Page 1

OxyTrans

Loop Powered Two Wire

Oxygen Transmitter

OPERATORS MANUAL

19 Brigham Street Unit 8

Marlborough, MA 01752

508-263-5900 Fax: 508-486-9348

www.edgetechinstruments.com

h2o@edgetechinstruments.com

Rev. A April 2009

Page 2

OxyTrans

QUICK STARTUP GUIDE

STARTUP

1. Using the supplied Mounting Kit, mount the OxyTrans in

position to measure the desired gas.

Caution: The cell must be mounted vertically with Digital

Display at the top.

2. Connect input and output tubing. See Manual for proper tubing

materials. Shutoff valves should be installed on both sides of

the sensor.

3. Connect loop power supply, using cable supplied.

4. Connect data acquisition system or other series load if

required.

5. Allow sufficient equilibration time before recording data.

Page 3

TABLE OF CONTENTS Page

1.0 Quick Startup Guide

2.0 Commitment to Quality 3

3.0 Introduction 4

3.1 General Description 4

3.2 Micro Fuel Sensor 4

3.3 The Effect of Pressure 4

3.4 Calibration Characteristics 5

3.5 Standard Configurations 5

3.6 Options and Accessories 6

4.0 Installation 8

4.1 Mounting 8

4.2 Plumbing 8

4.3 Electrical Connections 9

5.0 Operation 11

5.1 Digital Display 11

5.2 Analog Output 11

6.0 Maintenance

6.1 Calibration 12

6.2 Out of Service Procedure 13

6.3 Troubleshooting 13

6.4 Cell Replacement 14

7.0 Specifications 18

8.0 Appendix 19

8.1 Warranty 20

8.2 Oxygen Cell Housing Drawing 21

8.3 Intrinsically Safe Barrier (Optional) 22

1

Page 4

LIST OF ILLUSTRATIONS Page

3-1 Cell I/O Curve 5

3-2 Standard Configurations 6

4-1 Mounting Kit 8

4-2 Mounting the Transmitter 9

4-3 Electrical Connections 10

5-1 Digital Display 11

6-1 Calibration Adjustment 12

LIST OF TABLES Page

3-1 Standard Factory Ranges 6

2

Page 5

2.0 EDGETECH INSTRUMENTS INC.'S COMMITMENT

TO QUALITY

To Our Customers:

Thank you for purchasing one of our products. At Edgetech

Instruments Inc., it is our policy to provide cost-effective products and

support services that meet or exceed you requirements, to deliver

them on time, and to continuously look for ways to improve both. We

all take great pride in the products we manufacture.

We want you to be entirely satisfied with your instrument. The

information contained in this manual will get you started. It tells you

what you need to get your equipment up and running, and introduces

its many features.

We always enjoy hearing from the people who use our products. Your

experience with our products is an invaluable source of information

that we can use to continuously improve what we manufacture. We

encourage you to contact or visit us to discuss any issues whatsoever

that relate to our products or your application.

The Employees of Edgetech Instruments Inc.

3

Page 6

3.0 INTRODUCTION

3.1 GENERAL DESCRIPTION

The Edgetech Instruments Inc. OxyTrans 2-wire 4 to 20 mA Loop Powered

Oxygen Transmitter consists of two sub-systems:

1. The Analyzer Unit, which is an electro-chemical fuel sensor designed

for measuring oxygen.

2. The Electronics Unit, which provides sensor signal conditioning, digital

display, and electrical analog outputs.

The gas to be measured is transported to the sensor membrane of the Micro

Fuel sensor. This sensor is an electro-chemical and galvanic cell that transforms

the oxygen in the measured gas into an electrical current.

The Electronics Unit measures this electrical signal, providing visual and

electrical information to the operator, directly in either parts-per-million of oxygen

(ppm O2), or as a percentage of the total measured gas (%O2).

3.2 MICRO FUEL SENSOR

The oxygen sensor is a sealed plastic disposable electrochemical sensor. The

active components are a cathode and an anode, which are immersed in a 15%

aqueous KOH electrolyte solution. When oxygen in the sample gas is sensed by

the membrane, the cell converts the resulting chemical reaction into an electrical

current change. Its action is similar to that of a battery, with one important

difference. In a battery, all reactants are stored within the cell. In the oxygen

sensor, one of the reactants, oxygen, comes from outside the device as a

constituent of the sample gas being analyzed.

