Page 1

Model PPM1 & PPM2

Trace Moisture Analyzer

OPERATORS MANUAL

19 Brigham Street ● Unit #8 ● Marlborough, MA USA 01752

Tel. [508] 263-5900 ● [800] 276-3729 ● Fax [508] 486-9348

E-mail h2o@edgetechinstruments.com ● www.edgetechinstruments.com

Tel. [508] 263-5900 ● Fax [508] 486-9348

Rev. A June 2010

1

Page 2

PPM1 / PPM2

QUICK STARTUP GUIDE

STARTUP

PPM1:

1. Remove the cover, and mount the PPM1 in an easily visible position.

2. See Wiring Diagram in Installation, Section 4.

3. Wire Sensor connections.

4. Wire Power connections. Do not turn on Power at this time.

5. Wire two Analog (4 to 20 mA) Outputs if required.

6. Wire two Alarm Relays if required.

7. Wire and plug in the RS-232 connector if required.

8. Replace the outer cover. Do not over-tighten the screws.

9. Connect Sensor to dry gas source. Allow system time to dry out.

10. Turn on the Power Supply. Specifications are:

18 to 30 Vdc, unregulated, 100 mA max.

11. After the self-test procedure, start viewing or recording valid data.

PPM2:

1. Fully charge the rechargeable battery before operating.

2. Connect Sensor to dry gas source. Allow system time to dry out.

3. After the self-test procedure, start viewing valid data.

2

Page 3

TABLE OF CONTENTS Page

1.0 Quick Startup Guide 2

2.0 Commitment to Quality 5

3.0 Introduction 6

3.1 General Description 6

3.2 Technical Description 6

3.2.1 The PPM1/PPM2 System 6

3.2.2 The Phosphorous Pentoxide Sensor 6

3.2.3 Standard Factory Ranges 8

3.2.4 Gases to Avoid 9

4.0 Installation 9

4.1 Placement of Instrument 9

4.2 Mounting 9

4.2.1 Wall Mounting the Display 9

4.2.2 Sensor Mounting and Sampling 9

4.3 Electrical Wiring 10

4.3.1 Sensor Connections 10

4.3.2 Power Connections 10

4.3.3 Analog Outputs 10

4.3.4 Alarm Relays 10

4.3.5 RS-232 Serial Port 10

5.0 Operation

5.1 Startup 12

5.1.1 Dry Down Phase 1 12

5.1.2 Dry Down Phase 2 12

5.2 Measuring Dry Gases 13

5.2.1 Measurement Time 13

5.2.2 Materials 13

5.3 Operating the Instruments 13

