Page 1

EdgeTech

4 Little Brook Road

West Wareham, MA 02576

0057

2491

4

4125 SIDE SCAN SONAR SYSTEM

USER HARDWARE MANUAL

0004823_REV_C

Tel: (508) 291-

Fax: (508) 291-

www.EdgeTech.com

Page 2

ii

The information, figures, and specifications in this manual are proprietary and are issued in strict

confidence on condition that they not be copied, reprinted, or disclosed to a third party, either wholly or

in part, without the prior, written consent of EdgeTech. Any reproduction of EdgeTech supplied software

or file sharing is strictly prohibited.

©Copyright 2014 by EdgeTech. All rights reserved.

Microsoft® and Windows® are registered trademarks of Microsoft Corporation.

Kevlar® is a registered trademark of the DuPont Company.

Intel® and Pentium® are registered trademarks of Intel Corporation.

Novagard G624® is a trademark of Novagard Solutions, Inc.

Storm Case™ is a trademark of Pelican, Inc.

Centrino

TM

is a trademark of Intel Corporation.

Kellems® is a registered trademark of Hubbell Incorporated.

4125 SIDE SCAN SONAR SYSTEM 0004823_REV_C

Page 3

iii

WARNIN G – READ THIS FIRS T!

Radiation

High Voltages

Improper Line Voltage

W

All personnel involved with the installation, operation, or maintenance of the equipment described in this

manual should read and understand the warnings and recommendations provided below.

Static Sensitive Devices

This equipment contains devices that are extremely sensitive to static electrical charges. Therefore

extreme care should be taken when handling them, as static electricity may be present on the body and

clothing. Normal handling precautions involve the use of anti-static protection materials and grounding

straps for personnel.

This equipment generates, uses, and can radiate radio frequency energy. Therefore if the equipment is

not installed properly, it may cause interference with radio communications. The equipment has not been

tested for compliance with the appropriate FCC rules designed to provide reasonable protection against

such interference when operated in a commercial environment. Therefore when operating the equipment

in a residential area, the user may be required to take whatever measures are needed and incur any

expenses necessary to eliminate interference; it is the user's responsibility to verify that the system

complies with the applicable FCC emission limits.

High Voltage may be present in all parts of the system. Use caution when the electronics are removed

from their containers for servicing.

Operation with improper line voltage may cause serious damage to the equipment. Always ensure that

the proper line voltage is used.

Page 4

iv

HARDWA R E VA RIATI ONS AND COM PATIB I LITY

H

The 4125 SIDE SCAN SONAR SYSTEM contains both standard PC and proprietary hardware. At times

EdgeTech may change the standard components due to their availability or performance improvements.

Although the component manufacturers, along with their models and styles may change from unit to unit,

replacement components will generally be interchangeable.

EdgeTech will make every effort to see that replacement components are interchangeable and use the

same software drivers. At times, however, direct replacements may not exist. When this happens,

EdgeTech will provide the necessary drivers with the replacement part.

EdgeTech may also change certain hardware per customer requirements. Therefore, portions of this

manual, such as parts lists and test features, are subject to change. These sections should be used for

reference only. When changes are made that affect system operation, they will be explicitly noted. Also,

some options and features may not be active in the customer’s unit at time of delivery. Upgrades will be

made available when these features are implemented.

4125 SIDE SCAN SONAR SYSTEM 0004823_REV_C

Page 5

v

PREF A CE

Purpose of this Manual

Summary of Sections

P

We, the employees at EdgeTech, would like to thank you for purchasing 4125 SIDE SCAN SONAR SYSTEM.

At EdgeTech, it is our policy to provide high quality, cost effective products and support services that meet

or exceed your requirements. We also strive to deliver them on time and to continuously look for ways to

improve them. We take pride in the products we manufacture and want you to be entirely satisfied with

your equipment.

The purpose of this manual is to provide the user with information on the installation and use of

EdgeTech’s 4125 SIDE SCAN SONAR SYSTEM. For detailed information relating to software that came with

this device, refer to the appropriate user software manual.

Although this manual encompasses the latest operational features of 4125 SIDE SCAN SONAR SYSTEM,

some features may be periodically upgraded. Therefore the information in this manual is subject to

change and should be used for reference only.

This manual is divided into the following five sections and three appendices:

SECTION 1: Overview. Describes the 4125 system, its applications, major components, and available

options. Also includes a section about EdgeTech’s role as the leader in underwater technology over the

past few decades.

SECTION 2: Specifications. Details the topside processor, tow vehicle, cables, and options. Also includes

technical descriptions for some of the major computer components within the system.

SECTION 3: Set-up & Activation. Explains how to properly unpack, set-up, test, deploy, and recover the

4125 system.

SECTION 4: Maintenance. Describes the basic maintenance procedures required for different parts of the

system.

SECTION 5: Troubleshooting. Explains how to disassemble and reassemble the tow vehicle chassis.

Describes the procedure for recalibrating the compass. And provides basic troubleshooting techniques.

APPENDIX A: Backup & Restore. Provides the instructions for making a copy of the hard drive onto a

provided USB drive and then using this same drive to restore the system in the unlikely event of its failure.

APPENDIX B: Printers. Describes the various printers that may be used with the 4125 Series system.

APPENDIX C: Tow Characteristics. Includes graphical representations of the tow vehicle and cable at

various lengths, depths, and weights.

Page 6

vi

Warnings, Cautions, and Notes

Liability

W

Where applicable, warnings, cautions, and notes are provided in this manual as follows:

WARNING!

Identifies a potential hazard that could cause personal injury or death to

yourself or to others.

CAUTION!

Identifies a potential hazard that could be damaging to equipment or

could result in the loss of data.

NOTE: Recommendations or general information that is particular to

the material being presented. It may also refer to another part of this

manual or to another manual.

EdgeTech has made every effort to document 4125 SIDE SCAN SONAR SYSTEM in this manual accurately

and completely. However, EdgeTech assumes no liability for errors or for any damages that result from

the use of this manual or the equipment it documents. EdgeTech reserves the right to upgrade features

of this software and to make changes to this manual without notice at any time.

4125 SIDE SCAN SONAR SYSTEM 0004823_REV_C

Page 7

vii

WARRAN TY ST ATEMENT

W

All equipment manufactured by EdgeTech is warranted against defective components and workmanship

for a period of one year after shipment. Warranty repair will be done by EdgeTech free of charge.

