GALAXY

PROFESSIONAL

12 GALLON CARPET EXTRACTOR

OWNER’S/OPERATOR’S MANUAL

2000CX-HR

2000FX-HR

PROUDLY DESIGNED AND MANUFACTURED BY

WWW.EDIC-USA.COM

Revised 1-25-18

TABLE OF CONTENTS

RECEIVING YOUR EQUIPMENT...................................................................................

WARNINGS AND SAFETY..............................................................................................

ELECTRICAL INFORMATION.......................................................................................

GROUNDING INSTRUCTIONS......................................................................................

MAINTENANCE................................................................................................................

CORD STORAGE AND SAFETY....................................................................................

2000CX-HR MACHINE OVERVIEW..............................................................................

2000FX-HR MACHINE OVERVIEW...............................................................................

ACCESSORY HEATER OVERVIEW...............................................................................

HOW TO USE AN ACCESSORY HEATER...................................................................

PRIMING THE MACHINE.............................................................................................

ADJUSTING PRESSURE..................................................................................................

CLEANING CARPET.........................................................................................................

CLEANING UPHOLSTERY..............................................................................................

WIRING...............................................................................................................................

UPPER BREAKDOWN 2000CX-HR.............................................................................

UPPER BREAKDOWN 2000FX-HR..............................................................................

LOWER BREAKDOWN 2000CX-HR............................................................................

LOWER BREAKDOWN 2000FX-HR.............................................................................

TROUBLESHOOTING.....................................................................................................

NOTES.................................................................................................................................

WARRANTY INFO............................................................................................................

3

3, 4

4

4

5

5

6

7

8

9

10

10

11

11

12, 13

14, 15

16, 17

18. 19

20, 21

22

23

24

2

RECEIVING YOUR NEW 2000CX-HR OR

2000FX-HR: When your package is delivered, check

the carton carefully for signs of rough handling. If your

2000CX-HR/2000FX-HR is damaged, notify the carrier

immediately and request an inspection. Be sure to keep

the carton, packing inserts, packing lists and carrier’s

receipt until the inspector has veried your claim.

EDIC’s liability ceases when the carrier picks up the shipment. However, our customer service sta will be happy

to furnish any information needed in connection with

the claim and will attempt to expedite a resolution.

PLEASE READ BEFORE OPERATING YOUR

NEW 2000CX-HR/2000FX-HR:

Read the manual carefully and completely before attempting to operate the unit. is manual has important

information for the use and safe operation of the machine. Keep this manual handy at all times.

is equipment has been engineered and manufactured

to provide excellent performance and service. To ensure

that your equipment will continue to perform as intended:

• Maintain equipment regularly- following the suggested maintenance schedule provided.

• Use only original EDIC parts when servicing.

• Operate equipment with care.

If additional information is needed, please contact:

EDIC

800-338-3342

All information and specications printed in the manual are current at the time of printing; however because

of EDIC’s policy of continual product development, we

reserve the right to make changes at any time without

notice.

FAILURE TO COMPLY WITH THE FOL-

LOWING WARNINGS AND INSTRUCTIONS

WILL VOID THE WARRANTY.

WARNING!

• e machine was designed for use on carpet cleaning

applications as per instructions and recommendations written in this manual. Any deviation from its

proper use or purpose and the consequential damage

that may occur is the sole responsibility of the end

user.

• Disconnect the power cord from the outlet before

servicing. Do not leave machine connected to an electrical outlet when unattended.

• Do not immerse or use this machine in standing water. Such use may cause electric shock.

• When using an extension cord, use only a 3-prong

conductor grounding cord-12 gauge wire or heavier.

• To avoid electric shock, do not expose the unit to rain

or snow. Store it indoors in a heated location only.

• Do not use the machine for dry vacuuming.

• Use defoamer at all times to prevent damage to the

vacuum motor.

• Do not use water in excess of 130°F (54°C) in the

solution tank

• To prevent seal damage and chemical build-up to the

pump system, run clean water through the solution

lines aer each day’s use.

• Use only commercially available carpet cleaning solutions and defoamer intended for use with machines

of this type. Do not use dyes, bleaches, ammonia, or

other additives.

• e use of powdered cleaning solution, if not diluted

properly, may result in damage to the pump. Powdered chemical is not recommended. If powdered

chemicals are used, premix in a separate container

before placing in the solution tank.

• Always read and understand your chemical’s MSDS

(Material Safety Data Sheet) before use.

• is equipment is not designed to handle or use

combustible/volatile substances such as gasoline or

kerosene, in, on, or near the machine. e use of such

materials will cause extreme hazardous condition.

• Do not expose machine to freezing temperatures.

3

• All repairs must be done by an authorized

EDIC repair station.

• Do not use replacement parts other than original

EDIC parts.

• Do not allow your spray stream to remain in one

xed location as surface damage may occur.

• Check that all spray nozzles are securely fastened.

Loose nozzles could be ejected from equipment at

high speeds.

• is is not a toy. Keep away from children.

• Do not pull by the power or use power cord as a handle. Always unplug by grabbing the plug and pulling,

do not unplug by pulling the power cord.

• Inspect cord for damage. Do not use damaged cords.

Connect only to properly grounded outlets.

• Keep hair, ngers, loose clothing, and body parts

away from moving parts and openings.

• Turn o all controls before disconnecting machine

• Use caution with ejected liquid or chemicals. High

pressures and temperatures could be hazardous to

nearby people or surroundings.

• Do not run the heater dry. always make sure you have

water

• Do not expose heater to freezing temperatures.

• Prevent burns by wearing gloves or using a barrier to

remove hot quick disconnects.

• Never leave heater or equipment unattended when

connected or powered on.

• e accessory heater was designed for use on

2000CX-HR/2000FX-HR extractors for carpet, oor

and upholstery extraction applications. Any deviation

from its proper use or purpose and the consequential

damage that may occur is the sole responsibility of

the end user.

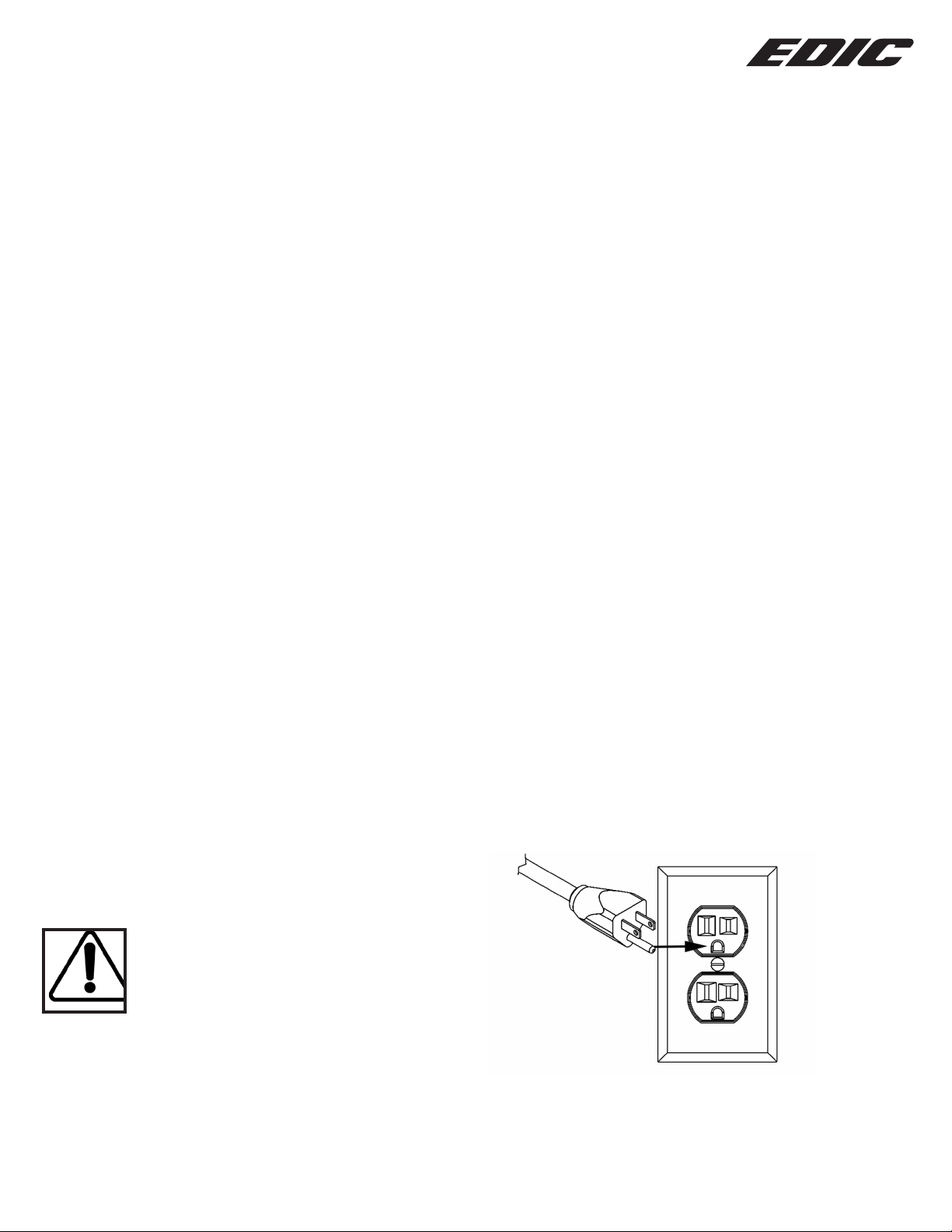

GROUNDING INSTRUCTIONS FOR

115VOLT:

is piece of equipment must be grounded. Should an

electrical malfunction occur, grounding provides a path

of least resistance for electrical current- reducing the risk

of electric shock. is piece of equipment is furnished

with a cord that has a grounding conductor and grounding plug. e grounded plug must only be plugged

into an appropriate outlet that is properly installed and

grounded in accordance with all local codes and ordinances.