3.3 THE EFFECT OF PRESSURE

In order to determine the amount of oxygen present in the gas sample, it is

necessary that the gas diffuse into the cell under constant pressure, by Dalton’s

Law. If the total pressure increases during a measurement, the rate that oxygen

reaches the cathode through the diffusing membrane will also increase. The

electron transfer, and therefore the resulting measured output current, will

increase even though the oxygen concentration in the sample has not changed.

Therefore, it is important that the sample pressure at the fuel cell remain

constant during measurements.

4

Page 7

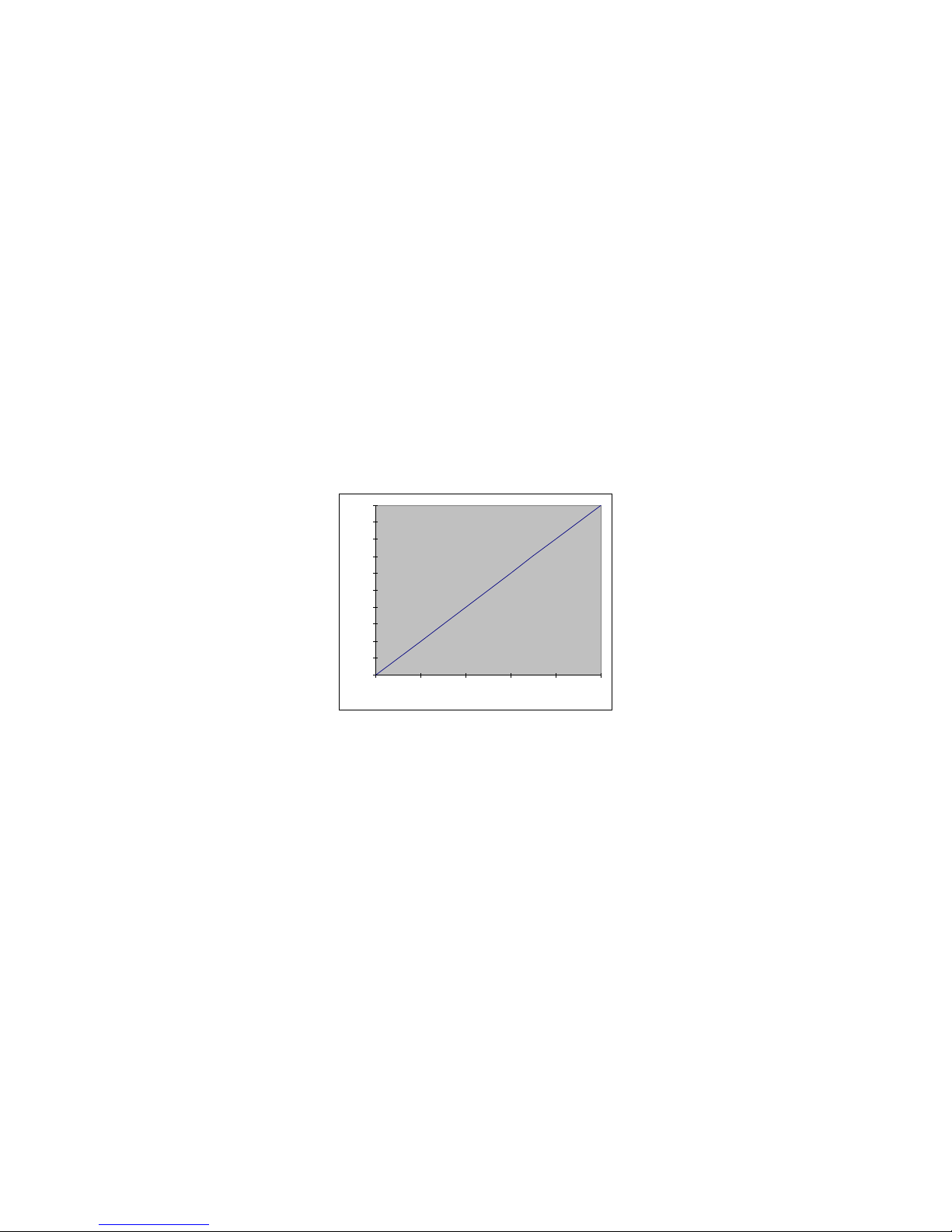

0

10

20

30

40

50

60

70

80

90

100

0 0,2 0,4 0,6 0,8 1

oxygen concentration %

output zell in µA

3.4 CALIBRATION CHARACTERISTICS

Since the total pressure of the sample gas at the input of the measuring cell

is constant, a convenient characteristic of the cell is that the current produced in

