Page 1

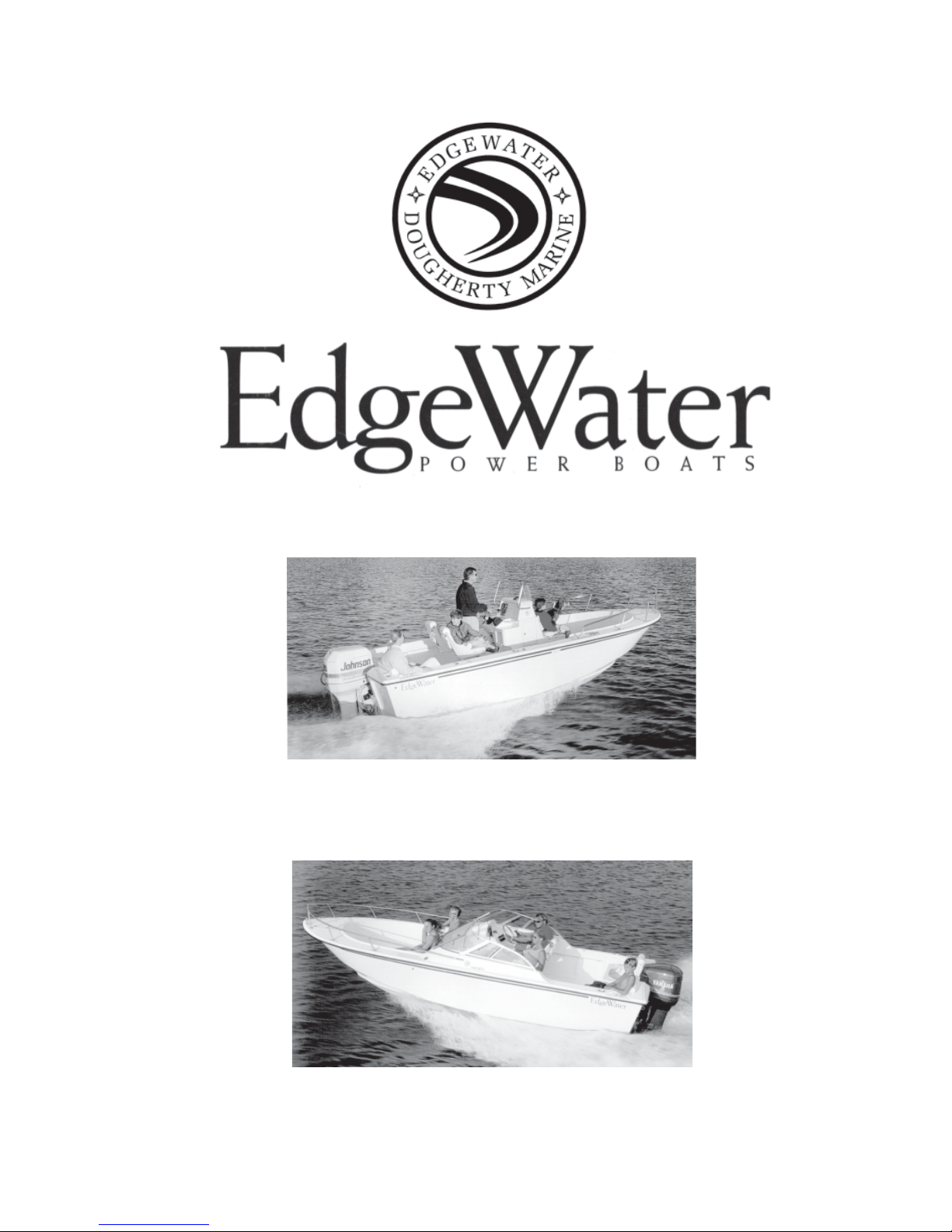

Owner’s Manual

200CC / DC

Page 2

200CC

200DC

Page 3

Dear EdgeWater 200CC / DC Owner:

Congratulations on purchasing one of the finest small boats ever built. It has been constructed with care

from the finest available materials. At EdgeWater we take great pride in the quality and craftsmanship that

goes into each boat, large or small. We believe you’ll have many years of enjoyment from your new

EdgeWater and thank you for entrusting your leisure time to one of our fine products.

This manual has been assembled to help you learn more about your new boat and increase your enjoyment of it. Your EdgeWater has been built for a “Lifetime on the Water”.

Boat safe and boat smart, we wish you many years of boating pleasure.

Sincerely,

Peter Truslow

President

EdgeWater Powerboats

Page 4

SerSer

Ser

SerSer

Please fill out the information below completely. It will help us in assisting you in the event your EdgeWater

needs service.

Customer Name

Address

City State Zip

Phone Home Office

Dealer Name

Address

City State Zip

Phone Fax

vice Infvice Inf

vice Inf

vice Infvice Inf

ormationormation

ormation

ormationormation

Purchase Date Engine Make/Model

Delivery Date Engine Serial #

Hull Number DMA Ignition Key #

Dougherty Marine Partnership, d.b.a. EdgeWater Powerboats reserves the right to make alterations in the

standard and optional equipment without incurring obligation to those boats already having been built.

Every effort has been made to ensure that the information in this manual accurately describes vessels

being built at the date of printing.

Page 5

Table of Contents

ChaptChapt

Chapt

ChaptChapt

ChaptChapt

Chapt

ChaptChapt

ChaptChapt

Chapt

ChaptChapt

ChaptChapt

Chapt

ChaptChapt

er 1 General Infer 1 General Inf

er 1 General Inf

er 1 General Infer 1 General Inf

1.1 General................................................................................................................................................ 13

1.2 Owner / Operator Responsibilities ................................................................................................... 13

er 2 Helm Contrer 2 Helm Contr

er 2 Helm Contr

er 2 Helm Contrer 2 Helm Contr

2.1 General................................................................................................................................................ 15

2.2 Steering System ................................................................................................................................. 15

2.3 Engine Throttle and Shift Controls.................................................................................................... 15

er 3 Prer 3 Pr

er 3 Pr

er 3 Prer 3 Pr

3.1 General................................................................................................................................................ 17

3.2 Engine Cooling System ...................................................................................................................... 17

3.3 Propellers ............................................................................................................................................ 18

3.4 Engine Power Tilt and Trim ................................................................................................................ 18

3.5 Engine Instrumentation ..................................................................................................................... 19

er 4 Fer 4 F

er 4 F

er 4 Fer 4 F

4.1 General................................................................................................................................................ 21

4.2 Fuel Fill................................................................................................................................................ 21

4.3 Fuel Vent ............................................................................................................................................. 21

4.4 Fueling................................................................................................................................................. 21

4.5 Fuel System Maintenance ................................................................................................................. 22

4.6 Fuel Filters .......................................................................................................................................... 22

opulsion Systopulsion Syst

opulsion Syst

opulsion Systopulsion Syst

uel Systuel Syst

uel Syst

uel Systuel Syst

ormationormation

ormation

ormationormation

ol Systol Syst

ol Syst

ol Systol Syst

emem

em

emem

emem

....................................................................................................................................................................................

em

..........................................................................................

emem

....................................................................................................................................................................................

........................................................................................................................................................

............................................................................

........................................................................................................................................................

emsems

................................................................................................................................................

ems

........................................................................

emsems

................................................................................................................................................

................................................................................................................................................................

................................................................................

................................................................................................................................................................