Shipping costs are to be borne by the customer. Malfunction due to improper use is not covered in the

warranty, and EdgeTech disclaims any liability for consequential damage resulting from defects in the

performance of the equipment. No product is warranted as being fit for a particular purpose, and there is

no warranty of merchantability. This warranty applies only if:

i. The items are used solely under the operating conditions and in the manner recommended in

Seller's instruction manual, specifications, or other literature.

ii. The items have not been misused or abused in any manner, nor have repairs been attempted

thereon without the approval of EdgeTech Customer Service.

iii. Written notice of the failure within the warranty period is forwarded to Seller and the directions

received for properly identifying items returned under warranty are followed.

iv. The return notice authorizes Seller to examine and disassemble returned products to the extent

Seller deems necessary to ascertain the cause for failure.

The warranties expressed herein are exclusive. There are no other warranties, either expressed or implied,

beyond those set forth herein, and Seller does not assume any other obligation or liability in connection

with the sale or use of said products. Any product or service repaired under this warranty shall be

warranted for the remaining portion of the original warranty period only.

Equipment not manufactured by EdgeTech is supported only to the extent of the original manufacturer's

warranties.

Page 8

viii

SOFT W A R E SE R VICE OVERVI EW

Software Updates and Enhancements

S

EdgeTech provides software services free of charge. The SSA does not address customer-specified

modifications or enhancements. These services may be ordered separately. Furthermore, EdgeTech

software upgrades are meant for the sole use of EdgeTech customer. Any reproduction of EdgeTech

supplied software or file sharing is strictly prohibited.

EdgeTech customers can download new software releases with all modifications and enhancements along

with user's manual changes from the EdgeTech ftp site. Major software issues, should they occur, will be

reported directly to the customer. New software releases consist of the following:

x Software enhancements that are not on the price list

x Software fixes and changes

x Product integration

x Documentation updates to on-line help

x Tests for compatibility with other modules

Software patches consist of software that has undergone the following:

x Minor software enhancements

x Software fixes and changes

x Software Telephone, Facsimile, and E-mail Support

The SSA entitles EdgeTech customers to contact EdgeTech Customer Service by telephone, facsimile, or

e-mail to report a difficulty, to discuss a problem or to receive advice on the best way to perform a task.

When contacted, EdgeTech Customer Service will do the following:

x Respond within 24 hours

x Immediately attend to serious problems affecting operations

x Attempt to find an immediate work-around

4125 SIDE SCAN SONAR SYSTEM 0004823_REV_C

Page 9

ix

RETU R NED MAT ERIAL AU T HORIZ ATION

R

Prior to returning any equipment to EdgeTech, a Returned Material Authorization (RMA) number must be

obtained. The RMA will help us identify your equipment when it arrives at our receiving dock and track

the equipment while it is at our facility. The material should be shipped to the address provided in the

EdgeTech Customer Service section. Please refer to the RMA number on all documents and

correspondences as well.

All returned materials must be shipped prepaid. Freight collect shipments will not be accepted. EdgeTech

will pay freight charges on materials going back to the customer after they have been evaluated and/or

repaired.

CAUTION!

Never attempt to ship portable topside units in their Storm Case alone.

Although rugged, these cases are not intended to be used as shipping

containers, and the delicate internal components could be damaged if

used in this manner.

The following steps apply only to material being returned from outside the Continental United States.

Follow them carefully to prevent delays and additional costs.

1. All shipments must be accompanied by three copies of your proforma invoice, showing the value

of the material and the reason for its return. If the reason is for repair, it must be clearly stated in

order to move through customs quickly and without duties being charged. Whenever possible,

please send copies of original export shipping documents with the consignment.

2. If the value of the equipment is over $1000, the following Shipper's oath must be sent with the

invoice. This oath can be typed on the invoice, or on a separate letterhead:

"I, ______________________________, declare that the articles herein specified are the growth,

produce, or manufacture of the United States; that they were exported from the United States

from the port of _____________________, on or about _______________; that they are returned

without having been advanced in value or improved in condition by any process of manufacture

or any other means; and that no drawback, or allowance has been paid or admitted hereof."

Signed ______________________________

3. If there is more than one item per consignment, a packing list must accompany the shipment. It

is acceptable to combine the proforma invoice and packing list as long as the contents of each

carton are clearly numbered and identified on the invoice.

4. Small items can be shipped prepaid directly to EdgeTech by FedEx, DHL, UPS, Airborne, etc.

Page 10

x

5. If the equipment is the property of EdgeTech (formerly EG&G Marine Instruments Division),

please insure for full value.

6. Fax one invoice, packing list, and a copy of the airway bill to EdgeTech upon shipment.

4125 SIDE SCAN SONAR SYSTEM 0004823_REV_C

Page 11

xi

CUSTOME R SE R VICE

C

Customer service personnel at EdgeTech are always eager to hear from users of our products. Your

feedback is welcome, and is a valuable source of information which we use to continually improve these

products. Therefore we encourage you to contact EdgeTech Customer Service to offer any suggestions or

to request technical support:

E-mail: service@edgetech.com

Mail: 4 Little Brook Road

West Wareham, MA 02576

Telephone: (508) 291-0057

Facsimile: (508) 291-2491

24-Hour Emergency

Technical Support Line: (508) 942-8043

For more information please go to www.EdgeTech.com.

Page 12

xii

COMPAN Y BACK GROUND

C

EdgeTech (formerly EG&G Marine Instruments) traces its history in underwater data acquisition and

processing back to 1966. EdgeTech has designed, developed and manufactured products, instruments and

systems for the acquisition of underwater data, including marine, estuarine, and coastal applications for

over 45 years.

The company has responded to the needs of the scientific, Naval and offshore communities by providing

equipment, such as sub-bottom profilers, side scan sonar, acoustic releases, USBL positioning systems and

bathymetric systems that have become standards in the industry.

EdgeTech has also consistently anticipated and responded to future needs through an active research and

development program. Current efforts are focused on the application of cutting edge CHIRP, DS, and

acoustic technology.

