Page 1

1

COM.AIR

Dew Point Monitor

Model COM.AIR

Compressed Air Dew Point Monitor

OPERATORS MANUAL

Edgetech Instruments Inc. 399River Rd, Hudson, MA 01749

508-263-5900 www.edgetechinstruments.com

04/02/2015 Rev. B

Page 2

2

TABLE OF CONTENTS

1.0 GENERAL DESCRIPTION

2.0 INSTALLATION

2.1 MOUNTING

2.2 WIRING CONNECTIONS

2.3 SAMPLE CONNECTIONS

2.4 ALARM RELAY CONNECTIONS

2.5 ANALOG OUTPUT CONNECTIONS

2.6 RS-232 SERIAL

COM.AIR

Dew Point Monitor

3.0 FUNCTIONAL DESCRIPTION

3.1 DISPLAY

3.2 MABC BUTTON

3.3 SILENCE ALARM BUTTON

3.4 FLOW CONTROL VALVE

3.5 ALARM RELAY OUTPUT

3.6 ANALOG OUTPUT

4.0 SETUP

4.1 ALARM SET POINT

4.2 ABC INTERVAL

5.0 MAINTENANCE

5.1 ROUTINE MAINTENANCE

5.2 MIRROR CLEANING SCHEDULE

5.3 MIRROR CLEANING PROCEDURE

6.0 SPECIFICATIONS

04/02/2015 Rev. B

Page 3

COM.AIR

3

Dew Point Monitor

Edgetech Instruments Inc.'s Commitment to Quality

To Our Customers:

Thank you for purchasing one of our products. At Edgetech Instruments, it is our policy to

provide cost-effective products and support services that meet or exceed your requirements,

to deliver them on time, and to continuously look for ways to improve both. We all take pride

in the products we manufacture.

We want you to be entirely satisfied with your instrument. The information in this manual will

get you started. It tells you what you need to get your equipment up and running, and

introduces its many features.

We always enjoy hearing from the people who use our products. Your experience with our

products is an invaluable source of information that we can use to continuously improve

what we manufacture. We encourage you to contact or visit us to discuss any issues

whatsoever that relates to our products or your application.

Edgetech Instruments is proud that our Com Air range is made here in the USA.

The Employees of Edgetech Instruments Inc.

04/02/2015 Rev. B

Page 4

Dew Point Monitor

4

1.0 GENERAL DESCRIPTION

The Edgetech Instruments Model COM.AIR is a chilled mirror based hygrometer designed

especially to monitor the dew point in compressed air systems.

It is an integrated system including a microprocessor-based instrument, a chilled mirror dew

point sensor, a sample flow meter and valve, and associated tubing and fittings.

The wall mount enclosure is easily mounted to any vertical surface.

The Instrument includes:

An eight-digit, alphanumeric, LED display to report the dew point and system status.

Periodic sensor balance check.

Programmable Alarm Set Point with visual, audible, and contact closure alarm indications.

A SPDT (Form C) Alarm Relay.

A 4 to 20mA analog output.