11

1

11

11

1

11

1

22

2

22

33

3

33

55

5

55

11

77

7

11

77

11

1

11

ChaptChapt

Chapt

ChaptChapt

ChaptChapt

Chapt

ChaptChapt

ChaptChapt

Chapt

ChaptChapt

er 5 Electrical Syster 5 Electrical Syst

er 5 Electrical Syst

er 5 Electrical Syster 5 Electrical Syst

5.1 General................................................................................................................................................ 23

5.2 Accessory Panel Switches ................................................................................................................. 23

5.3 Electrical System Maintenance ......................................................................................................... 23

er 6 Raer 6 Ra

er 6 Ra

er 6 Raer 6 Ra

6.1 General................................................................................................................................................ 25

6.2 Livewell Operation.............................................................................................................................. 25

6.3 High Pressure Washdown.................................................................................................................. 25

6.4 Raw Water System Maintenance ...................................................................................................... 25

er 7 Drainage Syster 7 Drainage Syst

er 7 Drainage Syst

er 7 Drainage Syster 7 Drainage Syst

7.1 General ................................................................................................................................................ 27

7.2 Drain System Maintenance ................................................................................................................ 27

7.3 Cockpit Drains .................................................................................................................................... 27

7.4 Transom Bilge ..................................................................................................................................... 27

7.5 Fishbox Drains.................................................................................................................................... 28

7.6 Livewell Drains ................................................................................................................................... 28

7.7 T-Top Drain (optional T-Top) .............................................................................................................. 28

w Ww W

w W

w Ww W

atat

er & Fer & F

at

er & F

atat

er & Fer & F

emem

..................................................................................................................................................................

em

.................................................................................

emem

..................................................................................................................................................................

reshwreshw

reshw

reshwreshw

emem

em

emem

atat

er Syster Syst

at

er Syst

atat

er Syster Syst

....................................................................................................................................................................

..................................................................................

....................................................................................................................................................................

emsems

..........................................................................................................

ems

.....................................................

emsems

..........................................................................................................

2323

23

2323

2525

25

2525

22

77

2

7

22

77

Page 6

Chapter 8 Safety EquipmentChapter 8 Safety Equipment

Chapter 8 Safety Equipment

Chapter 8 Safety EquipmentChapter 8 Safety Equipment

8.1 Required Safety Equipment ............................................................................................................. 29

8.2 Suggested Safety Equipment - Inshore .......................................................................................... 30

8.3 Suggested Safety Equipment – Offshore .......................................................................................30

......................................................................................................................................................

...........................................................................

......................................................................................................................................................

2929

29

2929

ChaptChapt

Chapt

ChaptChapt

ChaptChapt

Chapt

ChaptChapt

ChaptChapt

Chapt

ChaptChapt

er 9 Safer 9 Saf

er 9 Saf

er 9 Safer 9 Saf

9.1 Pre-Cruise Check List ......................................................................................................................... 31

9.2 Basic Rules of the Road .................................................................................................................... 32

9.3 Safe Operation ................................................................................................................................... 33

9.4 Towing or Being Towed ...................................................................................................................... 34

9.5 Stopping the Boat .............................................................................................................................. 35

9.6 Docking ............................................................................................................................................... 35

9.7 After Operation ................................................................................................................................... 35

9.8 Trailering Your Boat ............................................................................................................................ 36

9.9 Launching Your Boat .......................................................................................................................... 37

9.10 Retrieving Your Boat ........................................................................................................................ 37

er 1er 1

0 R0 R

er 1

0 R

er 1er 1

0 R0 R

10.1 Exterior Hull and Deck ..................................................................................................................... 39

10.2 Engine ............................................................................................................................................... 40

er 1er 1

1 Ext1 Ext

er 1

1 Ext

er 1er 1

1 Ext1 Ext

11.1 Anchor Locker................................................................................................................................... 41

11.2 Swim Platform (optional)................................................................................................................. 41

11.3 Trim Tabs (optional) ......................................................................................................................... 41

e Operatione Operation

e Operation

e Operatione Operation

outine Maintoutine Maint

outine Maint

outine Maintoutine Maint

erior Eqerior Eq

erior Eq

erior Eqerior Eq

uipmentuipment

uipment

uipmentuipment

..........................................................................................................................................................................

.....................................................................................

..........................................................................................................................................................................

enanceenance

enance

enanceenance

..............................................................................................................................................

.......................................................................

..............................................................................................................................................

........................................................................................................................................................

............................................................................

........................................................................................................................................................

33

11

3

1

33

11

3939

39

3939

44

11

4

1

44

11

ChaptChapt

Chapt

ChaptChapt

AppendixAppendix

Appendix

AppendixAppendix

er 12 Seasonal Mainter 12 Seasonal Maint

er 12 Seasonal Maint

er 12 Seasonal Mainter 12 Seasonal Maint

12.1 Engine ............................................................................................................................................... 43

12.2 Hull .................................................................................................................................................... 43

12.3 Trailer ................................................................................................................................................ 43

......................................................................................................................................................................................................................................

...................................................................................................................

......................................................................................................................................................................................................................................

enanceenance

enance

enanceenance

..........................................................................................................................................

.....................................................................

..........................................................................................................................................

4343

43

4343

4545

45

4545

Page 7

1

General Information

1.1 General

The EdgeWater 200CC / DC has been designed to be powered by a single outboard engine. If the

outboard you chose is two-cycle, make sure to monitor oil level in the oil tank, located in the aft port

locker.

Each outboard manufacturer provides manuals to carefully detail operation and maintenance of their

products. Please read and observe the instructions set forth in your outboard manual.

1.2 Owner / Operator Responsibilities

Registration

Registering your boat is important to you. Federal Law requires that all powered, undocumented vessels

be registered in their state of principal use. Contact the appropriate agency in your local state to obtain

specific registration information.

Reporting Boating Accidents

All boating accidents must be reported to the proper authorities in the state which the accident occurred. If someone dies or disappears as a result of the recreational boating accident, it must be

reported immediately, with a formal report being made within 48 hours. If there is damage of more than

$500, or if the boat is completely lost, a formal report must be made within 10 days.

A “Boating Accident Report” form is located in the back of this manual, and if you need additional

information you may obtain it by calling the Boating Safety Hotline, 800-368-5647.

Education

Whether or not you are an experienced boater, attending a Boating Education Course can be beneficial.

If you are inexperienced, it is the best, safest way to begin your life on the water. If you are an experienced

boater, it’s always good to sharpen your skills.

Required Equipment

The U.S. Coast Guard requires certain equipment on each boat. In addition, they also set minimum

equipment and safety standards. For more detailed requirement information, obtain “Federal

Requirements And Safety Tips For Recreational Boats”, by contacting the Boating Safety Hotline,

800-368-5647.

Some states and local agencies require equipment that is not required by the U.S. Coast

Guard. Your local agency or dealer can provide specific information regarding these nonstandard requirements.

EdgeWater 200CC / DC 13

Page 8

2

Helm Control Systems

2.1 General

The helm station is the control center for the boat. The main control systems are the engine throttle and

shift controls, the steering system, and the trim tab controls. These provide the operator the ability to

control speed, direction, boat trim, and attitude. Each manufacturer provides manuals on the operation

and use of their systems. On the EdgeWater 220CC the center console has been designed for

stand up operation. This is especially useful when operating with a sea running as your knees can flex to

help absorb the boat’s movement. The starboard helm station for the 200DC has been designed for

either standing or sitting operation.

2.2 Steering System

General

The manual, which comes with your steering system, will provide specific information on your steering

system.

There are two main components of your steering system: a helm assembly and hydraulic cylinder. Turning

the helm, which pumps fluid in the hydraulic hoses, activates the hydraulic cylinder and causes the motor

to turn. The helm acts as both pump and reservoir.

While running at slow speeds, most boats tend to wander slightly back and forth. Keeping the wheel in the

center without overcompensating for the slight wandering will prevent over steering and reduce the tendency

to wander.

Steering System Maintenance

Routine system inspection should occur regularly. Cables, hoses, linkage and helm assemblies should be

inspected for wear, corrosion, cracking, or deterioration. Cleaning and light grease should be applied to all

exposed metal parts and other damaged or deteriorated parts should be replaced as soon as possible.