WARNING:

Connecting the equipment to an improperly grounded

outlet can result in an increased risk of electric shock. A

qualified electrician should be consulted if you are unsure

that the outlet is properly grounded. Do not modify the

plug provided with the equipment. If it will not fit the

outlet, have a proper outlet installed by a qualified electrician.

is appliance is designed for use on a 120-volt circuit.

e grounding plug provided looks like the plug illustrated in Figure 1. Replace the power cord if the grounding

pin is damaged or broken.

Extension cords connected to this machine should be

12 gauge, three-wire cords with three-prong plugs and

outlets. DO NOT use extension cords more than 25 feet

(7.6 m) long.

ELECTRICAL - 115 Volt

Model: 2000CX-HR/2000FX-HR

is machine is designed to operate on a standard 15

amp, 120 volt, 60 Hz, AC circuit. Voltages below 105 volt

AC or above 125 volts AC could cause serious damage to

the motor.

4

Figure 1

MAINTENANCE:

is 2000CX-HR/2000FX-HR has been engineered and

built to require minimum maintenance. But like any

machine, it does require basic care to keep it in optimum

working condition. Careful attention to these maintenance instructions will give you maximum operating

performance and life expectancy of the machine.

Wee kl y :

• Check and clean solution lter

• Check for obstructions in vacuum pathways

• Quarterly:

• Check pump, plumbing and ttings for leaks

• Check power cords and hoses for tears

CAUTION: Disconnect the power cord from the outlet

before doing any clean up or maintenance on the machine

1. Keep the machine clean. Do not allow dust to accumulate on external surfaces or near any moving parts.

2. Aer every job, wipe down the surface of the machine

with a clean damp cloth.

3. Inspect cord for damage. Do not use machine with a

damaged cord.

PERIODIC MAINTENANCE

• Use only chemicals safe for extractors

• Adhere to the appropriate mix ratios for all chemicals

• For optimal performance, it is suggested that the

operator ush the system aer every job or at the end

of the day.

• Pump seals and valves may need to be replaced at the

1000 hour mark if a loss in pressure is noted

Daily:

CORD STORAGE:

While not in use, storage can be accomplished by winding cord around handle assy. Cord should be

completely unwound during operation.

CORD SAFETY

• Do not leave appliance when plugged in. Unplug

from outlet when not in use and before servicing

• Do not use with damaged cord or plug. If appliance is

not working as it should, has been dropped, damaged,

le outdoors, or dropped into water, return to service

center for inspection and repair.

• Do not pull or carry by cord, use cord as handle, close

a door on cord, or pull cord around sharp edges or

corners. Do not run this 2000CX-HR/2000FX-HR

over cord. Keep cord away from heated surfaces.

• Do not unplug by pulling cord. To unplug, grasp the

plug, not the cord.

• Do not handle plug or appliance with wet hands.

• is equipment should be stored indoors and not

exposed to rain.

1. Always keep the machine clean inside and out.

2. Pour 2 gallons of clean hot water in the solution

tank. Turn the pump on and ush the entire system

through the wand nozzles for about a minute to prevent alkaline build-up.

3. Remove dirt and lint build-up inside the lter screen

in the recovery tank. Lint should be cleaned o so

that air ow is not impeded.

4. Check the solution tank strainer in the solution tank.

If lint has accumulated in the screen, remove and

rinse it in clear running water.

