Page 1

APPLICATION NOTE

2016_03-02 SENTRY Rev 2

Edgetech Instruments Inc.

An ISO 9001 Certified Company

399 River Road . Hudson . MA . 01749

Main: +1 (508) 263-5900 . Fax:+1 (508) 486-9348

www.edgetechinstruments.com

Using the SENTRY Compressed Gas Alarm System

The SENTRY is designed to detect low pressure or high dew point condions within compressed air or inert

gas systems. It consists of a display control module and a SMART, Mul-Sense Probe. Using the supplied ½

inch Male NPT pipe ng, the probe is inserted directly within the compressed air system header,

accumulator tank, or at the point of use. The SENTRY system connuously monitors both pressure and dew

point and provides a warning system to alert an operator should there be a pressure loss or dryer failure.

There are two models available:

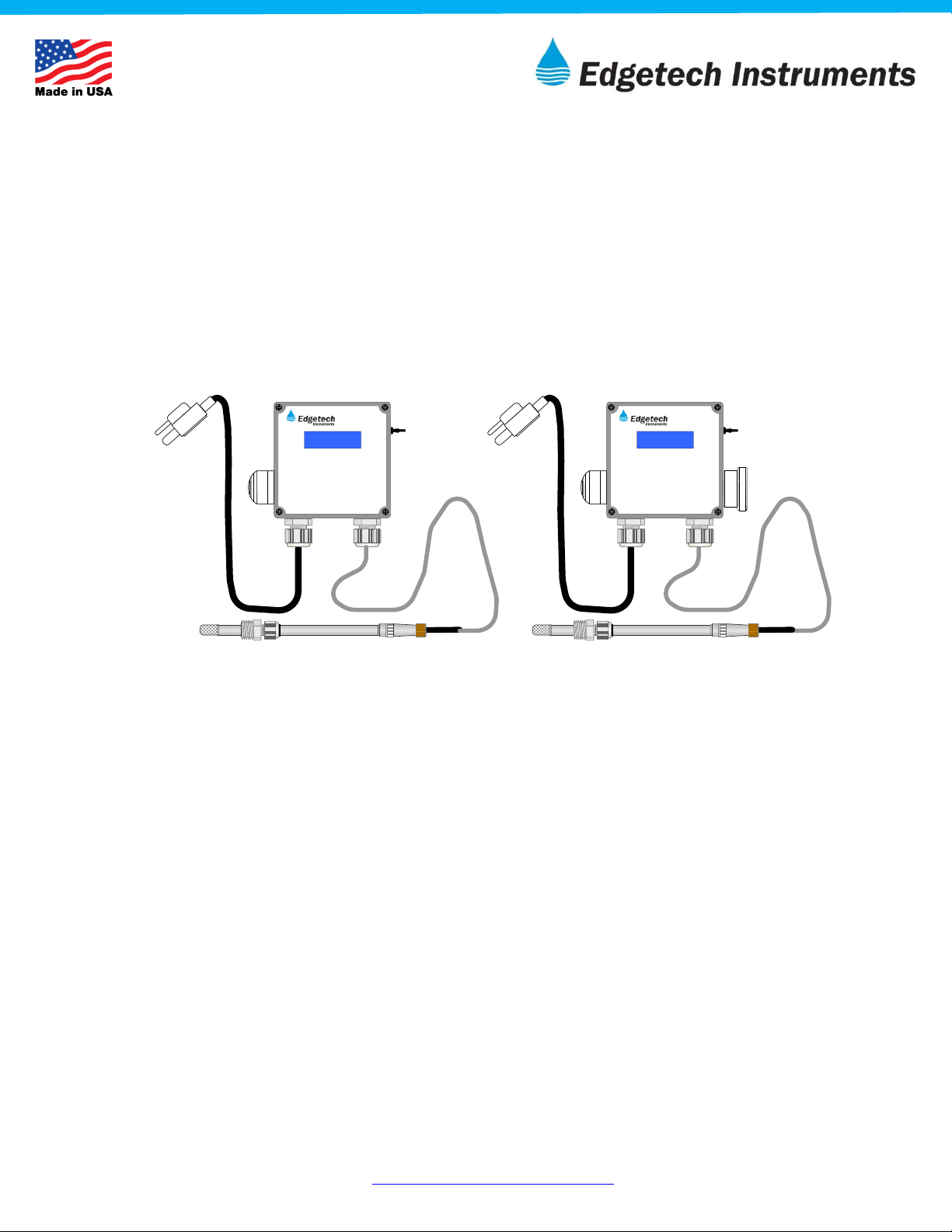

SENTRY 85: strobe light and 85dB Audible Alarms SENTRY 100: strobe light and 100dB Audible Alarms

SENTRY-85

Compressed Air Monitor

Dew Point -10C

Pressure: 120 PSIG

SENTRY-100

Compressed Air Monitor

Dew Point -10C

Pressure: 120 PSIG

Alarm

Disable

Switch

Mute

Switch

HPP125 Sensor ProbeHPP125 Sensor Probe

3m Power Cord

1 m Signal Cable

3m Power Cord

1 m Signal Cable

IMPROVE reliability of compressed air/ dryer systems

REDUCE maintenance expenses by idenfying problems before they happen

ELIMINATE corrosion, product loss or process damage because of high moisture

The SENTRY offers many standard features including:

Plug n’ Play Operation: typical options are standard

HPP125 Multi-Sense Smart Probe: Pressure and Calculated Dew Point

Arrives with NIST Traceable Calibration Certificate

Smart sensor tip is easily replaced- no need to send in for calibration

Smart Sensor tip comes with NIST traceable certificate, replace – Plug n’ Play

Simulated Strobe Lamp / Audible Alarm for low pressure or high dew point condition

Universal VAC Power Supply with 3 meter length power cord

1 meter length signal cable with quick connection to the Smart Probe

Local Digital Display of Pressure, Dew Point, and Temperature

Two 4-20mA Analog Outputs: Pressure and Dew Point & RS-232 Serial Interface

One User Accessible alarm relay for low pressure/ high dew point

Page 2

Edgetech Instruments Inc.