an external circuit is directly proportional to the rate at which oxygen molecules

reach the cathode, and this rate is directly proportional to the concentration of

oxygen in the gaseous mixture. In other words it has a linear characteristic

curve, as shown in Figure 3-1. An advantage is that measuring circuits do not

have to compensate for nonlinearities.

In addition, since there is zero output in the absence of oxygen, the

characteristic curve has close to an absolute zero (within ± 1 ppm oxygen).

In practical application, zeroing is still used to compensate for the

combined zero offsets of the cell and the electronics. The electronics is

zeroed automatically when the instrument power is turned on.

Figure 3-1 Characteristic Input/Output Curve for the Oxygen Cell

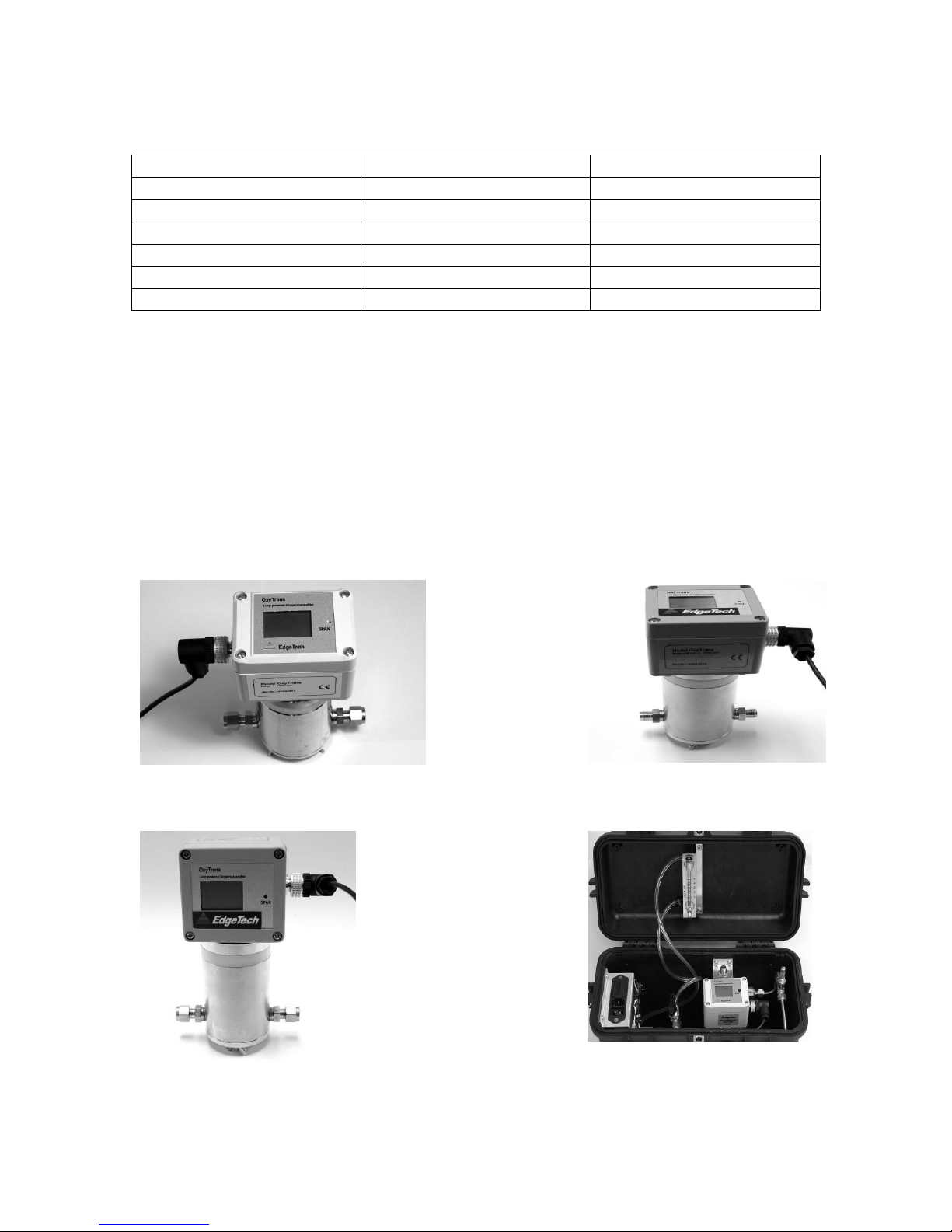

3.5 STANDARD FACTORY CONFIGURATIONS

The Edgetech Instruments Inc. OxyTrans series of transmitters are available in a

number of

convenient configurations. These include both vertical and horizontal mounts, so

that the digital display may be viewed either from the top or from the front.

Intrinsically Safe barriers are also available if required.

5

Page 8

A number of standard ranges are available. These include:

RANGE

PARTS-PER-MILLION

PERCENT OXYGEN

0 to 10

X

0 to 100

X

0 to 1000

X

0 to 10,000

X

0 to 1

X

0 to 25

X

Table 3-1 Standard Factory Ranges

3.6 OPTIONS AND ACCESSORIES

Other standard configurations include a Panel Mount unit with optional safety

barriers. A Portable unit is available in a carrying case with a built-in sampling

system, including a flow meter, flow adjustment valve, sintered filter, vacuum

pump, and power supply. Also available is an Explosion-Proof (ATEX approved)

version. A unit with electrical interface compatible with the Hart Protocol is a

standard option. Additional ranges are available on special order. Some ranges

provided in the past include 0 to 20,000 ppm, 0 to 50,000 ppm, and 0 to 100%

O2. See Figure 3-2 below.

Figure 3-2a Explosion-Proof Unit Figure 3-2b Vertical Mount

Figure 3-2c Horizontal Mount Figure 3-2d Portable Unit

6

Page 9

Figure 3-2e Panel Mount Unit