2.0 INSTALLATION

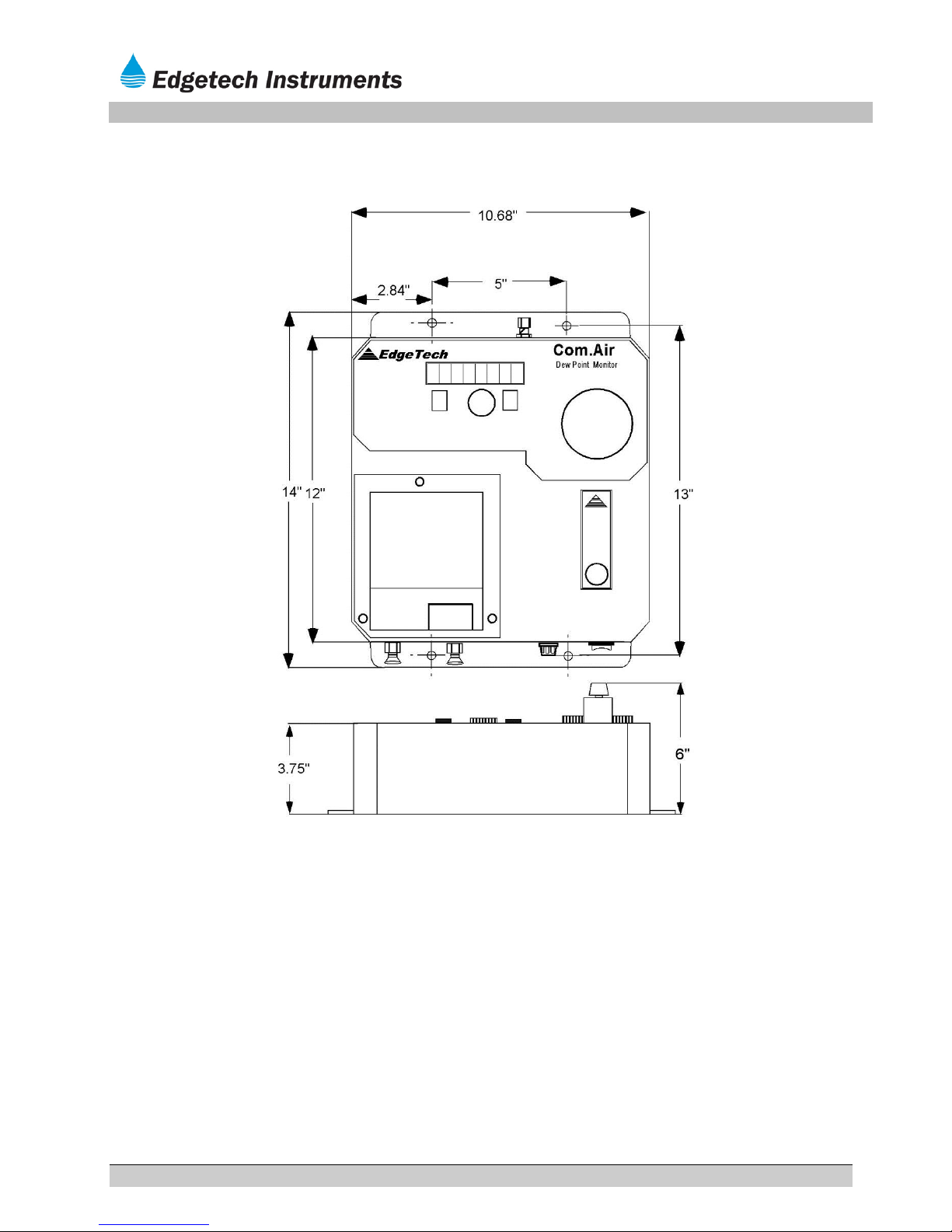

2.1 MOUNTING

The COM.AIR can be installed on any flat vertical surface with four ¼ inch screws. See Figure

2-1 for dimensional information.

COM.AIR

2.2 WIRING CONNECTIONS

The COM.AIR is designed to operate on AC voltages of 90 to 260 VAC with a maximum power

requirement of 40 Watts. The power entrance hole, located on the bottom of the enclosure, is

designed to accept a standard conduit, clamp type fitting or a compression type fitting

(supplied). The power line connections to the instrument are made using pigtail leads and wire

nuts.

Connect the power leads as follows:

1. Remove the three thumbscrews and the access cover as shown in Figure 2-2

2. Pull the three wires, black, white and green out of the wire box as shown in

Figure 2-3.

3. Insert the power line wires into the bottom of the enclosure and feed them up

through the wire box and out the access opening. Strip the wire ends back about

½". Using the three wire nuts, connect the wires black to black, white to white

and green to green. Tighten the wire nuts securely, making sure there are no

exposed wires.

4. Push the wires down into the wire box.

2.3 SAMPLE CONNECTIONS

The sample may be brought to the instrument with ¼" copper, stainless steel, or plastic tubing

and terminated in a ¼" female fitting.

Connect the sample supply line to the ¼" tubing fitting located on the top of the sensor. The

return line connect to the 1/4'” female fitting on the top of the enclosure Figure 2.2).

NOTE: The maximum inlet pressure is 150 PSIG.

04/02/2015 Rev. B

Page 5

Dew Point Monitor

5

2.4 ALARM RELAY CONNECTIONS

When the programmed Alarm Set Point is exceeded, the alarm relay will be energized. Before

connecting any device to the Alarm Relay contacts, check the contact ratings in the

Specifications section.

