Page 1

EdgeTech

8242XS RELEASE

USER HARDWARE MANUAL

0004815_Rev_G 3/30/2018

4 Little Brook Road

West Wareham, MA 02576

Tel: (508) 291-0057

Fax: (508) 291-2491

www.EdgeTech.com

Page 2

ii

The information, figures, and specifications in this manual are proprietary and are issued in strict

confidence on condition that they not be copied, reprinted, or disclosed to a third party, either wholly or

in part, without the prior, written consent of EdgeTech. Any reproduction of EdgeTech supplied software

or file sharing is strictly prohibited.

Copyright © 2011 – 2018 EdgeTech. All rights reserved.

8242XS Release 0004815_REV_G

Page 3

iii

ATTENTION – READ THIS FIRST!

All personnel involved with the installation, operation, or maintenance of the equipment described in this

manual should read and understand the warnings and cautions provided below.

CAUTION!

This equipment contains devices that are extremely sensitive to static

electricity. Therefore, extreme care should be taken when handling them.

Normal handling precautions involve the use of anti-static protection

materials and grounding straps for personnel.

WARNING!

High Voltage may be present in all parts of the system. Therefore, use

caution when the electronics are removed from their containers for

servicing.

Warnings, Cautions, and Notes

Where applicable, warnings, cautions, and notes are provided in this manual as follows:

WARNING!

Identifies a potential hazard that could cause injury or death.

CAUTION!

Identifies a potential hazard that could damage equipment or data.

NOTE: Recommendations or general information that is particular to the

material being presented.

Page 4

iv

HARDWARE VARIATIONS AND COMPATIBILITY

The 8242XS Release contains both standard and proprietary hardware. At times, EdgeTech may change

the standard components due to their availability or performance improvements. Although the

component manufacturers—along with their models and styles—may change from unit to unit,

replacement parts will generally be interchangeable.

EdgeTech will make every effort to see that replacement components are interchangeable and use the

same software drivers (if applicable). At times, however, direct replacements may not exist. When this

happens, EdgeTech will provide the necessary drivers with the replacement part, if applicable.

EdgeTech may also change certain hardware per customer requirements. Therefore, portions of this

manual, such as parts lists and test features, are subject to change. These sections should be used for

reference only. When changes are made that affect system operation, they will be explicitly noted. Also,

some options and features may not be active in the customer’s unit at time of delivery. Upgrades will be

made available when these features are implemented.

Contact E

DGETECH CUSTOMER SERVICE with any questions relating to compatibility.

8242XS Release 0004815_REV_G

Page 5

v

REVISION

DESCRIPTION

DATE

APPROVAL

A

Release to Production

01/02/2011

RM B Updates

N/A

RM C Updates

N/A

RM D Corrected to Historical Rev

10/05/2012

RM

E

Change Release Load Spec

10/05/2012

RM

F

Update Format & Pictures

11/10/2014

RM G Updates to Content, Drawings,

03/30/18

RM

ABOUT THIS DOCUMENT

We, the employees at EdgeTech, would like to thank you for purchasing the 8242XS Release. At EdgeTech,

it is our policy to provide high-quality, cost-effective products and support services that meet or exceed

your requirements. We also strive to deliver them on-time, and to continuously look for ways to improve

them. We take pride in the products we manufacture, and want you to be entirely satisfied with your

equipment.

Purpose of this Manual

The purpose of this manual is to provide the user with information on the setup and use of EdgeTech’s

8242XS Release. Although this manual encompasses the latest operational features of the 8242XS, some

features may be periodically upgraded. Therefore, the information in this manual is subject to change and

should be used for reference only.

Liability

EdgeTech has made every effort to document the 8242XS Release in this manual accurately and

completely. However, EdgeTech assumes no liability for errors or for any damages that result from the

use of this manual or the equipment it documents. EdgeTech reserves the right to upgrade features of

this equipment, and to make changes to this manual, without notice at any time.

Revision History

Page 6

vi

WARRANTY STATEMENT

All equipment manufactured by EdgeTech is warranted against defective components and workmanship

for a period of one year after shipment. Warranty repair will be done by EdgeTech free of charge.

Shipping costs are to be borne by the customer. Malfunction due to improper use is not covered in the

warranty, and EdgeTech disclaims any liability for consequential damage resulting from defects in the

performance of the equipment. No product is warranted as being fit for a particular purpose, and there is

no warranty of merchantability. This warranty applies only if:

i. The items are used solely under the operating conditions and in the manner recommended in

Seller's instruction manual, specifications, or other literature.

ii. The items have not been misused or abused in any manner, nor have repairs been attempted

thereon without the approval of EdgeTech Customer Service.

iii. Written notice of the failure within the warranty period is forwarded to Seller and the directions

received for properly identifying items returned under warranty are followed.

iv. The return notice authorizes Seller to examine and disassemble returned products to the extent

Seller deems necessary to ascertain the cause for failure.

The warranties expressed herein are exclusive. There are no other warranties, either expressed or implied,

beyond those set forth herein, and Seller does not assume any other obligation or liability in connection

with the sale or use of said products. Any product or service repaired under this warranty shall be

warranted for the remaining portion of the original warranty period only.

Equipment not manufactured by EdgeTech is supported only to the extent of the original manufacturer's

warranties.

8242XS Release 0004815_REV_G

Page 7

vii

RETURNED MATERIAL AUTHORIZATION

Prior to returning any equipment to EdgeTech, a Returned Material Authorization (RMA) number must be

obtained. The RMA will help identify returned equipment when it arrives at our receiving dock and enables

tracking of the equipment while at our facility. The material should be shipped to EdgeTech, 4 Little Brook

Road, West Wareham, MA 02576. Refer to the RMA number on all documents and correspondences.

All returned materials must be shipped prepaid. Freight collect shipments will not be accepted. EdgeTech

will pay freight charges on materials going back to the customer after they have been evaluated and/or

repaired. If the equipment is the property of EdgeTech, please insure for full value.

All shipments must be accompanied by three copies of your proforma invoice, with the value of the

material, and the reason for return. If the reason is for repair, it must be clearly stated in order to move

through customs quickly and without duties being charged. Whenever possible, please send copies of

original export shipping documents with the consignment. Fax one invoice, packing list, and a copy of the

airway bill to EdgeTech upon shipment to EdgeTech’s Main Office Fax: 1-508-291-2491.

If there is more than one item per consignment, a packing list must accompany the shipment, which can

be combined with the proforma invoice and packing list if the contents of each carton are clearly

numbered and identified on the invoice.

CAUTION!

If your product is a portable topside, never attempt to ship it in its Storm

CaseTM alone. Although rugged, these cases are not intended to be used

as shipping containers, and the delicate internal components could be

damaged if used in this manner.

Note: All shipping charges shall be the responsibility of the customer, and

the return shipment will be sent on the customer’s account.

Foreign and Domestic Shipping Return Instructions

1. The items must be sent prepaid to our door – using a reputable company. Freight collect

shipments will not be accepted. Small items can be shipped prepaid directly to EdgeTech via

FedEx, DHL, UPS, Airborne, etc.

2. For your protection, the items should be fully insured. EdgeTech will not assume any responsibility

for damage to the shipment while in transit inbound or outbound.

3. Items within the warranty period must be sent prepaid to our door – using a reputable company.

EdgeTech will only pay for return shipping charges, if damage was not caused by misuse.

Page 8

viii

International Shipping Return Instructions

The following steps only apply to material being returned from outside the Continental United States, and

must be followed carefully to prevent delays and additional costs:

1. The waybill and all shipment documentation associated with the shipment must clearly state that

the Country of Origin/Manufacturer is USA.

2. The waybill and all associated shipment documents must state the following to eliminate

taxes levied: United States goods returned to manufacturer for repair purposes only.

3. The waybill and all documents associated with the shipment must state the following for

description (HS Tariff Code eliminates duty charges): Geophysical Scientific Instrumentation; Side

Scan System, Beacons; HS Tariff Code: 9015.80.80.80

4. If using a freight forwarder, ensure they understand that the goods are duty & tax free United

States goods returned to manufacturer for repair only. Additionally, please instruct the freight

forwarder that the shipment is FREE DOMICILE and must be delivered to our door.

5. Please send all shipping documents in advance of the shipment by email to

service@edgetech.com

. Providing EdgeTech with the shipping documents will enable us to

follow up with the carrier on our end.

Also include EdgeTech’s broker information below on the commercial invoice:

Attn: Brenda Richards | Terri DiOrio

TransGroup BOS INTL, 140 Eastern Ave, Chelsea MA 02150

Office: 617-889-5089 TF: 877-839-3353 Fax: 617-889-5189

brendar.bos@transgroup.com | teresad.bos@transgroup.com

NOTE: For International Shipments, If the value of the equipment is over

$1000, the following Shipper's oath must be sent with the invoice. This

oath can be typed on the invoice or on a separate letterhead:

"I, ______________________________, declare that the articles herein specified are the growth,

produce, or manufacture of the United States; that they were exported from the

United States from the port of _____________________, on or about _______________; that they

are returned without having been advanced in value or improved in condition by any

process of manufacture or any other means; and that no drawback, or allowance has

been paid or admitted hereof."