4125 SIDE SCAN SONAR SYSTEM 0004823_REV_C

Page 13

xiii

TABL E OF C ONTEN T S

T

WARNING – READ THIS FIRST! ..................................................................................................................... iii

Radiation .................................................................................................................................................. iii

High Voltages ........................................................................................................................................... iii

Improper Line Voltage ............................................................................................................................. iii

HARDWARE VARIATIONS AND COMPATIBILITY ........................................................................................... iv

PREFACE ........................................................................................................................................................ v

Purpose of this Manual ............................................................................................................................. v

Summary of Sections ................................................................................................................................ v

Warnings, Cautions, and Notes ................................................................................................................ vi

Liability ..................................................................................................................................................... vi

WARRANTY STATEMENT ............................................................................................................................. vii

SOFTWARE SERVICE OVERVIEW ................................................................................................................ viii

Software Updates and Enhancements................................................................................................... viii

RETURNED MATERIAL AUTHORIZATION ...................................................................................................... ix

CUSTOMER SERVICE ..................................................................................................................................... xi

COMPANY BACKGROUND ........................................................................................................................... xii

TABLE OF CONTENTS ...................................................................................................................................xiii

LIST OF FIGURES .......................................................................................................................................... xix

LIST OF TABLES ............................................................................................................................................. xx

SECTION 1: OVERVIEW ......................................................................................................................... 1-1

1.1 4125 Series Applications ............................................................................................................... 1-1

1.2 Main System Components ............................................................................................................ 1-2

1.3 4125-P Portable Topside Processor .............................................................................................. 1-2

1.4 Tow Vehicle ................................................................................................................................... 1-3

1.5 Tow Cable ...................................................................................................................................... 1-6

1.6 Optional Equipment ...................................................................................................................... 1-6

1.6.1 Additional Telemetry ................................................................................................. 1-6

1.6.2 Depressor Wing .......................................................................................................... 1-6

1.6.3 Keel Weight ................................................................................................................ 1-7

1.6.4 HullScan W/O and W/ Telemetry Kits ........................................................................ 1-7

Page 14

xiv

1.6.5 Over the Side Option .................................................................................................. 1-7

SECTION 2: SPECIFICATIONS ..................................................................................................... ............ 2-1

2.1 4125-P Portable Topside Processor .............................................................................................. 2-1

2.1.1 Technical Descriptions of Internal Components ........................................................ 2-2

2.2 4125 Tow Vehicle .......................................................................................................................... 2-6

2.3 Over the Side Mounting Option .................................................................................................... 2-9

2.4 Cables ............................................................................................................................................ 2-9

SECTION 3: SETUP AND ACTIVATION ................................................................................................... 3 -1

3.1 Unpacking and Inspection ............................................................................................................. 3-1

3.2 Power Requirements .................................................................................................................... 3-1

3.2.1 Use of an Uninterrupted Power Supply ..................................................................... 3-2

3.2.2 Changing a Non-US Power Plug ................................................................................. 3-2

3.3 Navigation Interface ..................................................................................................................... 3-2

3.4 Placement of the 4125-P Portable Topside Processor ................................................................. 3-2

3.5 Topside Controls and Indicators ................................................................................................... 3-3

3.6 4125-P Portable Topside Processor Connections ......................................................................... 3-5

3.7 TCP/IP Address Settings ................................................................................................................ 3- 6

3.8 Assembling the 4125 Tow Vehicle ................................................................................................ 3-6

3.9 Connecting the System Components ............................................................................................ 3-7

3.9.1 Connecting and Attaching the Tow Cable to the Tow Vehicle ................................... 3-8

3.9.2 Connecting the 4125-P Portable Topside Processor .................................................. 3-9

3.10 System Activation and Test ...................................................................................... 3-10

3.10.1 Preparing a Wired ETHERNET LAN Connection ....................................................... 3-10

3.10.2 Preparing a Wireless ETHERNET LAN Connection .................................................... 3-11

3.10.3 Activating the 4125 Series System ........................................................................... 3-11

3.11 Performing Pre-deployment Checks ........................................................................ 3-12

3.12 Tow Vehicle Deployment ......................................................................................... 3-14

3.13 Tow Vehicle Recovery .............................................................................................. 3-16

SECTION 4: MAINTENANCE .................................................................................................................. 4 -1

4.1 Cleaning the 4125-P Portable Topside Processor ......................................................................... 4-1

4.2 Inspecting and Cleaning the Connections ..................................................................................... 4-1

4.3 Re-arming the Tow Vehicle ........................................................................................................... 4-2

4125 SIDE SCAN SONAR SYSTEM 0004823_REV_C

Page 15

xv

SECTION 5: TROUBLESHOOTING .......................................................................................................... 5-1

5.1 Restoring the Operating System to the Hard Drive ...................................................................... 5-1

5.2 Disassembling and Reassembling the Tow Vehicle ...................................................................... 5-1

5.2.1 Disassembly ................................................................................................................ 5-2

5.2.2 Reassembly ................................................................................................................ 5-4

5.3 Calibrating the Compass ............................................................................................................... 5-5

5.3.1 Entering the Known Magnetic Deviation ................................................................... 5-5

5.3.2 Hard Iron Calibration .................................................................................................. 5-6

5.3.3 Soft Iron Calibration ................................................................................................... 5-8

5.4 General Troubleshooting ................................................................................................... ........... 5-9

5.5 4125-P Portable Topside Processor Troubleshooting................................................................. 5-10

5.6 4125 Tow Vehicle Troubleshooting ............................................................................................ 5-10

5.7 Tow Cable Inspection .................................................................................................................. 5-11

5.7.1 Locating a Shorted Conductor.................................................................................. 5-12

5.7.2 Locating an Open Conductor ................................................................................... 5-12

5.7.3 Locating a Resistance Breakdown ............................................................................ 5-13

5.7.4 Damaged Tow Cable Connector ............................................................................... 5-13

5.8 Part Numbers for Major Topside Components .......................................................................... 5-13

5.9 Part Numbers for Major Tow Vehicle Components.................................................................... 5-14

APPENDIX A: BACKUP AND RESTORE ..................................................................................................... A-1

A.1 Backing up the System Drive .................................................................................................... A-1

A.2 Restoring the System Drive ...................................................................................................... A-1

APPENDIX B: PRINTERS ........................................................................................................................... B-1

APPENDIX C: TOWING CHARACTERISTICS............................................................................................... C-1

C.1 4125 Standard Towfish Cable Layback Plots ............................................................................. C-1

C.1.1 Config. 1: 4125, 207551 Cable - 50m Long ........................................................................ C-3

C.1.2 Config. 2: 4125, 207551 Cable - 100m Long ...................................................................... C-4

C.1.3 Config. 3: 4125, 207551 Cable - 150m Long ...................................................................... C-5

C.1.4 Config. 4: 4125 + 15 lb. Keel Weight, 207551 Cable - 50m Long....................................... C-6

C.1.5 Config. 5: 4125 + 15 lb. Keel Weight, 207551 Cable - 100m Long..................................... C-7

C.1.6 Config. 6: 4125 + 15 lb. Keel Weight, 207551 Cable - 150m Long..................................... C-8