5

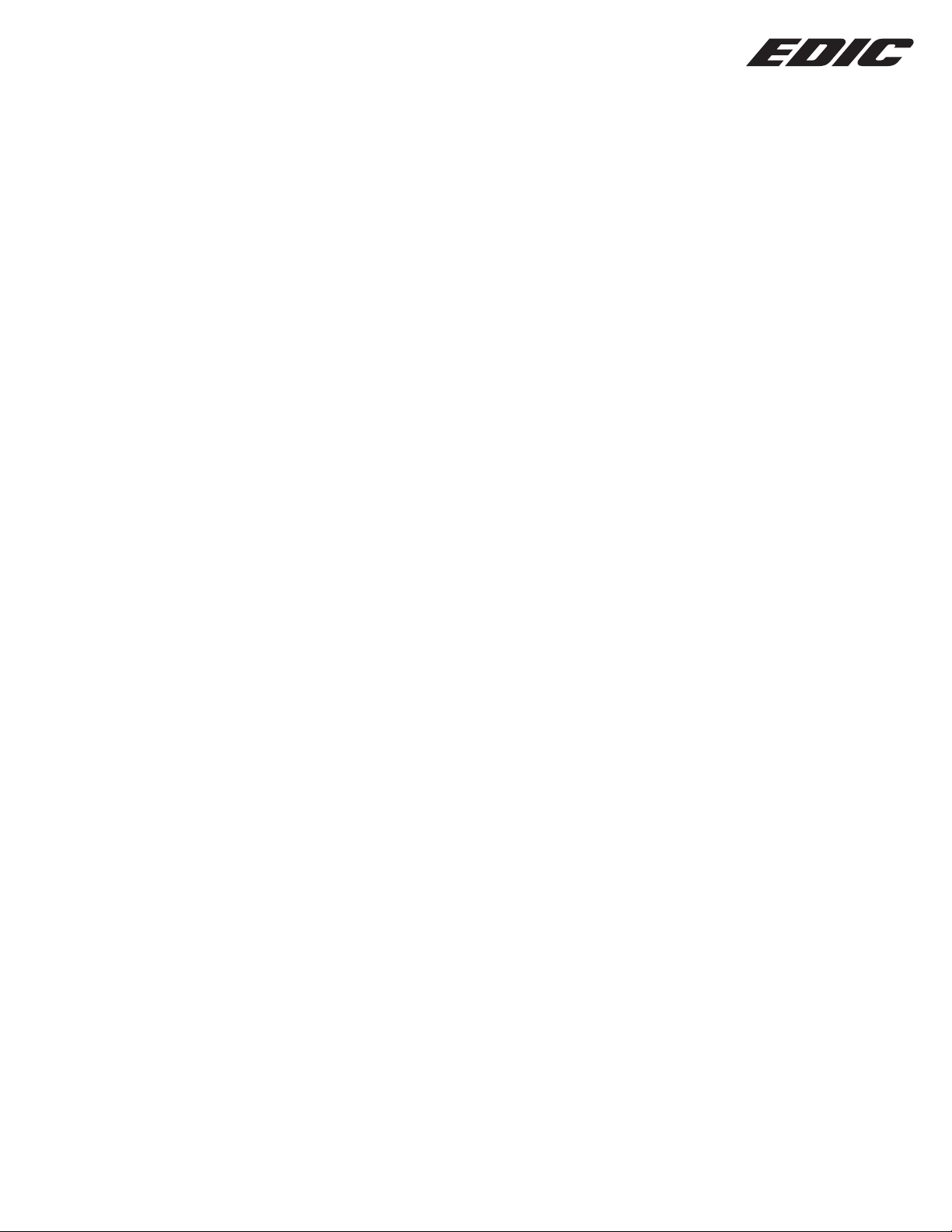

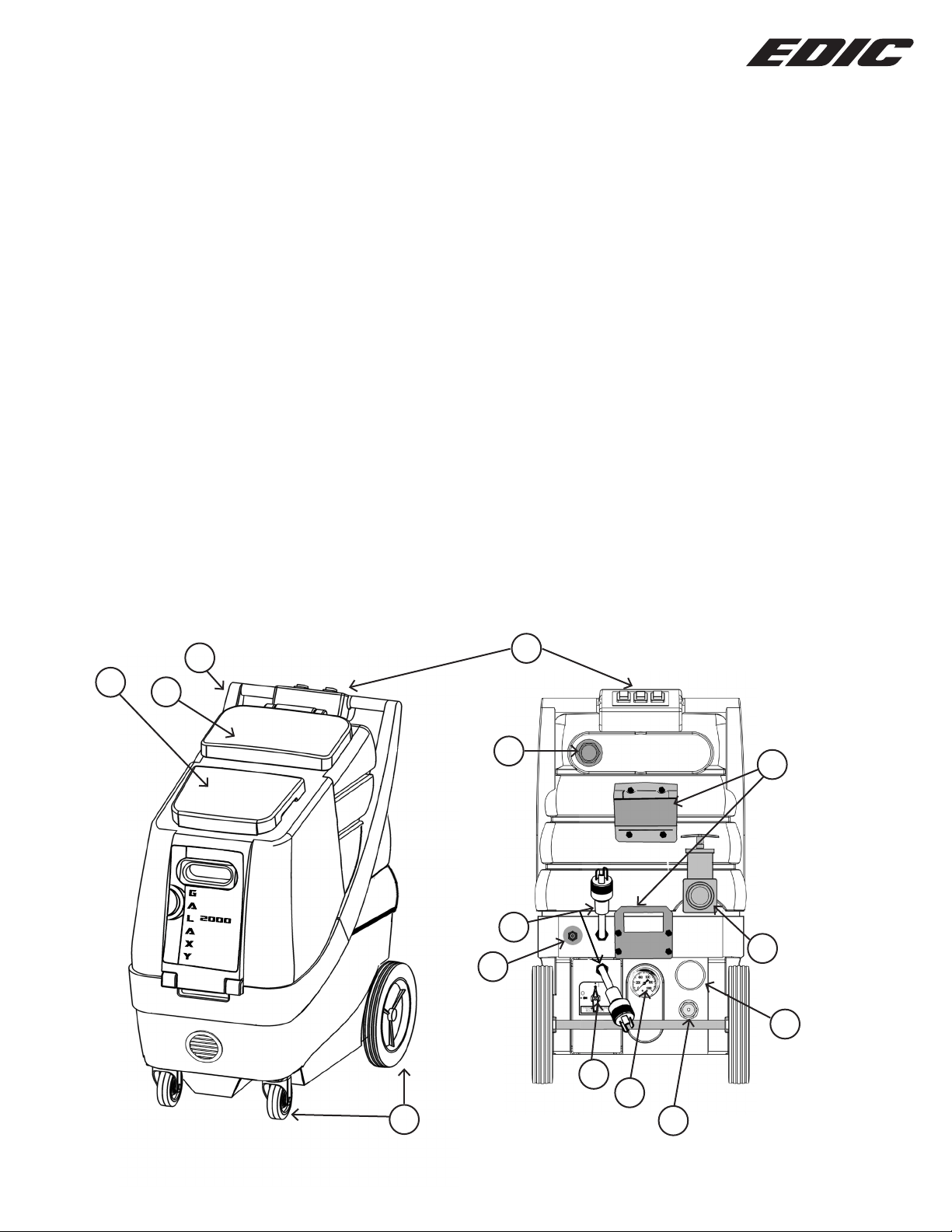

2000CX-HR

OVERVIEW

1. Handle- Used to maneuver and position the 2000CXHR/2000FX-HR. Contains switch box (for switchbox,

see #12).

2. Recovery tank and lid- Tank collects recovered waste

water. Lid allows access to recovery tank and creates a

seal to ensure suction.

3. Solution tank and lid- Tank used to store clean water

or solution for your job. Lid allows access to the

solution tank and prevents external contamination of

solution tank.

4. Non-marking front 4” locking casters and rear 10”

wheels.

5. Recovery/vacuum hose inlet barb- connect your

recovery vacuum hose to this barb.

1

3

2

6. Male twist lock pigtail- Connects to 50 power cord.

One circuit per cord.

7. Solution line Q.D.- Pressurized connection for solution line.

8. Pressure Relief/ Power Prime

9. Pressure Gauge

10. Pressure regulator

11. Cool air intake for vacuum.

12. Recovery tank dump valve

13. Heater mounting brackets.

14. Switch box- Two switches marked “VACUUM” and

one switch marked “PUMP”.

14

5

13

6

7

8

9

4

10

12

11

6

2000FX-HR

OVERVIEW

1. Handle- Used to maneuver and position the 2000CXHR/2000FX-HR. Contains switch box (for switchbox,

see #12).

2. Recovery tank and lid- Tank collects recovered waste

water. Lid allows access to recovery tank and creates a

seal to ensure suction.

3. Solution tank and lid- Tank used to store clean water

or solution for your job. Lid allows access to the

solution tank and prevents external contamination of

solution tank.

4. Non-marking front 4” locking casters and rear 10”

wheels.

5. Recovery/vacuum hose inlet barb- connect your

1

3

2

recovery vacuum hose to this barb.

6. Two male twist lock pigtails- Connect to two 50

power cord. One circuit per cord

7. Solution line Q.D.- Pressurized connection for solution line.

8. Pressure Relief/ Power Prime

9. Pressure Gauge

10. Pressure regulator

11. Cool air intake for vacuum.

12. Recovery tank dump valve

13. Heater mounting brackets.

14. Switch box- Two switches marked “VACUUM” and

one switch marked “PUMP”.

14

5

13

6

7

8

9

4

10

12

11

7

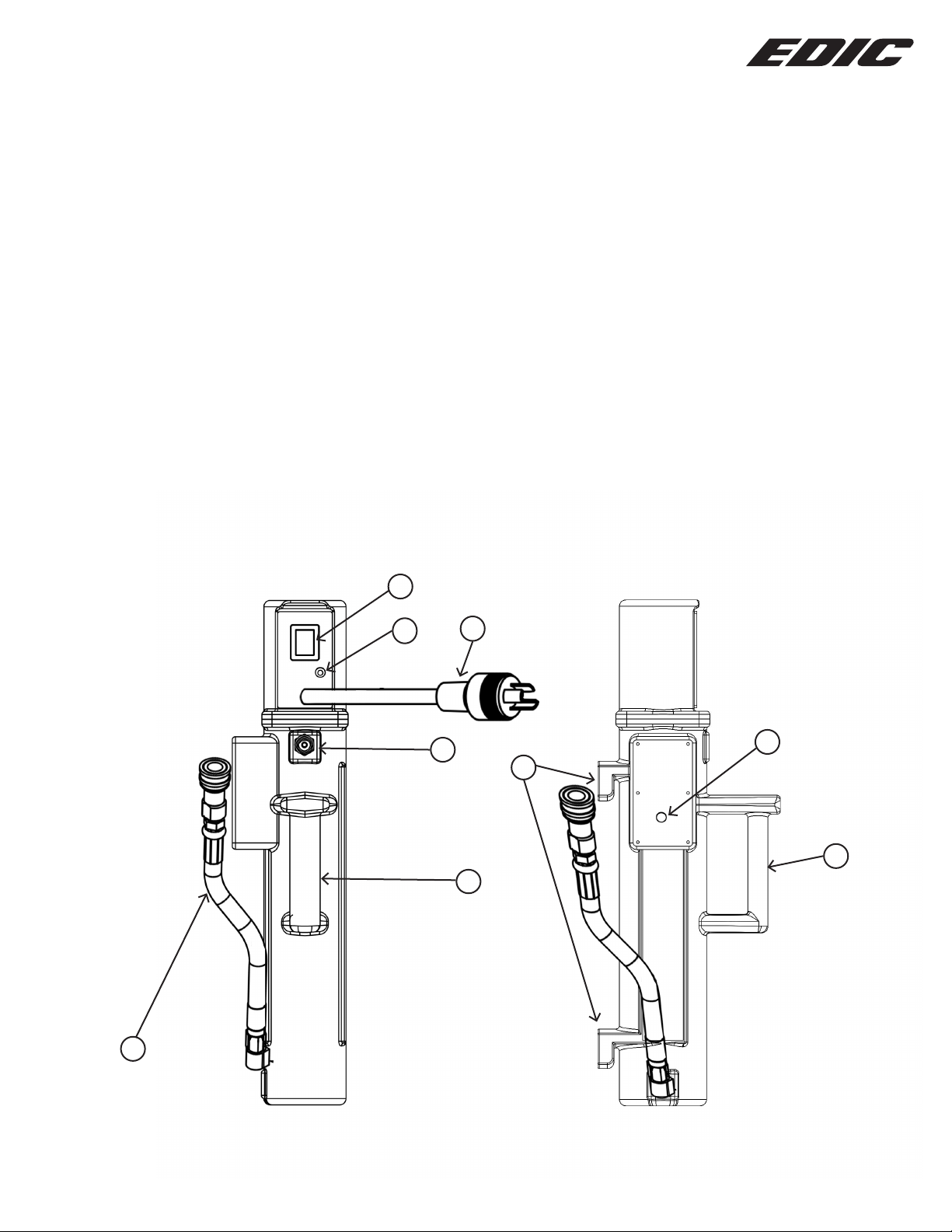

1. INLET QUICK DISCONNECT AND HOSE- Connects to machine’s outlet.

2. POWER SWITCH.

3. LAMP- Indicates when heat element is on and working.

4. TWIST LOCK PIG-TAIL- is connects to the

female twistlock plug on the rear of the 2000CXHR/2000FX-HR.

5. OUTLET QUICK DISCONNECT- Connects to

working solution line.

ACCESSORY HEATER KIT 605HR/705HR

OVERVIEW

(PURCHASED SEPARATELY)

2

6. HANDLE- Used to hold and transport the heater

7. MOUNTING FEET- Used to engage the mounting

brackets on an 2000CX-HR/2000FX-HR extractor

and secure the heater.

8. RESET ACCESS POINT- Allows access to the breaker switch in the event the unit has been run dry.

3

1

4

5

7

6

8

6

8

How to use an accessory heater:

1. Fill the solution tank of your 2000CX-HR/2000FXHR extractor with sucient water or solution for the

task at hand. Do not use water over 130 degrees F.

2. Mount the Heater by lining up the two mounting

legs (See #7 on page 8) to the two mounting brackets on the rear of the machine (#11 on pages 6&7).