Signed ______________________________

8242XS Release 0004815_REV_G

Page 9

ix

CUSTOMER SERVICE

Customer service personnel at EdgeTech are always eager to hear from users of our products. Your

feedback is welcome, and is a valuable source of information which we use to continually improve these

products. Therefore, we encourage you to contact EdgeTech Customer Service to offer any suggestions

or to request technical support:

NOTE: Please have your system Serial Number available when contacting

Customer Service.

E-mail: service@edgetech.com

Mail: 4 Little Brook Road

West Wareham, MA 02576

Telephone: (508) 291-0057

Facsimile: (508) 291-2491

24-Hour Emergency

Technical Support Line: (508) 942-8043

For more information please go to www.EdgeTech.com

.

Page 10

x

COMPANY BACKGROUND

EdgeTech (formerly EG&G Marine Instruments) traces its history in underwater data acquisition and

processing back to 1966. EdgeTech has designed, developed, and manufactured products, instruments,

and systems—for the acquisition of underwater data, including marine, estuarine, and coastal

applications—for over 50 years.

The company has responded to the needs of the scientific, Naval, and offshore communities by providing

equipment—such as sub-bottom profilers, side scan sonar, acoustic releases, USBL positioning systems,

and bathymetric systems—that have become standards in the industry.

EdgeTech has also consistently anticipated and responded to future needs through an active research and

development program. Current efforts are focused on the application of cutting-edge CHIRP and acoustic

technology.

8242XS Release 0004815_REV_G

Page 11

xi

TABLE OF CONTENTS

ATTENTION – READ THIS FIRST! ......................................................................................................... iii

Warnings, Cautions, and Notes ................................................................................................................ iii

HARDWARE VARIATIONS AND COMPATIBILITY .................................................................................. iv

ABOUT THIS DOCUMENT .................................................................................................................... v

Purpose of this Manual ............................................................................................................................. v

Liability ...................................................................................................................................................... v

Revision History ........................................................................................................................................ v

WARRANTY STATEMENT ................................................................................................................... vi

RETURNED MATERIAL AUTHORIZATION ........................................................................................... vii

Foreign and Domestic Shipping Return Instructions ............................................................................... vii

International Shipping Return Instructions ............................................................................................ viii

CUSTOMER SERVICE .......................................................................................................................... ix

COMPANY BACKGROUND .................................................................................................................. x

TABLE OF CONTENTS ......................................................................................................................... xi

LIST OF FIGURES .............................................................................................................................. xiv

LIST OF TABLES ............................................................................................................................... xvi

1.0 OVERVIEW ................................................................................................................................1-1

Basic Functionality ........................................................................................................................ 1-1

2.0 SPECIFICATIONS ........................................................................................................................2-1

Mechanical & Physical Specifications ........................................................................................... 2-1

Printed Circuit Board (PCB) ........................................................................................................... 2-1

Acoustic Specifications .................................................................................................................. 2-2

BACS Command Structure.......................................................................................... 2-2

BACS Command Coding ............................................................................................. 2-3

Standard Command Functions ................................................................................... 2-3

Environmental Specifications ....................................................................................................... 2-3

Battery Types ................................................................................................................................ 2-3

Mechanical Drawings .................................................................................................................... 2-3

3.0 SETUP AND INSTALLATION.........................................................................................................3-1

Acoustic ......................................................................................................................................... 3-1

Page 12

xii

Mechanical .................................................................................................................................... 3-1

Status Reply .................................................................................................................................. 3-1

4.0 OPERATING INSTRUCTIONS .......................................................................................................4-1

Tools ....................................................................................................................................................... 4-1

Turning the Unit On ...................................................................................................................... 4-1

Removing the Purge Port Plug ................................................................................... 4-1

Removing the Lifting Support .................................................................................... 4-3

Removing the Transducer End ................................................................................... 4-5

Applying Power .......................................................................................................... 4-6

Closing the Transducer End ........................................................................................ 4-7

Attaching the Lifting Support ..................................................................................... 4-8

Replace the Purge Port Plug ..................................................................................... 4-12

Leak Detection and Condensation Prevention ........................................................................... 4-13

Arming the Instrument ............................................................................................................... 4-14

Release Function ......................................................................................................................... 4-18

Release Latch Inspection (following high load in-air releases): ............................... 4-19

ON/OFF Option ........................................................................................................................... 4-19

On/Off Instructions .................................................................................................. 4-20

4.5.1.1 On Instructions ......................................................................................................... 4-21

4.5.1.2 Off Instructions ........................................................................................................ 4-22

Air Acoustic Testing ..................................................................................................................... 4-23

Setup ........................................................................................................................ 4-23

Tests ......................................................................................................................... 4-23

Post Deployment ........................................................................................................................ 4-24

5.0 MAINTENANCE ..........................................................................................................................5-1

Housing and Release Preparation and Care ................................................................................. 5-1

To Open the 8242XS ..................................................................................................................... 5-2

Tools ................................................................................................................................................... 5-2

8242XS Disassembly ................................................................................................... 5-2

Remove the Clevis End Cap ........................................................................................ 5-4

8242XS Assembly .......................................................................................................................... 5-7

Clevis End Cap Assembly ............................................................................................ 5-7

8242XS Release 0004815_REV_G

Page 13

xiii

Battery Replacement .................................................................................................................... 5-9

Battery Replacement Procedure .............................................................................. 5-10

Battery Replacement Considerations ...................................................................... 5-12

5.4.2.1 Battery Replacement ............................................................................................... 5-13

O-Ring Considerations ................................................................................................................ 5-14

Additional O-Rings.................................................................................................... 5-14

O-Ring Service Disassembly ..................................................................................... 5-14

General Cleaning and Inspection ................................................................................................ 5-16

Inspection Particulars ............................................................................................... 5-16

General Inspection and Replacement Schedule ...................................................... 5-17

Field Service Kit ........................................................................................................ 5-17

Callout Assembly Drawings ......................................................................................................... 5-17

0002737 BOM ............................................................................................................................. 5-19

0002650 BOM ............................................................................................................................. 5-21

0002780 BOM .......................................................................................................... 5-25

A.0 REMOTE RELEASE ..................................................................................................................... A-1

A.1 Mechanical Drawings ................................................................................................................... A-1

B.0 TANDEM RELEASE OPTION ....................................................................................................... B-1

B.1 Parts List ........................................................................................................................................ B-1

B.2 Mechanical Drawings .................................................................................................................... B-1

Page 14

xiv

LIST OF FIGURES

Figure 1-1: An 8242XS Release in the Arctic Sea ....................................................................................... 1-1

Figure 2-1: PCB Connectors ....................................................................................................................... 2-1

Figure 2-2: ICD 8272-XS Short – 0010816 .................................................................................................. 2-4

Figure 2-3: ICD 8242XS Long – 0011329 ................................................................................................... 2-5

Figure 4-1: The Purge Port Plug ................................................................................................................. 4-1

Figure 4-2: Remove the Purge Port Plug Retainer ..................................................................................... 4-2

Figure 4-3: Removing the Purge Port Plug ................................................................................................. 4-2

Figure 4-4: Removing the (3) Top Nut from the (3) Titanium Bolts ........................................................... 4-3

Figure 4-5: Using a Wrench to Pry the Cage Apart .................................................................................... 4-4

Figure 4-6: Tapping the Cage Free with a Mallet ....................................................................................... 4-4

Figure 4-7: Removing the Transducer End Cap .......................................................................................... 4-5

Figure 4-8: The Removed Transducer End Cap .......................................................................................... 4-5

Figure 4-9: Battery Connection Location and One Method for Plugging in the Board .............................. 4-6

Figure 4-10: The Proper Orientation of the Battery Pin Connector and JP5 ............................................. 4-6

Figure 4-11: Apply Pressure to the Base of the Transducer End to Fully Seat it into the Housing ............ 4-7

Figure 4-12: Cage Assembly for Transducer End Cap ................................................................................ 4-8

Figure 4-13: Attach One Part of the Lifting Support .................................................................................. 4-8

Figure 4-14: Applying the Second Part of the Lifting Support, Including the ½” Spreader Rods ............... 4-9

Figure 4-15: Use the Mallet to Ensure the Lifting Support is Securely Attached .................................... 4-10

Figure 4-16: Replace the Two Titanium bolts .......................................................................................... 4-10

Figure 4-17: Using the Wrench on the top bolt, at the bottom, tighten the first nut. ............................ 4-11

Figure 4-18: Top End Cap Completed Assembly ...................................................................................... 4-11

Figure 4-19: Replace the Purge Port Plug ................................................................................................ 4-12

Figure 4-20: The Replaced Purge Port Plug Retainer ............................................................................... 4-12