An ISO 9001 Certified Company

399 River Road . Hudson . MA . 01749

Main: +1 (508) 263-5900 . Fax:+1 (508) 486-9348 . www.edgetechinstruments.com

Page1

Benefits

Detect Dryer Failures

Detect Compressor failures or system leaks

Protect downstream processes and pneumatic equipment

Ensure Protection at the source or at point of use

No wait for annual calibration- just replace the smart sensor tip

Notes/ Sampling Configuration Options

1. The HPP125 Probe comes standard with a 1/2inch NPT male ng. This can be inserted directly into the

pressurized gas stream or it may be used in conjuncon with the CAM sample extracon unit.

2. The CAM sample extracon unit provides a sample valve that allows isolaon of the HPP125 probe from the

pressurized process for sensor p replacement or maintenance.

3. There are no atude restricons for sensor probe or display control module mounng.

4. Maximum power requirements for the SENTRY system are less than 0.5 AMP at 110 VAC.

5. The SENTRY 85 features an alarm disable switch that will mute the horn and disable the strobe lamp.

6. The SENTRY 100 features a mute switch that will mute the horn. The strobe lamp will remain acve.

7. The Sentry may be located at mulple points along the path of the pressurized gas stream to be monitored. This

may be useful to sense upset condions at point of use to prevent sensive process or equipment failures.

8. Remote monitoring of the SENTRY condion is available through the 4-20mA analog output signals provided for

both pressure and dew point.

9. Although no alarm condion is triggered, the SENTRY also monitors and displays the sample gas temperature.

10. The SENTRY arrives factory set but you can adjust the set points in the eld using a serial interface.

How to order the Sentry System

1. Determine the alarm set points for Dew Point and Pressure.

2. Determine if you want the Dew Point Units in C° or F°

3. Determine if you want the Pressure Units in PSIG or BAR.

4. Determine the preferred method of mounting the HPP125 sensor probe.

5. List as separate line items additional choices such as CAM, Accessories and Spare Parts.

SENTRY85- - -

Pressure Setpoint Dew Point Setpoint

SENTRY100- - -

Pressure Setpoint Dew Point Setpoint

For Example: SENTRY85-75PSIG – 10F would be a Sentry 85 unit with a low pressure alarm

set to 75 psig and the high dew point alarm set to +10°F.

Page 3

Edgetech Instruments Inc.

An ISO 9001 Certified Company

399 River Road . Hudson . MA . 01749

Main: +1 (508) 263-5900 . Fax:+1 (508) 486-9348 . www.edgetechinstruments.com

Page2

Installaon:

1. The SENTRY features a standard 1/2inch male NPT ng on the HPP125 probe for connecon to the

process point. The ¾ inch ng is oponal and may be ordered as an accessory.

2. The HPP125 probe may be mounted directly into the process take-o point or may be installed to extract a

small sample of gas (less than 1CFH) using the CAM accessory.

3. Mount the SENTRY display in a conspicuous area for easy viewing.

4. Mount the HPP125 probe in an easy to access area.

2.4" (60.96 mm)

9.5" (24.13 cm)

0.5" (12.7 mm)

twist

Maximum Insertion Depth: 6.0" (15.24 cm)

Minimum Insertion Depth: 2.5" (63.5 mm)

Sensor Tip

Filter Cap

Easy On – Easy Off

Sensor Tip shown fully inserted

Edgetech Instruments Inc.

Humidity Probe

Edgetech Instruments Inc.

Humidity Probe

Edgetech Instruments Inc.

Humidity Probe

CAM

Dew Point -10C

Pressure: 120 PSIG

Ball

Valve

Closed

Ball

Valve

Open

Trickle of gas by

the sensor

Compressed Air

Accumulator Tank

Dew Point -10C

Pressure: 120 PSIG

CAM

or

Direct Insertion

Flange Mount

Replacing the Sensor Tip

Using the oponal CAM

Module in an air header

Using the CAM at the accumulator tank

or

Direct Inseron of the Probe into tank

Page 4

Edgetech Instruments Inc.

An ISO 9001 Certified Company

399 River Road . Hudson . MA . 01749

Main: +1 (508) 263-5900 . Fax:+1 (508) 486-9348 . www.edgetechinstruments.com

Page3

RH 49.0% P 150 PSIG

T 23.7C DP 12.4C

4.53in (115.0mm)

5.12in (130.0mm)

5.12in (130.0mm)

4.53 in (115mm)

4.53in (115.0mm)

4.53 in (115mm)

COVER

REMOVED TO

SHOW

MOUNTING

HOLES

5.12in (130.0mm)

3

.

90

in

(

99

.

0

mm

)

Dew Point -10C

Pressure: 120 PSIG

1.32 in

(34mm)

POWER

Signal

Cable

1.38 in

(35.1mm)

Optional

100dB HORN

PIPE FLANGE

MOUNT

Dew Point -10C

Pressure: 120 PSIG

Loading...

Loading...