3. Connect your heater’s inlet hose (#1 on page 8) to the

machine’s outlet quick disconnect (#7 on pages 6&7).

4. Connect your 25 solution hose

to the heater’s Q.D. (#5 on page 8)

5. Connect your 50FT power cord to the twist

lock pigtail on the heater (#4 on page 8). Plug

the 50 power cord(s) to the twist lock pigtail

on the back of the machine (#6 on pages 6&7)

6. Connect the power cord(s) to the machine and

an approved 15 amp outlet. If your machine is a

2000FX-HR, each of the two cords must be on a separate 15 am circuit.

7. Connect your 25 vacuum hose to the extractor’s

vacuum inlet barb (#5 on pages 6&7)

8. Connect your vacuum and solution line to a carpet

wand or upholstery attachment.

9. COMPLETE THIS STEP BEFORE TURNING

HEATER ON: Turn the pump switch to the “ON”

position using the pump switch on the handle of

your 2000CX-HR/2000FX-HR. Pressing the solution

valve trigger of your attachment, spray water for 1015 seconds until you have a steady ow. is ensures

the heater is lled with uid.

10. Turn heater on using the power switch (#2 on page

8) and allow up to 3 minutes for the unit to heat up.

11. e heater is ready for use once the green lamp (#3

on page 8) shuts o. Once you start cleaning, the

green lamp will turn on and o throughout your job

as the thermostats automatically regulate the temperature.

9

PRESSURE RELIEF/POWER PRIME VALVE:

For location, see #8 on page 6 and 7.

CLOSED

OPEN

PRIMING THE PUMP:

is machine is equipped with a PRESSURE RELIEF/

POWER PRIME VALVE. To prime the machine, turn on

the pump and turn the valve to open position (“O”) wait

a few seconds until the pump changes pitch and place it

back to the closed position. You may “POWER PRIME”

the pump by following the above steps, placing your hand

over the RECOVERY HOSE/ VACUUM INLET BARB

(#5 on pages 6&7)

ADJUSTING PRESSURE USING THE

PRESSURE REGULATOR:

Pressure gauge

Pressure regulator

is machine is equipped with a PRESSURE REGULATOR and PRESSURE GAUGE. You may adjust the

pressure between 100PSI and 500PSI. e machine

has been set to the max pressure at the factory. DO

NOT exceed 500PSI. For location, see #9 & #10 on

pages 6 & 7.

TO REDUCE PRESSURE:

1. Turn on the pump. Prime, if necessary.

2. DO NOT SPRAY WHILE ADJUSTING.

3. Turn the PRESSURE REGULATOR counter-clockwise and monitor the PRESSURE

GAUGE until you have reached the desired

Pressure.

RELIEVING PRESSURE:

In the event that you cannot connect or disconnect the

hoses, attachments or accessories to or from the solution

system, you must rst relieve the pressure. To do so, Turn

o the pump and turn the PRESSURE RELIEF/POWER PRIME VALVE to the open position (“O”) and then

connect or disconnect the attachment. Always place the

Pressure relief valve back to the closed position.

WARNING: DO NOT LEAVE THE MACHINE UNATTENDED WITH THE PRESSURE RELIEF/PRIMING

VALVE OPEN! FLOODING MAY OCCUR. CLOSE

THE VALVE DURING USE TO PREVENT PRESSURE

LOSS. DO NOT USE THE PRIMING VALVE TO REGULATE PRESSURE.

10

TO INCREASE PRESSURE:

1. Turn on the pump. Prime, if necessary.

2. DO NOT SPRAY WHILE ADJUSTING.

3. Turn the PRESSURE REGULATOR clockwise

and monitor the PRESSURE GAUGE until you

have reached the desired Pressure.

WARNING: DO NOT EXCEED 500PSI!

CLEANING CARPET:

1. Using a dedicated dry vacuum, pre-vacuum the space

to be cleaned to remove as much dirt as possible. Do

not use the extractor to dry vacuum as it does not

have a dry lter.

2. Pre-spray the carpet

3. See steps 1-11 in section “How to use an accessory

heater”

4. Make sure the drain valve (#10 on page 6) is closed by

pushing the T-handle all the way in.

5. Always use de-foamer- Previously shampooed carpets

usually have a heavy build-up of old shampoo residue

which can cause the vacuum system to ingest foam

and result in damage to the vacuum motor.

6. With the vacuum and pump switches in the “ON”

position, slowly pull the tool towards you with the

solution valve trigger pressed. Make a dry pass forward and backward over the cleaned area to recover

residual dirt and solution.

7. Do not overwet carpet! Make overlapping passes to

prevent streaking.

8. If the carpet is heavily soiled, squeeze solution valve

trigger on the forward pass as well as backwards,

allowing cleaning solution a few seconds longer to

work prior to vacuuming. Another method is to raise

the wand 8” above the carpet and pre-spray lightly

prior to cleaning passes. On extremely soiled carpets,

we recommend using a pre-spray solution.

9. When you are close to running out of solution, turn

o the pump and the heater. Attach the drain elbow

on the drain valve. Place a pail under the downspout

and pull up the drain valve T-handle. Dirty solution

will pour out until the tank is empty. Close the drain

valve. Use a clean bucket when you rell the solution

tank so you do not create contamination.

10. When the job is completed, turn the switches o,

including the heater, and disconnect the vacuum and

solution hoses from the carpet tool and the machine.

Drain the recovery tank through the drain valve as

before.

CLEANING UPHOLSTERY:

Cleaning upholstery with success requires a good knowledge of the type of fabric to be worked on. Look for the

cleaning instruction label sewn on the underside of the

furniture for the recommended method of cleaning the

fabric. If it calls for dry cleaning, do not attempt to clean

with the wet extraction method. Otherwise, damage to

the fabric could occur. Extraction works perfectly on

most synthetic fabrics including synthetic velvets.

Before proceeding, test the fabric for colourfastness.

Apply a small amount of ready-to-use cleaning solution

on the fabric in an inconspicuous spot. Wait for 2 to 3

minutes and rub the area with a white terry cloth towel.

If no color comes o the towel, the fabric should be safe

to clean. If a little color comes o, there is some risk of

colors running when you clean. It may be possible to

stabilise colors by cleaning with an acidic rinse.

1. Using a dedicated dry vacuum, pre-vacuum the space

to be cleaned to remove as much dirt as possible. Do

not use the extractor to dry vacuum as it does not

have a dry lter.

2. See steps 1-11 in section “How to use an accessory

heater”

3. Make sure the drain valve (#10 on page 6) is closed by

pushing the T-handle all the way in.

4. Attach an upholstery tool to the hose set.

5. Always use de-foamer. Previously cleaned upholstery

may have a heavy build-up of old shampoo residue

which can cause the vacuum system to ingest foam

and result in damage to the vacuum motor.

6. With the vacuum and pump switches in the “ON” position, slowly pull the tool backward with the solution

valve trigger pressed. Make a dry pass forward and

backward over the cleaned area to recover residual

dirt and solution.

7. Clean using as little solution as possible. Do not

overwet the upholstery! Make overlapping passes to

prevent streaking.

8. On heavily soiled areas like arm rests, pre-treat with a

recommended pre-spray and /or hold the upholstery

tool a few inches above the fabric and press lever to

spray on the solution before making a pass.

11

2000CX-HR

2700CX-HR

7-6-16

MOTOR HOUSING

HANDLE

WHITE

BLACK

WIRING DIAGRAM

12

BLACK

RECTIFIER

2

RED

YELLOW

PINK

2000FX-HR

2700FX-HR

7-6-16

AC

AC

MOTOR HOUSING

HANDLE

WHITE

WHITE

BLACK

BLACK

WIRING DIAGRAM

13

14 15

13

11

12

10

3

1

2

17 1816

201921

27

24

26

22 23

25

28

29

30

31

32

33

34

35

38

39

40

41

42

34

43

44

45

46

47

47

48

5 49

51

52

37

36

8

36

6

4

50

9B

9A

9C

9D

9

9A

9B

9C

9D

2000CX-HR UPPER

6-23-16

ITEM

NO.