C.1.7 Config. 7: 4125 + Depressor Wing, 207551 Cable - 50m Long .......................................... C-9

Page 16

xvi

C.1.8 Config. 8: 4125 + Depressor Wing, 207551 Cable - 100m Long ...................................... C-10

C.1.9 Config. 9: 4125 + Depressor Wing, 207551 Cable - 150m Long ...................................... C-11

C.1.10 Config. 10: 4125 + 15 lb. Keel Wt. + Dep. Wing, 207551 Cable - 50m ............................ C-12

C.1.11 Config. 11: 4125 + 15 lb. Keel Wt. + Dep. Wing, 207551 Cable - 100m Long .................. C-13

C.1.13 Config. 12: 4125 + 15 lb. Keel Wt. + Depressor Wing, 207551 Cable – 150m ................. C-14

C.2 4125 Telemetry Towfish Cable Layback Plots ......................................................................... C-15

C.2.1 Config. 1: 4125, 23080 Cable - 50m Long ........................................................................ C-19

C.2.2 Config. 2: 4125, 23080 Cable - 100m Long ...................................................................... C-20

C.2.3 Config. 3: 4125, 23080 Cable - 200m Long ...................................................................... C-21

C.2.4 Config. 4: 4125, 23080 Cable - 300m Long ...................................................................... C-22

C.2.5 Config. 5: 4125 + 15 lb. Keel Weight, 23080 Cable - 50m Long ....................................... C-23

C.2.6 Config. 6: 4125 + 15 lb. Keel Weight, 23080 Cable - 100m Long..................................... C-24

C.2.7 Config. 7: 4125 + 15 lb. Keel Weight, 23080 Cable - 200m Long..................................... C-25

C.2.8 Config. 8: 4125 + 15 lb. Keel Weight, 23080 Cable - 300m Long..................................... C-26

C.2.9 Config. 9: 4125 + Depressor Wing, 23080 Cable - 50m Long .......................................... C-27

C.2.10 Config. 10: 4125 + Depressor Wing, 23080 Cable - 100m Long ...................................... C-28

C.2.11 Config. 11: 4125 + Depressor Wing, 23080 Cable - 200m Long ...................................... C-29

C.2.12 Config. 12: 4125 + Depressor Wing, 23080 Cable - 300m Long ...................................... C-30

C.2.13 Config. 13: 4125 + 15 lb. Keel Wt. + Depressor Wing, 23080 Cable - 50m ..................... C-31

C.2.14 Config. 14: 4125 + 15 lb. Keel Wt. + Depressor Wing, 23080 Cable – 100m ................... C-32

C.2.15 Config. 15: 4125 + 15 lb. Keel Wt. + Depressor Wing, 23080 Cable - 200m ................... C-33

C.2.16 Config. 16: 4125 + 15 lb. Keel Wt. + Depressor Wing, 23080 Cable – 300m ................... C-34

C.2.17 Config. 17: 4125, A304874 Cable - 50m Long ................................................................. C-35

C.2.18 Config. 18: 4125, A304874 Cable - 100m Long ............................................................... C-36

C.2.19 Config. 19: 4125, A304874 Cable - 200m Long ............................................................... C-37

C.2.20 Config. 20: 4125, A304874 Cable - 300m* Long ............................................................. C-38

C.2.21 Config. 21: 4125 + 15 lb. Keel Weight, A304874 Cable - 50m Long ................................ C-39

C.2.22 Config. 22: 4125 + 15 lb. Keel Weight, A304874 Cable - 100m Long .............................. C-40

C.2.23 Config. 23: 4125 + 15 lb. Keel Weight, A304874 Cable - 200m Long .............................. C-41

C.2.24 Config. 24: 4125 + 15 lb. Keel Weight, A304874 Cable - 300m* Long ............................ C-42

C.2.25 Config. 25: 4125 + Depressor Wing, A304874 Cable - 50m Long .................................... C-43

C.2.26 Config. 26: 4125 + Depressor Wing, A304874 Cable - 100m Long .................................. C-44

4125 SIDE SCAN SONAR SYSTEM 0004823_REV_C

Page 17

xvii

C.2.27 Config. 27: 4125 + Depressor Wing, A304874 Cable - 200m Long .................................. C-45

C.2.28 Config. 28: 4125 + Depressor Wing, A304874 Cable - 300m* Long ................................ C-46

C.2.29 Config. 29: 4125 + 15 lb. Keel Wt. + Depressor Wing, A304874 Cable - 50m ................. C-47

C.2.30 Config. 30: 4125 + 15 lb. Keel Wt. + Dep. Wing, A304874 Cable - 100m ........................ C-48

C.2.31 Config. 31: 4125 + 15 lb. Keel Wt. + Dep. Wing, A304874 Cable - 200m ........................ C-49

C.2.32 Config. 32: 4125 + 15 lb. Keel Weight + Dep. Wing, A304874 Cable - 300m* ................ C-50

C.2.33 Config. 33: 4125, A320327 Cable - 50m Long ................................................................. C-51

C.2.34 Config. 34: 4125, A320327 Cable - 100m Long ............................................................... C-52

C.2.35 Config. 35: 4125, A320327 Cable - 200m Long ............................................................... C-53

C.2.36 Config. 36: 4125, A320327 Cable - 300m Long ............................................................... C-54

C.2.37 Config. 37: 4125, A320327 Cable - 400m Long ............................................................... C-55

C.2.38 Config. 38: 4125 + 15 lb. Keel Weight, A320327 Cable - 50m Long ................................ C-56

C.2.39 Config. 39: 4125 + 15 lb. Keel Weight, A320327 Cable - 100m Long .............................. C-57

C.2.40 Config. 40: 4125 + 15 lb. Keel Weight, A320327 Cable - 200m Long .............................. C-58

C.2.41 Config. 41: 4125 + 15 lb. Keel Weight, A320327 Cable - 300m Long .............................. C-59

C.2.42 Config. 42: 4125 + 15 lb. Keel Weight, A320327 Cable - 400m Long .............................. C-60

C.2.43 Config. 43: 4125 + Depressor Wing, A320327 Cable - 50m Long .................................... C-61

C.2.44 Config. 44: 4125 + Depressor Wing, A320327 Cable - 100m Long .................................. C-62

C.2.45 Config. 45: 4125 + Depressor Wing, A320327 Cable - 200m Long .................................. C-63

C.2.46 Config. 46: 4125 + Depressor Wing, A320327 Cable - 300m Long .................................. C-64

C.2.47 Config. 47: 4125 + Depressor Wing, A320327 Cable - 400m Long .................................. C-65