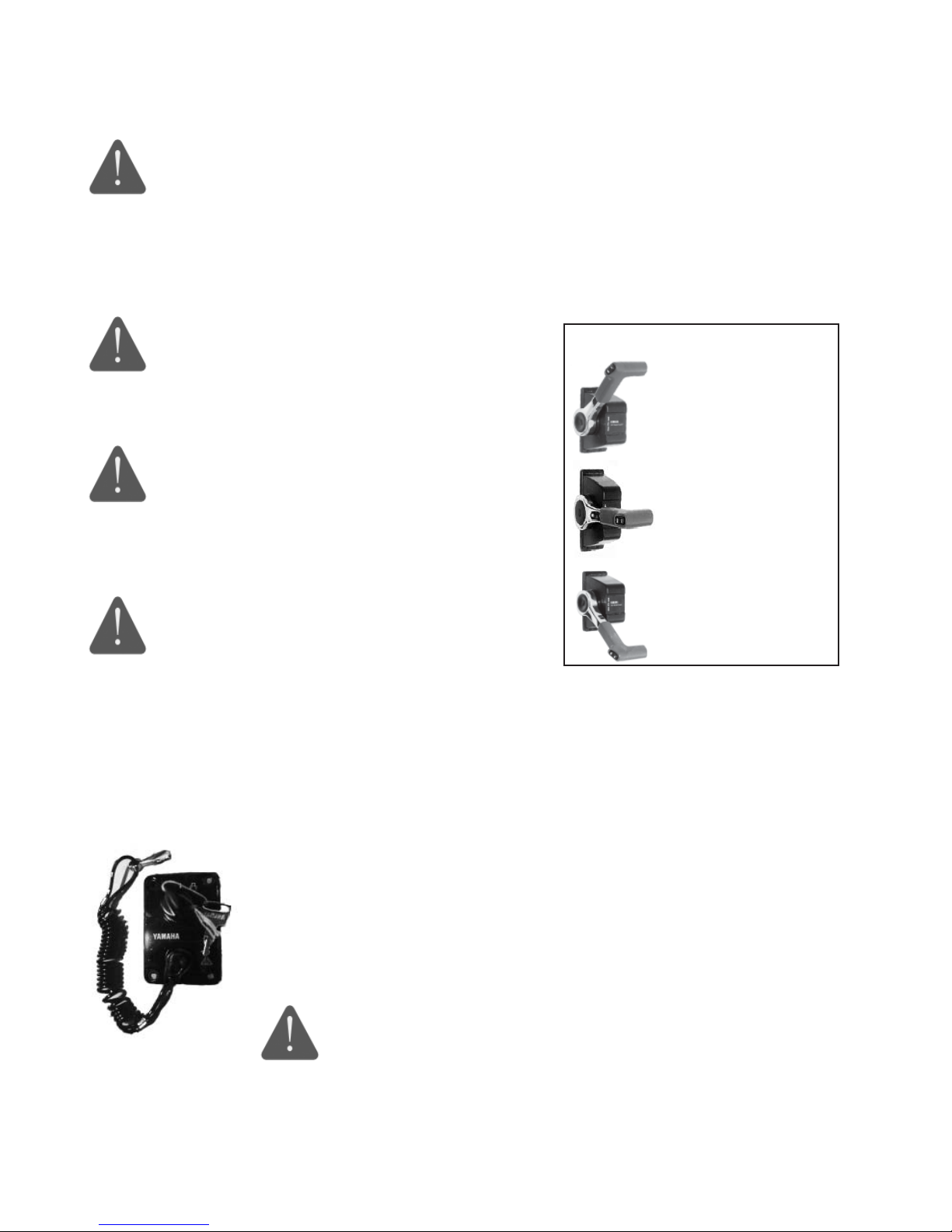

2.3 Engine Throttle and Shift Controls

Refer to the engine manual supplied with your engine for specific information on your controls. The ones

depicted are those supplied by Yamaha.

Your EdgeWater 200CC / DC comes only with a single engine. There are three major components of the

engine throttle and shift controls: handles, throttle cable, shift cable. Throttle and shift cables are pushpull and are connected to the fuel system (carburetor or fuel injection) and the other to the shift rod

linkage. By moving the handles forward and back, the operator engages the cables thus controlling the

amount of fuel being used and the gear selector for forward neutral and reverse. Careful use of the

controls provides smooth, responsive and safe operation.

EdgeWater 200CC / DC 15

Page 9

Chapter 2 Helm Control Systems

Do not bring the throttle back abruptly to stop the boat unless it is an emergency . Allow time

for the engine RPM to come down to idle before shifting to reverse or severe gearbox damage could occur.

The control is generally in neutral when the lever is 90o to the control box. Moving the lever 15o forward

will engage forward gear. Moving the lever 15o aft from center will engage reverse gear. There is usually

a slight detent at the point where a gear is engaged.

When shifting from neutral to forward or reverse,

the operator should always perform a brief pause to

allow time for the gear box to engage in the proper

gear at a minimum rpm. This pause will reduce gear

clash and provide for longer gear life.

THROTTLE POSITIONS

The levers should never be moved forward for back

without the engine running, with the following exception. With the Y amaha control, pushing the center of the rubber plate on the left side of the control

box disengages the gear shift and provides throttle

only operation with the gear-box remaining in neutral. This provides additional throttle for cold starts

or other warm-up operation.

Do not attempt to control adjustments unless you

are very familiar with their function, operation and

adjustment. Failure to properly adjust the system

components can adversely affect your boat’s

performance and safety. Misadjustment can also

cause severe control, engine or lower unit damage.

Forward

Neutral

Reverse

Each manufacturer’s engine controls contain a neutral safety switch to prevent accidental starting with

a gear engaged. The adjustment of this device should be done only by a certified technician. If the

engine will not start in neutral, a slight movement of the control may be necessary to locate the actual

“neutral” position of the neutral safety switch.

Engine Stop Switch

This device in designed to prevent the operator falling overboard while the engine

remains running. The engine stop switch lanyard should always be worn by the

operator, while the boat is in motion. Pulling the lanyard from the control will

stop the engine. If the engine will not crank properly, the lanyard may not be

properly attached to the engine stop switch.

16 EdgeWater 200CC / DC

Do not use the engine stop switch to stop the boat unless it is an

emergency as it may impair your ability to quickly re-start the engine.

Page 10

3

Propulsion System

3.1 General

Your new EdgeWater 200CC / DC is designed to be powered by a single outboard motor. Most 2-cycle

outboards currently use an automatic system to mix the oil with the gasoline before the engine uses it.

If equipped with a 2-cycle engine, there will be an oil tank in the aft, starboard locker. Make sure this

tank always has a sufficient amount of the recommended 2-cycle oil for your cruise, plus some reserve.

4-cycle engines require oil be maintained in the crankcase. Always check the crankcase oil level before

each day’s run.

Always follow the manufacturer’s recommendations and use only the recommended oil types.

Don’t attempt to service your outboard or any of its components unless you are thoroughly

familiar with its operation and dangers. Many of the moving part components are exposed

and can pose an extreme danger to anyone unfamiliar with their operation. Always leave

the servicing to a qualified technician.

Each manufacturer provides manuals designed to assist you in the proper operation and maintenance

of your new engine. Follow their guidance and schedules for proper operation of your new engine. With

a modern outboard there is little to do as long as proper maintenance is performed, in accordance with

the manufacturer’s recommendations. If the boat is to be kept in saltwater for an extended period,

electrolysis and marine growth can become a problem. When leaving your boat in salt water overnight or

for an extended period, tilt the engine as high out of the water as possible. This will decrease the

possibility of marine growth on the outside of the engine, as well as reduce the potential of marine

growth compromising the cooling water inlets in the lower unit, which can cause overheating.

Do not paint your outboard’s lower unit with paints designed for boat hulls. Some can cause

severe damage to your engine. Check with your engine manufacturer to get their

recommendation.

Do not attempt to control adjustments unless you are very familiar with their function, operation and

adjustment. Failure to properly adjust the system components can adversely affect your boat’s

performance and safety. Misadjustment can also cause severe control, engine or lower unit damage.

Please return all warranty cards for boat, engine and other related items. This will assist you

in the event you have a warranty problem.