1

F11787 Solution Tank

2

F11788 Recovery Tank

3

F11791 Lid, Solution Tank

8

E11124 Gasket, Recovery Tank

9

12904A Stand Pipe Assembly

K11965 Elbow, 180 Deg. Float Ball

K00672 Pvc Pipe, 1.5 X 12 in, Sch 40 Wht

K00741 Adapter

10989-2A Float Ball Screen

10

F11785 Lid, Recovery Tank

11

C12039 Washer, 1-4 X 1, SS

12

C02322 1-4 X 20 Bolt

13

B11769 Extension Cord, 12-3 SJTW

14

C11177 Velcro Strap

15

H02548-2 Label, Important, Cord

16

B00185-30 Wires, 73 in

17

B00185-40 Wires, 73 in

18

B010314 Wire Harness

19

F11786 Handle

20

B00177 Terminal Lug, Female, QD, .25 X .032, 16-14 AWG, Fully Insulated

21

B00185-40 Wire,14 GA Black, UL1015, 10 in

22

C00295-1 #10 X .75in Pan, Black SMS, Phillips

23

C00293 #8 X .5in Pan, Black SMS, Phillips

24

D11168 Cover, Switchplate, Galaxy

25

B02211-1 Switch, Rocker, Green Light

26

D010284 Switchplate

27

E010453 Gasket, Switchplate

28

B00177-1 Terminal Lug, Female, QD, .25 X .032

29

B00185-30 Wire,14 GA White, UL1015, 10 in

30

C02315 Lockwasher, #10 Int. Str, SS

31

C00264 Nut, 10-32

32

C11141 Screw, Allen Head, 10-24 X 1.25 in

33

K00665-1 Hose Adapter, 1.5in, Black

34

E11128 Gasket, Drain Valve

35

C00313 Hex Bolt, 1-4 X 20 X .5 SS

36

C00233 Washer, Flat, .25 in

37

C02312 Lockwasher, .25 in., Internal Star

38

D010283 Plate, Heater Mounting

39

F11804 Heater Mount

40

C00261 Nut, .25-20, Hex

41

K00710 Elbow, Drain Valve, Black

42

K00711 Drain Valve, Black

43

C00254 Lock Washer, 1-4in Split

44

C02294 Screw, 1-4 20 X 1.25

45

K11185 Elbow, 90, 1.5 in, MT-MS, PVC

46

K00672-1 Pvc Pipe, 1.5 X 2.25 in, Sch 40 Wht

47

E11129 Gasket, 5 ft. Long

48

A90004 .50 Barb X .25 MP, Brass

49

D00373 Inlet Filter, .25 NPT

50

A00124 Hex Nut, .25 NPT Brass

51

C11143 Screw, 1-4 20 X 1.5 in, SS Pan Head, Phillips

52

S11179 Non-Skid Tape, 1 in. Roll

A00060 3-8 Barb X 1-4MP, Brass

A00052 90 Elbow, .25MP X .25FP

C11244 Washer, .56 X 1.5 X .05

4

5

6

14

2000CX-HR UPPER

6-23-16

ITEM

NO.

1

F11787 Solution Tank

F11788 Recovery Tank

2

3

F11791 Lid, Solution Tank

A00060 3-8 Barb X 1-4MP, Brass

4

5

A00052 90 Elbow, .25MP X .25FP

C11244 Washer, .56 X 1.5 X .05

6

8

E11124 Gasket, Recovery Tank

9

12904A Stand Pipe Assembly

K11965 Elbow, 180 Deg. Float Ball

9A

K00672 Pvc Pipe, 1.5 X 12 in, Sch 40 Wht

9B

K00741 Adapter

9C

9D

10989-2A Float Ball Screen

F11785 Lid, Recovery Tank

10

11

C12039 Washer, 1-4 X 1, SS

C02322 1-4 X 20 Bolt

12

13

B11769 Extension Cord, 12-3 SJTW

14

C11177 Velcro Strap

H02548-2 Label, Important, Cord

15

16

B00185-30 Wires, 73 in

17

B00185-40 Wires, 73 in

B010314 Wire Harness

18

19

F11786 Handle

B00177 Terminal Lug, Female, QD, .25 X .032, 16-14 AWG, Fully Insulated

20

B00185-40 Wire,14 GA Black, UL1015, 10 in

21

22

C00295-1 #10 X .75in Pan, Black SMS, Phillips

23

C00293 #8 X .5in Pan, Black SMS, Phillips

24

D11168 Cover, Switchplate, Galaxy

25

B02211-1 Switch, Rocker, Green Light

26

D010284 Switchplate

27

E010453 Gasket, Switchplate

B00177-1 Terminal Lug, Female, QD, .25 X .032

28

29

B00185-30 Wire,14 GA White, UL1015, 10 in

C02315 Lockwasher, #10 Int. Str, SS

30

C00264 Nut, 10-32

31

C11141 Screw, Allen Head, 10-24 X 1.25 in

32

33

K00665-1 Hose Adapter, 1.5in, Black

E11128 Gasket, Drain Valve

34

35

C00313 Hex Bolt, 1-4 X 20 X .5 SS

C00233 Washer, Flat, .25 in

36

C02312 Lockwasher, .25 in., Internal Star

37

38

D010283 Plate, Heater Mounting

F11804 Heater Mount

39

40

C00261 Nut, .25-20, Hex

41

K00710 Elbow, Drain Valve, Black

42

K00711 Drain Valve, Black

C00254 Lock Washer, 1-4in Split

43

44

C02294 Screw, 1-4 20 X 1.25

K11185 Elbow, 90, 1.5 in, MT-MS, PVC

45

K00672-1 Pvc Pipe, 1.5 X 2.25 in, Sch 40 Wht

46

47

E11129 Gasket, 5 ft. Long

48

A90004 .50 Barb X .25 MP, Brass

D00373 Inlet Filter, .25 NPT

49

A00124 Hex Nut, .25 NPT Brass

50

C11143 Screw, 1-4 20 X 1.5 in, SS Pan Head, Phillips

51

52

S11179 Non-Skid Tape, 1 in. Roll

PART NUMBER

QTY.

1

1

1

2

3

3

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

2

1

2

2

1

3

1

1

4

1

2

1

8

1

2

6

8

2

1

1

2

1

1

2

2

1

1

1

1

2

2

2

1

15

14 15

13

11

12

10

3

1

2

17 1816

201921

27

24

26

22 23

25

28

29

30

31

32

33

34

35

38

39

40

41

42

34

43

44

45

46

47

47

48

5 49

51

52

37

36

8

36

6

4

50

9B

9A

9C

9D

9

9A

9B

9C

9D

2000FX-HR Upper

6-23-16

ITEM

NO.

1

F11787 Solution Tank

2

F11788 Recovery Tank

3

F11791 Lid, Solution Tank

8

E11124 Gasket, Recovery Tank

9

12904A Stand Pipe Assembly

K11965 Elbow, 180 Deg. Float Ball

K00672 Pvc Pipe, 1.5 X 12 in, Sch 40 Wht

K00741 Adapter

10989-2A Float Ball Screen

10

F11785 Lid, Recovery Tank

11

C12039 Washer, 1-4 X 1, SS

12

C02322 1-4 X 20 Bolt

13

B11769 Extension Cord, 12-3 SJTW

14

C11177 Velcro Strap

15

H02548-2 Label, Important, Cord

16

B00185-30 Wires, 73 in

17

B00185-40 Wires, 73 in

18

B010314 Wire Harness

19

F11786 Handle

20

B00177 Terminal Lug, Female, QD, .25 X .032, 16-14 AWG, Fully Insulated

21

B00185-40 Wire,14 GA Black, UL1015, 10 in

22

C00295-1 #10 X .75in Pan, Black SMS, Phillips

23

C00293 #8 X .5in Pan, Black SMS, Phillips

24

D11168 Cover, Switchplate, Galaxy

25

B02211-1 Switch, Rocker, Green Light

26

D010284 Switchplate

27

E010453 Gasket, Switchplate

28

B00177-1 Terminal Lug, Female, QD, .25 X .032

29

B00185-30 Wire,14 GA White, UL1015, 10 in

30

C02315 Lockwasher, #10 Int. Str, SS

31

C00264 Nut, 10-32

32

C11141 Screw, Allen Head, 10-24 X 1.25 in

33

K00665-1 Hose Adapter, 1.5in, Black

34

E11128 Gasket, Drain Valve

35

C00313 Hex Bolt, 1-4 X 20 X .5 SS

36

C00233 Washer, Flat, .25 in

37

C02312 Lockwasher, .25 in., Internal Star

38

D010283 Plate, Heater Mounting

39

F11804 Heater Mount

40

C00261 Nut, .25-20, Hex

41

K00710 Elbow, Drain Valve, Black

42

K00711 Drain Valve, Black

43

C00254 Lock Washer, 1-4in Split

44

C02294 Screw, 1-4 20 X 1.25

45

K11185 Elbow, 90, 1.5 in, MT-MS, PVC

46

K00672-1 Pvc Pipe, 1.5 X 2.25 in, Sch 40 Wht

47

E11129 Gasket, 5 ft. Long

48

A90004 .50 Barb X .25 MP, Brass

49

D00373 Inlet Filter, .25 NPT

50

A00124 Hex Nut, .25 NPT Brass

51

C11143 Screw, 1-4 20 X 1.5 in, SS Pan Head, Phillips

52

S11179 Non-Skid Tape, 1 in. Roll

16

2000FX-HR Upper

6-23-16

ITEM

NO.