5.3.1 The PPM1 13

5.3.2 The PPM2 13

5.4 Using the RS-232 Port for Programming 14

5.4.1 Serial Port Setup 14

5.4.2 Changing the Digital Display 14

5.4.3 Changing the Analog Outputs 15

5.4.4 Programming the Alarm Relays 17

5.4.5 Calibrating the Analog Outputs 20

5.4.6 Modifying the RS-232 Parameters 21

3

Page 4

6.0 Maintenance 23

6.1 General 23

6.1.1 Filters 23

6.1.2 Battery Maintenance 23

6.2 Gases 23

7.0 Specifications 24

8.0 Appendix 26

8.1 PPM1 Mounting Dimensions 26

8.2 Sensor Dimensions 27

8.3 Warranty 28

8.4 Notes 29

8.5 Basic Humidity Definitions 30

LIST OF ILLUSTRATIONS

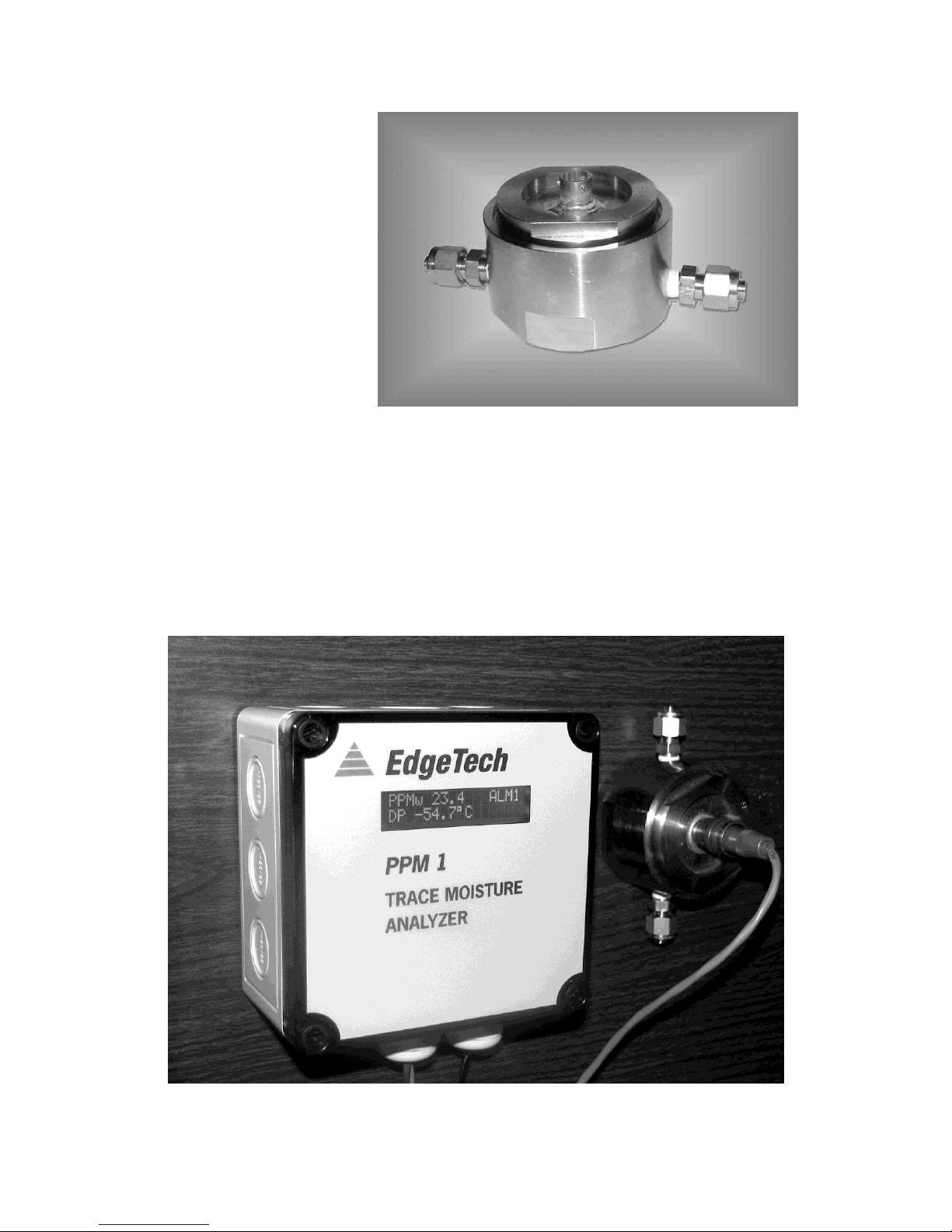

3-1 Phosphorous Pentoxide Sensor 7

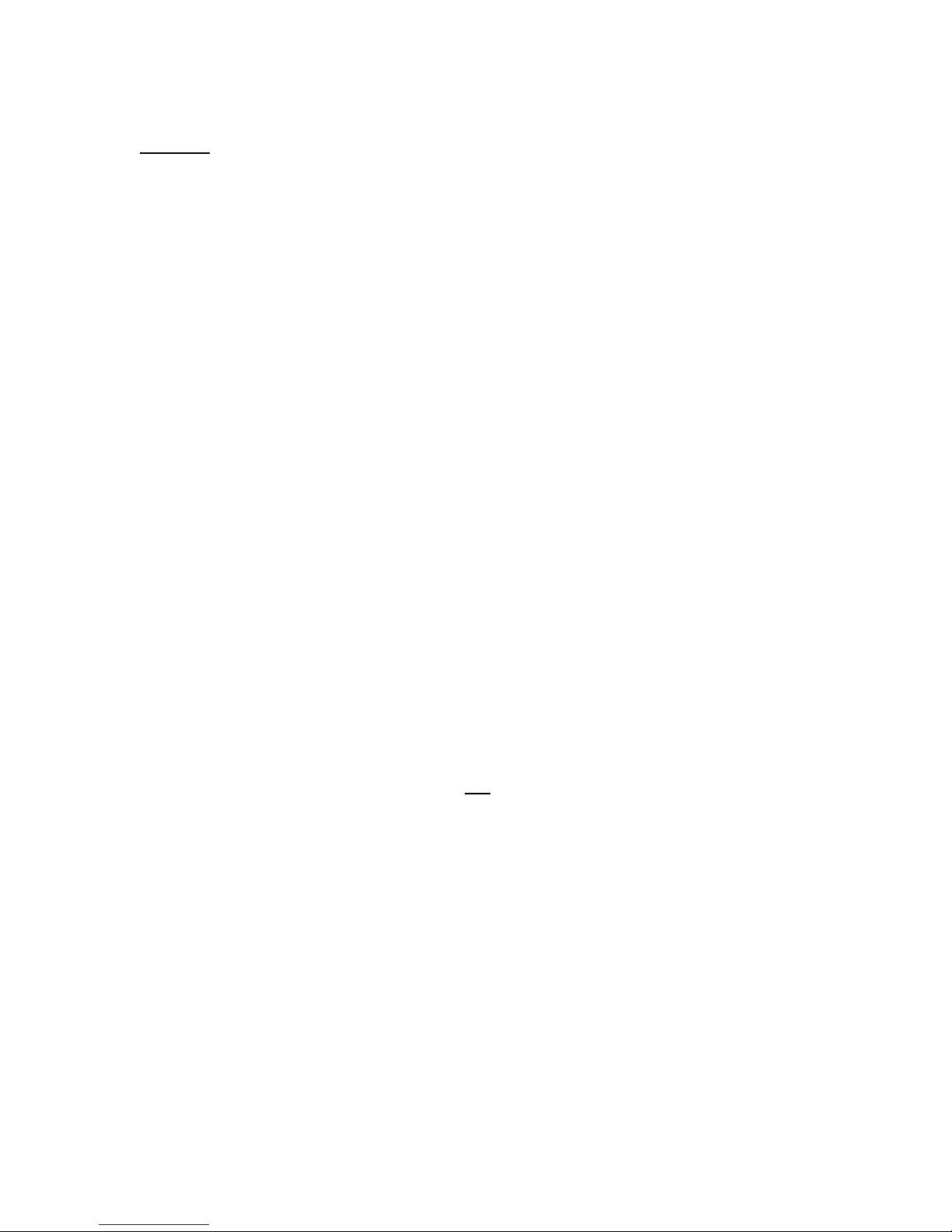

3-2 PPM1 Wall Mounted 7

3-3 PPM2 Portable 8

4-1 Wiring Connections 11

4

Page 5

2.0 EDGETECH'S COMMITMENT TO QUALITY

To Our Customers:

Thank you for purchasing one of our products. At EdgeTech, it is our

policy to provide cost-effective products and support services that

meet or exceed you requirements, to deliver them on time, and to

continuously look for ways to improve both. We all take great pride in

the products we manufacture.

We want you to be entirely satisfied with your instrument. The

information contained in this manual will get you started. It tells you

what you need to get your equipment up and running, and introduces

its many features.

We always enjoy hearing from the people who use our products. Your

experience with our products is an invaluable source of information

that we can use to continuously improve what we manufacture. We

encourage you to contact or visit us to discuss any issues whatsoever

that relate to our products or your application.

The Employees of EdgeTech

5

Page 6

3.0 INTRODUCTION

3.1 GENERAL DESCRIPTION

The PPM1 is a trace moisture analyzer designed specifically for monitoring low

levels of moisture, and reading them out in units of dew point and parts-permillion. This trace moisture analyzer utilizes an electro-chemical (P2O5) sensor in