Figure 4-21: Clevis Rotation Drawing ....................................................................................................... 4-14

Figure 4-22: The Armed 8242XS .............................................................................................................. 4-15

Figure 4-23: The Release Link Captured by the Release Hook ................................................................. 4-16

Figure 4-24: Capture the End of The Hook onto the Latch Recess .......................................................... 4-16

Figure 4-25: Rotating the Shaft Using the Arming Wrench ..................................................................... 4-17

Figure 4-26: The Armed T-Shaft ............................................................................................................... 4-18

Figure 4-27: The Two Possible On/Off Actuator Plug Positions ............................................................... 4-19

8242XS Release 0004815_REV_G

Page 15

xv

Figure 4-28: On/Off Actuator Plug on the Clevis End .............................................................................. 4-20

Figure 4-29: The ON and OFF Positions of the On/Off Actuator Plug ...................................................... 4-20

Figure 4-30: Loosen the Retainer and Move It Out of the Way ............................................................... 4-21

Figure 4-31: Push in the On/Off Actuator ................................................................................................ 4-21

Figure 4-32: Return Retainer and Tighten ............................................................................................... 4-21

Figure 4-33: Pull the On/Off Actuator Out ............................................................................................... 4-22

Figure 5-1: The Plugged in Battery and Transducers Cables ...................................................................... 5-2

Figure 5-2: The Unplugged Battery and Transducer Cables ...................................................................... 5-3

Figure 5-3: Removing the (2) Top Nut from the (2) Titanium Bolts ........................................................... 5-4

Figure 5-4: Using a Wrench to Pry the Clevis End Cap Apart ..................................................................... 5-5

Figure 5-5: Tapping the other end of the clamp with a soft Mallet........................................................... 5-5

Figure 5-6: The Electronics Assembly Completely Removed from the Housing ........................................ 5-6

Figure 5-7: O-Rings in Clevis End Cap ......................................................................................................... 5-7

Figure 5-8: Cross Section of the Face Seal, Gland, and Back-up O-Rings ................................................... 5-8

Figure 5-9: Clamping Hardware ................................................................................................................. 5-9

Figure 5-10: The Plugged in Battery Cable and Transducer Cable ........................................................... 5-11

Figure 5-11: The Battery Pack is on the Underside of the Electronics Chassis ........................................ 5-12

Figure 5-12: Close-up view of the (4) Bracket Screws and (2) Retainer Brackets .................................... 5-12

Figure 5-13: The Transducer End O-Rings ................................................................................................ 5-15

Figure 5-14: The Release End O-Rings ..................................................................................................... 5-15

Figure 5-15: The Purge Port Plug O-Rings ................................................................................................ 5-15

Figure 5-16: Cross Section of the Face Seal, Gland, and Back-up O-Rings ............................................... 5-16

Figure 5-17: 8242XS MART Main Sub Assembly – 0002737 .................................................................... 5-18

Figure 5-18: 8242XS Release Sub Electronics Release Assembly – 0002650 .......................................... 5-20

Figure 5-19: 8242XS Acoustic Release Transducer Assembly – 0003226 ................................................ 5-22

Figure 5-20: 8242XS Release Mechanism Sub Assembly – Page 1 of 2 – 002780 ................................... 5-23

Figure 5-21: 8242XS Release Mechanism Sub Assembly – Page 2 of 2 – 002780 .................................. 5-24

Figure A-1: 8242XS Remote Release – 0018268 ........................................................................................ A-2

Figure B-1: 8242XS Tandem Kit Drawing – 0006657 ................................................................................. B-2

Figure B-2: 8242XS Tandem Short – 0017034 ........................................................................................... B-3

Figure B-3: 8242XS Tandem Long – 0018532............................................................................................ B-4

Page 16

xvi

LIST OF TABLES

Table 2-1: Mechanical & Physical Specifications ....................................................................................... 2-1

Table 2-2: Acoustic Specifications .............................................................................................................. 2-2

Table 2-3: BACS Command Structure Specifications ................................................................................. 2-2

Table 2-4: Allowed BACS Tone Pair Breakdown ........................................................................................ 2-3

Table 2-5: Standard Command Functions .................................................................................................. 2-3

Table 2-6: Environmental Specifications—Temperature ........................................................................... 2-3

Table 2-7: Battery Type Specifications ....................................................................................................... 2-3

Table 3-1: Status Reply Meanings .............................................................................................................. 3-2

Table 5-1: General Inspection and Replacement Schedule ..................................................................... 5-17

Table 5-2: Field Kit – 0003102 .................................................................................................................. 5-17

Table 5-3: 0000002737 BOM ................................................................................................................... 5-19

Table 5-4: 0002650 BOM ......................................................................................................................... 5-21

Table 5-5: 0002780 BOM ......................................................................................................................... 5-26

Table B-1: 8242XS Tandem Parts List – 0006657 ....................................................................................... B-1

8242XS Release 0004815_REV_G

Page 17

1-1

1.0 OVERVIEW

This manual describes the 8242XS, a field-proven, reliable, and versatile mooring instrument, functioning

as both an Acoustic Release and Transponder. The 8242XS can also be used for specialized applications,

such as the opening/closing of underwater valves and in Emergency Recovery Systems. The 8242XS has

been designed for use as an instrument location and recovery system on oceanographic moorings and

platforms. Additionally, the precision, high-output power transponder feature makes this instrument ideal

for use in Long Baseline (LBL) Positioning and Navigation Systems. Constructed entirely of a NickelAluminum-Bronze alloy, the 8242XS is rugged and durable, even in the harshest marine environments.

The 8242XS uses a version of the EdgeTech’s field-proven, Binary Acoustic Command System (BACS) code

structure and is compatible with the 8011M and PACS EdgeTech Deck Units, shown below. The BACS

coding structure provides 12,000 possible command codes. The release has an enable/disable command

for controlling the transponder function as a standard feature. When disabled, the transponder will not

reply when interrogated. The RELEASE command causes the 8242XS to manually disconnect from its

mooring. The RELEASE command can be sent and will cause a release whether the system is enabled or

disabled. The ENABLE and DISABLE function only controls the transponder section.

Figure 1-1: An 8242XS Release in the Arctic Sea

Basic Functionality

The transponder function can be turned ON or OFF with the ENABLE and DISABLE commands, respectively.

When disabled the transponder will not reply when interrogated, which ensures the Unit will not interfere

with nearby instruments and that no battery energy will be wasted replying to spurious noise sources

during the deployment. The ENABLE and DISABLE commands has no effect on the RELEASE command.

Page 18

Page 19

2-1

SPECIFICATIONS

VALUE

Release mechanism

Spring-driven, rotary type with advantage hook

Recommended max static load rating (working)

5,500 kg (12,000 lbs) central axis loading

Depth rating (working)

6,000 meters (19,700 ft)

Length

94.6 cm (38.00 in) (standard unit)

Housing O.D.

13 cm (5.12 in)

Housing I.D.

10 cm (4.0 in)

Weight in air

36 kg (79 lbs) (standard unit)

Weight in water

28 kg (62 lbs) (standard unit)