C.2.48 Config. 48: 4125 + 15 lb. Keel Wt. + Dep. Wing, A320327 Cable - 50m .......................... C-66

C.2.49 Config. 49: 4125 + 15 lb. Keel Wt. + Dep. Wing, A320327 Cable – 100m ....................... C-67

C.2.50 Config. 50: 4125 + 15 lb. Keel Wt. + Dep. Wing, A320327 Cable - 200m ........................ C-68

C.2.51 Config. 51: 4125 + 15 lb. Keel Wt. + Dep. Wing, A320327 Cable - 300m ........................ C-69

C.2.52 Config. 52: 4125 + 15 lb. Keel Wt. + Dep. Wing, A320327 Cable - 400m ........................ C-70

C.2.53 Config. 53: 4125, A302799 Cable - 50m Long ................................................................. C-71

C.2.54 Config. 54: 4125, A302799 Cable - 100m Long ............................................................... C-72

C.2.55 Config. 55: 4125, A302799 Cable - 200m Long ............................................................... C-73

C.2.56 Config. 56: 4125, A302799 Cable - 300m Long ............................................................... C-74

C.2.57 Config. 57: 4125, A302799 Cable - 400m Long ............................................................... C-75

C.2.58 Config. 58: 4125, A302799 Cable - 500m Long ............................................................... C-76

Page 18

xviii

C.2.59 Config. 59: 4125, A302799 Cable - 600m Long ............................................................... C-77

C.2.60 Config. 60: 4125 + 15 lb. Keel Weight, A302799 Cable - 50m Long ................................ C-78

C.2.61 Config. 61: 4125 + 15 lb. Keel Weight, A302799 Cable - 100m Long .............................. C-79

C.2.62 Config. 62: 4125 + 15 lb. Keel Weight, A302799 Cable - 200m Long .............................. C-80

C.2.63 Config. 63: 4125 + 15 lb. Keel Weight, A302799 Cable - 300m Long .............................. C-81

C.2.64 Config. 64: 4125 + 15 lb. Keel Weight, A302799 Cable - 400m Long .............................. C-82

C.2.65 Config. 65: 4125 + 15 lb. Keel Weight, A302799 Cable - 500m Long .............................. C-83

C.2.66 Config. 66: 4125 + 15 lb. Keel Weight, A302799 Cable - 600m Long .............................. C-84

C.2.67 Config. 67: 4125 + Depressor Wing, A302799 Cable - 50m Long .................................... C-85

C.2.68 Config. 68: 4125 + Depressor Wing, A302799 Cable - 100m Long .................................. C-86

C.2.69 Config. 69: 4125 + Depressor Wing, A302799 Cable - 200m Long .................................. C-87

C.2.70 Config. 70: 4125 + Depressor Wing, A302799 Cable - 300m Long .................................. C-88

C.2.71 Config. 71: 4125 + Depressor Wing, A302799 Cable - 400m Long .................................. C-89

C.2.72 Config. 72: 4125 + Depressor Wing, A302799 Cable - 500m Long .................................. C-90

C.2.73 Config. 73: 4125 + Depressor Wing, A302799 Cable - 600m Long .................................. C-91

C.2.74 Config. 74: 4125 + 15 lb. Keel Wt. + Dep. Wing, A302799 Cable - 50m .......................... C-92

C.2.75 Config. 75: 4125 + 15 lb. Keel Wt. + Dep. Wing, A302799 Cable – 100m ....................... C-93

C.2.76 Config. 76: 4125 + 15 lb. Keel Wt. + Dep. Wing, A302799 Cable - 200m ........................ C-94

C.2.77 Config. 77: 4125 + 15 lb. Keel Wt. + Dep. Wing, A302799 Cable - 300m ........................ C-95

C.2.78 Config. 78: 4125 + 15 lb. Keel Wt. + Dep. Wing, A302799 Cable - 400m ........................ C-96

C.2.79 Config. 79: 4125 + 15 lb. Keel Wt. + Dep. Wing, A302799 Cable - 500m ........................ C-97

C.2.80 Config. 80: 4125 + 15 lb. Keel Weight + Dep. Wing, A302799 Cable - 600m .................. C-98

4125 SIDE SCAN SONAR SYSTEM 0004823_REV_C

Page 19

xix

LIS T OF FIGURE S

L

Figure 1-1: Readying the Towfish for Deployment .................................................................................... 1-2

Figure 1-2: 4125 Series Towfish, Topside, and Tow Cable ......................................................................... 1-5

Figure 1-3: Depressor Wing ....................................................................................................................... 1-6

Figure 2-1: 4125 Series Dual Frequency Side Scan Sonar System Overall Block Diagram ......................... 2-3

Figure 2-2: 4125-P Portable Topside Processor Wiring Diagram ............................................................... 2-4

Figure 2-3: 4125 Portable Topside Processor Chassis................................................................................ 2-5

Figure 2-4: Kevlar Reinforced Tow Cable ................................................................................................. 2-10

Figure 2-5: Kevlar Reinforced Tow Cable, Telemetry .............................................................................. 2-11

Figure 2-6: AC Power Cable ...................................................................................................................... 2-12

Figure 2-7: DC Power Cable ..................................................................................................................... 2-13

Figure 2-8: ETHERNET Cable .................................................................................................................... 2-14

Figure 3-1: 4125-P Portable Topside Processor Side Panel ....................................................................... 3-4

Figure 3-2: 4125 Tow Vehicle Tail Fins Assembly ...................................................................................... 3-7

Figure 3-3: AC Power, DC Power, and ETHERNET Cables .......................................................................... 3-8

Figure 3-4: Tow Vehicle with Tow Cable Connected and Attached ........................................................... 3-9

Figure 3-5: DISCOVER 4125 Towfish Control Tab .................................................................................... 3-12

Figure 3-6: Rub Test being Performed ..................................................................................................... 3-13

Figure 3-7: Rub Test Screen Shot ............................................................................................................. 3-13

Figure 3-8: 4125 Tow Vehicle being Deployed ........................................................................................ 3-15

Figure 3-9: Bottom Track Tab................................................................................................................... 3-16

Figure 5-1: Tow Vehicle Parts of Note ....................................................................................................... 5-2

Figure 5-2: Electronics Bottle and Transducer Array Sections Separated ................................................. 5-2

Figure 5-3: Cables Disconnected from the Electronics Bottle ................................................................... 5-3

Figure 5-4: Removing the Phillips Head Screws from the Electronics Bottle............................................. 5-3