3.2 Engine Cooling System

Most outboard engines are cooled by water taken in through ports in the lower part of the drive section.

Make sure these ports are free of debris or other items that might cause the flow to be restricted.

Maintain a routine vigilance to see that the visual inspection streams have a steady flow of water. If

they do not, shut down the engine to see if they are clogged or if there is a more serious problem. Be

especially watchful if you have gone through an area of vegetation or shallow water as the intake ports

can become clogged with weeds, dirt or other debris.

EdgeWater 200CC / DC 1 7

Page 11

Chapter 3 Propulsion System

Do not run your outboard without water coming into the lower unit. The water pump impeller

can be damaged in only seconds of this type of operation.

3.3 Propellers

A turning propeller moves the boat through the water, forward

or backward. They should always be clean and free from nicks

or dings, which can adversely affect performance. Your dealer

can assist you in the proper selection of a propeller for your

boat. This selection is based on the horsepower of the engine

and its relationship to the size and weight of the boat.

Propeller sizes are determined by two numbers, which appear

on different propellers at various locations. They are listed in

sequence, for example 13 x 17. The first number is the diameter

of the propeller and the second is the pitch. Pitch is the

theoretical distance the propeller moves through the water with each complete revolution. The larger

the number the greater the theoretical movement. It also follows that the larger the number the greater

horsepower is required to turn it. With a load which is “normal”, or usual for your boating activities, the

engine should be able to reach its maximum operating RPM range at wide open throttle (WOT). With a

light load on smooth water, the engine should reach its manufacturer’s rated maximum operating RPM

at wide open throttle (WOT) and maximum trim. If it does not, you may have a propeller which has too

much pitch. If it goes beyond the maximum recommended RPM range, you may have too little pitch.

Neither condition is good for the engine. You will get shorter engine life and poorer performance than

your boat and motor were designed to provide.

If your boat came from the factory with a propeller selected by EdgeWater , it should already

be optimized for the performance of your boat. Before changing the pitch or diameter of

your propeller always check with your dealer to determine how the changes will affect your

boat and engine performance.

3.4 Engine Power Tilt and Trim

The power tilt and trim system on your outboard provides the ability

to optimize the running angle of your EdgeWater 200CC / DC to

allow for load and sea conditions. Moving the outboard lower unit

toward the transom is generally referred to as trimming “in”, while

moving the outboard lower unit away from the transom is referred

to trimming “out”. It is generally best to have the engine trimmed

in for acceleration from displacement to planning mode. This brings

the bow down and requires less fuel and effort on the engine’s

part to plane off the hull.

The first 20o of movement aft of the transom is referred to as

trim and is the area generally used to operate the boat while on

plane. The area beyond the first 20o is referred to as tilt and is

usually reserved for operating in shallow water or pulling up on a

beach.

Max

Trim

Engine

Tilt

Tilt

Under

18 EdgeWater 200CC / DC

Page 12

Chapter 3 Propulsion System

While running under normal conditions, the bow should be in a 3o to 5o up angle to maximize the hull’s

ride and performance. When sea conditions are rougher than normal, bringing the bow slightly down may

improve the ride and will also allow the boat to remain on plane at a lower speed.

Watch the hoses and cable on your engine as it is tilted to its full tilt position. They may

become caught and damaged if the engine is in the wrong position.

3.5 Engine Instrumentation

The following is presented to familiarize you with the instruments, which may be on your boat. Every

boat is not equipped with full instrumentation.

All factory installed Yamaha engines include Y amaha’s digital multifunction t achometer and

speedometer. Refer to your engine operators manual for use details.

Tachometer

The tachometer displays the number of revolutions per minute (RPM) the engine is turning. There is a

designed operation RPM range for the engine. Become familiar with the operating range of your engine

and its operating characteristics. The tachometer is designed to aid the boater to assure the engine

performs within that designed range. The tachometer can be used to better understand the performance

of your engine and your EdgeWater 200CC / DC. By monitoring your tachometer as you operate your

EdgeWater, you will find RPM ranges that work better in certain sea and load conditions. Be alert the

tachometer operation may provide an early indication of difficulty, before it becomes irreversible.

Speedometer

The speedometer indicates the boat speed in miles per hour. Some types work using a spinning wheel

to determine the boat speed. Their accuracy can vary from the actual over the bottom speed due to

many factors. Other boat speedometers calculate the speed by amount of pressure the moving water

forces into a “pitot” tube. These gauges should only be used as indicators of approximate speed and not

used as absolute speed indicators.

Temperature Gauge

This is designed to monitor the operating temperature of your engine’s cooling system. A sudden rise

from the normal should be investigated to determine if there is an obstruction in the cooling system.

Water Pressure Gauge

This gauge measures pressure in the engine cooling system. If the pressure changes from the norm it

could indicate a complete or partial blockage in the system or a water pump problem. If this does not

return to normal, your dealer should check it to make sure the cooling system is operating properly.

Fuel Gauge

This gauge indicates the amount of fuel in the fuel tank. It is always prudent to follow the “rule of

thirds”, one-third of the tank to get the destination, one-third to return, and one-third in reserve.

EdgeWater 200CC / DC 19

Page 13

Chapter 3 Propulsion System

This gauge is a measure of relative fuel supply and is not a calibrated instrument!

Voltmeter

This meter displays the voltage for the battery and charging system.

Hour Meter

The hour meter keeps a record of operating time and is very useful for scheduling maintenance.

Engine Alarms

Most outboards are equipped with several audible engine alarms. Your engine owner’s manual will

familiarize you with these and their sometimes-distinctive sounds.

WarningWarning

Warning: If an engine alarm sounds, shut down the engine until the source of the problem is determined.

WarningWarning

Compass

The compass assists in determining your location by indicating your

position relative to magnetic north. For accuracy, your compass may

need to be adjusted to take into account specifics of your boat and

geographic location. Please refer to the material provided with your

compass for “compensation”.

Instrument Maintenance

Your instrument faces should be periodically cleaned to keep them free of salt and atmospheric debris.

The ignition switches should be periodically sprayed with a contact cleaner/lubricant to keep them free

of corrosion and dirt.

20 EdgeWater 200CC / DC

Page 14

4

Fuel System

4.1 General

All fuel systems and components on your EdgeWater 200CC / DC have been checked and each fuel

tank has been pressure tested. This inspection and pressure testing assure that your fuel system is

leakproof and safe. It is the purchaser’s responsibility to maintain the fuel system in a safe manner.

Make periodic inspections to determine the system is still safe and free from leaks. Special care should

be taken when inspecting joints and connections to make sure they have not loosened with vibration.

The EdgeWater fuel system has been designed to meet or exceed the requirements of the U.S. Coast

Guard, the National Marine Manufacturers Association, and the American Boat and Yacht Council, which

were in effect at the time of your boat’s manufacture.

If any odor of gasoline is detected, immediately shut off all engines and electrical devices

until the source and condition of the odor has been determined and eliminated. Have a fire

extinguisher at the ready until the condition has been resolved.

4.2 Fuel Fill

The fuel fill cap is located on the port side and is labeled “GAS”. The fill is opened

by turning it counterclockwise, and closed by turning the cap clockwise. Tighten

the cap until it is snug, not so tight it cannot be removed at the next fuel stop, or

so tight that the rubber o-ring is damaged, allowing water to enter the system.

4.3 Fuel Vent

This vent is located on the portside of the boat on the hull. This vent allows air to

escape from the tank and thus allows fuel to enter. Make sure this vent is kept

free from debris.

4.4 Fueling

Your EdgeWater 200CC / DC is equipped with a built-in 92 gallon fuel tank. Before fueling, you should

follow these procedures.

• Make sure the boat is securely moored.

• Make sure all switches are off and all cigarettes are extinguished.

• Know the location of the fire extinguisher in case of an emergency.

• Remove the fuel fill cap.

• Place the nozzle firm against the side of the opening.

• Begin fueling.

• When the tank is full, stop fueling.

• Remove the fuel nozzle.

• Install the fuel cap.