combination with a proprietary semi-permeable diffusion membrane. The

principal of operation applies the Faraday’s Law of Electrolysis. It is a

fundamental measurement of the moisture present. The PPM1 is ideally used

in relatively clean, dry, inert gas applications. It is provided in a wall-mount

configuration. See Figure 3-2.

The PPM2 is a portable, battery operated version of the PPM1. It is provided in a

carrying case, with two gel-cell rechargeable batteries built in. See Figure 3-3.

3.2 TECHNICAL DESCRIPTION

3.2.1 THE PPM1/PPM2 SYSTEM

The gas passing through the phosphorous pentoxide cell results in a small

electrical current proportional to the quantity of water molecules (moisture) in the

sample. The small electrical current from the cell is conditioned so that it directly

corresponds to the concentration of moisture in the measured gas. This linear

output signal is available to actuate the programmable Alarm Relays, and also

provides information to the Digital Display and Analog Outputs. A

microprocessor controls all data processing and input and output functions of the

Instrument, ensuring a high accuracy measurement of moisture. Two separate

humidity parameters may be monitored and displayed.

3.2.2 THE PHOSPHOROUS PENTOXIDE (P2O5) MOISTURE SENSOR

The Sensor utilizes an electrochemical (phosphorous pentoxide - P2O5 - coated)

sensor in combination with a proprietary semipermeable diffusion membrane.

This membrane allows the water vapor molecules to pass from the dry gas

stream into the sensor cavity at a rate that is a function of the partial pressure of

the water across the membrane. It also allows the hydrogen and oxygen

molecules, the byproducts of the electrolysis, to diffuse back into the gas stream.

The membrane “meters” the gas flowing into the sensor cavity, ELIMINATING

THE NEED FOR PRESSURE REGULATION AND CONSTANT FLOW, which

are required in most other electrolytic hygrometers.