1

F11787 Solution Tank

F11788 Recovery Tank

2

3

F11791 Lid, Solution Tank

8

E11124 Gasket, Recovery Tank

9

12904A Stand Pipe Assembly

K11965 Elbow, 180 Deg. Float Ball

9A

K00672 Pvc Pipe, 1.5 X 12 in, Sch 40 Wht

9B

K00741 Adapter

9C

9D

10989-2A Float Ball Screen

F11785 Lid, Recovery Tank

10

11

C12039 Washer, 1-4 X 1, SS

C02322 1-4 X 20 Bolt

12

13

B11769 Extension Cord, 12-3 SJTW

14

C11177 Velcro Strap

15

H02548-2 Label, Important, Cord

16

B00185-30 Wires, 73 in

17

B00185-40 Wires, 73 in

B010314 Wire Harness

18

19

F11786 Handle

B00177 Terminal Lug, Female, QD, .25 X .032, 16-14 AWG, Fully Insulated

20

B00185-40 Wire,14 GA Black, UL1015, 10 in

21

22

C00295-1 #10 X .75in Pan, Black SMS, Phillips

23

C00293 #8 X .5in Pan, Black SMS, Phillips

24

D11168 Cover, Switchplate, Galaxy

25

B02211-1 Switch, Rocker, Green Light

26

D010284 Switchplate

27

E010453 Gasket, Switchplate

B00177-1 Terminal Lug, Female, QD, .25 X .032

28

29

B00185-30 Wire,14 GA White, UL1015, 10 in

C02315 Lockwasher, #10 Int. Str, SS

30

C00264 Nut, 10-32

31

C11141 Screw, Allen Head, 10-24 X 1.25 in

32

33

K00665-1 Hose Adapter, 1.5in, Black

E11128 Gasket, Drain Valve

34

35

C00313 Hex Bolt, 1-4 X 20 X .5 SS

C00233 Washer, Flat, .25 in

36

C02312 Lockwasher, .25 in., Internal Star

37

38

D010283 Plate, Heater Mounting

F11804 Heater Mount

39

40

C00261 Nut, .25-20, Hex

41

K00710 Elbow, Drain Valve, Black

42

K00711 Drain Valve, Black

C00254 Lock Washer, 1-4in Split

43

44

C02294 Screw, 1-4 20 X 1.25

K11185 Elbow, 90, 1.5 in, MT-MS, PVC

45

K00672-1 Pvc Pipe, 1.5 X 2.25 in, Sch 40 Wht

46

47

E11129 Gasket, 5 ft. Long

48

A90004 .50 Barb X .25 MP, Brass

D00373 Inlet Filter, .25 NPT

49

A00124 Hex Nut, .25 NPT Brass

50

C11143 Screw, 1-4 20 X 1.5 in, SS Pan Head, Phillips

51

52

S11179 Non-Skid Tape, 1 in. Roll

DESCRIPTION

QTY.

1

1

1

2

3

3

1

1

1

1

1

1

1

1

2

2

2

2

2

1

1

1

1

2

1

2

2

1

3

1

1

4

1

2

1

8

1

2

6

8

2

1

1

2

1

1

2

2

1

1

1

1

2

2

2

1

17

70

ITEM

QTY.

ITEM

QTY.

1

J13152 Double grip hose Clamp

1

2

J11863 Vac Exhaust hose, 2” diameter

1 ft

3

J00639 Screw Clamp, 1.63

4

4

J00618 Hose , V ac base to waste tank

22”

5

F11178-BLK Intercooler, Galaxy, Black

1

6

C00273 Locknut, 1-4 X 20, Nylon, SS

18

7

C00233 Washer, Flat, .25 in

31

8

E00449 Grommet

6

9

C00284 Screw, 10-32 X .375 Ground

2

10

B11150 Ground Wire, Galaxy

2

11

G13394 Vacuum,115 V, 5.7 in

2

12

J00618 Vacuum Hose, 2 in Grey

6”

13

C00261 Nut, .25-20, Hex

12

14

C00254 Lock Washer, 1-4in Split

1

15

D11134-1 Vac Plate

1

16

C11189 Screw, 1 -4 X 20 X 4.5 in, Hex

5

17

C11516 Screw, 1 -4 X 20 X 4.5 in, Flat

1

18

J11154 Hose, regulator to solution tank

28”

19

J00651 Hose Clamp 1-5/8 x 2 -7/16

4

20

A00060 .25 Male X .375 Barb, Brass

1

21

A00053 45 Elbow, .25MP X .25 FP

1

22

G13441 Regulator Valve

1

23

A00052 90 Elbow, .25MP X .25FP

4

24

00580 -10in-MF -A Hose Assembly

1

25

00580 -12IN -MF-A Hose Assembly

1

26

A00114B Hex Nipple 1/4MP x 1/8MP

1

27

G13380 Pressure relief/ Power prime

1

28

A00134 90 elbow, 1/4B x 1/8MP

1

29

A13881 Check valve, 450 series

30

C11244 Washer, .56 X 1.5 X .05

7

31

C12021 Washer, 9/16 ID

1

32

A00139 Hose Barb 1/4MPx1/4B

1

33

34

A00161 Tee, .25 FP, Brass

1

35

A00111 Nipple, .25 in

1

36

A00104 QD, 1-4 M X 1-4 FP, Brass

1

37

G13051 Gauge, 0-1000PSI

1

38

C11440 Spacer, Heater Mounting Plate

4

39

C02322 Hex Bolt,1-4 X 20 X 1.75 in

4

40

D010379 Heater Mounting Plate

1

41

C11165, Screw, #8 X 1 in, Pan, Black

5

42

F

11790 Heater, Tunnel Cover, Blue

1

43

B11779 12-3 Twist lock plug

1

44

B00191 Nylon Tie, 11in Black

5

45

C00293 #8 X .5in Pan, Black SMS, Phillips

2

46

B00192 Tie Holder with Glue

2

47

B11606 Strain Relief, Pigtail

1

48

C02305 Cap Nut, .5in Push

2

49

C00240 Washer, Shoulder, Nylon

4

50

G11767 Wheel, 10 in

2

51

D11170 Axle

1

52

F11789 Base

1

53

C00314-1 Hex Bolt, 1/4 X 20 X 1in

8

54

G03518-L Locking Caster, 4 in

2

55

F13820 3” Louver

1

56

B00177 Terminal Lug

2

57

C 11955 Flat Washer, #10

1

58

C13026 Screw 10-32 x 1 ” hex

4

59

B02229 Bridge rectier

1

60

G13872 Pump, 500 PSI, 120 V

1

61

A13430 90 E lbow 3/8MP x .5B

1

62

A12917 90 E lbow 1/4F x 3/8M NPT

2

63

J00632 -1 Pulse Hose, 32 in

2

64

B00190 Nylon Tie, 4in

12

65

D13866 Pump mounting plate

1

66

H02564 -2 Label, Caution, Motor

1

67

J11508 Hose Clamp 1/ 2" - 3/4"

2

68

J11933 Hose Solution Tank to Pump “IN ”

17”

69

J00618 Vacuum Hose. Exhaust to plate

7”

70

E11169 Gasket, Vac Motor, Galaxy

2

J11554-1 Hose- pressure relief to waste tank

69

16

1

2

3546

7

2000CX-HR

8

9

10

BASE 6-23-16

11

3

12

3

13

14

15

16

23

7

18

20

21

22

24

25

33

26

27

28

29

23

30

19

32

31

14

64

65

17

66

30

26

34

19

6

7

67

68

38

35

39

36

40

30

37

41

63

61

60

58

59

57

56

10

62

53

54

46

42

43

4445

47

55

49

5152 50 4849

7

18

ITEM

QTY.

ITEM

QTY.

1

1

2

1 ft

3

4

4

J00618 Hose , Vac base to waste tank

22”

5

1

6

18

7

C00233 Washer, Flat, .25 in

31

8

6

9

2

10

2

11

2

12

6”

13

12

14

1

15

1

16

C11189 Screw, 1 -4 X 20 X 4.5 in, Hex

517C11516 Screw, 1 -4 X 20 X 4.5 in, Flat

1

18

28”

19

4

20

A00060 .25 Male X .375 Barb, Brass

1

21

A00053 45 Elbow, .25MP X .25 FP

1

22

G13441 Regulator Valve

1

23

4

24

1

25

00580 -12IN -MF-A Hose Assembly

1

26

A00114B Hex Nipple 1/4MP x 1/8MP

1

27

1

28

A00134 90 elbow, 1/4B x 1/8MP

1

29

30

C11244 Washer, .56 X 1.5 X .05

7

31

1

32

1

33

34

A00161 Tee, .25 FP, Brass

1

35

A00111 Nipple, .25 in

1

36

1

37

1

38

C11440 Spacer, Heater Mounting Plate

4

39

4

40

D010379 Heater Mounting Plate

1

41

C11165, Screw, #8 X 1 in, Pan, Black

5

42

1

43

1

44

B00191 Nylon Tie, 11in Black

5

45

C00293 #8 X .5in Pan, Black SMS, Phillips

2

46

B00192 Tie Holder with Glue

247B11606 Strain Relief, Pigtail

1

48

C02305 Cap Nut, .5in Push

2

49

C00240 Washer, Shoulder, Nylon

4

50

G11767 Wheel, 10 in

2

51

D11170 Axle

1

52

1

53

8

54

2

55

1

56

B00177 Terminal Lug

2

57

C 11955 Flat Washer, #10

1

58

4

59

B02229 Bridge rectier

1

60

1

61

A13430 90 E lbow 3/8MP x .5B

1

62

A12917 90 E lbow 1/4F x 3/8M NPT

2

63

2

64

B00190 Nylon Tie, 4in

12

65

D13866 Pump mounting plate

1

66

H02564 -2 Label, Caution, Motor

1

67

2

68

17”

69

7”

70

E11169 Gasket, Vac Motor, Galaxy

2

2000CX-HR 6-23-16

PART NUMBER

J13152 Double grip hose Clamp

J11863 Vac Exhaust hose, 2” diameter

J00639 Screw Clamp, 1.63

F11178-BLK Intercooler, Galaxy, Black

C00273 Locknut, 1-4 X 20, Nylon, SS

E00449 Grommet

C00284 Screw, 10-32 X .375 Ground

B11150 Ground Wire, Galaxy

G13394 Vacuum,115 V, 5.7 in

J00618 Vacuum Hose, 2 in Grey

C00261 Nut, .25-20, Hex

C00254 Lock Washer, 1-4in Split

D11134-1 Vac Plate

J11154 Hose, regulator to solution tank

J00651 Hose Clamp 1-5/8 x 2 -7/16

A00052 90 Elbow, .25MP X .25FP

00580 -10in-MF -A Hose Assembly

G13380 Pressure relief/ Power prime

- 2.43in.