1. Remove the Access Panel as in Figure 2-2.

2. Referring to Figure 2-3, feed the wires to be connected to the relay through the “signals out”

fitting on the bottom of the enclosure and up to the PCB connector, marked P2, “ALARM

RELAY”.

NOTE: To connect a wire to the terminal, loosen the screw, insert the wire in the

opening, and tighten the screw.

3. Connect one of the signal wires to the CA (Center Arm) and the other wire to either the NO

(Normally Open) or NC (Normally Closed) terminal.

4. Replace the Access Cover.

2.5 ANALOG OUTPUT CONNECTIONS

1. Remove the Access Panel as in Figure 2-2.

2. Referring to Figure 2-3, feed the wires to be connected to the analog output through the

‘signals out’ fitting on the bottom of the enclosure and up to the PCB connector, P1, “4-20mA

out”.

NOTE: To connect a wire to the terminal, loosen the screw, insert the wire in the opening,

and tighten the screw.

3. Connect the high signal wire to the “+” terminal and the low side to the “-“ terminal.

4. Replace the Access Cover.

COM.AIR

2.6 RS232 SERIAL(Optional)

1. For hygrometers equipped with optional RS232 only. The RS232 is 2 wire, Simplex,

RS232 serial output, data is transmitted at an interval of 1/sec, and is space delimited.

The BAUD rate is fixed at 19.2kbps. The protocol is N81(No Parity, 8 data bits, 1 stop

bit). The parameter sequence is “dew point ABC status.” (example:”xx.xC(or F)””

“’ABC on”)

2. For RS232 output connect to P11-1 for LO(-) and P11-2 for HI(+) located on the small

Pressure X-Ducer input/ Analog output/ RS232 PCB which is mounted parallel to the

main PCB.

04/02/2015 Rev. B

Page 6

6

COM.AIR

Dew Point Monitor

FIGURE 2-1 MOUNTING

04/02/2015 Rev. B

Page 7

7

COM.AIR

Dew Point Monitor

FIGURE 2-2 ACCESS PANEL REMOVAL

04/02/2015 Rev. B

Page 8

8

COM.AIR

Dew Point Monitor

FIGURE 2-3 WIRING CONNECTIONS

04/02/2015 Rev. B

Page 9

Dew Point Monitor

9

3.0 FUNCTIONAL DESCRIPTION

The front panel of the COM.AIR consists of an LED Display, an audible alarm, two push-button

switches, and a sample flow meter with valve.

3.1 Display

The eight character alphanumeric LED display is used to display dew point data

and status messages.

Dew point data is displayed as “DP 34.8 F”, with the units in degrees C or F. (See Set-Up

section)

When a status message is necessary, the display will alternate between the data and the

message at about 2 second intervals.

The possible status messages and their meanings are:

“ABC CYCL” : Indicates that an Automatic Balance Cycle is in progress.

During an ABC Cycle;

The mirror is heated above the ambient temperature for a period of 1 to 3

minutes as determined by the last measured dew point.

After sufficient time has elapsed to ensure that the mirror is dry, the reflected light level of

the mirror is measured and if necessary, adjusted to the reference level.

After the adjustment is made, the instrument will begin cooling and seeking the dew

point. When a stable lock on the dew point is achieved, the “ABC CYCL” message will

disappear, and normal operation will resume.

The analog output is held to the dew point value just before the cycle started until the

completion of the ABC cycle.

If an alarm condition is present when the ABC cycle begins, the audible alarm and the

ALARM display are disabled but the Alarm Relay remains energized.

“ ALARM ” : The Alarm Set Point has been exceeded. The Alarm Relay will be energized

and the audible alarm will sound. The audible alarm can be silenced for one hour by

depressing the “SILENCE” push-button.

“CLN MIRR” : During an ABC Cycle, the condition of the sensor mirror and optics are

analyzed and a correction is made for changes in the reflectivity since the last cycle. If the

mirror reflectivity has decreased beyond the automatic correction range, this message will

appear at the end of the ABC cycle and indicates that the sensor mirror needs a manual.