The phosphorous pentoxide moisture sensor, also called an electrolytic cell, has

the ability to measure trace quantities of water vapor in a dry gas. Operation is

based on the fact that if a small dc voltage is applied, water vapor molecules can

be electrolyzed into their elements of hydrogen and oxygen. To electrolyze each

water molecule, it is known that two electrons are required. Therefore, the

6

Page 7

quantity of current used by

the cell is proportional to

the number of water

molecules being

electrolyzed. If the dc

excitation current is

measured, water vapor

content of the gas can be

displayed. This

measurement process

provides a fundamental

measurement of water

vapor. While in a typical

electrolytic cell the rate of

gas flow must be carefully Figure 3-1 The Phosphorous Pentoxide

controlled by the user for (P2O5) Moisture Sensor

accurate measurements,

this cell is independent of

gas flow rate. Although a fundamental measurement technique normally does

not require calibration, each cell is calibrated at the Factory before shipment to

the user to compensate for variations in the diffusion membranes. Figure 3-1

shows the moisture sensor.

Figure 3-2 The PPM1 with Wall Mount housing and Moisture Sensor

7

Page 8

Figure 3-3 The PPM2 Portable Trace Moisture Analyzer

Figure 3-2 shows the wall mounted PPM1, and Figure 3-3 shows the portable

battery-operated PPM2.

3.2.3 STANDARD FACTORY RANGES

As received from the Factory, the instrument is programmed for the following

standard conditions. These may be field modified by the user by using the RS232 serial port. See the Operation section for complete programming

information.

Digital Display Units: Set for ppmv and Dew Point

Analog Output Ranges: Set for 0 to 1250 ppmv, and -100°C to 0°C Dew Point

Alarm Relays Switching: Actuated at 100 ppmv, and -50°C Dew Point

RS-232 Port Update Rate: 5 seconds

8

Page 9

3.2.4 GASES TO AVOID

Caution: This instrument should not be used with gases that are corrosive or that

readily combine with phosphorous pentoxide to form water. GASES AND

MATERIALS THAT SHOULD BE AVOIDED INCLUDE CERTAIN ACIDS,

ALCOHOLS, CHLORINE, FLUORINE, HYDROGEN CHLORIDE, HYDROGEN

FLUORIDE, AMINES, AMMONIA, ALKYNES, ALKADIENES, AND ALKENES.

4.0 INSTALLATION

4.1 PLACEMENT OF INSTRUMENT

If possible, locate the PPM1 in a clean area. Choose a location where the

display may be conveniently observed. Depending on the location selected, it

may be convenient to wire the instrument prior to mounting.

4.2 MOUNTING

4.2.1 WALL MOUNTING THE DISPLAY

The plastic wall mount housing is mounted to a flat surface as follows:

1. Remove the front cover. Using a flat screwdriver, carefully unscrew the

four slotted plastic screws.

2. Mounting screws (not provided) are inserted in the same holes as the

cover screws. They must have a head diameter that is small enough

to fit inside the clearance holes, but large enough to press against the

collar located at the bottom of the holes. No. 8 pan head or round

head screws are recommended. See the wall mounting hole pattern in

the Appendix of this manual.

3. Reinstall the front cover. Do not over-tighten the cover mounting

screws.

4.2.2 SENSOR MOUNTING AND SAMPLING SYSTEM

The P2O5 Moisture Sensor is designed to measure very small quantities of Water

Vapor in the presence of other gases. It is manufactured of carefully selected

non-hygroscopic materials such as stainless steel. The use of more porous

materials such as plastic in your measuring system is strongly discouraged. In

order to obtain correct readings and acceptable response times, the sensor

sampling system must be carefully planned. Here are some recommendations:

Tubing should be clean stainless steel, not plastic.

If gas is brought from a long distance, use larger diameter tubing for faster

response time. Reduce diameter at the sensor fitting.

9

Page 10

Leak check the system after installation.

Purge the sampling system with dry gas after installation.

Do not expose the sensor to excess pressure.

Allow sufficient time for the system to dry out before attempting to take

measurements.

The sensor gas connections are ¼ inch (6.35 mm) compression fittings. See the

sensor mounting hole information in the Appendix of this manual.

If the gas to be measured is not completely clean, you may wish to install an

upstream filter in the system. A sintered stainless steel filter element is

recommended.

4.3 ELECTRICAL WIRING

See Figure 4-1, the electrical wiring diagram. All connections are clearly marked

on the circuit board.