A13881 Check valve, 450 series

C12021 Washer, 9/16 ID

A00139 Hose Barb 1/4MPx1/4B

J11554-1 Hose- pressure relief to waste tank

A00104 QD, 1-4 M X 1-4 FP, Brass

G13051 Gauge, 0-1000PSI

C02322 Hex Bolt,1-4 X 20 X 1.75 in

F

11790 Heater, Tunnel Cover, Blue

B11779 12-3 Twist lock plug

-on

F11789 Base

C00314-1 Hex Bolt, 1/4 X 20 X 1in

G03518-L Locking Caster, 4 in

F13820 3” Louver

C13026 Screw 10-32 x 1 ” hex

G13872 Pump, 500 PSI, 120 V

J00632 -1 Pulse Hose, 32 in

J11508 Hose Clamp 1/ 2" - 3/4"

J11933 Hose Solution Tank to Pump “IN ”

J00618 Vacuum Hose. Exhaust to plate

19

70

ITEM

QTY.

ITEM

QTY.

1

J13152 Double grip hose Clamp

1

2

J11863 Vac Exhaust hose, 2” diameter

1 ft

3

J00639 Screw Clamp, 1.63

4

4

J00618 Hose , V ac base to waste tank

22”

5

F11178-BLK Intercooler, Galaxy, Black

1

6

C00273 Locknut, 1-4 X 20, Nylon, SS

18

7

C00233 Washer, Flat, .25 in

31

8

E00449 Grommet

6

9

C00284 Screw, 10-32 X .375 Ground

2

10

B11150 Ground Wire, Galaxy

2

11

G002522L Vacuum,115 V, 5.7 in

2

12

J00618 Vacuum Hose, 2 in Grey

6”

13

C00261 Nut, .25-20, Hex

12

14

C00254 Lock Washer, 1-4in Split

1

15

D11134-1 Vac Plate

1

16

C11189 Screw, 1 -4 X 20 X 4.5 in, Hex

5

17

C11516 Screw, 1 -4 X 20 X 4.5 in, Flat

1

18

J11154 Hose, regulator to solution tank

28”

19

J00651 Hose Clamp 1-5/8 x 2 -7/16

4

20

A00060 .25 Male X .375 Barb, Brass

1

21

A00053 45 Elbow, .25MP X .25 FP

1

22

G13441 Regulator Valve

1

23

A00052 90 Elbow, .25MP X .25FP

4

24

00580 -10in-MF -A Hose Assembly

1

25

00580 -12IN -MF-A Hose Assembly

1

26

A00114B Hex Nipple 1/4MP x 1/8MP

1

27

G1 3380 Pressure relief/ Power prime

1

28

A00134 90 elbow, 1/4B x 1/8MP

1

29

A13881 Check valve, 450 series

30

C11244 Washer, .56 X 1.5 X .05

7

31

C12021 Washer, 9/16 ID

1

32

A00139 Hose Barb 1/4MPx1/4B

1

33

34

A00161 Tee, .25 FP, Brass

1

35

A00111 Nipple, .25 in

1

36

A00104 QD, 1-4 M X 1-4 FP, Brass

1

37

G13051 Gauge, 0-1000PSI

1

38

C11440 Spacer, Heater Mounting Plate

4

39

C02322 Hex Bolt,1-4 X 20 X 1.75 in

4

40

D010379 Heater Mounting Plate

1

41

C11165, Screw, #8 X 1 in, Pan, Black

5

42

F

11790 Heater, Tunnel Cover, Blue

1

43

B11779 12-3 Twist lock plug

44

B00191 Nylon Tie, 11in Black

5

45

C00293 #8 X .5in Pan, Black SMS, Phillips

2

46

B00192 Tie Holder with Glue

2

47

B11606 Strain Relief, Pigtail

48

C02305 Cap Nut, .5in Push

2

49

C00240 Washer, Shoulder, Nylon

4

50

G11767 Wheel, 10 in

2

51

D11170 Axle

1

52

F11789 Base

1

53

C00314-1 Hex Bolt, 1/4 X 20 X 1in

8

54

G03518-L Locking Caster, 4 in

2

55

F13820 3” Louver

1

56

B00177 Terminal Lug

2

57

C 11955 Flat Washer, #10

1

58

C13026 Screw 10-32 x 1 ” hex

4

59

B02229 Bridge rectier

1

60

G13872 Pump, 500 PSI, 120 V

1

61

A13430 90 E lbow 3/8MP x .5B

1

62

A12917 90 E lbow 1/4F x 3/8M NPT

2

63

J00632 -1 Pulse Hose, 32 in

2

64

B00190 Nylon Tie, 4in

12

65

D13866 Pump mounting plate

1

66

H02564 -2 Label, Caution, Motor

1

67

J11508 Hose Clamp 1/ 2" - 3/4"

2

68

J11933 Hose Solution Tank to Pump “IN ”

17”

69

J00618 Vacuum Hose. Exhaust to plate

7”

70

E11169 Gasket, Vac Motor, Galaxy

2

J11554-1 Hose- pressure relief to waste tank

69

16

1

2

3546

7

2000FX-HR

8

9

10

BASE 6-23-16

11

3

12

3

13

14

15

16

23

7

18

20

21

22

24

25

33

26

27

28

29

23

30

19

32

31

14

17

30

26

34

19

64

65

66

6

7

67

68

38

35

39

36

40

30

37

41

63

61

60

58

59

57

56

10

62

53

54

46

42

43

4445

47

55

49

5152 50 4849

7

20

ITEM

QTY.

ITEM

QTY.

1

1

2

1 ft

3

4

4

J00618 Hose , Vac base to waste tank

22”

5

1

6

18

7

C00233 Washer, Flat, .25 in

31

8

6

9

2

10

2

11

2

12

6”

13

12

14

1

15

1

16

C11189 Screw, 1 -4 X 20 X 4.5 in, Hex

517C11516 Screw, 1 -4 X 20 X 4.5 in, Flat

1

18

28”

19

4

20

A00060 .25 Male X .375 Barb, Brass

1

21

A00053 45 Elbow, .25MP X .25 FP

1

22

G13441 Regulator Valve

1

23

4

24

1

25

00580 -12IN -MF-A Hose Assembly

1

26

A00114B Hex Nipple 1/4MP x 1/8MP

1

27

G1 3380 Pressure relief/ Power prime

1

28

A00134 90 elbow, 1/4B x 1/8MP

1

29

30

C11244 Washer, .56 X 1.5 X .05

7

31

1

32

1

33

34

A00161 Tee, .25 FP, Brass

1

35

A00111 Nipple, .25 in

1

36

1

37

1

38

C11440 Spacer, Heater Mounting Plate

4

39

4

40

D010379 Heater Mounting Plate

1

41

C11165, Screw, #8 X 1 in, Pan, Black

5

42

1

43

44

B00191 Nylon Tie, 11in Black

5

45

C00293 #8 X .5in Pan, Black SMS, Phillips

2

46

B00192 Tie Holder with Glue

247B11606 Strain Relief, Pigtail

48

C02305 Cap Nut, .5in Push

2

49

C00240 Washer, Shoulder, Nylon

4

50

G11767 Wheel, 10 in

2

51

D11170 Axle

1

52

1

53

8

54

2

55

1

56

B00177 Terminal Lug

2

57

C 11955 Flat Washer, #10

1

58

4

59

B02229 Bridge rectier

1

60

1

61

A13430 90 E lbow 3/8MP x .5B

1

62

A12917 90 E lbow 1/4F x 3/8M NPT

2

63

2

64

B00190 Nylon Tie, 4in

12

65

D13866 Pump mounting plate

1

66

H02564 -2 Label, Caution, Motor

1

67

2

68

17”

69

7”

70

E11169 Gasket, Vac Motor, Galaxy

2

2000FX-HR 6-23-16

PART NUMBER

J13152 Double grip hose Clamp

J11863 Vac Exhaust hose, 2” diameter

J00639 Screw Clamp, 1.63

F11178-BLK Intercooler, Galaxy, Black

C00273 Locknut, 1-4 X 20, Nylon, SS

E00449 Grommet

C00284 Screw, 10-32 X .375 Ground

B11150 Ground Wire, Galaxy

G002522L Vacuum,115 V, 5.7 in

J00618 Vacuum Hose, 2 in Grey

C00261 Nut, .25-20, Hex

C00254 Lock Washer, 1-4in Split

D11134-1 Vac Plate

J11154 Hose, regulator to solution tank

J00651 Hose Clamp 1-5/8 x 2 -7/16

A00052 90 Elbow, .25MP X .25FP

00580 -10in-MF -A Hose Assembly

A13881 Check valve, 450 series

C12021 Washer, 9/16 ID

A00139 Hose Barb 1/4MPx1/4B

J11554-1 Hose- pressure relief to waste tank

- 2.43in.

