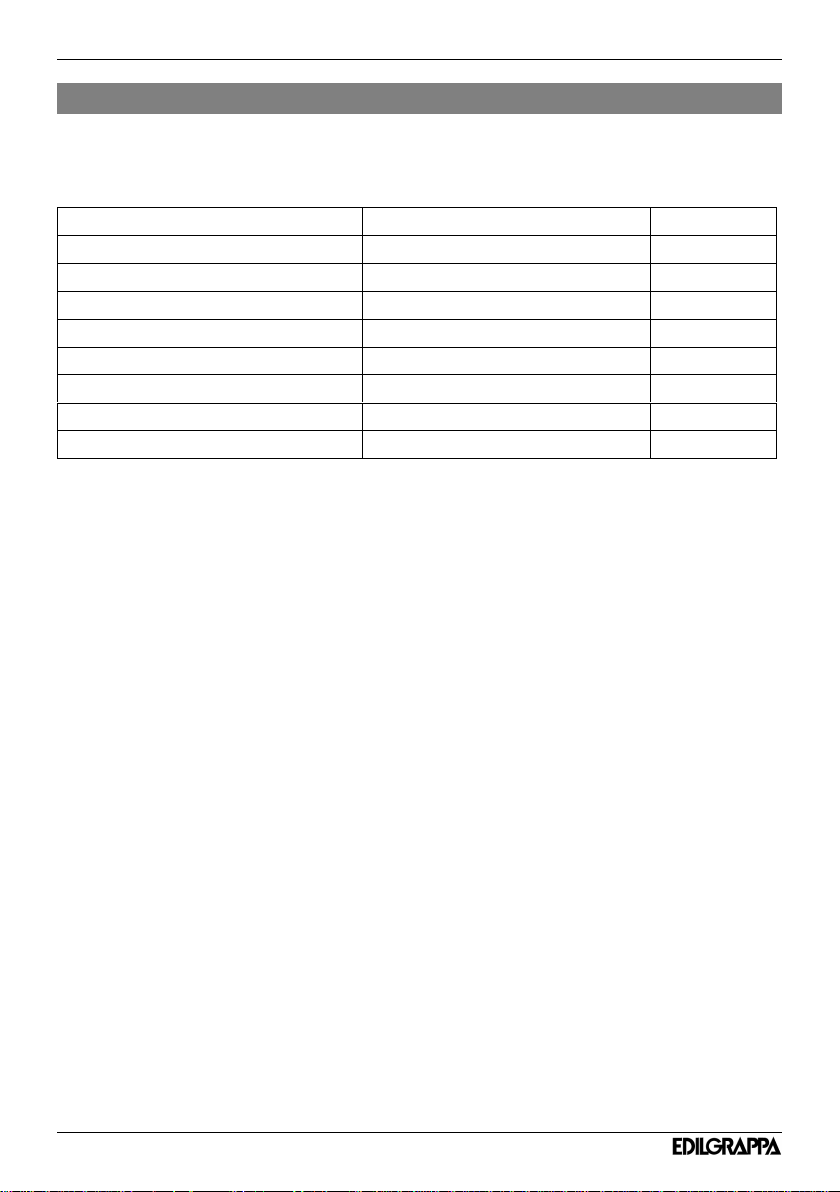

MU22N MACHINE BODY WITH INTERCHANGEABLE HEADS

AVAILABLE IN THE FOLLOWING VERSIONS:

· MU22N SINGLE-PHASE ELECTRIC MOTOR 230 V 50 Hz P/N 1.50.1952

AVAILABLE HEADS NAME P/N

T22 CUTTING HEAD 1.50.117

P22 CUTTING HEAD 1.50.1915

TS 500 STONE CUTTING HEAD 1.50.106

TW19 CUTTING HEAD 1.50.118

TF32 CUTTING HEAD 1.50.064

TR40 CUTTING HEAD 1.50.061

RD26 NUT-CRACKING HEAD 1.50.115

D180 SPREADING HEAD 1.50.112

2

MU 22N

INDEX

0 DESCRIPTION OF THE MACHINE ...................................................... 5

0.01 MACHINE COMPONENTS ...................................................................................................... 5