Perform the “Mirror Cleaning Procedure” in the MAINTENANCE and CALIBRATION

Section.

Note: The instrument may appear to operate normally with this message present, but

the data should not be relied upon, until the appropriate maintenance is performed.

COM.AIR

04/02/2015 Rev. B

Page 10

Dew Point Monitor

10

3.0 FUNCTIONAL DESCRIPTION (CONTINUED)

“CHK SNSR” : If during the ABC Cycle, the reflectivity has increased significantly due to

excessive drift of the optics, or abnormal circuit performance, this message will appear. To

determine the cause, take the following steps.

-Clean the mirror.

-Initiate an MABC Cycle.

-Check the sample system for proper flow.

-Check for loose connections or components on the printed circuit board and sensor.

If the condition cannot be resolved with these checks, contact Edgetech for service

3.2 MABC Button

Pressing the MABC Button (Manual Automatic Balance Cycle) at any time will initiate an ABC

Cycle.

3.3 SILENCE Button

If the measured dew point exceeds the Alarm Set Point, the audible alarm will sound. Pressing

this button will silence or disable the audible alarm for a period of about 60 minutes. After the 60

minutes, the audible alarm will be automatically re-enabled. The alarm message on the display

and the alarm relay will remain on.

COM.AIR

3.4 Flow Control Valve

The sample flow rate is adjusted using this valve. Although the sample flow rate is not critical for

proper operation, the recommended rate is 1 – 2 SCFH (Standard Cubic Feet per Hour).

3.5 Alarm Relay Output

The Alarm Relay is a SPDT relay that is energized whenever the dew point exceeds the Alarm

Set Point.

During an ABC cycle, all alarm functions, including the relay, are disabled.

However, if an ABC Cycle is initiated when an alarm condition is present, the relay will remain

energized until the cycle is complete.

At the end of the cycle the relay will remain energized if the alarm condition is still present or be

de-energized if the alarm condition has passed.

3.6 Analog Output

The analog output is a 4 to 20 ma output, proportional to the dew point, and scaled at the

factory for –58 to 122 °F (-50 to 50 °C) for S1 and S2 Sensors; -103 to 167°F (-75 to 75°C) for

S3 sensors.

During an ABC Cycle, the output is “held” at the last dew point until the routine is completed.

04/02/2015 Rev. B

Page 11

COM.AIR

11

Dew Point Monitor

4.0 SETUP

4.1 Alarm Set Point (Figure 4.1)

The alarm set point temperature is set by dip switch S2 as an integer. The switch setting

represents an eight bit binary number in degrees C with position 8 as the least significant bit

(LSB) and position 2 as the most significant bit (MSB). Position 1 is the sign bit.

An ‘open’ switch is a ‘1’ and ‘closed’ is a ‘0’.

If the desired set point is in degrees F, convert it to Celsius before proceeding.

Set the switches as follows:

1. Convert the desired set point temperature from degrees C to its eight bit binary equivalent

code. Table 4.1 is provided to convert F to C and the equivalent eight bit binary code.

2. Set S1-1 ‘closed’ and S1-2 ‘open’. The alarm temperature setting will be displayed in degrees

C.

NOTE: S1-1 determines whether C or F is displayed in both the measurement and alarm set

modes.

S1-2 will switch the display between the dew point and the Alarm Setting.

3. Set S2, positions 1 through 8 according to the eight bit binary number determined in step 1. A

‘1’ is ‘open’, and a ‘0’ is ‘closed’.