4.3.1 SENSOR CONNECTIONS

The connector end of the Sensor cable is plugged into the Sensor. The other

(wired) end should be routed through the left hand feed-thru fitting at the bottom

of the electronics housing. Two wires are connected to the terminals marked

“SENSOR,” and the shield wire is connected to the terminal marked “CH GND”.

4.3.2 POWER CONNECTIONS

Power is supplied by a user-furnished unregulated DC power supply. Voltage

range may be between 18 and 30 VDC, at 100 mA maximum. Connect the

positive side to +VIN, and the negative side to RTN.

4.3.3 ANALOG OUTPUTS

The 4 to 20 mA Analog Outputs, if used, may be routed through the left-hand

feed-thru fitting. The positive side of Output 1 is connected to the terminal

marked OUT1, and the return to the adjacent terminal marked RTN. Similarly,

Output 2 is connected to OUT2 and RTN.

4.3.4 ALARM RELAYS

The Alarm Relays, if used, may be routed through the right-hand feed-thru fitting.

The contacts are Normally Open. Two alarm wires may be connected to the

terminals marked K1, and two may be connected to the terminals marked K2.

4.3.5 RS-232 SERIAL PORT

The built-in serial port is bi-directional, and includes a Type DB-9 RS-232

connector mounted on the circuit board. Any industry standard RS-232 cable

may be used. It is recommended that the installer wire the connector to one end

of the cable after routing it through one of the feed-thru fittings mounted to the

bottom of the electronics housing.

10

Page 11

Digital

Display

4 – 20 mA

Output 1

4 – 20 mA

Output 2

Sensor Cable

Connections

DC Power

Connections

Alarm

Relay K2

Alarm

Relay K1

RS-232

Type DB-9

Connector

Figure 4-1 PPS1/PPS2 Wiring Connections

11

Page 12

5.0 OPERATION

5.1 STARTUP

IT IS RECOMMENDED THAT A NEWLY INSTALLED INSTRUMENT BE DRIED

DOWN WITH DRY INERT GAS SUCH AS BOTTLED NITROGEN BEFORE

FINAL CONNECTION IS MADE BETWEEN THE SAMPLING SYSTEM AND

THE PROCESS GAS STREAM.

5.1.1 DRY DOWN PHASE 1

THE DRY GAS SHOULD FLOW THROUGH THE SAMPLING SYSTEM ONLY

(BYPASSING THE SENSOR) FOR THE FIRST FEW HOURS.

This procedure is recommended because during construction of the sampling

system, the components are exposed to the moisture in the ambient air, which

under normal conditions, can easily exceed 30,000 ppmv. These components

will be in equilibrium with the ambient air (having adsorbed moisture on their

surfaces). This water vapor will be desorbed from the walls of the tubing and

other surfaces of the sampling system components once the gas sample starts to

flow.

Unless steps are taken to remove any moisture in advance by following the

PHASE 1 dry down procedure, much of the moisture desorbed from the surfaces

of the sampling system will enter the electrochemical cell, most probably

exceeding the moisture concentration that the cell is designed to handle.

5.1.2 DRY DOWN PHASE 2

THE FLOW OF DRY GAS SHOULD THEN BE ROUTED THROUGH BOTH THE

CELL AND THE SAMPLING SYSTEM ASSEMBLY FOR AT LEAST ONE OR

TWO HOURS.

This procedure is recommended to dry down the measurement cell, and to

equilibrate the entire sampling system.

NOTE: ONCE THE ANALYZER HAS BEEN POWERED, THE POWER

SHOULD NOT BE SHUT OFF. FAILURE TO ADHERE TO THIS PROCEDURE

COULD SHORTEN THE USEFUL LIFE OF THE MEASUREMENT CELL.

The rationale behind this recommendation is that if power is always applied to

the measurement cell, any moisture that accidentally gets into the sampling

chamber will be eliminated by electrolyzing the water vapor molecules. This

keeps the moisture level on the phosphorous pentoxide low, lengthening its life.

12

Page 13

NOTE: IT IS GOOD PRACTICE TO INSTALL A SHUTOFF VALVE ON EACH

SIDE OF THE MEASUREMENT CELL, TO KEEP IT DRY WHEN OPENING

THE SAMPLING SYSTEM.

5.2 MEASURING DRY GASES

5.2.1 MEASUREMENT TIME

Measuring extremely dry gases is an art. Time and patience are involved. If you

are in a hurry, you may not obtain accurate results. As discussed above, all

materials are hygroscopic. That is, they have pores that retain water molecules.

When the level of moisture in a gas is decreased, for example, it may take a very

long time for all of the materials in the entire sampling system to outgas, or give

off all the excess water molecules that are trapped in the pores of every inside

surface of the system. Depending upon your unique conditions, it could take a

number of hours for complete stabilization of the moisture level in your gas. Be

sure you wait long enough before taking readings.