7

Page 10

4.0 INSTALLATION

The installation of the transmitter is very simple. However, it must be done with

care to ensure successful operation and data collection. Select a mounting

location that will allow convenient viewing of the built-in Digital Display.

Note: The cylindrical portion of the cell must be mounted vertically for

proper operation, with the display at the top. Both horizontal and vertical

digital displays are available. The correct one should be carefully selected.

4.1 MOUNTING

A Mounting Kit, shown in

Figure 4-1, is provided for

easy installation. It

includes the mounting

hardware, and also an

interconnecting cable and

extra compression fitting

nuts.

First, screw the supplied

Mounting Plate securely to

a wall or other vertical

surface, using two No. 10

screws. Hole centers are

1-1/16 inch (27mm) apart.

Then, run the large

stainless steel pipe clamp Figure 4-1 Mounting Kit

through the slots in the sides

of the Mounting Plate. Insert the OxyTrans transmitter as shown in Figure 4-2.

Tighten the screw, locking the cell housing in place. Do not over-tighten.

4.2 PLUMBING

For low percentages of oxygen in the sample gas, proper selection and

installation of tubing is critical for successful measurements.

Recommendations for trace O2 measurements:

1. Use only stainless steel tubing.

2. If there is a possibility that the tubing is contaminated, it should be cleaned

before installation.

3. The entire plumbing system should be leak-checked after installation.

8

Page 11

4. After the plumbing installation has been completed, the system may have

PIPE CLAMP

MOUNTING

PLATE

to be operated overnight to purge it.

Figure 4-2 Mounting the Transmitter

A good stainless steel sintered filter or a borosilicate glass filter can increase the

length of maintenance-free operation if the gas contains dust particles or other

impurities.

Install shut-off valves on both sides of the sensor so that it may be isolated from

the system when not being used. This ensures a longer cell life.

For higher Oxygen concentrations, some plastic materials such as Tygon™ are

acceptable. Do not use soft PVC tubing.