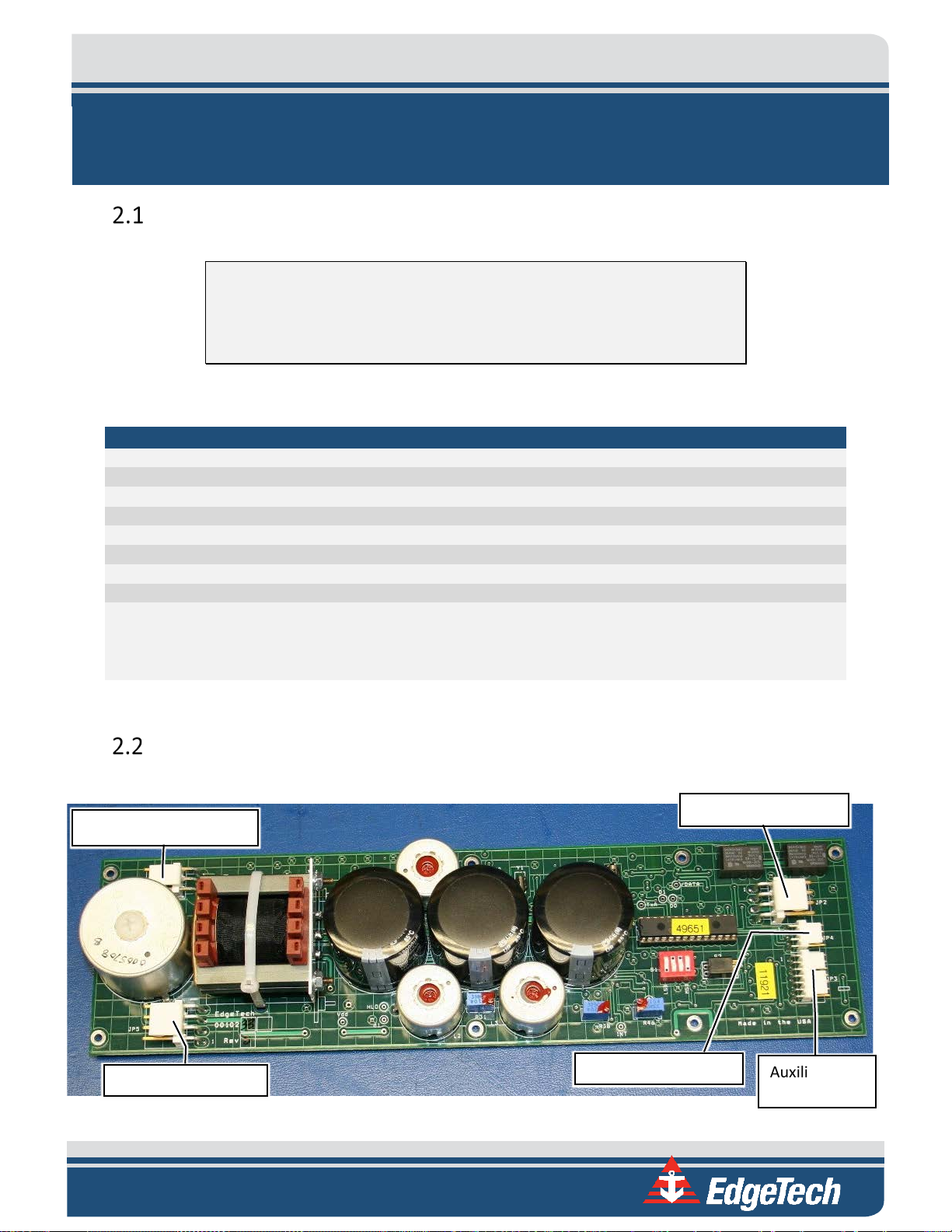

Acetal (washers, etc.)

Titanium

Transducer Connector

Battery Connector

Auxiliary I/O

Connector

Motor Connection

System Sense Lines

2.0 SPECIFICATIONS

Mechanical & Physical Specifications

WARNING!

The 8242XS is not intended for overhead lifting. Exercise extreme caution

to prevent serious personal injury.

Mechanical specifications for the 8242XS Release are as follows:

Exposed materials

NiAlBz (housing, end caps, and mechanism)

Buna –N (O-Rings)

Table 2-1: Mechanical & Physical Specifications

Printed Circuit Board (PCB)

The PCB connectors on the 8242XS board are shown below:

Figure 2-1: PCB Connectors

Page 20

SECTION 2: SPECIFICATIONS 2-2

SPECIFICATIONS

VALUE

Transmit source level

192 dB re 1 µPascal-meter

Command codes

BACS commands

Transponder sensitivity

-80 dB re 1 µPascal

> or = 44 dB re root Hz for jitter < +/- 0.5 milliseconds (3 σT).

Jitter =+/- 0.1 milliseconds for noise-free field

Interrogate frequency

11 kHz (standard unit)

Post filter bandwidth

330 Hz

Minimum interrogate pulse width

5 milliseconds

Reply frequency

Default 12 kHz

Transmit/Reply source level

192 dB re 1 µPascal-meter

Reply pulse width

10 milliseconds (standard unit)

Turnaround time delay

12.5 milliseconds (standard unit)

Lockout time

1.0 seconds

Receiver sensitivity

-100 dB re 1 µPascal-meter

Receiver SNR

> or = 36 dB re root Hz

Receiver type

Hard-limited (2000 Hz / 330 Hz bandwidths)

SPECIFICATION

VALUE

Coding

General to 8000 series – Binary FSK

Allowed tone pairs

Six (see TABLE 2-4) for full breakdown of pairs

Two successive 8 bit words with a 5 sec. interval between them.

Pulse width

22 milliseconds

Period

250 milliseconds

Total command time

9 seconds

Total lockout time

14 seconds re beginning

Total command

capacity per tone pair

Standard functions

Release, Disable Transponder, Enable Transponder

Acoustic Specifications

The acoustic specifications for the 8242XS unit are described in the following sub-sections.

Transponder SNR

Table 2-2: Acoustic Specifications

BACS Command Structure

The BACS’ command structure consists of two 8-bit words separated by a 5-sec interval. Each word is

comprised of 8 bits from a 16-bit command. The 16-bit command is a 15 bit, 11 block cyclic code with an

overall parity bit appended to the end to form a 16-bit code with a minimum Hamming distance of 4 bits.

Two transitions are required within each word, and no repetitions of words are allowed in a command.

Each word comprised of 8 bits from a 16 bit command. The 16 bit command is a 15,

Structure

11 block cyclic code with an overall parity bit appended to the end to form a 16, 11

code with a minimum Hamming distance of 4 bits.

Additionally, two transitions are required within each word, and no repetitions of

words are allowed in a command.

2,000 or 12,000 commands for six tone pairs

Table 2-3: BACS Command Structure Specifications

Page 21

2-3

TONE PAIR NUMBER

“0” (VALUE IN kHz)

“1” (VALUE IN kHz)

2

9.5

10.3

3

9.5

10.7

4

9.9

10.3

5

9.9

10.7

6

10.3

10.7

RELEASE

Activate mechanical release

SPECIFICATIONS

VALUE

2 years & 100,000 replies

4 years & 200,000 replies

BACS Command Coding

BACS command coding is described in the following table:

1 9.5 9.9

Table 2-4: Allowed BACS Tone Pair Breakdown

Standard Command Functions

Functions for the three standard commands are given in the table below:

COMMAND FUNCTION

ENABLE Enable Transponder

DISABLE Disable Transponder

Table 2-5: Standard Command Functions

Environmental Specifications

TEMPERATURE VALUE

Operating

Storage (Batteries Removed)

-10°C to +40°C (14°F to 104°F)

-20°C to +85°C (-4°F to 185°F)