5.2.2 MATERIALS

As discussed in the Installation chapter of this manual, selection of materials is

extremely critical for proper dry gas sampling. For dry gas measurements, do

not use PVC or other porous tubing. Some plastic tubing such as Impolene™

may be used for gases in the higher ppm ranges. For measuring gases in the

lower ppm ranges, only stainless should be used.

If readings do not seem to stabilize after waiting a reasonable amount of time,

check to see if you have a leak from outside the system where the vapor

pressure is higher, or have excessively hygroscopic tubing, or possibly your

stainless tubing is contaminated and requires cleaning.

5.3 OPERATING THE INSTRUMENTS

5.3.1 THE PPM1

There are no controls to operate on the PPM1. The operator simply monitors the

digital display, or allows the analog and digital outputs to communicate with the

data acquisition system. When you first turn on the system, a short self-check

period occurs on the display, and then it quickly starts to show the two moisture

parameters that it is programmed to display. These are changeable in the field,

as shown in the following section on the Serial Port. The digital displays, as well

as the electrical outputs, are constantly updated.

5.3.2 THE PPM2

The PPM2 is a portable version of the PPM1. It is necessary to charge the builtin batteries before using it, and then to recharge them periodically. The charger

is supplied with the system.

13

Page 14

5.4 USING THE RS-232 SERIAL PORT TO PROGRAM YOUR

SETTINGS

5.4.1 SERIAL PORT SETUP

Plug a standard RS-232 cable into the DB-9 connector on the circuit board in the

PPM1 or PPM2. Plug the other end into your terminal or computer. If your

computer does not have a serial port, you will have to obtain a USB to Serial

adaptor, install the driver for it, and use the USB port.

Using a communications program such as Hyperterminal or equivalent, program

the settings as follows:

Baud Rate: 19.2K

Data Bits: 8

Parity: None

Stop Bit: 1

Flow Control: None

You should now see flowing data on your monitor,

displaying the same information that is shown on the

PPM1 or PPM2 Digital Display, with a periodic

update rate. If you do not, check your serial port

settings and cable connections.

NOTES:

1. WHEN PROGRAMMING ALPHABETIC CHARACTERS, USE UPPER

CASE ONLY.

2. IF YOU HAVE MORE THAN ONE WINDOW OPEN ON YOUR

DESKTOP, CLICK ON THE HYPERTERMINAL WINDOW TO SELECT

IT BEFORE PROGRAMMING.

5.4.2 CHANGING THE DIGITAL DISPLAY

You can select any two of several measured

or calculated parameters to appear on the

front panel Digital Display. Proceed as

follows:

Press the “Escape” key on your keyboard.

You will see three items that you can

program; D)isplay, C)al outputs, and R)s232,

as shown here. Since we are planning to

14

Page 15

select Display parameters, press “D” for Display. (We will C)alibrate the Outputs

and modify the R)s232 later.)

Note that initially, the displays are showing

units of ppmv (parts-per-million by volume)

and Dew Point in degrees C. First, we will

change ppmv to ppmw (parts-per-million by

weight).

You are given a choice whether to keep the

present units or to C)hange them. In this

case, we will select to C)hange them. Press

“C” on your keyboard. Select “Value 1” to change ppmv.

NOTE:

PRESSING THE SPACE BAR SCROLLS

THROUGH ALL THE AVAILABLE

SELECTIONS. PRESS “ENTER” TO

SELECT THE ONE YOU WANT TO KEEP.

Press the Space Bar several times to see

what units are available. When you see

ppmw, press “Enter”. You will then see the

window below. Press “Enter” again.

Than, you will be given a choice whether to

A)ccept or C)hange this modification. Press

“A” for A)ccept.

5.4.3 CHANGING THE

ANALOG OUTPUT RANGES

Continuing on, you will now be

given the opportunity to modify

the Analog Outputs. You do not

have to go back to the main

menu to do this, since it will

automatically be the next step.

15

Page 16

Again, use the Space Bar to

scroll through the available

options, and then use Enter to

select the one you want. If you

wish, you can also change the

measurement range that 4 to 20

mA corresponds to at this time.

Finally, press “A” to A)ccept the

change. You have completed

the process of modifying the

Analog Output.

In this example, let’s change the

4 to 20 mA Analog Output so that

it corresponds to Dew Point in °F

instead of Dew Point in °C.

Press “C” for C)hange. You will

than see this window. Press “2”

to Set Output 2, which

corresponds to Dew Point in °C.

We have selected DP°F, as

shown here. Next, press “X” for

eX)it.