• Check the area for fuel odors.

EdgeWater 200CC / DC 2 1

Page 15

Chapter 4 Fuel System

Warning: If fuel odors are detected, do not start the engine! Check to make certain there are

no leaks or system problems before starting the engine.

Warning: Do not fill the fuel tank while the engine is running. Do not allow smoking or open

flames within 50 ft. of the fueling area. Fuel is very flammable. To prevent damage to the

engine, use only fuels without harsh additives or alcohol. Refer to your engine owner’s

manual for specific fuel requirements.

4.5 Fuel System Maintenance

Regularly inspect the fuel system components. All lines, fittings, and bulbs should be flexible and not

corroded. If fittings or other components are found to be cracked, they should be replaced at once. If

you use your boat infrequently or do not use it for an extended period of time, a fuel conditioner should

be added to a full tank of fuel to prevent fuel deterioration and damage to the fuel system.

4.6 Fuel Filters

A fuel filter is installed in the transom area of your EdgeWater 200CC / DC.

This is a fuel/water separator type of filter and is designed to prevent water

from entering your engine. The fuel filter element is a spin-off type element. At

a minimum, this element should be replaced at the beginning of every boating

season. Always carry a filter wrench and spare filter of the type supplied on

your boat.

22 EdgeWater 200CC / DC

Page 16

5

Electrical System

5.1 General

Your EdgeWater 200CC / DC operates on a 12 volt DC system, similar to your automobile. The

battery or batteries are typically lead acid type and require similar maintenance to your car’s battery. An

electrical schematic is included in the appendix for specific location of electrical components.

5.2 Accessory Panel Switches

Your EdgeWater 200CC / DC is equipped with panel breakers. One switch

is for the running/anchor lights, one for the optional livewell, one for an

optional washdown system, and one to activate the bilge pump manually.

The 200DC has an additional switch for accessories and the 200CC has

three additional switches for the owner to use other accessories. In

addition, there is a cigarette lighter type plug to provide for plug-in accessories. A wiring diagram is

included with this manual to assist you in troubleshooting the boat’s electrical system. Please note that

the accessory circuits are each protected by a 20 amp breaker. Check the requirement of any device

you install and change the breaker to the required capacity if necessary.

There is a battery selector switch which provides isolation for each battery and also provides the ability

to have a back-up in case of a dead or weak battery. When in port and running accessories such as

entertainment equipment or pumps, the selector switch should be set on “1” or “2”. When leaving the

boat unattended, the selector switch should be in the “OFF” position.

“2” Position

Current is supplied to the automatic float switch and the bilge pump even when the battery selector

switch is in the “OFF” position.

Do not switch the battery position if the engine is running, as damage to the engine’s electrical system may occur.

“OFF” Position

5.3 Electrical System Maintenance

At the beginning and end of each season the exposed electrical components of the switch panel should be

sprayed with a non-conductive rust/corrosion inhibiting spray. Light bulb connections and running light

connections should be covered with a non-water soluble lubricant. Care must be taken not to get grease

on the glass portion of the lights as it will cause them to overheat and burn out. Inspect all wiring for

breaks, loose terminals and sound insulation. Replace worn or deteriorated components. Check the

electrolyte level in the batteries regularly and fill with distilled water, as necessary.

EdgeWater 200CC / DC 2 3

DO NODO NO

DO NO

DO NODO NO

T OT O

VERFILL.VERFILL.

T O

VERFILL.

T OT O

VERFILL.VERFILL.

Page 17

6

Raw Water & Freshwater Systems

6.1 General

If your boat is equipped with an optional freshwater system, the components will be a freshwater

tank, distribution lines and a pump. The standard raw water system consists of a high speed

pick-up, located on the transom, a pump and one or more livewells and washdowns.

high speed

pick-up

6.2 Livewell Operation

The livewell is located in the port aft corner of the cockpit. It is filled by a low maintenance magnetic drive

centrifugal pump installed in the bilge. This system is part of Edgewater Powerboats “Bait Sentry System”

introduced for the 2000 model year. The magnetic drive is used to prevent damage to the electric motor

in the event that debris clogs the pump. The pump is controlled by the livewell switch on the control panel.

To operate properly, the valve inside the livewell must be adjusted to provide an even flow in and out of the

livewell. Too much and it will be more than the drain can handle, too little and the water will not get the

proper circulation. The valve should be turned counterclockwise to open and clockwise to close. There is

a standpipe and strainer installed in the livewell drain to regulate the height of the water level. The livewell

drains through a hose connected to a thru hull fitting in the transom. To completely drain the livewell,

remove the standpipe and allow the water to drain overboard. A diagram of the raw water system is

included with this manual.

6.3 High Pressure Washdown

The washdown system is comprised of a diaphragm pump mounted on the starboard

side of the transom locker and a washdown fitting to attach a hose. The pump is

controlled by the washdown switch on the control panel. The diaphragm pump is fed

through the same thru hull and high speed pickup as the livewell pump. The washdown hose connector is located in the transom engine well and uses a standard

garden hose fitting. With an attached hose this system can be used to wash debris

from the boat. The pump, located in a transom locker, is activated by a switch on

the control panel. This switch should be turned on immediately prior to use and turned off when not in

use. When activated, the pump’s pressure switch will automatically control the pump. It is normal for the

pump to cycle on and off in response to flow rates and water demand.

Always turn off the high pressure wash down pump switch when leaving the boat unattended.

6.4 Raw Water System Maintenance

The following checks should be made periodically to assure your system operates properly:

• Periodically spray pumps with a protective silicone solvent to reduce corrosion.

• Fishboxes and livewells should be drained and cleaned after each use.

• Periodically check hoses and connections for signs of deterioration.

EdgeWater 200CC / DC 25

Page 18

7

Drainage System

7.1 General

All water drains from your EdgeWater 200CC / DC by gravity. Your boat is self-bailing at rest. It is important

to check drains frequently to make sure they are clear and free flowing. Review the schematic in the

Appendix and become familiar with the location of each thru-hull drain.

7.2 Drain System Maintenance

Essential tasks must be done periodically to maintain boat’s ability to drain in adverse conditions.

• Clean cockpit drains to remove debris or other foreign objects which could prevent boat from

draining properly.

• Check bilge area for debris and foreign material, which can cause automatic switches to

malfunction.

• Flush drains to keep free flowing and clean.

7.3 Cockpit Drains

Your EdgeWater 200CC / DC drains aft thru two cockpit drains located in the aft corners of the cockpit.

These exit the boat through the transom, using hoses to pass through the aft storage areas. The deck

is designed to take water from other draining parts of the boat such as the forward lockers and cupholders and drain it overboard. These should be checked periodically to make sure they are clear running

and free from debris. When washing the boat down, after use, use a hose nozzle with a high pressure

stream to make sure they are free running.

7.4 Transom Bilge

Your EdgeWater 200CC / DC has a hull bilge where the raw water pump and

automatic bilge pump are located. The bilge pump is designed with an internal

float so that it automatically turns on if the water in the sump rises, or it may

also be activated by a momentary switch on the panel. This pump should be

periodically checked to make sure it is working properly and that the drain

screen is clear. To check the pump, squeeze the pump sides and lift it from

the base, which is fastened to the hull. The screen will be easily seen and if

there is debris, it may be cleaned and replaced. Replace the pump assembly

and check its operation by turning on the momentary switch on the helm

switch panel.

When the boat is out of the water it may be drained by a thru hull drain located at the bottom of the

transom. This drain has a brass plug that may be removed with a ½” wrench. This plug should be

periodically checked for tightness.

EdgeWater 200CC / DC 2 7

Page 19

Chapter 7 Drainage System

The bilge sump area should be checked for oil before operating the bilge pump. The discharge of oil from a bilge area is illegal and is subject to a fine. The Federal Water Pollution

Control Act prohibits the discharge of oil or oily waste into or upon the navigable waters of

the United States or the waters of the contiguous zone if such discharge causes a film or

sheen upon, or a discoloration of the surface of the water, or causes a sludge or emulsion

beneath the surface of the water. Violators are subject to a penalty of $10,000.