0.02 SAFETY AND DANGER STICKERS - CE PLATE ................................................................... 6

0.03 LIST OF ACCESSORIES INCLUDED IN THE SUPPLY ........................................................... 6

1 TECHNICAL FEATURES ..................................................................... 7

1.01 HYDRAULIC, MECHANICAL AND ELECTRICAL SPECIFICATIONS .................................... 7

2 DELIVERY, COMMISSIONING AND SET-UP ...................................... 8

2.01 DELIVERY ................................ ............................................................................................... 8

2.02 ELECTRIC MOTOR ................................................................................................................. 8

2.02.01 ELECTRICAL CONNECTIONS ...................................................................................... 8

2.02.02 COMMISSIONING ......................................................................................................... 8

2.03 MANUAL RETURN LEVER ..................................................................................................... 9

2.04 MOUNTING THE TOOL HEADS .............................................................................................. 9

2.05 EQUIPMENT OPERATION ................................................................ .................................... 10

2.05.01 STARTING ................................................................................................................... 10

2.06 FORESEEN USE AND RESIDUAL RISKS ............................................................................ 10

3 ROUTINE MAINTENANCE ................................................................. 12

3.01 CHANGING AND TOPPING UP THE OIL .............................................................................. 12

3.02 CHECKING SCREWS ................................................................ ........................................... 14

3.03 HYDRAULIC COMPONENTS................................................................................................ 14

3.03.01 MANUAL RETURN VALVE DOES NOT CLOSE .......................................................... 14

3.03.02 MAX. PRESSURE VALVE INCORRECTLY ADJUSTED .............................................. 14

3.03.03 MAIN CHECKS ON THE MOTOR ................................................................................ 14

4 POTENTIAL PROBLEMS AND MEASURES TO BE ADOPTED

4.01 GENERAL ............................................................................................................................. 15

4.02 TROUBLESHOOTING THE MOTOR ..................................................................................... 15

4.03 TROUBLESHOOTING THE HYDRAULIC COMPONENTS ................................................... 16

................. 15

5 STORAGE AND RESTARTING .......................................................... 17

5.01 STORAGE ............................................................................................................................. 17

5.01.01 ELECTRIC MOTOR ..................................................................................................... 17

5.01.02 CYLINDER AND HYDRAULIC COMPONENTS ........................................................... 17

5.02 RESTARTING ....................................................................................................................... 17

6 MACHINE DISPOSAL ......................................................................... 18

3

MU 22N

A brief legend indicating the most important symbols used in this manual is shown below.

THIS SYMBOL WARNS USERS TO P AY SPECIAL ATTENTION WHEN FOLLOWING

THE RELATIVE INSTRUCTIONS.

FAILURE TO OBSERVE THESE INSTRUCTIONS CAN CAUSE THE MACHINE TO

OPERATE INCORRECTLY.

THIS SYMBOL INDICATES POSSIBLE HAZARDS, TAKE ALL PRECAUTIONS TO

PREVENT THESE SITUATIONS FROM OCCURRING.

BEFORE WORKING ON THE MACHINE, CAREFULLY READ ALL THE

INSTRUCTIONS, ESPECIALLY THOSE CONTAINED IN BOXES.

“OPERATOR”: A person suitably trained and authorised to operate,

adjust, clean and transport the machine.

“MAINTENANCE MAN”: A person trained and authorised to perform routine

maintenance on the machine and replace certain

components.

“MACHINE BODY”: The equipment described in this manual.

“ELECTRIC TOOL”: Used in the safety precautions, it is a more general

definition of the machine in question as it refers to

mains-powered electric tools (with cable) or batterypowered electric tools (cordless).