Figure 5-5: Removing the Electronics Chassis from the Electronics Bottle ............................................... 5-4

Figure 5-6: The COM3 Window in Hyper Terminal .................................................................................... 5-7

Figure 5-7: Hard Iron X Y Calibration Complete ......................................................................................... 5-7

Figure 5-8: Hard Iron Z Calibration Complete ............................................................................................ 5-8

Figure 5-9: Soft Iron Calibration Screen Prompts ...................................................................................... 5-9

Page 20

xx

LIS T OF TABLE S

L

Table 2-1: 4125-P Portable Topside Processor .......................................................................................... 2-2

Table 2-2: Tow Vehicle Specifications ........................................................................................................ 2 -8

Table 3-1: AC Power Cord Wiring .............................................................................................................. 3-2

Table 3-2: Topside Processor or ETHERNET Devices TCP/IP Addresses .................................................... 3-6

Table 3-3: Tow Vehicle ETHERNET Devices IP Addresses .......................................................................... 3-6

Table 5-1: Topside Processor System Troubleshooting Guide ................................................................ 5-10

Table 5-2: 4125 Tow Vehicle Troubleshooting Guide .............................................................................. 5-11

Table 5-3: Part Numbers for Major 4125-P Topside Processor Components .......................................... 5-14

Table 5-4: Part Numbers for Major 4125 Tow Vehicle Components ....................................................... 5-15

4125 SIDE SCAN SONAR SYSTEM 0004823_REV_C

Page 21

1-1

SECT I ON 1 : OVERV I EW

1.1

4125 Series Applications

S

The EdgeTech 4125 Series Dual-frequency Side Scan Sonar System is a frequency-modulated (FM), dualfrequency, side scan sonar that uses EdgeTech’s proprietary Full Spectrum “chirp” technology to generate

high-resolution, side scan imagery at longer ranges than conventional continuous-wave (CW) systems.

The system is designed primarily for search and recovery operations, along with surveys in shallow water.

The 4125 Series is available in two, dual simultaneous frequency configurations depending on the

application: 400/900 kHz and 600/1600 kHz. For shallow water survey applications, the 400/900-kHz

frequency set is the best choice, as it provides an ideal combination of range and resolution. For ultrahigh resolution imagery at shorter ranges, the 600/1600 kHz set is the recommended choice.

In both configurations, the frequencies are transmitted as linearly-swept, wide-band, high energy acoustic

pulses, and the received echoes are processed into high signal-to-noise (SNR) images that can be directly

displayed as shades of gray or color on a computer monitor. The SNR images can also be printed on a

continuous feed thermal printer, or stored in real time onto a large capacity hard drive and archived onto

a DVD.

Applications for the 4125 Series Dual-frequency Side Scan Sonar System are many, including:

x Hydrographic surveys

x Geological surveys

x Search and recovery

x Channel conditioning/clearance surveys

x Bridge, pier, and harbor wall inspections

x Hull inspections

x Port security

x Archaeological surveys

Page 22

1-2

1.2

Main System Components

1.3

4125-P Portable Topside Processor

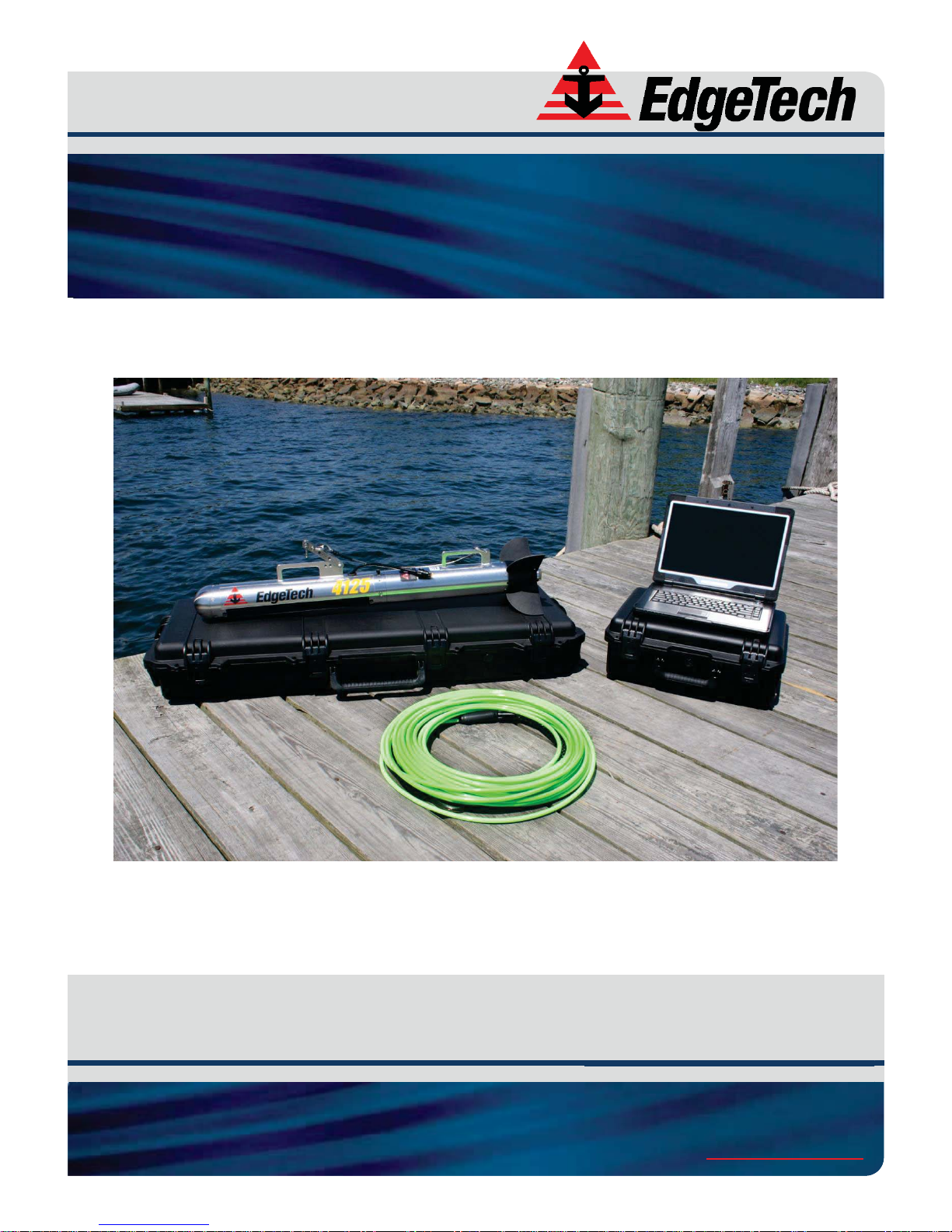

Figure 1-1: Readying the Towfish for Deployment

1

The 4125 Series Dual-frequency Side Scan Sonar System is composed a 4125-P Portable Topside Processor,

a 4125 Tow Vehicle (commonly called a Towfish), and a tow cable. These components are shown in Figure

1 2.