Table 2-6: Environmental Specifications—Temperature

Battery Types

Welded Alkaline pack 2 years & 40,000 replies

Replaceable Alkaline

Replaceable Lithium

Table 2-7: Battery Type Specifications

4.5 years & 250,000 replies

9 years & 500,000 replies

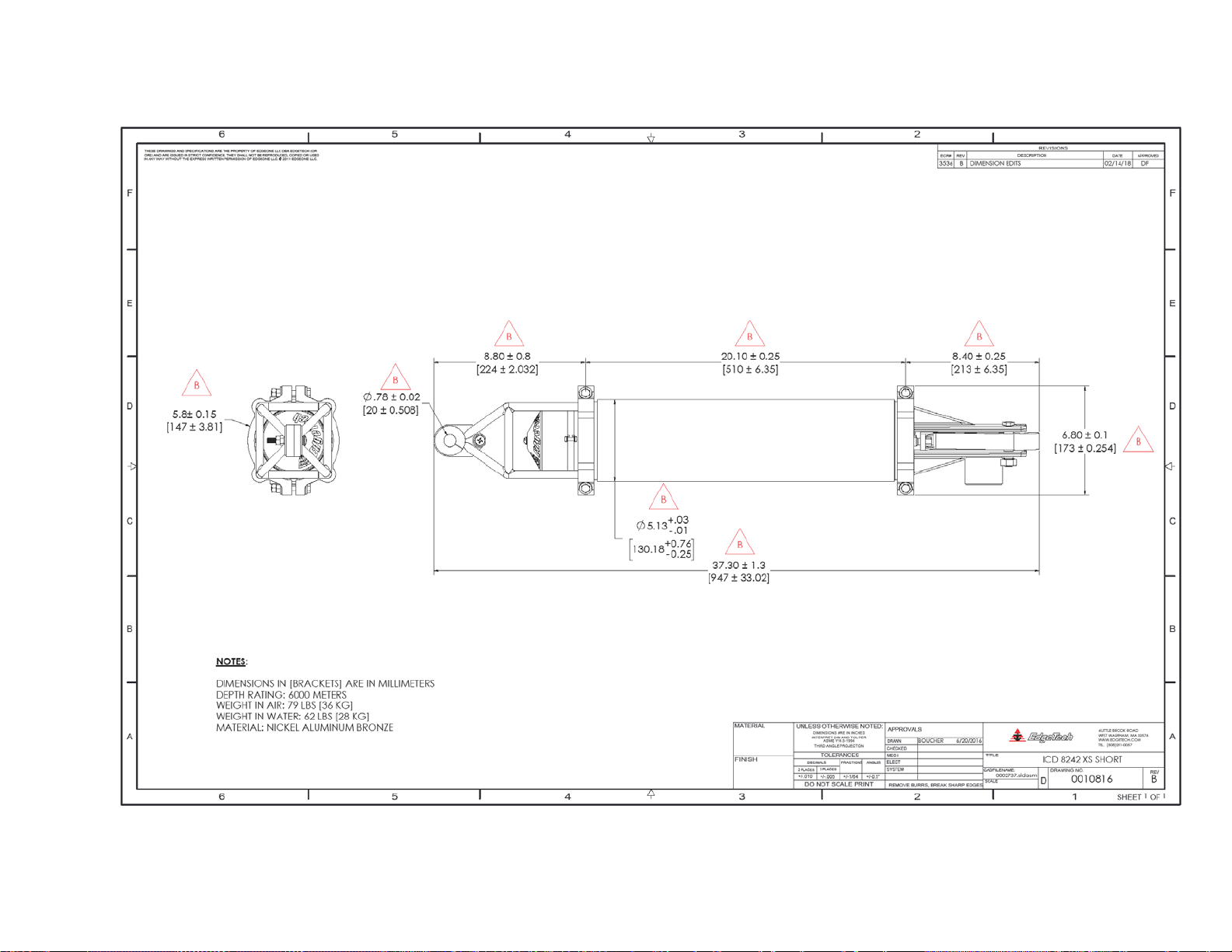

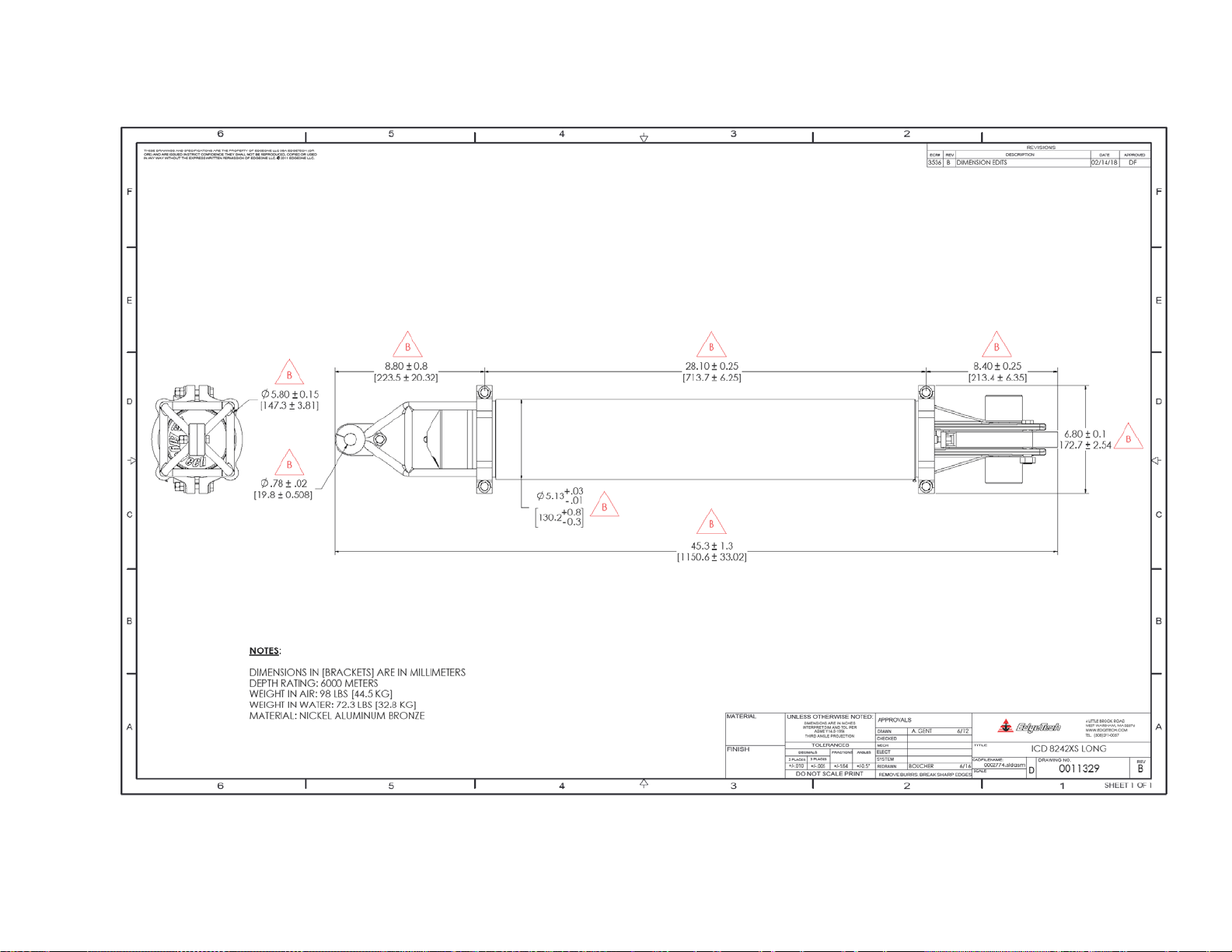

Mechanical Drawings

Mechanical Drawings for the 8242XS are shown below:

Page 22

SECTION 2: SPECIFICATIONS 2-4

Figure 2-2: ICD 8272-XS Short – 0010816

Page 23

2-5

Figure 2-3: ICD 8242XS Long – 0011329

Page 24

Page 25

3-1

3.0 SETUP AND INSTALLATION

This section contains the information relative to the basic set up and operation of the Model 8242XS

acoustic release. Refer to the specific information sheet that shipped with the unit, for details of its specific

equipment. This sheet includes the 8242XS’s commands, and transponder frequencies.

Acoustic

Efforts should be made to ensure that there is a clear acoustic path between the 8242XS Transducer and

the source (typically a dunking Transducer from a deck unit). Structural elements of a mooring system

which have significantly different acoustic impedance than that of seawater will cause absorption or

reflection of acoustic signals, which will degrade the operation of the unit. Floatation, including glass

spheres, syntactic foam and plastic floats are particularly problematic. Floats placed physically close to

the Transducer can create a blind area in the Transducers beam pattern.

Mechanical

The Release Load is held through the Lifting Support, and Release Hook. There are isolation shoulder

washers on the top pad eye to prevent electrical contact with the mooring. In some installations (such as

a trawl resistant Benthic Landers) the unit needs to be secured to the structure. It is important to verify

that the Release Hook is not obstructed in its motion, which could prevent it from disengaging.

The release mechanism is designed for in-line loads; side loading will severely degrade performance.

Generally, the Release Link is treated as a disposable item. It is used to electrically isolate the release from

the rest of the mooring.

Status Reply

Upon receiving a valid command, the instrument will return a series of pings which are an indication of

the status of the tilt and release sense switches.

The 8242XS is equipped with sensors that monitor the tilted or not tilted orientation of the system. This

information allows the unit to send a coded status reply, based on the instruments orientation and release

state. The tilt status is useful for ascertaining whether the mooring or platform that has been deployed

has landed as planned. At the end of a deployment, the information is useful in determining whether

forces such as strong currents or trawl activity have affected the mooring or platform.

The tilt sensor is a 45° mechanical switch that is mounted on the Release Circuit Board assembly. In the

standard instrument configuration, with the release mechanism down, the unit is defined as “not tilted”.

For applications requiring a narrower maximum allowable angle of tilt optional tilt switches are

available. The switch can also be installed at different angles to change the standard orientation.

Page 26

SECTION 3: SETUP AND INSTALLATION 3-2

15 pings at 2 second intervals

Upright ; Not Released

7 pings at 2 second intervals

Tilted ; Not Released

15 pings at 1 second rate

Upright ; Released

The status reply indicates one of four states:

• "upright (within 45° of upright)" and released

• "upright (within 45° of upright)" and not released

• "tilted (more than 45° from upright)" and released

• "tilted (more than 45° from upright)" and not released

After a command has been received, the unit transmits a series of encoded pings. The 4 possible status

replies are:

PATTERN STATUS

7 pings at 1 second rate Tilted ; Released

Table 3-1: Status Reply Meanings

Page 27

4-1

Purge Port Plug

4.0 OPERATING INSTRUCTIONS

This section of the manual covers instructions for normal operations, including opening and closing the

Transducer End.

To start using the 8242XS, the Housing must be opened so that the battery can be plugged in. The

instructions for this continue below in

The 8242XS is not intended for overhead lifting. Exercise extreme caution

to prevent serious personal injury.

Tools

SUB-SECTION 4.2.

WARNING!

• ½” Socket

• ½” Wrench

• Soft Mallet

Turning the Unit On

8242XS’ are carefully tested and shipped from the factory with a new battery pack installed. Unless

otherwise requested, all battery packs are disconnected in transit, to prolonging the battery life.

To use the 8242XS, the Housing MUST be opened so that the battery can be plugged into the JP5 header

connector on the electronic board. Then, the unit must be closed and the Housing purged.

Removing the Purge Port Plug

Figure 4-1: The Purge Port Plug

Page 28

SECTION 5: MAINTENANCE 4-2

1. Remove the Purge Port Plug Retainer from the Release end of the Instrument by unscrewing the nylon

screw that holds it in place, shown in F

IGURE 4-2.