During the first few months of operation, inspect the bilge area for small bits of foam leftover

from the boat’s construction. These small bits may wash into the bilge over time and be

drawn into the bilge pump, thereby clogging it. The pump should be periodically checked

and cleaned to ensure proper operation.

7.5 Fishbox Drains

The forward fishbox drains overboard.

7.6 Livewell Drains

In each livewell there is a standpipe and strainer installed in the drain to regulate the height of the water

level. The livewell drains through a hose connected to a thru hull fitting in the transom. To completely

drain the livewell, remove the standpipe and allow the water to drain overboard. A diagram of the raw

water system is included in the Appendix.

7.7 T-Top Drain (optional T-Top for the 200CC)

There are small holes drilled into the bottom of the hard-top to facilitate the removal of any water that

might inadvertently get into the structure. These should be periodically checked, especially during freezing

weather, as trapped water could freeze, expand, and damage the hard-top.

28 EdgeWater 200CC / DC

Page 20

8

Safety Equipment

8.1 Required Safety Equipment

Contact the U.S. Coast Guard Boating Safety Hotline at 1-800-368-5647, or 1-202-267-1070 to obtain a

pamphlet on the latest required and suggested safety equipment. The Coast Guard Auxiliary also offers

“Courtesy Examinations” to help ensure your boat is properly equipped.

The following is a list of required safety equipment to be aboard your boat. This may be modified from time

to time and it is suggested that you contact the U.S. Coast Guard Boating Safety Hotline at 800-368-5647

or pick up a copy of the latest “Federal Requirements and Safety Tips of Recreational Boats” pamphlet.

PP

erer

•

•

sonal Floatation Desonal Floatation De

P

er

sonal Floatation De

PP

erer

sonal Floatation Desonal Floatation De

These must bear a tag that they have been approved by the U.S. Coast Guard and must be in serviceable

condition. They must also be of the appropriate size for the wearer, i.e. for children there must be

children’s life vests on board. Many states now require children to wear PFD’s at all times. You should

check with your state to determine the proper requirements. You should maintain at least one Type I,

II, or III PFD for each person on board, plus one throwable device, a ring or boat cushion, Type IV.

Visual Distress SignalsVisual Distress Signals

Visual Distress Signals

Visual Distress SignalsVisual Distress Signals

These are now required in virtually all waters of the United States. If in doubt, please check with the

U.S. Coast Guard Boating Safety Hotline at 1-800-368-5647 for a specific answer.

vices (PFD’s)vices (PFD’s)

vices (PFD’s)

vices (PFD’s)vices (PFD’s)

PyrPyr

oo

tt

•

•

•

•

echnic Visual Distress Signalsechnic Visual Distress Signals

Pyr

o

t

echnic Visual Distress Signals

PyrPyr

oo

tt

echnic Visual Distress Signalsechnic Visual Distress Signals

These must be U.S. Coast Guard approved, be in a serviceable condition, and be readily accessible.

They each have a service life date and are not counted beyond this date. These types include both

hand held flares and aerial flares.

Sound Signaling DeSound Signaling De

Sound Signaling De

Sound Signaling DeSound Signaling De

You must have an efficient means of making a proper sound signal in the event of distress or poor

visibility. This may be a horn, whistle, or bell.

NaNa

vigation Lightsvigation Lights

Na

vigation Lights

NaNa

vigation Lightsvigation Lights

These come with your EdgeWater and meet U.S. Coast Guard requirements. It is important that you

periodically check to make sure they are in working order. It is very important these be checked prior to

any cruise which will keep you on the water after dark.

Fire ExtinguisherFire Extinguisher

Fire Extinguisher

Fire ExtinguisherFire Extinguisher

A fire extinguisher is standard on all EdgeWater boats. These require regular inspection to make

certain they are ready for use. Questions may be directed to the U.S. Coast Guard Boating Safety

Hotline at 1-800-368-5647, or 1-202-267-1070. You should, as part of routine boat

maintenance, check to make sure your extinguisher is still operable.

Never discharge your fire extinguisher to see if it still works. This will cause it to lose pressure. If it is accidentally discharged or if it is used on a fire, replace it immediately.

vicevice

vice

vicevice

EdgeWater 200CC / DC 2 9

Page 21

Chapter 8 Safety Equipment

8.2 Suggested Safety Equipment - Inshore

Suggested safety equipment, over and above the required equipment is:

• First aid kit and manual

• Boat hook

• Tool kit

• Adequate number and size of line. Bow lines should be at least 1/3 longer than the boat’s length and

stern lines at least as long as the boat. When operating in areas with unusually high tidal range, this

should be lengthened. The minimum size line for a small boat is 3/8” diameter 3 strand nylon. Refer

to one of the listed references in the Appendix for a complete discussion on line size relative to boat

length.

• Waterproof flashlight, with good batteries

• Spare batteries

• Spare boat keys

• Binoculars

• Tow line. This should be a minimum of 50’ long with at least one size increase over the boat’s

mooring lines.

• Day/Night visual distress signals

• Local charts and compass

• Properly sized anchor and line

• Fenders of the proper size

Always carry water, even for a 10 minute cruise.

8.3 Suggested Safety Equipment – Offshore

In addition to the required equipment, and the suggested inshore equipment, there is additional equipment

which is prudent to have when venturing offshore. No matter what the conditions at the start of the trip,

the situation can change rapidly and all your equipment and skill can be required to safely bring your crew

home to safety.

• VHF radio

• A supplemental, portable VHF is also a good back-up

• Sunscreen

• Spare propeller and the knowledge of how to properly change it, if required

• Extra clothing for changeable weather conditions

• Spare anchor with sufficient line for the water depth

• Mirror

• Charts

30 EdgeWater 200CC / DC

Page 22

9

Safe Operation

9.1 Pre-Cruise Check List

• Check provisions. Make sure you have plenty of water in the event you have a problem and are

delayed.

• Check the weather forecast. Avoid sea conditions that are beyond the experience of yourself and

your crew.

• Do you have the correct safety gear aboard and is it in good working order?

• Make sure all fire extinguishers are in good working order.

• It is advisable to carry jackets or foul weather gear in the event of adverse weather conditions.

Your EdgeWater 200CC / DC is equipped with a maximum capacity rating plate permanently

affixed to the helm area of your boat. It will provide information regarding the maximum

number of people you can safely have aboard, the maximum amount of weight the boat can

safely carry, and the maximum horsepower your boat was designed to handle.

Note: Do Not Overload your boat.

Before Starting the Engine

• Determine if the trip can be safely made by checking the weather.

• Are all the proper boat and personal documents on board?

• Check operational equipment, such as running lights and horns to make sure they are on board,

and operable.

• Make sure there are enough provisions for the cruise.

• Leave a float plan with someone who can notify authorities in the event you do not return

in the allotted time.

• Double check the fuel and engine oil levels.

• Set the battery switch for the proper setting.

REMEMBER: Avoid changing the setting while the engine is running.

• Check the emergency stop lanyard to see if it is properly attached, and that the shift lever

is in the neutral position.

• Check fuel and oil to make sure you have more than enough for the planned trip.

Remember the rule of thirds: 1/3 out, 1/3 back, and 1/3 in reserve.

EdgeWater 200CC / DC 3 1

Page 23

Chapter 9 Safe Operation

After Starting the Engine

• Upon initial start-up, make sure to follow the manufacturer’s recommendations for engine break-in

• Check to be sure there is a tell-tale water stream exiting the engine.

• Check the gauges to determine if everything is nominal.

• Check to make sure everything is secure and properly stowed away; remember the boat’s

movement is dynamic and anything that is loose will become a hazard at the worst possible

time.

• Have a great time on the water

Remember that the captain is responsible for the safety of the crew and passengers and for

his/her boat’s wake damage.

Never operate the boat while under the influence of alcohol!