In addition, the tow vehicle is available with or without the additional telemetry option, which enables

the use of longer tow cables. Without the additional telemetry option, tow cables up to 150 meters in

length can be used. With the additional telemetry option, the system will perform with cable lengths up

to 600 meters. Contact EdgeTech Customer Service for the specific cable types.

The 4125-P Portable Topside Processor is shown in Figure 1-2. It provides power and downlink telemetry

to the tow vehicle for sonar control and receives uplink side scan data, sensor data, and status information

from the tow vehicle for processing, storage, and display.

The topside unit includes a laptop computer with Windows 7 and the EdgeTech DISCOVER 4125 Side Scan

Sonar software preinstalled. DISCOVER 4125 provides control, storage, and display of the sonar data. The

data can be stored in XTF and JSF formats.

4125 SIDE SCAN SONAR SYSTEM 0004823_REV_C

Page 23

1-3

1.4

Tow Vehicle

The 4125-P Portable Topside Processor interfaces with the tow vehicle either over a direct 10/100BaseT

connection or, with the additional telemetry option, over a 10BaseT connection that uses very high bit

rate digital subscriber line (VDSL) modems. The topside unit also interfaces with a global positioning

system (GPS) over a USB to serial or RS-232 serial interface.

The topside processor integrates tow vehicle and DC power supplies, an ETHERNET switch, a wireless

router, and, with the additional telemetry option, an VDSL modem, all housed within a single, compact,

rugged, water-tight (when closed) Pelican Storm Case. It runs on either AC or DC power, and interfaces

with the laptop computer over a wired or wireless 10/100BaseT ETHERNET connection. The computer can

be stored inside the enclosure when not in use.

CAUTION!

Never attempt to use the portable topside’s storm case as a shipping

container. Doing so could void warranties and/or result in system

damage.

1

The 4125 Tow Vehicle is available with a choice of 400/900 kHz or 600/1600 kHz operating frequencies,

and with or without the additional telemetry option. It contains the sonar transducer arrays and the

electronics required to transmit and receive the sonar signals; to receive the downlink commands from

the topside processor; and to provide the uplink side scan data, sensor data, and status information to

the topside processor.

The electronics are contained inside a single, lightweight stainless steel, 200-meter depth-rated housing,

comprising the aft section of the tow vehicle. The forward section is flooded and includes both the port

and starboard transducer arrays. A single O-ring sealed end cap is attached to each end of the housing to

seal it, and the forward end cap contains bulkhead connectors for connecting to the transducer arrays. An

adapter cable also connects to this end cap.

The cable snakes through a hole in the transducer array section and includes an inline connector for

connecting to the tow cable. The tow vehicle interfaces with the topside processor either over a

10/100BaseT ETHERNET connection, or (with the additional telemetry option only) over a 10BaseT

connection that uses VDSL modems in both the tow vehicle and the topside processor.

The tow vehicle is also equipped with four stabilizer fins, a stainless steel nose for hydrodynamic balance,

and two convenient carrying handles. A towing arm is rigidly mounted to a tow point on the top of the

tow vehicle housing adjacent to the tow cable connector. The tow cable attaches to a shackle on the

towing arm.

Additional mounting holes are provided on the tow point should it be necessary to reposition the towing

arm forward or aft to adjust the balance of the tow vehicle. The towing arm also includes a safety release

Page 24

1-4

mechanism, which causes a shear pin to release the tow point should the tow vehicle hit an obstruction

or become snagged. If this happens, the tow vehicle will rotate nose down, and a safety cable, which is

attached from the tow point to the rear of the tow vehicle, will pull the tow vehicle over the obstruction

or through the snag, stern first.

4125 SIDE SCAN SONAR SYSTEM 0004823_REV_C

Page 25

1-5

Towing arm

Stainless steel

housing

Shear pin

Shackle

Safety cable

Tow cable

connector

Port transducer array

4125-P Portable Topside Processor with Laptop Computer

Laptop computer

4125-P Portable

Topside Processor

Tow cable

4125 Tow vehicle

Kellems grip

Tow cable

Safety cable

Tow cable

connector

Tie wraps

Waterproof

splice

Shackle

Shear pin

Figure 1-2: 4125 Series Towfish, Topside, and Tow Cable

Page 26

1-6

1.5

Tow Cable

1.6

Optional Equipment

1.6.1

Additional Telemetry

1.6.2

Depressor Wing

Figure 1-3: Depressor Wing

1

The 4125 Series Dual-frequency Side Scan Sonar System includes a 50-meter tow cable, terminated at

both ends. The tow cable is used both to connect to the tow vehicle, and to tow it behind the survey

vessel. Tow cables are available as either a Kevlar-reinforced six conductor or an RG-58 coax cable, which

includes a single conductor and a shield.

The coax cable is used only for systems that include the additional telemetry option. Up to 150 meters of

6 conductor cable or 600 meters of coax cable can be used. Contact EdgeTech Customer Service for

available cable lengths other than the supplied 50-meter cable. A cable grip is also included for attaching

the tow cable to a shackle on the towing arm of the tow vehicle.

Optional equipment that can be installed and used with a 4125 Series Dual-frequency Side Scan Sonar

System includes:

x Additional telemetry (specified when ordering tow vehicle)

x Keel Weight Kit (p/n 0008464)

x Depressor Wing Kit (p/n 0007860)

x HullScan Kit, W/O Telemetry (p/n 0008478)

x HullScan Kit, W/ Telemetry (p/n 0008477)

x Over the Side Mount (p/n 0007633)

The additional telemetry option increases the maximum

length tow cable that can be used from 150 meters to 600

meters by using VDSL modems to establish the

communications link between the tow vehicle and the

topside processor instead of a direct ETHERNET connection.

Contact EdgeTech Customer Service for the specific cable

types.

The Depressor Wing Kit provides a depressor wing (shown in Figure 1-3) that can be attached to the tow

vehicle, allowing it to be towed deeper and faster without increasing the length of tow cable in the water.