16

Page 17

5.4.4 PROGRAMMING THE ALARM RELAYS

Next, you will be given the opportunity to modify the alarm settings if you wish.

Again you do not have to go back to the main menu, since the next step will

automatically put you in this mode.

The PPM1 and PPM2 have two alarms. They are Form A, (single-pole, singlethrow) normally open. You can make them correspond to any of the available

measured or calculated measurement parameters. You can independently

program the “ON” point and the “OFF” point for each relay. To enter the menu,

press “C” for C)hange.

You will then see the window shown below. In this example, we would like to

change Alarm 2. Note that it is now set for Dew Point in °C, and the relay

switches at 0.0 degrees. We are going to change it so that the alarm is now on

Dew Point in °F. We want the relay to open when the measurement is above

25°F, and we want it to close when the measurement is below 24°F. Therefore,

press “C” for C)hange.

You will now see the window shown here. Press “2” to select Alarm 2.

As before, you can use the Space Bar to select the desired unit and the Enter

key to lock it in. You can also choose to Enable or Disable any alarm. See the

following window.

17

Page 18

As you cycle through, you will be given the opportunity to replace DP°C with

DP°F, as shown here. At this time you can also change the measurement range

if you wish to. We will leave the default °F range of 50.0 to 0.0.

Next, we will program the alarm relay to open when the measurement is above

25 degrees, and close when the measurement is below 24 degrees.

NOTE: IT IS NOT GOOD PRACTICE TO SET THE “OPEN” POINT AND THE

“CLOSE” POINT TO THE SAME NUMBER. THIS MAY CAUSE EXCESSIVE

RELAY CHATTERING WHEN THE MEASUREMENT IS AT THAT QUANTITY.

18

Page 19

Next, we are asked if we want to Save the Changes, and we press “Y” for Y)es.

Now, we can select “X” for eX)it, and then “A” to A)ccept the changes.

19

Page 20

We have now made all the desired changes, and the display defaults to the

standard Hyperterminal window with periodic updates. See the illustration below.

5.4.5 CALIBRATING THE ANALOG OUTPUTS

If you have a precise

milliammeter, the PPM1 and

PPM2 allow you to check the

calibration of the two 4 to 20 mA

analog outputs. In order to utilize

this capability, connect the meter

in series with one of the analog

outputs and the load. Observe

the correct meter polarity.

Press the “Escape” key on your

keyboard, which will interrupt the

data stream and give you the

Calibration option. Than, press

“C” for C)alibrate. For this

example, select Output 1 to

calibrate. Next, read your

precision ammeter, which will give

you the high end current. It

should read around 20 mA. In

this case, the actual reading is

19.9 mA as shown. Type this

value in.

20

Page 21

Next, read the low end output current. It should be about 4 mA.

Type it in as shown above. The system then will

show you the predicted midpoint reading, which in

this case should be within the range of between

11.975 and 12.025 mA. This takes the cumulative

system errors in account.

As shown here the reading is exactly 12 mA,

and the system is within specifications.

Finally, press “X” for E)xit, and the

Hyperterminal window will return to the

default mode, showing continuous updates.

5.4.6 MODIFYING THE RS-232 PORT PARAMETERS

Two RS-232 Port parameters may be

changed in the field. You can enable the

Elapsed Time Stamp, and you can modify the

Update Rate. To start, proceed as follows:

From the

normal

updating

mode as

shown here, press “R” for Rs232. You can

then press “T” to select the Elapsed T)ime

Stamp, or press “R” to select the Update

R)ate. In this example we will leave the

Elapsed Time Stamp disabled, but we will change the Update Rate. See the

Windows shown below.

21

Page 22

First, press “R” to select the Update R)ate.

You have a choice of rates from 1 to 3600

seconds (1 second to 1 hour).

For this example we will insert an Update

Rate of 5 seconds, which is a convenient rate

to watch data updating on the computer

monitor.

See the

window on the right. Once that is done, you

only have to press “X” for eX)it, and you will

be back in the default updating mode as

shown below.

You have now completed all the

programming of the PPM1 or PPM2. You

can go back at any time and easily modify

any parameter in the field.

22

Page 23

6.0 MAINTENANCE

6.1 GENERAL

Very little maintenance is required for long term operation of the PPM1 and

PPM2 Trace Moisture Analyzers. They have been designed for continuous

operation over very long periods of time. The electronics unit needs no

maintenance. The trace moisture sensor may gradually get contaminated, and

may have to be returned to the Factory for cleaning after very long periods of

operation.

6.1.1 FILTERS

It is considered good practice to have an upstream particle filter in the line. It will

keep the moisture sensor clean and will keep dust and other contaminants out of

the cavity. The filter should be non-hygroscopic, and preferably should be made

of sintered stainless steel. A maintenance schedule should be set up to clean or

replace the element periodically. A clogged filter will retain moisture and slow

down the system.