Figure 4-2: Remove the Purge Port Plug Retainer

2. Equalize pressure by removing the purge port plug, shown in F

IGURE 4-3.

Figure 4-3: Removing the Purge Port Plug

Page 29

4-3

Removing the Lifting Support

1. Remove the three titanium bolts from the top cage-clamp assembly. This must be done carefully.

NOTE: The Bolt at the top of the Cage is shorter than the other two.

CAUTION!

Never put the socket wrench over both nuts when attempting to

removing the Top Nut from the three titanium bolts. This can cause the

nuts to seize together and prevent loosening the bolt.

a. Remove the second nut from each of the three titanium bolts using a ½” wrench and ½”

socket wrench, as shown in F

IGURE 4-4.

Figure 4-4: Removing the (3) Top Nut from the (3) Titanium Bolts

b. Remove the remaining nut from each of the three titanium bolts with the same tools,

using the same method depicted in F

IGURE 4-4.

Page 30

SECTION 5: MAINTENANCE 4-4

2. Place a wrench into the gap between the Cages to pry one side of it off, shown in FIGURE 4-5.

Figure 4-5: Using a Wrench to Pry the Cage Apart

3. With a soft mallet, tap the cages free of the End Cap (two 1/2-inch diameter spreader rods are

loose and will fall free of the cage as it is disassembled).

Figure 4-6: Tapping the Cage Free with a Mallet

Page 31

4-5

Removing the Transducer End

CAUTION!

Take care when removing the Transducer End Cap from the Housing, as

the Transducer is plugged into the Electronics Assembly.

1. Grip the Transducer by its base close to the metal end cap, and pull the Transducer End Cap from

the Housing, taking care not to squeeze or deform the Transducer.

Figure 4-7: Removing the Transducer End Cap

Figure 4-8: The Removed Transducer End Cap

Page 32

SECTION 5: MAINTENANCE 4-6

Applying Power

The Electronics Assembly and Battery Pack are mounted to an aluminum tray, which is attached to the

Release End Cap. Once the Transducer End Cap is removed, the battery can be plugged in.

1. Plug the 4-pin battery connector into the header JP5 on the circuit board. When doing so, ensure

to line the pins up correctly as shown in F

IGURE 4-9 and FIGURE 4-10.

Figure 4-9: Battery Connection Location and One Method for Plugging in the Board

CAUTION!

Ensure the 4-pin battery pack cable connector alignment tabs are

properly aligned with the power connector on the electronics assembly

before pressing into place. If misaligned, damage to the electronics may

occur, rendering the Release unusable until repaired.

Figure 4-10: The Proper Orientation of the Battery Pin Connector and JP5

Page 33

4-7

Closing the Transducer End

Before closing the Transducer End, inspect the O-rings and O-ring mating surfaces and service if needed,

refer to O-R

1. Gently guide the Transducer End cap into the Housing, taking care not to pinch the Transducer

ING SERVICE AND INSPECTION.

CAUTION!

Ensure the 4-pin battery pack cable connector alignment tabs are

properly aligned with the power connector on the electronics assembly

before pressing into place. If misaligned, damage to the electronics may

occur, rendering the Release unusable until repaired.

Cable and Battery Cable. As the O-ring enters the Housing, firm but gentle pressure must be

applied to seat the end cap fully against the Housing as shown in

FIGURE 4-11.

Figure 4-11: Apply Pressure to the Base of the Transducer End to Fully Seat it into the Housing

Page 34

SECTION 5: MAINTENANCE 4-8

Attaching the Lifting Support

Figure 4-12: Cage Assembly for Transducer End Cap

1. Put one side of the cage on. Tap it down softly with a mallet as shown in F

IGURE 4-13.

Figure 4-13: Attach One Part of the Lifting Support

Page 35

4-9

2. Flip the unit over and put the other part of the cage on the top of the unit.

a. Before tapping the other part of the cage with the mallet, align each of the two 1/2-inch

diameter spreader rods into the spaces one at a time, as shown in F

IGURE 4-14.

Note: If inserting the spreader Rods is difficult, remove one part of the

Lifting Support and try again without pushing it down.

Figure 4-14: Applying the Second Part of the Lifting Support, Including the ½” Spreader Rods

b. Gently use a mallet to tap the cage together and try to keep the gaps between the

clamps on both sides even, as shown in F

IGURE 4-15.

Page 36

SECTION 5: MAINTENANCE 4-10

Figure 4-15: Use the Mallet to Ensure the Lifting Support is Securely Attached

CAUTION!

The load capacity is less than 1/10 the rated load if the two 1/2 in. (1.27

cm.) diameter x 4 in. (10 cm.) spreaders are not installed in the cage. The

horizontal members of the cage must form a complete box.

CAUTION!

Ensure the Nylon washers are included in the reassembly procedure and

are placed between the titanium washer and the Support Brackets. They

are vital to the operation of the 8242XS. Refer to FIGURE 5-9.

3. Start by replacing the two titanium bolts on the two sides of the top cage-clamp assembly. Replace

the bolts with only one nut first as shown in F

Figure 4-16: Replace the Two Titanium bolts

IGURE 4-16.

Page 37

4-11

Spreaders (2)

Three sets of 5/16”

Three sets of 5/16”

NOTE: There are two different bolt lengths, the shorter bolt goes into the

Top of the cage.

4. Replace the third titanium bolt on the top cage-clamp assembly. Replace with one nut at a time.

a. It is impossible to use a wrench between the cage, so this is the only time to put the

wrench on the bolt instead of the nuts.

Figure 4-17: Using the Wrench on the top bolt, at the bottom, tighten the first nut.

titanium hardware

titanium hardware

with nylon

with nylon

shoulder washers

shoulder washers

between titanium

between titanium

and bronze.

and bronze.

Figure 4-18: Top End Cap Completed Assembly

Page 38

SECTION 5: MAINTENANCE 4-12

Replace the Purge Port Plug

CAUTION!

Before reinserting the Purge Port Plug, ensure it is clean and free of

debris. Even small debris can cause the unit to flood.

Note: The shoulder on the Purge Port Plug is approximately flush with the

end cap when it is inserted fully and the glass epoxy retainer is wrapped

around the .19-inch diameter stub

1. Purge the instrument as per the following sub-section 4.2.

2. Replace the Purge Port Plug as shown in F

IGURE 4-19.

Figure 4-19: Replace the Purge Port Plug

3. Replace the Purge Port Retainer using the nylon screw as shown in F

IGURE 4-20.

Figure 4-20: The Replaced Purge Port Plug Retainer

Page 39

4-13

Leak Detection and Condensation Prevention

EdgeTech 8242XS releases are provided with a 3/8-inch diameter purging port in the Clevis End Cap. The

following procedure assumes the user has a vacuum pump, dry nitrogen gas cylinder, and compound

pressure/vacuum gauge all arranged on a manifold setup. The recommended procedure for preparation

of the instruments atmosphere is as follows:

After checking that all other ports are sealed, draw a near -3 PSIG vacuum via the purging port. Verify with

a gauge that the release holds the vacuum. Backfill with dry nitrogen then draw a near -3 PSIG vacuum.

Quickly insert the purging plug before the -3 PSIG vacuum is lost. If the environment where the release

was assembled was very humid then repeat the purging procedure 2 to 4 times before replacing the plug,

to remove all moisture.

1. Verify that all (except purge port) O-ring seals have been cleaned, lubricated and assembled.

2. Prepare the purge port plug for installation by cleaning and greasing it, the plug must be ready for

immediate insertion.

3. Insert a purge port adaptor and draw a -3 PSIG vacuum, do not exceed -5 PSIG.

4. Close the manifold valve to the instrument and allow the instrument to sit for 15 minutes. Check

the gauge afterwards and verify that the vacuum did not change. This step is done to detect gross

O-ring problems (cut or missing).

5. Open the valve to the instruments purge port and:

a. Backfill the Housing with dry nitrogen gas, do not exceed +5 PSIG.

b. Draw a -3 PSIG vacuum on the instrument, do not exceed -5PSIG.

c. In humid environments, you should repeat this process up to four times.

d. After drawing the final vacuum in this process, remove the purge hose and quickly insert

the purging plug before the -3 PSIG vacuum is lost.

e. Replace the Purge Port Plug Retainer with the instructions in subsection 4.1.7.

Note: If the environment where the release was assembled was very

humid then repeat the purging procedure 2 to 4 times before replacing

the plug, to remove all moisture.

CAUTION!

When purging the instrument, be careful not to draw more than -5 PSIG

vacuum. Exceeding this figure can damage the battery or electronic

components, which in turn can result in instrument failure. If a purging

set up is not available, then place a desiccant pack inside the Housing to

help reduce moisture.

Page 40

SECTION 5: MAINTENANCE 4-14

Arming the Instrument

The release mechanism is easily armed using only the slotted arming tool that is provided with the system.

No disassembly is required even after multiple firings (except for battery replacement).