4. The display should now read the set point temperature in degrees Celsius.

5. If Fahrenheit units are desired, set S1-1 to ‘open’.

6. Return to dew point display by setting S1-2 ‘closed’.

04/02/2015 Rev. B

Page 12

12

COM.AIR

Dew Point Monitor

FIGURE 4-1 SETUP

04/02/2015 Rev. B

Page 13

13

C F BINARY C F BINARY

-50.0 -58.0 10110010 0.0 32.0 00000000

-49.0 -56.0 10110001 1.0 33.0 00000001

-48.0 -54.0 10110000 2.0 35.0 00000010

-47.0 -52.0 10101111 3.0 37.0 00000011

-46.0 -50.0 10101110 4.0 39.0 00000100

-45.0 -49.0 10101101 5.0 41.0 00000101

-44.0 -47.0 10101100 6.0 42.0 00000110

-43.0 -45.0 10101011 7.0 44.0 00000111

-42.0 -43.0 10101010 8.0 46.0 00001000

-41.0 -41.0 10101001 9.0 48.0 00001001

-40.0 -40.0 10101000 10.0 50.0 00001010

-39.0 -38.0 10100111 11.0 51.0 00001011

-38.0 -36.0 10100110 12.0 53.0 00001100

-37.0 -34.0 10100101 13.0 55.0 00001101

-36.0 -32.0 10100100 14.0 57.0 00001110

-35.0 -31.0 10100011 15.0 59.0 00001111

-34.0 -29.0 10100010 16.0 60.0 00010000

-33.0 -27.0 10100001 17.0 62.0 00010001

-32.0 -25.0 10100000 18.0 64.0 00010010

-31.0 -23.0 10011111 19.0 66.0 00010011

-30.0 -22.0 10011110 20.0 68.0 00010100

-29.0 -20.0 10011101 21.0 69.0 00010101

-28.0 -18.0 10011100 22.0 71.0 00010110

-27.0 -16.0 10011011 23.0 73.0 00010111

-26.0 -14.0 10011010 24.0 75.0 00011000

-25.0 -13.0 10011001 25.0 77.0 00011001

-24.0 -11.0 10011000 26.0 78.0 00011010

-23.0 -9.0 10010111 27.0 80.0 00011011

-22.0 -7.0 10010110 28.0 82.0 00011100

-21.0 -5.0 10010101 29.0 84.0 00011101

-20.0 -4.0 10010100 30.0 86.0 00011110

-19.0 -2.0 10010011 31.0 87.0 00011111

-18.0 0.0 10010010 32.0 89.0 00100000

-17.0 1.0 10010001 33.0 91.0 00100001

-16.0 3.0 10010000 34.0 93.0 00100010

-15.0 5.0 10001111 35.0 95.0 00100011

-14.0 6.0 10001110 36.0 96.0 00100100

-13.0 8.0 10001101 37.0 98.0 00100101

-12.0 10.0 10001100 38.0 100.0 00100110

-11.0 12.0 10001011 39.0 102.0 00100111

-10.0 14.0 10001010 40.0 104.0 00101000

-9.0 15.0 10001001 41.0 105.0 00101001

-8.0 17.0 10001000 42.0 107.0 00101010

-7.0 19.0 10000111 43.0 109.0 00101011

-6.0 21.0 10000110 44.0 111.0 00101100

-5.0 23.0 10000101 45.0 113.0 00101101

-4.0 24.0 10000100 46.0 114.0 00101110

-3.0 26.0 10000011 47.0 116.0 00101111

-2.0 28.0 10000010 48.0 118.0 00110000

-1.0 30.0 10000001 49.0 120.0 00110001

0.0 32.0 00000000 50.0 122.0 00110010

TABLE 4.1 SETUP

04/02/2015 Rev. B

COM.AIR

Dew Point Monitor

Page 14

Dew Point Monitor

14

ABC

INTERVAL

S1- 6

S1- 7

S1- 8

OFF

0 0 0

4 hrs.

0 0 1

8 hrs.

0 1 0

12 hrs.

0 1 1

16 hrs.

1 0 0

10 hrs.

1 0 1

24 hrs.

1 1 0

28 hrs.

1 1 1

4.2 ABC Interval

The ABC Interval is the time between the automatic initiation of ABC Cycles. In typical

applications, an interval of 24 hours is recommended and set at the factory. However, in cases

where ambient conditions are more variable, or the sample gas is higher in contaminants, a

shorter interval may be required.

The times listed below are approximate.

The interval is adjustable in 4 hour increments from 4 to 28 hours.

Switch positions S1-6, -7, and -8 represent a three bit binary code with a weight of 4 hrs. per

unit.

To set the interval, set S1-6, S1-7, and S1-8 according to the binary number from Table 4.2

below. The factory default is 24 hrs.

NOTE: ‘CLOSED’ is a zero and ‘OPEN’ is a one.

COM.AIR

Table 4.2 converts the required interval in hours to a three bit binary number.