Adjust the flow rate between 1-2 SCFH (0.5 to 1 L/min).

4.3 ELECTRICAL CONNECTIONS

The system provides a loop-powered 4 to 20 mA output signal, corresponding to

the oxygen measurement range specified. “Loop powered” means that the

OxyTrans is powered by the current loop itself. The OxyTrans, power supply,

and the (optional) signal-conditioning device used to measure the 4 to 20 mA

signal are all connected in a series loop, so that the same current flows through

all. The loop power supply voltage should be between 10 and 36 VDC. See

Figure 4-3 below for OxyTrans connections.

9

Page 12

Pin 4: + RED

Pin 3: – BLUE

Output: 4 – 20 mA

Load: 0 to 500 Ohms

PIN 3 (-)

PIN 4 (+)

Figure 4-3 Electrical Connections

The electrical interface cable supplied is approximately 57 inches (22 cm) long.

It is color coded for easy installation. The positive side (Pin 4) is red, and the

return side (Pin 3) is blue. The pin numbers are marked on the connector on the

body of the OxyTran, in case you wish to fabricate your own cables.

After applying power to the loop, you will see a value on the display. Allow

sufficient time for the entire system to equilibrate before attempting to record

valid data. Equilibration time is longer for low concentrations of oxygen than it is

for higher concentrations.

10

Page 13

5.0 OPERATION

Operation of the OxyTrans is very simple. Open the shut-off valves on the

upstream and downstream sides of the sensor. For most models, there are no

switches or other controls. The operator simply has to be sure that the gas flow

rate is within the specified range (1 to 2 SCFH, or 0.5 to 1 L/min.), and that new

readings have completely equilibrated before data is taken.

5.1 DIGITAL DISPLAY

The Digital Display shows you the current oxygen value. A bar graph at the top

symbolizes the analog output signal. See Figure 5-1.

Figure 5-1 Digital Display

5.2 ANALOG OUTPUT

The 4 to 20 mA electrical output will follow the changes in value of the measured

Oxygen, just as the digital display does. It may be remotely measured with a

series DC milliammeter, or used to drive a process controller or data acquisition

system.

11

Page 14

MAINTENANCE

6.1 CALIBRATION

Although the OxyTrans comes Factory-calibrated, you may wish to recalibrate

the unit at some time. Calibration of the OxyTrans is very simple. A calibration

gas with a known Oxygen value is required.

CALIBRATION ADJUSTMENT SCREW

Figure 3

Figure 6-1 Calibration Adjustment

Notes:

1. Select a calibration gas that is equivalent to your measurement range.

For example, if you have the 0 to 100 ppm unit, select a gas with an

Oxygen value of approximately 40 – 50 ppm O2 in N2.

2. Be sure that line pressure remains constant during the calibration.

3. If you have the 0 to 25% Oxygen range, air may be used for the

calibrating gas. Air consists of approximately 21% Oxygen.

4. Be sure to wait until complete equilibration before calibrating the unit.

If the Oxygen concentration is very low, or if the sampling system is

large, waiting a long time may be required.

12

Page 15

To calibrate the OxyTrans:

1. Locate the Calibration adjustment screw. See Figure 6-1.

2. Connect the calibration gas to the compression fitting. For low ranges, do

not leave the downstream fitting open to room air. We recommend that you

use a few feet of tubing on the downstream side, to keep room air from entering

the cell.

3. After complete equilibration (see Note 4 above), the Digital Display will show

the current Oxygen value.

4. Once the value is stable, adjust the Calibration screw with a small

screwdriver until the Digital Display shows the correct value.

6.2 WHAT TO DO WHEN OUT OF SERVICE

If the OxyTran is not going to be used for a period of 12 hours or more, Step 1

below should be followed. To put it back into operation, see Steps 2 and 3

below:

1. Make sure that the shut-off valves on the upstream and downstream sides

of the measurement cell are closed, isolating the cell. No oxygen from the

outside air or from the gas pipeline should be in contact with the

measurement cell. This will increase the cell life.

2. After restarting the equipment, purge the sampling system with dry

nitrogen before using it for O2 measurements.