Figure 4-21: Clevis Rotation Drawing

The Model 8242XS release is designed to be used with the EdgeTech Release Link. The release link will

accept a standard 5/8inch shackle (maximum .77in [1.9 cm.] pin diameter and minimum 1.06in [2.7 cm.])

opening. The external moving components of the release mechanism are shown in F

IGURE 4-22.

Page 41

4-15

T-Shaped Release Shaft

Zinc Anode

Release Link

Release Hook

Slotted Release Latch

Figure 4-22: The Armed 8242XS

Page 42

SECTION 5: MAINTENANCE 4-16

To Arm the Instrument:

1. When capturing the anchor link in the hook, be sure to support the Anchor Link and the Hook.

pivoting the latch back over the T-Shaft.

Figure 4-23: The Release Link Captured by the Release Hook

Capture the end of the hook behind the latch while passing the slot in the latch down over

2.

the T-shaft, as shown in

FIGURE 4-24.

Figure 4-24: Capture the End of The Hook onto the Latch Recess

Page 43

4-17

3. Using the slotted arming tool, rotate the shaft clockwise until the internal mechanism ‘clicks’ and

holds position. DO NOT FORCE THE MECHANISM FURTHER THAN NEEDED (approximately 40-inch-

pounds torque is required to rotate the shaft 30 degrees clockwise).

CAUTION!

The Release Mechanism is armed after rotating the shaft. Do not attempt

reverse rotation with the arming tool. Forced reverse rotation will

jeopardize optimum performance.

Figure 4-25: Rotating the Shaft Using the Arming Wrench

Page 44

SECTION 5: MAINTENANCE 4-18

Figure 4-26: The Armed T-Shaft

Release Function

After the RELEASE command has been decoded, the power supply is switched on to the motor. The

internal torsion spring is released by the motor and provides torque to the t-shaped release shaft. When

the T-shaped end of the shaft turns and aligns with the slot in the latch, a release will occur. The shaft

carries a small percentage of the mooring tension along its axis with support via two thrust washers at the

top (inside end) of the shaft.

The torque created by the spring needs to overcome the friction between the shaft and the latch. Because

the torque generated by the spring is a fixed quantity, the electrical current requirement of the motor is

purely a function of the size of the spring. The central design parameter of the mechanical release

assembly is the size (magnitude) of the spring force. The effective battery life is based on the minimum

voltage required to release the spring and the maximum release capability is defined by the mooring

tension frictional force that the spring must overcome.

Page 45

4-19

Release Latch Inspection (following high load in-air releases):

It should be routine practice after any release (air or water) to inspect the release latch and release latch

pin for flatness. In the absence of the damping effect of water or if very high loads are released, the hook

latch and Release Hook exhibits significant dynamics.

When testing the release in air, the hook and latch will strike one another. Slight bending of the latch or

latch pin (a few thousandths of an inch) may occur. Bending greater than .002-inch in the latch or pin will

impair the release performance and may warrant replacement of the bent part. To prevent binding during

in-air tests, bond a 3/8-inch thick by 2-inch long strip of rubber to the hook. This will absorb the shock of

impact when the latch strikes the hook. This is only necessary if a heavy load will be used for the test.

ON/OFF Option

When the On/Off Option is included, the instrument may be fully prepared and sealed before powering

the electronics. The power supply is an open loop until the On/Off Actuator Plug is fully inserted. The

On/Off Actuator Plug is a keyed four-pin plug that closes the power supply circuit when it engages the

connector inside the instrument.

WARNING!

NEVER twist or attempt to rotate the On/Off Actuator Plug, as this may

break the male connector pins inside the On/Off Mechanism.

There are two proper alignment positions of the 1/8-inch milled slot on the top of the On/Off Actuator

Plug. For Releases machined prior to the year 2000 the 1/8-inch milled slot on the top of the On/Off

Actuator Plug pointed away from the center of the end; and for Releases manufactured after 2000 the

1/8-inch milled slot on the top of the On/Off Actuator Plug pointed to the bottom left, approximately 200

degrees from the top center position. Both alignments are shown in F

IGURE 4-27.

Figure 4-27: The Two Possible On/Off Actuator Plug Positions

Page 46

SECTION 5: MAINTENANCE 4-20

On/Off Actuator

Purge Port Plug

OFF Position

ON Position

Milled Slot

Figure 4-28: On/Off Actuator Plug on the Clevis End

Figure 4-29: The ON and OFF Positions of the On/Off Actuator Plug

On/Off Instructions

Turning the On/Off Actuator On and Off is extremely simple. If this option was purchased, follow the

instructions below. If this option was not purchased, disregard this section, as the On/Off Actuator Plug

was replaced with a Dummy Plug.

Note: When powered on, the On/Off Actuator Plug is approximately flush

with the End Cap and the epoxy retainer is wrapped around the .19-inch

diameter stub, as shown in FIGURE 4-29.

Page 47

4-21

4.5.1.1 On Instructions

1. Loosen Retainer, and move it out of the way, as shown in FIGURE 4-30.

Figure 4-30: Loosen the Retainer and Move It Out of the Way

2. Push On/Off Actuator Plug in. This will turn the On/Off Option ON, as shown in F

Figure 4-31: Push in the On/Off Actuator

3. Return Retainer to its proper position and tighten it, as shown in F

IGURE 4-32.

IGURE 4-31.

Figure 4-32: Return Retainer and Tighten

Page 48

SECTION 5: MAINTENANCE 4-22

4.5.1.2 Off Instructions

1. Loosen Retainer, move it out of the way, as shown in FIGURE 4-30.

2. Pull the On/Off Actuator Plug out so the off position groove is flush with the unit, as shown in

F

IGURE 4-33. This will turn the On/Off Option OFF.

Figure 4-33: Pull the On/Off Actuator Out

3. Return Retainer and tighten, as shown in F

IGURE 4-32.

Page 49

4-23

Air Acoustic Testing

CAUTION!

Do not exceed -3 PSIG while purging the housing, as an excess vacuum

can damage the batteries.

Always perform an air acoustic test of the commands and interrogate the instrument after assembling to

assure proper working order. Every time the instrument is powered up, repeat the air acoustic test to

assure proper engagement of the On/Off plug. Place the deck box transducer within 1 meter of the

underwater unit transducer when sending commands. The position of the transducers relative to one

another may need to be adjusted to allow commands to get through in air. Ranges will not be accurate in

air; these systems are designed to operate in water. The speed of sound in air can cause errors in

command decoding and prevents accurate ranging however the systems can be tested in air. Test all

functions of the system by sending each command and verifying that the state changed according to the

command including status reply.

Setup

The specific acoustic impedance of air is quite different from that of seawater, which renders the

Transducer a far less efficient receiver when out of water. For this reason, it is necessary to place the

source (Deck Unit Transducer) within a meter or two of the 8242XS Transducer, with no obstructions to

the acoustic path. Depending on the environment, some experimentation may be necessary to find a

suitable location.

Tests

For the following tests, it will be necessary to have the proper six digit commands unique to the unit being

tested. If it appears that commands are not getting through, verify that the serial number of the unit being

tested matches that on the sheet of command codes.

Using a deck unit, ascertain whether the 8242XS is enabled or disabled by interrogating it if the unit has

just been powered up it will be enabled. Unless otherwise specified, the 8242XS will be shipped from

EdgeTech with the interrogate frequency tuned to 11 kHz and the reply frequency set to 12 kHz.

a. Upright and Not Released: 15 pings at a 2 second rate

b. Tilted and Not Released: 7 pings at a 2 second rate

c. Upright and Released: 15 pings at a 1 second rate

d. Tilted and Released: 7 pings at a 1 second rate

Page 50

SECTION 5: MAINTENANCE 4-24

1. Arm the release and orient it horizontally. Using the deck unit, send the ENABLE command. The

instrument should reply with a series of 7 pings at a 2 second rate indicating the instrument is

tilted more than 45 degrees and not released.

2. Send the RELEASE command. The instrument should release and reply with a series of 7 pings at

a 1 second rate indicating the instrument is tilted more than 45 degrees and has released.

3. Interrogate the instrument using the Deck Unit set at the appropriate interrogate frequency for

the release being tested and tuned to the proper reply frequency.

It is unlikely that the Deck Unit will display a valid range because it is being tested in air, but you

should be able to verify that the instrument transmits a reply pulse by listening to the alarm on

the front panel of the Deck Unit.

4. Orient the release vertically (Transducer up) and send the DISABLE command. The instrument

should reply with a series of 15 pings at a 1 second rate indicating released and tilted less than 45

degrees. Now range on the instrument again with the deck unit. This time the unit should not

transmit a reply pulse.

It is good practice DISABLE the release after deployment, as ambient noise sources could run down the

battery.

Post Deployment

After recovery, the Unit should be cleaned and rinsed with fresh water to avoid salt buildup and

deterioration of mechanical parts.

A visual inspection of the Housing and release mechanism should be performed to detect any signs of

damage, excessive wear, corrosion, etc.