04/02/2015 Rev. B

Page 15

COM.AIR

15

Dew Point Monitor

5.0 MAINTENANCE

5.1 ROUTINE MAINTENANCE

To ensure the maximum in accurate and reliable operation of any optical chilled mirror system,

a periodic maintenance program should be established.

5.2 MIRROR CLEANING SCHEDULE

Over time, particulates and other matter present in the sample gas and not captured by filters,

build up on the mirror. The result of the buildup of contaminants on the mirror surface is reduced

dry mirror reflectivity and a change in the optical reference point. The ABC Cycle will

automatically readjust the optics to the reference point periodically, but eventually the

adjustment range will be exceeded and a manual cleaning of the mirror may be necessary.

When the contamination becomes too much to be adjusted automatically, an error will be

displayed at the end of the ABC Cycle.

Normally, intervals of 90 days between routine mirror cleanings can be easily achieved.

However, if the sample gas contaminants are particularly high, more frequent mirror cleanings

may be required.

5.3 MIRROR CLEANING PROCEDURE (Figure 5.1)

When mirror cleaning is required as a periodic maintenance item or the “CLN MIRR” or “CHK

SNSR” message appears on the display, proceed as follows.

1. Turn power off.

CAUTION

When operating with a pressurized sampling system, be sure to

remove pressure from the Sensor prior to removing the Sensor cover.

2. Remove the spin-off cover from the Sensor to expose the mirror.

3. Moisten a clean cotton swab with isopropyl alcohol. Cotton swabs and cleaner are provided in

the Cleaning Kit supplied with the system.

4. Wipe the mirror surface and the optics surface in a circular motion.

5. After cleaning the mirror surface, wipe the surfaces dry with a clean Q-tip.

6. Next, moisten a clean Q-tip with clean, preferably distilled water and wipe the

mirror and optics areas.

7. Dry these areas thoroughly with a clean, dry Q-tip.

8. Replace the sensor cover.

9. Re-establish sample pressure and flow.

10. Turn power on.

04/02/2015 Rev. B

Page 16

Dew Point Monitor

16

FIGURE 5.1 SENSOR COVER REMOVED FOR MIRROR CLEANING

COM.AIR

04/02/2015 Rev. B

Page 17

17

6.0 SPECIFICATIONS

Measurement Range

-Dew/ Frost Point -58 to 122°F(–50 to 50 °C)(Optional S2Sensor)*

Measurement Accuracy

-Dew/ Frost Point (+0.28°C) ±0.5°F (Entire Range)

Functional

Power: 90-260VAC, 50-400Hz, 40 Watts

Operating Temperature:

Control Unit/Sensor 32 to 122°F (0 to 50°C)

Sample Connection: ¼ female compression tubing fitting

Sample Flow: 0.5 to 5.0scfh, Integral flow meter and valve

Sample Pressure: 0 to 150psig max.

Analog Output: 4 to 20mA,

Range: –58 to 122°F (–50 to 50 °C)

Compliance: 9.0 VDC, 450 ohms

Display: Eight Digit Alphanumeric LED, 0.5” High.

High dew point Alarm:

- Audible >98 dba at 2 ft

- Visual Flashing Message on Display

- Relay Contacts 1 Form C, non-latching,

Physical

Dimensions: 14“ (35.6 cm)H, 10.7“ (27.18 Kg)W,

Weight: 7 lbs. (3.18 Kg)

Mounting: Wall mount standard

Material: Aluminum

Standard Features

- Microprocessor Controlled.

- 8 Digit Alphanumeric LED Display.

- Automatic Balance Control (ABC)

- User settable high alarm limit.

- Alarm Relay, Form C.

Optional Accessories

Low Dew Point Kit: 2 or 3 stage sensor.

Filter Kit: In-line, particulate/coalescing filter.

Dual Alarms

RS232 (2-wire)

COM.AIR

Dew Point Monitor

-103 to 167°F(–75 to 75 °C)(Optional S3Sensor)*

10A @ 240VAC

8A @ 24 VDC

½ HP @ 240VAC

3.75“ (9.525 Kg)D.

- Analog Output, 4 – 20mA.

- Integral flow meter and valve.

- Audible and visual alarms.

- Wall mountable.

04/02/2015 Rev. B

Loading...

Loading...