3. If the system has not been used for a long time, recalibrate against an

Oxygen standard gas.

6.3 TROUBLESHOOTING

If the OxyTrans displays incorrect or erratic readings of the Oxygen concentration

in the measured gas:

Possible Causes May Be:

1. Inaccurate calibration.

2. Leakage in the sampling system.

3. Atmospheric Oxygen may be diffusing in through the downstream port.

4. Unstable system pressure.

5. Defective Oxygen Cell.

13

Page 16

Possible Solutions May Be:

1. Turn the analyzer off, and then back on again. Now proceed to

carefully calibrate the analyzer.

2. Check the complete sampling system for leaks, and be sure that

everything is tight.

3. Increase the flow rate and/or add downstream tubing in order to dilute

or minimize the introduction of oxygen from the room back into the

sensor.

4. Be sure that the measurement gas pressure is stable. Changes in the

operating pressure will cause measurement value variations. The cell

is designed to measure Oxygen at atmospheric pressure. There

should be nothing downstream that could restrict gas flow and increase

cell pressure.

Caution: The measurement cell could be destroyed if the

maximum pressure rating is exceeded.

If necessary, use a non-adjustable pressure reducer on the

measurement gas inlet.

5. If none of these steps correct the problem, than replace the sensor.

6.4 CELL REPLACEMENT

The sensor used in this analyzer uses electrolytes which contain toxic

substances, mainly lead and potassium hydroxide. These can be harmful

if touched, swallowed, or inhaled. Avoid contact with any fluid or powder

in or around the unit. What may appear to be plain water could contain

one of these toxic substances. In case of eye contact, immediately flush

eyes with water for at least 15 minutes. Call physician. (A Material Safety

Data Sheet is available from the Factory.)

CAUTION: Do not disturb the integrity of the cell package until the

cell is to actually be used. If the cell package is punctured and air is

permitted to enter, the cell may require an excessively long time to

reach zero after installation, possibly as long as one to two weeks!

6.4.1 WHEN TO REPLACE A CELL

The ageing characteristic of the Oxygen measurement cell shows an almost

constant output throughout its useful life. Near the end of its life it falls off

sharply, reaching zero output at the end.

14

Page 17

Before replacing the cell:

a. Check your calibration gas to make sure it is within specifications.

b. Check for leaks both upstream and downstream of the cell, where oxygen

may be leaking into the system.

c. Are you trying to measure trace quantities of Oxygen with a large sampling

system that has a large amount of surface area? The response time of the

system in this case may be very slow.

d. Has the power supply and the entire electrical system been checked?

If there are no leaks and the calibration gas is known to good, but you still get no

response, replace the cell.

6.4.2 STORING AND HANDLING OF REPLACEMENT CELLS

To have a replacement cell available when it is needed, we recommend that one

spare cell be purchased 9-10 months after installing the OxyTrans, or shortly

before the end of the cell's one year warranty period.

Note: Do not stockpile cells. The warranty period starts on the day of

shipment.

The spare cell should be carefully stored at room temperature, in an area that is

not subject to large variations in ambient temperature, and not subject to rough

handling.

6.4.3 REMOVING THE MEASUREMENT CELL

The Oxygen cell is built into the cell housing. To take out a defective or unusable

cell, proceed as follows:

1. Shut off the unit.

2. Unscrew the wing nut from the cell block.

3. Carefully remove the bottom of the cell block that contains the cell.

4. Take the cell carefully from the bottom. Do not touch the sensor

surface.

5. Correctly dispose of old cells according to proper disposal regulations.

A Material Safety Data Sheet (MSDS) is available from the Factory.

15

Page 18

6.4.4 INSERTION OF A NEW MEASUREMENT CELL

Caution: Do NOT touch the sensor membrane. The surface has a small

Teflon® membrane which can be destroyed by contact. The sensor will

have to be replaced if the membrane surface is destroyed.

For installation of the new cell, proceed as follows:

1. Shut off the unit.

2. Take the new cell out of the package.

3. Unscrew the wing nut from the cell block. Be careful that you don’t shift

or destroy the O-Ring.

4. Carefully place the cell at the center of the cell block bottom. The

sensor membrane wall will be below.