4

0 DESCRIPTION OF THE MACHINE

CAUTION!! FIRST READ THE MANUAL REGARDING THE GENERAL AND SAFETY

REGULATIONS!

MU 22N

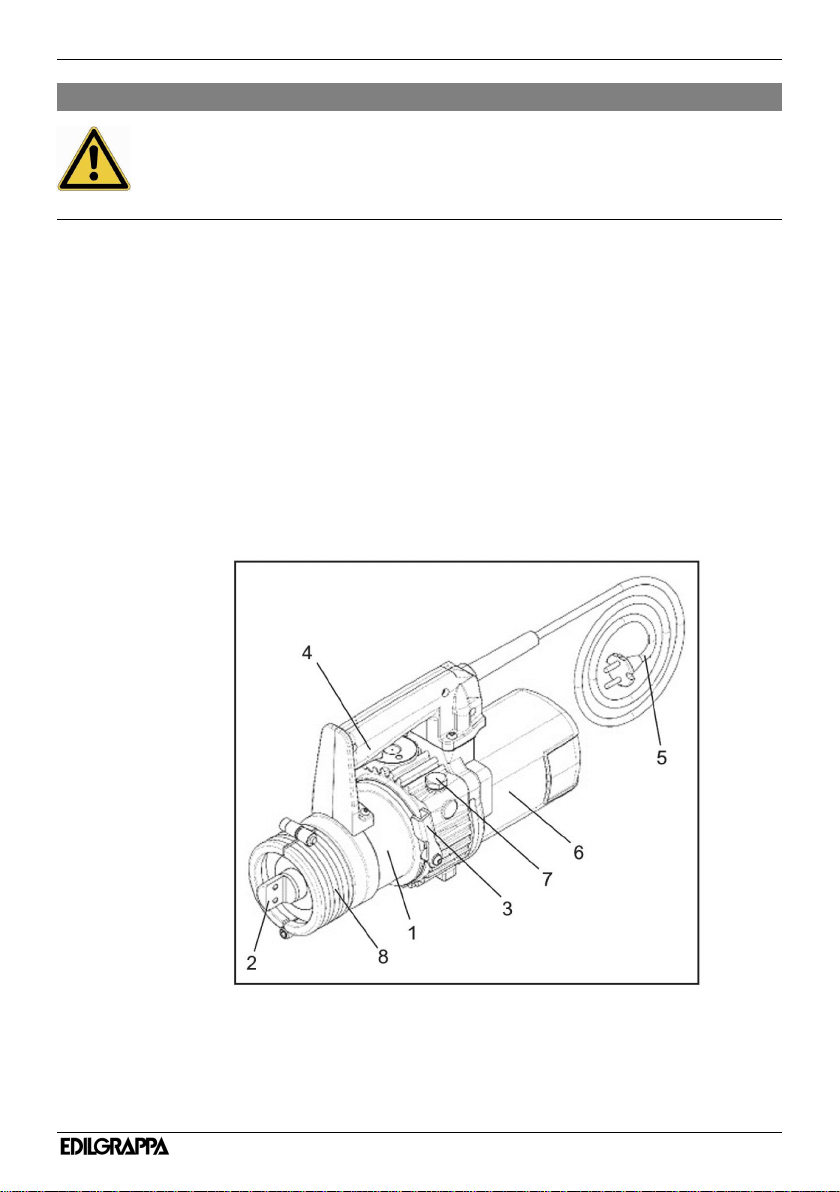

0.01 MACHINE COMPONENTS

This machine is fitted with a single-phase alternating current motor.

The equipment comprises:

- a motor,

- a hydraulic pump driven by the motor,

- a rod actuator (piston) driven by the oil pressured by the pump,

- an interchangeable head with tool (purchased separately).