• Make sure someone else on-board knows how to operate the boat in the event you are injured

and unable to operate the boat.

If you are operating the boat for the first time, make sure you follow the engine manufacturer’s

break-in recommendations. This will assure proper break-in and reduce the possibility of

engine problems.

9.2 Basic Rules of the Road

The following is not intended to be a comprehensive course in seamanship and rules of the road,

but instead an introduction. It is strongly recommended that a boating safety course be taken

from your local Coast Guard Auxiliary or local Department of Natural Resources. There are also

many good reference books in your local library as well as numerous sites on the internet.

Remember, paddle boats, sailboats and other vessels (such as barges) which are unable to

maneuver, always have the right of way over powerboats. Sail boats, when under power,

are considered motor boats. However, always boat defensively.

Aids to Navigation

Along the coast lines and in navigable inland waters, aids to navigation have been placed by the U.S. Coast

Guard. These have been placed for the boating public’s safety. Please become familiar with them and

learn to use them to make your boating safer and more fun.

32 EdgeWater 200CC / DC

Page 24

Federal Waterways Marking System Aids

Chapter 9 Safe Operation

5

Daymark

Lateral Aids as seen from Seaward (starboard side red)

6

Daymark

3

Can Buoy

4

Nun Buoy

7

Lighted Buoy

(green light)

2

Lighted Buoy

(red light)

Lateral Aids as seen from Seaward (port side green)

9.3 Safe Operation

Getting Underway

After clearing the dock, make sure the power trim (if so equipped) is trimmed down. (This will bring the

boat up on plane more quickly and easily.) Give the engine sufficient throttle to bring it to plane briskly,

then back down to the cruising speed of your choice, based on the sea conditions and your planned

activity.

• After coming on plane, raise the trim to a point where the engine is level with or slightly

above the plane of the water. This is usually with the bow at about 3o to 5o above level. This

will provide the smoothest, most economical operation.

EdgeWater 200CC / DC 33

Page 25

Chapter 9 Safe Operation

• Keep a constant vigil for other boats and watercraft and be prepared to give way, or slow down, if

necessary. (We suggest you enroll in a boating safety course offered by the U.S. Power Squadron

or the Coast Guard Auxiliary.)

• When coming off plane, allow the engine to come back to an idle speed until the boat slows down.

• Shift to the neutral position.

Never allow anyone to sit on the gunwale while the boat is moving!

While underway keep a constant vigil for other craft that may be approaching, the gauges on your boat,

location of passengers and the general sound and feel of your craft. Often, a change in the way the

engine sounds or the boat feels will presage a problem. Your early attention may prevent a more serious

problem.

If you should strike an underwater object, bring the throttle to neutral and stop the engine.

Inspect the lower unit for damage. If none is apparent, proceed as before but heighten your

awareness of the engine and its operation to make sure a problem has not gone undetected.

9.4 Towing or Being Towed

Sooner or later your will have the misfortune of having to be towed in or needing to tow someone back to

a safe landing. It is important that this be done properly so that a difficult situation does not

become worse. This comes under a longstanding, unwritten law of the sea that one boater will aid

another in time of distress. The 1971 Boating Safety Act grants protection to those assisting

others at sea as ”Good Samaritans” and absolves them of civil liability rising from the aid being provided.

When being towed, it is best to have a line passed from the tow boat to the one

being towed, assuming the towing boat has a line of adequate size and length.

The tow boat should also tow the disabled vessel from as close to amidships as

possible. This reduces the tendency to yaw. If possible, the towing boat should

use a bridle attached to the two stern ski tow eyes. The vessel being towed

should attach the tow line to the bow eye that holds the boat onto the trailer. This

provides an optimal tow position and a strong tow point. Have the occupants of

the boat being towed sit aft of amidships, but not all in the stern. Attention should

be given so the boat remains balanced and on an even keel. Some boats tow

better with the engine tilted out of the water, others need the engine to act as a

rudder to be able to maintain a straight line. Start with the engine tilted. If that

does not work well lower the engine until it is about perpendicular.

You should never attempt to plane off the boat being towed.

34 EdgeWater 200CC / DC

Page 26

Chapter 9 Safe Operation

9.5 Stopping the Boat

Gradually bring the controls back to the low forward position and allow the boat to gradually slow down.

After the boat has dropped into the displacement mode, shift to the neutral position. If you have been

running the boat hard for some time, allow the engine to idle for several minutes to gradually cool down.

After docking and securing the boat, raise the trim tabs to the fully upright position and turn off the

ignition.

9.6 Docking

Safe docking keeps your boat from being damaged and is an indicator of a

capable and knowledgeable captain. There are many docking maneuvers,

which will be done while boating; only the basics will be discussed here.

Several constants to always use as guides while docking:

Perform docking at idle or no wake speeds. Always try to come into wind or

current, whichever is stronger. This allows you to use the natural forces which

affect on your boat to act as a natural brake. The skipper is free to use the

boat’s power to control speed and direction.

Wind / Current

The approach to the dock should be at roughly a 45o angle, when possible.

This approach angle allows the captain to bring the bow close to the dock,

and then to use reverse, while turning the wheel toward the dock, to bring

the boat to a safe, controlled stop.

Never approach a dock on plane. Even after reducing engine speed, the wake will push the boat

uncontrollably into the dock.

9.7 After Operation

• Refill the fuel tank and engine oil, if yours is a two-cycle engine. A full fuel tank is less subject to

condensation and therefore, less fuel problems. If you will be leaving the boat for an extended

period, use a good fuel stabilizer. Each engine manufacturer makes their own and proper use will

avoid many fuel related and lay-up problems. Remember, always follow the manufacturer’s

recommendation.

• If the boat is to be left in the water, make sure it is secure and free to properly accommodate any

tide.

• Turn off all electronics and leave the battery switch in the off position. Remember, the bilge pump

will operate properly even with the battery switch turned off. On a comforting note, your EdgeWater

200CC / DC is fully self bailing and unsinkable. Proper precautions, however, are always prudent.

EdgeWater 200CC / DC 35

Page 27

Chapter 9 Safe Operation

r

9.8 Trailering Your Boat

Note: If you have doubts or questions about your tow vehicle or towing, contact

your dealer.

Before going on the highway, make sure your tow vehicle and trailer meet the

local regulations for trailers and towing in your state.

Before leaving the driveway make sure the lights on the trailer are operating prop-

erly. If necessary, get a second person to make sure of the operation.

At least once a season, check and repair/replace the trailer wheel bearings.

The trailer should be adequately sized for your boat. Allow about 10% above the maximum boat weight

for trailer capacity.

Make sure your vehicle is properly equipped to handle the load. This includes

engine, hitch, frame, brakes, transmission cooler, and vehicle capacity.

Tow

vehicle

Securely attached the boat trailer to the vehicle hitch, hook the safety chains

and and cross them under the hitch and check the lights to ensure they are

hooked up and working.

If you are new to trailering your boat, it is best to practice before actually getting

in a situation where you are not sure of your ability. If possible use a trailer

without a boat to practice with as you can see the trailer’s movement without

Bottom View of

Crossed Trailer

Chains

Traile

the boat. Also, your vision will not be impaired by the boat’s presence.

When going forward, remember that your trailer turns inside the tow vehicle, therefore the tow vehicle

must start the turn slightly later than without the trailer. This allow the trailer to turn inside the tow

vehicle radius without leaving the roadway.

When backing, remember, the bottom of the steering wheel will move in the direction the trailer will

ultimately go. Backing consists of two parts, breaking the trailer by turning the vehicle’s backward

motion in the opposite direction from the ultimate trailer direction, then following the trailer toward the

correct direction with the tow vehicle. It is prudent to go to a large paved area with little traffic to

practice these maneuvers before attempting them on the boat ramp.

Remember to check to see if the tow ball is the same size as the trailer coupler. Never use a

different size.

36 EdgeWater 200CC / DC

Page 28

Chapter 9 Safe Operation

9.9 Launching Your Boat

When you arrive at the ramp, prepare your boat before getting in the ramp line.