PART NUMBER

A00104 QD, 1-4 M X 1-4 FP, Brass

G13051 Gauge, 0-1000PSI

C02322 Hex Bolt,1-4 X 20 X 1.75 in

F

11790 Heater, Tunnel Cover, Blue

B11779 12-3 Twist lock plug

-on

F11789 Base

C00314-1 Hex Bolt, 1/4 X 20 X 1in

G03518-L Locking Caster, 4 in

F13820 3” Louver

C13026 Screw 10-32 x 1 ” hex

G13872 Pump, 500 PSI, 120 V

J00632 -1 Pulse Hose, 32 in

J11508 Hose Clamp 1/ 2" - 3/4"

J11933 Hose Solution Tank to Pump “IN ”

J00618 Vacuum Hose. Exhaust to plate

2

2

21

TROUBLESHOOTING

ELECTRICAL SYSTEM

PROBLEM SOLUTION

NO ELECTRICAL POWER 1. Defective power cord.

2. House or building circuit breaker tripped

POWER IS INTERMITTENT TO ONE OR ALL MOTORS

VACUUM SYSTEM

PROBLEM SOLUTION

NO VACUUM SUCTION 1. Drain Valve open.

LOW VACUUM SUCTION 1. Accumulated dirt on intake lter screen.

1. Faulty electrical cable.

2. Defective switches.

3. Loose terminal or discolored terminal connections.

2. Vacuum lid is not sealed against tank.

3. Loose vacuum hose, vacuum connection

2. Worn out vacuum lid gasket.

3. Lint & dirt build-up on wand head.

4. Defective vacuum hose.

5. Loose connection in the vacuum motor.

SOLUTION SYSTEM

PROBLEM SOLUTION

PUMP MOTOR RUNS BUT NO SPRAY THROUGH

SPRAY TIPS

UNEVEN OR WEAK SPRAY FOR SPRAY TIPS 1. Clogged or dirty spray tips.

ERRATIC PRESSURE 1. Pump check valves defective or dirty

1. Clogged spray tips.

2. Clogged solution intake lter screen.

3. Clogged female quick disconnect coupler.

4. Quick disconnects not fully connected

5. Dirty or damaged pump head valves.

6. Defective pump check valve.

7. Crack in pump housing.

8. Lost Prime.

2. Accumulated dirt on solution intake lter screen.

3. Accumulation of debris inside pump and plumbing.

4. Worn pump bearing (excessive noise).

5. Punctured pump diaphragm.

6. Defective rectier or motor.

7. Worn nozzles.

8. Priming valve is open. Close Pressure relief/priming

valve

2. Lost prime.

22

NOTES

_________________

23

Quality Above All

The following Limited 5-year Warranty is given by EDIC with respect to the following specific

EDIC products:

Polaris

Saturn High Speed

Aviator

Supernova

Saturn Low Speed

Galaxy Pro

Aqua Dri

2 Years Parts & Labor

TORO HD Orbital

TORO Orbital

FloodBuster

Extractors

1725-TES has a 4-year

1725-TPT has a 2-year

Warranty Registration:

To register your product warranty, visit our website at:

www.edic-usa.com/warranty-registration/

EDIC STANDARD LIMITED WARRANTY PLAN FOR MACHINES MANUFACTURED AFTER 2/14/2017

Galaxy 5

Endeavor

Heat N Run

The following Warranty is given by EDIC with respect to the following specific EDIC products:

Dynamo Vacuums

Pilot Autoscrubber

Galaxy Automotive

LIFETIME on rotationally molded polyethylene tanks, stainless steel heater tank and Saturn stainless steel

brush covers.

5 YEARS on service labor, and all other parts not covered by the Lifetime terms.

2 YEARS on service labor, and all other parts not covered by the Lifetime terms.

Fivestar

Galaxy

Bravo

parts warranty and a

2-year labor warranty

Saturn Dual Speed

Saturn HD Low Speed

Atlas

CR2 Restroom Cleaner

parts warranty and a

1-year labor warranty

EDIC REPLACEMENT PARTS LIMITED WARRANTY PLAN

All parts sold as replacement parts for out-of-warranty EDIC products have the following Limited Warranty,

with no warranty on labor: 30 DAYS

Your product is warranted to be free of defects in material and workmanship for the period set forth above,

after the date of delivery to the retail purchaser, when operated in normal service and used in accordance

with the operating and maintenance instructions in the Owner’s Manual. This warranty is limited to and

provides at no cost to the retail purchaser repair or replacement of parts determined to be defective, at EDIC’s

option, and labor, if provided for above, to replace or repair the parts (“service labor”) according to EDIC’s

Standard Rates, during the warranty period set forth above. This warranty excludes transportation charges

unless authorized in writing by EDIC. No warranty returns for refund or credit will be permitted. In the event of

a defect, these are your exclusive remedies. Warranty claims must be made in writing to EDIC prior to

returning the product and no products will be accepted for repair or replacement without prior authorization

by EDIC. Use of parts not approved by EDIC in EDIC products will void this warranty. Warranty repair or

replacement shall not extend the original warranty period of the product, and replacement parts used for in-

1753 Blake Ave., Los Angeles, CA 90031 | 800.338.3342 | www.edic-usa.com

24

Quality Above All

warranty repairs will only be warranted for the remainder of the original warranty and not from their

installation date. Any parts or product replaced under this Limited Warranty will become the property of EDIC.

EXCEPTIONS AND EXCLUSIONS FROM THE WARRANTY. This Limited Warranty only covers product issues

caused by defects in material or workmanship during normal service. It does not cover product issues from

any other cause, including but not limited to (a) transportation damages; (b) alteration by unauthorized

persons; (c) unauthorized use, unreasonable use, misuse, or abuse (including the use of incompatible or

corrosive chemicals or overloading of capacity); (d) failure caused by lack of proper maintenance and cleaning;

(e) normal wear on items such as cords, belts, hoses, switches, bumpers, gaskets, seals, carbon brushes,

squeegees, harnesses, valves, cams, extraction brushes, bearings, handle grips, filters and finishes; (f) acts of

God; or (g) modification of or any part of the product. This Limited Warranty does not cover EDIC products

sold AS IS and WITH ALL FAULTS. This Limited Warranty is valid only in the United States and Canada.

We suggest that you complete and return the enclosed product registration card promptly to facilitate

verification of the date of the original purchase. However, return of the product registration card does not

eliminate the need for the retail purchaser to maintain the original proof of the purchase in order to obtain

the warranty benefits. In the event that you do not have proof of purchase date, the purchase date for

purposes of this warranty will be the date of manufacture.

For specific information on how to obtain warranty services for your product, please write to:

EDIC/Warranty Department

1753 Blake Ave.

Los Angeles, CA 90031

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE OF THIS STATEMENT.

THERE IS NO IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY USE ON THESE GOODS.

NO IMPLIED WARRANTY, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE, APPLIES TO THE PRODUCT AFTER THE APPLICABLE PERIOD OF THE EXPRESS LIMITED

WARRANTY STATED ABOVE, AND NO OTHER EXPRESS WARRANTY, EXCEPT AS MENTIONED ABOVE, GIVEN

BY ANY PERSON OR ENTITY WITH RESPECT TO THE PRODUCT SHALL BIND EDIC. EDIC SHALL NOT BE LIABLE

FOR ANY FORM OF ACTION FOR ANY DAMAGES, WHETHER DIRECT, SPECIAL, INCIDENTAL, CONSEQUENTIAL,

OR INDIRECT, TO PROPERTY OR PERSON, INCLUDING BUT NOT LIMITED TO, DAMAGE OR LOSS OF INCOME,

LOSS OF PRODUCTION, OR LOSS OF PROFITS DUE TO MALFUNCTIONING OF ANY PRODUCT, REGARDLESS OF

THE LEGAL THEORY ON WHICH THE CLAIM IS BASED. IN NO EVENT SHALL RECOVERY OF ANY KIND AGAINST

EDIC BE GREATER IN AMOUNT THAN THE PURCHASE PRICE OF THE PRODUCT SOLD BY EDIC, AND CAUSING

THE ALLEGED DAMAGE. WITHOUT LIMITING THE FOREGOING, YOU ASSUME ALL THE RISK AND LIABILITY

FOR LOSS, DAMAGE OR INJURY TO YOU AND YOUR PROPERTY AND TO OTHERS AND THEIR PROPERTY

ARISING OUT OF USE OR MISUSE OF, OR INABILITY TO USE, THE PRODUCT NOT CAUSED DIRECTLY BY

NEGLIGENCE OF EDIC. THIS LIMITED WARRANTY STATES YOUR EXCLUSIVE REMEDY.

Some states do not allow the exclusion or limitation of incidental or consequential damages, or allow

limitations on how long an implied warranty lasts, so the above limitations or exclusions may not apply to you.

This Limited Warranty gives you specific legal rights and you may have other rights which vary from state to

state (or province).

0900.002/9989

1753 Blake Ave., Los Angeles, CA 90031 | 800.338.3342 | www.edic-usa.com

25

Loading...

Loading...