Figure 1 shows the main parts of the equipment, in particular:

1. cylinder with hydraulic components

2. head supporting surface and centring guides

3. release lever or double-acting lever

4. grip with start button

5. electrical connecting cable complete with plug

6. electric motor

7. oil cap

8. head locking ring

5

MU 22N

DANGER

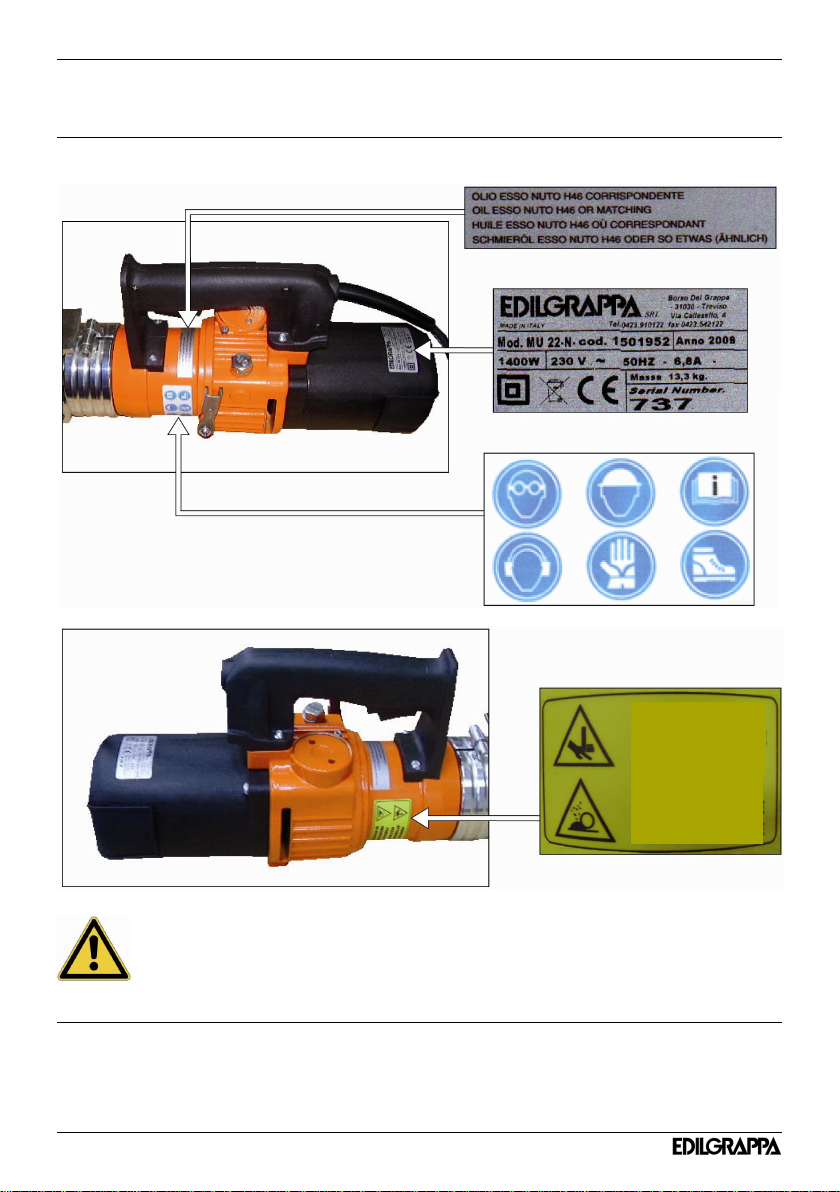

0.02 SAFETY AND DANGER STICKERS - CE PLATE

Position of plate and safety and danger stickers on the machine:

0.03 LIST OF ACCESSORIES INCLUDED IN THE SUPPLY

Observe the warnings on the plates and stickers. Failure to do so could lead to

injury or death. Make sure the plates and stickers are attached and legible. If not,

apply them or request the maker for replacements.

· Case

· General safety rules, Use and maintenance instructions

· Declaration of conformity

· Warranty certificate

· Emergency key

6

BEWARE OF

HANDS

3

DANGER

FLYING

SPLINTERS

Loading...

Loading...