6.1.2 BATTERY MAINTENANCE

The PPM2 Portable Analyzer contains a pair of gel call batteries. These must be

periodically recharged. A plug-in charger is included with the system. After a

few discharge cycles to determine available operating time, you should be able to

initiate a preventative maintenance program for periodic recharging that will keep

the unit ready for use. If desired, the battery charger may be plugged into the

PPM2 continuously without harm.

6.2 GASES

Certain gases must never be used with this system. See GASES TO AVOID in

the Introduction section of this manual. The use of these gases may damage or

contaminate the moisture sensor.

23

Page 24

7.0 SPECIFICATIONS

Technology Used: P2O

Measured Parameter: PPMv (Parts-per-Million by Volume)

Calculated Parameters: Dew Point, PPMw (Parts-per-Million by

Weight), Others

Accuracy: ± 5% of PPMv reading, typical

Measurement Range: PPMv: 1250 to 0.1 ppm

Dew Point: -20°C to -95°C

Pressure: 0 to 200 psig

Response Time: 90% of step change in one minute, typical

Hysteresis: None

Temperature: Ambient: 0 to 50°C

Sample Gas: 0 to 50°C

Electrical Outputs: Analog Outputs (2): 4 to 20 mA

(Field Programmable) Load: 0 to 400Ω

Digital Interface: RS-232C, bi-directional

Alarm Relays (2): Form A (Normally Open)

Contact Rating: 3A at 250VAC/30VDC

Digital Display: LCD, 2 line, backlit

Sensor Gas Connections: ¼ inch (6.35 mm) compression fittings

Model PPM1:

Power Requirements: 18 to 30 VDC unregulated, 100 mA maximum

Standard Cable: 6 feet (1.8 meter)

Dimensions: Enclosure (LWD): 5.1 in (13cm) X 5.1 in

(13cm) X 3 in (7.6cm)

Phosphorous Pentoxide Cell

5,

DB-9 Connector

24

Page 25

Weight: Entire System: 4 lbs (1.8kg)

MODEL

APPLICATION

DESCRIPTION

PPM2 – FV

Positive Pressure

A portable battery

powered trace moisture

analyzer with built-in

Flow Valve

PPM2 - VP

Atmospheric Pressure

or Vacuum

A portable battery

powered trace moisture

analyzer with built-in

Vacuum Pump

Available PPM1

Options/Accessories: Right angle mounting bracket (-MB)

Additional sensor cable length (-SCBL)

Note: Specify length to 500 ft. max.

Model PPM2:

Power Requirements: Battery Powered, 2 gel cells (12 VDC) in series

Battery Charger included

(115/230Vac to 24Vdc)

Nominal Operating Time: 8 to 10 hours

Standard Cable: 6 feet (1.8 meter)

Dimensions: Carry Case (LWD): 19 in (48cm) X 14 in

(36cm) X 7 in 18cm)

Weight: Entire System: 15 lbs. (6.8kg)

Available PPM2 Optional Configurations:

25

Page 26

8.0 APPENDIX

8.1 PPM1 MOUNTING DIMENSIONS

26

Page 27

8.2 SENSOR DIMENSIONS

27

Page 28

8.3 EDGETECH INSTRUMENT’S WARRANTY

All equipment manufactured by Edgetech Instruments Inc. is warranted

against defective components and workmanship, and will be repaired at

their plant in Massachusetts, free of charge, for a period of twelve

months. Malfunction due to improper use is not covered in this warranty

and Edgetech Instruments disclaims any liability for consequential

damage resulting from defects in the performance of the equipment. No

product is warranted as being fit for a particular purpose and there is no

warranty of merchantability. This warranty applies only if (i) the items are

used solely under the operating conditions and in the manner

recommended in the instruction manual, specifications, or other

literature; (ii) the items have not been misused or abused in any manner

or repairs attempted thereon; (iii) written notice of the failure within the

warranty period is forwarded to Edgetech Instruments and the directions

received for properly identifying items returned under warranty are

followed; and (iv) the return notice authorizes Edgetech Instruments to

examine and disassemble returned products to the extent Edgetech

Instruments deems necessary to ascertain the cause for failure. The

warranties expressed here are exclusive. There are no other warranties,

either expressed or implied, beyond those set forth here, and Edgetech

Instruments does not assume any other obligation or liability in

connection with the sale or use of these products.

Equipment not manufactured by Edgetech Instruments is supported only

to the extent of the original manufacturer’s warranties.

28

Page 29

Notes

29

Loading...

Loading...