If the 8242XS is not to be used again soon, the Unit should be turned off (battery unplugged - follow

procedure described in sub-section 4.1).

If the Unit is to be stored for a long period of time, the batteries should be removed. See Maintenance

procedures in

SECTION 6: MAINTENANCE.

Page 51

5-1

5.0 MAINTENANCE

The 8242XS requires minimal maintenance. Pre-deployment preparations and checks, and postdeployment cleaning will fulfill most of the maintenance requirements. The important tasks are battery

replacement, 'O' ring care and maintenance, and general cleaning, inspection, and lubrication of

operational elements.

Housing and Release Preparation and Care

To access the electronics assembly or mechanical assemblies, remove the five sets of titanium hardware

holding the upper and clevis End Caps in place, as shown in F

The 8242XS releases are shipped with 12 PSIA (-2.5 PSIG) of dry nitrogen, which reduces moisture in the

housing and helps to seat the O-Rings. Equalization of pressure by removal of the purge port plug will be

necessary to gain entry into the instrument.

IGURE 5-6.

WARNING! If the underwater unit has been deployed, there is the

possibility of leakage and internal pressurization of the housing. If the

housing is pressurized, be sure to exercise extreme caution when

relieving the pressure. The resulting violent motion of some parts can

result in serious personal injury.

NOTE: In some releases the cable from the electronics to the transducer

is short (12 inches (30 cm.)). To prevent parting the cable, always remove

the top (transducer) end cap first, and disconnect the transducer from

the electronics.

WARNING! High voltage is present at this connector when the unit

transmits reply bursts.

Page 52

SECTION 5: MAINTENANCE 5-2

Transducer Cable

Battery Cable

To Open the 8242XS

Should the need arise for service or replacement of parts, the following instructions detail complete

disassembly and reassembly of the Unit. These instructions will build upon the instructions in section

as they follow some of the same initial steps, but are more in depth.

NOTE: It is essential that the nickel-aluminum bronze material be isolated

from any dissimilar metal. Because of this, the instrument is supplied with

a disposable anchor link with nylon insulating bushings. This link or its

equivalent must be used to prevent harmful galvanic corrosion between

dissimilar metals.

Tools

• ½” Socket

• ½” Wrench

• Soft Mallet

4.1,

8242XS Disassembly

To Disassemble the 8242XS:

1. Remove the Purge Port Plug, referring to sub-section

2. Remove the Lifting Support, referring to sub-section 4.1.2.

3. Remove the Transducer End, referring to sub-section 4.1.3.

4.1.1.

Figure 5-1: The Plugged in Battery and Transducers Cables

Page 53

5-3

4. Disable power supply by disconnecting the connector from the battery pack to the main board.

Note: Always unplug the Battery before unplugging the Transducer Cable.

5. Disconnect the transducer cable.

Figure 5-2: The Unplugged Battery and Transducer Cables

Page 54

SECTION 5: MAINTENANCE 5-4

Remove the Clevis End Cap

4. Remove the two titanium bolts from the lower clamp assembly. This must be done carefully.

Follow the sub-steps below:

CAUTION!

Never put the socket wrench over both nuts when attempting to

removing the Top Nut from the three titanium bolts. This can cause the

nuts to seize together and prevent loosening of the bolt.

a. Remove the second nut from each of the three titanium bolts using a ½” wrench and ½”

socket wrench, as shown in F

IGURE 4-4.

Figure 5-3: Removing the (2) Top Nut from the (2) Titanium Bolts

b. Remove the remaining nut from each of the three titanium bolts with the same tools,

using the same method depicted in F

IGURE 5-3.

Page 55

5-5

5. Place a wrench into the gap between the two parts of the Clevis End Cap to pry one side of it off,

shown in F

IGURE 5-4.

Figure 5-4: Using a Wrench to Pry the Clevis End Cap Apart

6. With a soft mallet, tap the other half of the clamp to free the End Cap.

Figure 5-5: Tapping the other end of the clamp with a soft Mallet

Page 56

SECTION 5: MAINTENANCE 5-6

CAUTION!

When removing the Release End Cap Assembly with the electronics

attached, take care to pull the chassis out straight and not drag the

chassis edge on the housing bore seal.

6. Remove the Release End Cap by carefully sliding the Electronics Assembly out of the Housing.

Take care not to scratch the O-ring surfaces, shown in F

IGURE 5-6.

Figure 5-6: The Electronics Assembly Completely Removed from the Housing

Page 57

5-7

8242XS Assembly

The instructions below detail the Clevis End Cap Assembly.

Clevis End Cap Assembly

1. Prepare the sealing surfaces for assembly by cleaning with a lint-free towel or swab, moistened if

needed with alcohol. Inspect for scratches or nicks which will impair the O-ring efficiency. Apply

a Very light coat of O-ring lubricant (EdgeTech recommends the use of Parker Super O-lube) to

the piston O-ring surface to aid sliding insertion of the piston seal. Inspect the O-Rings for damage

or manufacturing flaws such as tears, dimples or inclusions in the rubber. Lightly coat the O-Rings

with O-ring lubricant. Protect O-Rings when stretching them over large diameters (i.e., cover

diameter. with plastic sleeve). See F

Only a light coating of lubricant is required. Excess lubricant between

seals may cause excessive hydraulic pressure between O-Rings, resulting

in improper seating.

IGURE 5-7, FIGURE 5-9, and FIGURE 4-12.

CAUTION!

Figure 5-7: O-Rings in Clevis End Cap

2. Slip the electronics into the housing. After the electronics is in the housing and before the

transducer end cap is inserted, connect the transducer cable and then the battery.

CAUTION!

Do not pinch or damage wires when inserting assembly into the housing.

There are large diameter plates in the electronics assembly which will not

allow clearance for cables or connectors.

3. Carefully press the piston seal into the housing. The backup O-ring is properly aligned if it enters

the housing before the O-ring while the curved side of the backup ring faces the O-ring.

Page 58

SECTION 5: MAINTENANCE 5-8

Figure 5-8: Cross Section of the Face Seal, Gland, and Back-up O-Rings

4. When the End Cap flange mates against the housing, be sure the O-ring is properly seated in the

groove and is not crushed outside the groove between the end cap and housing.

5. The end cap is secured to the housing by gently starting one of the clamps onto the 15-degree

tapered flanges. After both sides of the clamp have been started, seat the clamp with

progressively sharper taps using a soft mallet. Clamping hardware includes 5/16” titanium nuts,

bolts and washers, are shown in F

IGURE 5-9.

NOTE: Nylon shoulder washers, also included, are essential and must be

positioned between the titanium and bronze to prevent damaging

galvanic corrosion of the bronze, as shown in FIGURE 5-9.

Page 59

5-9

(2) Titanium Hex Nuts

Titanium Hex Head Bolt

Nylon

Washer

Titanium

Washer

Nylon

Washer

Titanium

Washer

Shoulder

Shoulder

Figure 5-9: Clamping Hardware

6. Continue tapping all parts of both clamps with the soft mallet until no further tightening of the

hardware is possible. Use a torque wrench if available and torque all five of the titanium fasteners

to between 175 and 200 in. lbs. (200-230 centimeter kilograms).

Battery Replacement

Remove the electronics chassis from the housing according to the disassembly procedure. Make sure that

the battery connector is disconnected from the board and remove the brackets which hold the battery

pack to the aluminum plate. Discard the old battery. Install the new battery and replace the brackets

which hold it in. Route the battery connection in such a way that it will not be crushed when assembling

the electronics in to the housing. After replacing the batteries, the user is advised to perform an air

acoustic check of the release. Assemble the electronic chassis in the release housing.

Page 60

SECTION 5: MAINTENANCE 5-10

Battery Replacement Procedure

There are three different replacement battery options:

WARNING!

IF THE UNDERWATER UNIT HAS BEEN DEPLOYED, THERE IS THE

POSSIBILITY OF INTERNAL PRESSURIZATION, EXERCISE EXTREME

CAUTION WHEN OPENING THE INSTRUMENT!

CAUTION!

The 8242XS’ Battery Pack is on the underside of the Electronics’

Assembly. To replace the battery, the Electronics board must be flipped

upside down. This is safe. No components will touch the table if properly

handled. Battery replacements should always be done on a hard surface,

such as a table or work bench to prevent damage to all components.

When replacing the battery, take special care to install the Battery

Connection Wires to avoid pinching them with the Battery Pack Retaining

Brackets during reassembly.

To Replace the Batteries:

1. Open the instrument, referring to sub-section 4.1.1.

2. Remove the Lifting Support, referring to sub-section

4.1.2.

3. Open the Transducer End from the Housing by gently pulling them apart. Be careful not to scratch

the Housing then pulling the assembly from the tube, referring to sub-section 4.1.3. Do not

advance to 4.1.4.

4. Disconnect the Battery Cable from the Electronics Assembly (JP5), as shown in F