• Make sure the hull plug is in place.

• Place a line on the bow and stern cleats to be at the dock ready.

• Have fenders out and on the proper side.

• Raise the engine so it will not be damaged during launching.

• Make sure the battery switch is in one of the “on” positions, and the boat key is in the ignition.

• Remove any tie-down straps.

• If someone is with you, hand them the free end of the bow line and have them follow the trailer as

you enter the ramp.

• Back the boat into the water until it barely floats. Remove the winch line. The boat should now come

free with a gentle tug on the bow line.

• Lower the engine, pump the fuel bulb until firm and crank the engine.

• Let it idle for a few minutes to warm up before getting under way.

9.10 Retrieving Your Boat

There are several ways to retrieve your boat. The method described herein requires two persons.

• Drop someone off to back the trailer into the water, or do it yourself. If doing it yourself,

make sure you make it easy and safe to exit the boat after it is loaded onto the trailer.

• Back the trailer into the water until the bunks are completely submerged, or until the middle roller is

just touching the water. (This depth should provide enough to float the boat until the last minute and

yet provide enough resistance from the trailer to stop the boat short of the winch stand.)

• Drive the boat onto the middle of the trailer. This is assuming it is a trailer designed for drive on.

Speed should not be over one or two knots. Fast enough to maintain steerage but slow enough to

be easily controlled.

• Once the boat has touched the trailer, a little forward throttle should secure the boat on the trailer and

allow you to put the engine in neutral and have the winch line attached to the bow eye. The boat should

now be easily winched onto the last several feet of the trailer.

When properly done, this method is easy, safe and will not harm boat ramps by powering

away the soil from the base of the ramp.

EdgeWater 200CC / DC 37

Page 29

10

Routine Maintenance

10.1 Exterior Hull and Deck

Fiberglass

When you remove the boat from the water, clean it as soon as possible. Dirt, debris and grime will come

off easier while it is still wet. Use a brush and biodegradable boat cleanser. Stubborn areas may be

cleaned with a non-abrasive cleaner. Harsh abrasives and chemical cleaners are not recommended as

they can damage the gelcoat, shorten its life, and make it more susceptible to stains. When used in

saltwater, the boat should be washed after each use.

The hull should be waxed periodically, at least once a year, with a high quality wax. This will keep it shiny

looking and help prevent chalking and aging. The wax will also make it easier to keep clean by closing

the pores that trap the grime.

If the boat is to be kept in freshwater or saltwater for an extended period, a proper barrier

coat and bottom paint must be applied.

DO NOT WAX non-skid areas. It could make them slippery and increase the possibility of

injury.

Stainless Steel Hardware

The stainless steel hardware of your boat should be cleaned and washed after each boat use, especially

in salt or polluted water. While it is “stainless” it is not “stain-proof”. If it is not cleaned, it can develop

surface rust stains. It can be protected with a high quality automotive or boat wax. It can also be

protected with a commercial metal cleaner and protectant.

Anodized Aluminum

The aluminum can be maintained with a regular washing with soap and water. Otherwise it can develop

a surface corrosion, which can penetrate the anodizing and attack the aluminum underneath. If badly

scratched, it can be repaired with an aluminum or silver paint.

Chrome Hardware

Use a good metal polish and protect with wax. This should be done every couple of months or as soon as

you notice any finish deterioration.

Plexiglas

Do not use products with ammonia on your Plexiglas windscreen. It can mar the surface and reduce its

transparency. A mild soap and water or non-ammonia cleaner will work well. In addition to ammonia,

cleaners should not be used which contain solvents, acetone, or alcohol.

EdgeWater 200CC / DC 39

Page 30

Chapter 10 Routine Maintenance

Upholstery

Soap and water should be periodically used to clean the vinyl. Vinyl protector products can make the

seats slippery, which may not be desirable. When cleaning the vinyl, be gentle. Do not use cleaners that

contain ammonia, acetone, strong solvents, or powdered abrasive cleaners. They can damage and

shorten the vinyl’s life.

Sump Area

Your EdgeWater does not have a true bilge but rather a small sump area in the after part of the boat.

This can be maintained well by periodically using a boat bilge cleaner. Follow the directions carefully.

10.2 Engine

If you have a new engine with a built-in flushing device, the engine may be flushed without cranking. If

the engine does not have a built-in flush device one may be purchased to fit.

To flush the engine, after connecting a water hose to the proper connection, turn on the water. Put the

engine control in the idle position and crank the engine. Only let it run a couple of minutes. The gear

case is water-cooled and is not designed to run out of the water for extended periods.

Do not crank the engine without water running. Water acts as a coolant and also a lubricant

for the water pump.

Do not rev the engine when flushing; idle speed is sufficient!

The exterior of the engine will respond well to a good quality wax. This should be re-applied every several

months as the marine environment is a very harsh one and the constant sun exposure will deteriorate

your motor’s finish. Consult the engine manufacturer’s owner’s manual for specific instructions. In

areas where there is a conflict between this manual and the engine manufacturer’s manual, the engine

owner’s manual will take precedence.

40 EdgeWater 200CC / DC

Page 31

11

Exterior Equipment

11.1 Anchor Locker

The anchor locker on your new EdgeWater 200CC / DC has been designed for a danforth style 13 S

anchor. Your anchor line should have a shackle attached to the free end which is then attached to the

eye in the anchor locker.

Remember, your anchor line should be a minimum of 7 times the depth in which you routinely operate.

Your EdgeWater 200CC / DC should have a minimum of 150 to 200 feet of ½” three strand

nylon line. If you routinely venture offshore, remember the 7 times depth rule. This may

sound like a lot but if your engine fails in 100 feet of water, maint aining your position will be

very important to being recovered.

11.2 Swim Platform (optional)

If your EdgeWater 200CC / DC is equipped with the optional swim platform,

there are several important things to remember for safe use and operation of

this useful option.

• Always shut down the engine if persons will be using the platform. Do not

just settle for the engine being in neutral.

• Make sure the folding ladder portion has been properly stowed before

getting underway.

11.3 Trim Tabs (optional)

The optional trim tabs on the EdgeWater 200CC / DC can assist the captain

in maintaining trim and level running attitude. When used in conjunction with

the engine trim, a great deal of flexibility is available to the operator. On the

EdgeWater hull, the tabs are most useful to affect lateral trim. The best

results for lateral trim are usually achieved by using only one tab. For example,

if the boat is loaded heavier to the port side, lowering the port side trim tab

will elevate that side and assist the boat in running trim and level. This is

important for seaworthiness and fuel consumption. A hull is usually more

efficient when running level and with the bow at roughly 3 to 5 degrees

above level. Tabs can also be useful when running in a heavy wind, which is

blowing from the side. If the boat tends to turn into the side blowing wind,

elevating the tab on the windward side will elevate that side and assist the

boat in running level.

EdgeWater 200CC / DC 4 1

Page 32

12

Seasonal Maintenance

12.1 Engine

Refer to your engine manual for any specific information pertaining to your engine. For the fuel system, add

a fuel stabilizer to a full fuel tank as per the stabilizer’s instructions. Run the engine for a minimum of 10

minutes to allow the fuel stabilizer to reach the engine.

• Wax the engine exterior.

• Remove the engine cowl and spray the engines powerhead with a non-conductive lubricant spray. Do

not spray directly on joints that are lubricated with grease as some lubricant sprays may dissolve

grease.

• Grease all external zert fittings on the engine and steering system. Use a grease that is

consistent with engine manufacturer’s recommendations.

• Change the engine lower unit lubricant. This will remove contaminants that may have built up

throughout the boating season. This is also a good time to check for lower unit seal problems. If

there is a leak, have it repaired by your dealer.

• Remove the propeller and grease the propeller shaft. Inspect the shaft and propeller for unusual

wear or signs of deterioration.

12.2 Hull

• Wax the entire boat. The hull will maintain its factory delivered luster much longer if waxed at least