5. Press the cell together with the cell bottom in the cell block. The

contact surface will be on the top. Screw the wing nut back on securely.

Note: The cover will fit correctly only in one direction.

6. Restart the equipment and purge the sampling system with dry

nitrogen immediately.

6.4.5 CELL WARRANTY

Warranty period begins on the date of shipment. The customer should purchase

only one spare cell. Do not attempt to stockpile spare cells.

Note: These cells are not designed for applications where CO2 is a

major component in the sample.

However, concentrations of 1,000 ppm or less of CO2 will not adversely affect the

cell performance. Consult us for available options for either intermittent or

continuous CO2 exposure.

If a cell was working satisfactorily, but ceases to function before the warranty

period expires, the customer will receive credit toward the purchase of a new cell.

If you have a warranty claim, you must return the cell in question to the factory

for evaluation. If it is determined that failure is due to faulty workmanship or

material, the cell will be replaced at no cost to you.

16

Page 19

Note: If there is evidence of damage due to tampering or

mishandling, the cell warranty will be null and void.

6.4.6 CLEANING THE MEASUREMENT CELL HOUSING

If you have a reason to clean the cell housing, this may be done very carefully

with a lint-free clean cloth. Be cautious not to damage or break the gold colored

spring contacts inside.

Note: If there is heavy contamination inside the cell housing, send

the unit to the Factory for cleaning. The electronics will have to

be removed and then remounted.

17

Page 20

7.0 SPECIFICATIONS

Measurement Range: 0-10; 0-100; 0-1000; 0-10000 ppm O2

0-1; 0-25 % O2

Calibration Accuracy: With calibration gas (example: 80 ppm O2 in N2)

+/- 2% FS at constant temperature

+/- 5% FS over full temperature range

(at 0 -10ppm +/- 1ppm)

Resolution: 0.1 ppm

Response time: To 90 % of FS at 25°C

0-10 ppm < 45 s

0-100 ppm < 30 s

0-1000 ppm < 10 s

Operating Temperature: 0 - 50°C

Sample Pressure: 0.1 - 1 bar

Output signal: 4 -20 mADC isolated

Display: LCD Digital Dispay

Loop Power Supply: 10 - 36 VDC

Oxygen sensor: Chemical Cell

Expected Sensor Life: >2 years

Size: (H x W x D) 6.3 x 4.7 x 2.6 inches (160 x 120 x 65mm)

Weight: 3lbs (1.4 kg)

18

Page 21

8.0 APPENDIX

8.1 Warranty Statement

8.2 Oxygen Cell Housing Drawing

8.3 Intrinsically Safe Barrier for Panel Mount (Optional)

19

Page 22

8.1 WARRANTY STATEMENT

All equipment manufactured by Edgetech Instruments Inc. is warranted

against defective components and workmanship for repair at their plant

in Massachusetts, free of charge, for a period of twelve months.

Malfunction due to improper use is not covered in this warranty and

Edgetech Instruments Inc. disclaims any liability for consequential

damage resulting from defects in the performance of the equipment. No

product is warranted as being fit for a particular purpose and there is no

warranty of merchantability. This warranty applies only if (i) the items are

used solely under the operating conditions and in the manner

recommended in the instruction manual, specifications, or other

literature; (ii) the items have not been misused or abused in any manner

or repairs attempted thereon; (iii) written notice of the failure within the

warranty period is forwarded to Edgetech Instruments Inc. and the

directions received for properly identifying items returned under warranty

are followed; and (iv) the return notice authorizes Edgetech Instruments

Inc. to examine and disassemble returned products to the extent

Edgetech Instruments Inc. deems necessary to ascertain the cause for

failure. The warranties expressed herein are exclusive. There are no

other warranties, either expressed or implied, beyond those set forth

herein, and Edgetech Instruments Inc. does not assume any other

obligation or liability in connection with the sale or use of said products.

Equipment not manufactured by Edgetech Instruments Inc. is supported

only to the extent of the original manufacturer’s warranties

20

Page 23

8.2 OXYGEN CELL HOUSING DRAWING

21

Page 24

8.3 INTRINSICALLY SAFE BARRIER FOR PANEL MOUNT

(OPTIONAL)

22

Page 25

NOTES

23

Loading...

Loading...