The depressor wing attaches to the top of the tow vehicle and pushes it deeper by exerting a downward

force on the tow vehicle as it moves through the water. A safety cable with a shear pin mechanism is

attached to prevent loss of the wing should it become snagged.

4125 SIDE SCAN SONAR SYSTEM 0004823_REV_C

Page 27

1-7

1.6.3

Keel Weight

1.6.4

HullScan W/O and W/ Telemetry Kits

1.6.5

Over the Side Option

1

The Keel Weight Kit provides an additional 15 lbs. of weight to the tow vehicle.

Two HullScan Kits are available, W/O Telemetry and W/ Telemetry. Each of these kits enables a tow vehicle

to be inverted such that the transducer arrays are angled upward instead of downward. In this

configuration the tow vehicle can be used to scan the hulls of ships. The HullScan W/O Telemetry kit is for

tow vehicles that do not have the additional telemetry option. The HullScan W/ is for those that do.

This option allows the towfish to be mounted on a pole for shallow water survey or for vertical imaging.

Contact EdgeTech Customer Service for more information.

Page 28

Page 29

2-1

SECT I ON 2 : SPEC I FIC A T IONS

2.1

4125-P Portable Topside Processor

Size:

19.0

49.0

39.0

Weight:

13.2 kg (29 lbs.)

(w/ laptop computer)

10 kg (22 lbs.)

(w/o laptop computer)

Case construction:

High

Case

Black

Case sealing method:

Watertight cover with O

Shipping container type:

Carton

Shipping container size:

63.5 cm (25 in.) high

53.3 cm (21 in.) wide

53.3 cm (21 in.) deep

Shipping weight:

21.8 kg (48 lbs.)

Operating

-41

Storage temperature:

-20

Operating relative humidity:

0

S

The specifications for the EdgeTech 4125 Series Dual-frequency Side Scan Sonar System include electrical,

mechanical, and environmental characteristics for the main system components as follows:

x 4125-P Portable Topside Processor

x 4125 Tow Vehicle

x Cables

NOTE: All specifications are subject to change without notice.

The specifications for the 4125 Portable Topside Processor are shown below:

color:

Temperature:

4125-P PORTABLE TOPSIDE PROCESSOR

cm (7.3 in.) high

cm (19.2 in.) wide

cm (15.2 in.) deep

-impact structural polypropylene

–40°C (-40–104°F)

–60°C (-4–140°F)

-ring seal and purge valve

–80% (non condensing)

Page 30

2-2

Non

0

AC input power:

90

110 watts operating, auto switching

0.6 A/1.1 A at 120 VAC idling/operating

0.3 A/0.56 A at 240 VAC idling/operating

DC input power:

12

4.3 A/6.0 A at 12 VDC idling/operating

2.4 A/3.3 A at 24 VDC idling/operating

Power to tow vehicle:

7

Processor:

Intel Pentium M 730, 2.4 GHz

Memory:

2 GB

Data storage:

160 GB hard drive

Operating system:

Windows

Application software:

DISCOVER 4

Display:

15.4

Keyboard:

Laptop keyboard

Pointing device:

Laptop mouse pad

Wireless

Centrino 802.11b

Tow vehicle interface:

10/100BaseT TCP/IP

2.1.1

Technical Descriptions of Internal Components

4125-P PORTABLE TOPSIDE PROCESSOR

-operating storage relative humidity:

–100%

–260 VAC, 50/60 Hz, 72–

–24 VDC, 72 watts operating

5 VDC at 1 A max

7

125

-inch LCD

ETHERNET:

ETHERNET w/o telemetry

Table 2-1: 4125-P Portable Topside Processor

2

This section provides an overall general description of the hardware elements comprising the 4125-P

Portable Topside Processor of the 4125 Series Dual-frequency Side Scan Sonar System. This information,

which includes printed circuit board summary descriptions, chassis photos, component call-outs, and a

wiring diagram, can be useful for troubleshooting purposes and installing optional equipment. The 4125

Tow Vehicle is considered non-user-serviceable and therefore specific information of this type is not

provided for it. However, an overall block diagram of the system is shown in Figure 2-1.

A wiring diagram of the 4125-P Portable Topside Processor is shown in Figure 2-2, and the electronics

chassis is shown in Figure 2-3:

4125 SIDE SCAN SONAR SYSTEM 0004823_REV_C

Page 31

2-3

Figure 2-1: 4125 Series Dual Frequency Side Scan Sonar System Overall Block Diagram

Page 32

4125 SIDE SCAN SONAR SYSTEM 0004823_REV_C

2-4

Figure 2-2: 4125-P Portable Topside Processor Wiring Diagram

Page 33

Power board

(under panel)

Power Separation

board

VDSL Modem

board

15-amp fuse

AC Line Filter

(under panel)

Power Supply

Wireless

Bridge /

ETHERNET

Switch board

2-5

Figure 2-3: 4125 Portable Topside Processor Chassis

Page 34

2-6

2.2

4125 Tow Vehicle

The main hardware elements in the 4125-P Portable Topside Processor include the following components

and circuit boards:

Power board. The Power board inputs +24 VDC on J2 from the 24 VDC Power Supply and

generates the 75 VDC tow vehicle power, which is output on J5 to the Power Separation board,

and from this board to the tow vehicle.

The Power board also includes +5, +12, and +15 VDC power supplies. The +5 VDC is output on J3

to the Wireless Bridge/ETHERNET Switch board, and the +12 VDC is output on J6 and J8 to the

VDSL Modem board and the fans, respectively. For DC operation, 12–24 VDC is input on J1.

VDSL Modem board. The VDSL Modem board, which is used only with the additional telemetry

option, converts the uplink data VDSL signals received from the tow vehicle and input on P4 from

J3 of the Power Separation board into ETHERNET 10/100BaseT signals. These signals are then

output on P2 to the Wireless Bridge/ETHERNET Switch board, and from J1 of this board to the

laptop computer.

Similarly, the VDSL Modem board converts the downlink ETHERNET 10/100BaseT based command

signals from the laptop computer into the VDSL downlink command signals, which are then output

on P4 to J3 of the Power Separation board to be combined with 75 VDC tow vehicle power, and

transmitted to the tow vehicle.

24 VDC Power Supply. The 24 VDC Power Supply inputs AC power from the AC Line Filter to

generate +24 VDC, which is output to the Power board.

AC Line Filter. The AC Line Filter filters the AC power input and outputs the filtered power to the

24 VDC Power Supply.

Wireless Bridge/ETHERNET Switch. The Wireless Bridge/ETHERNET Switch board connects the

VDSL Modem board, the tow vehicle, and the laptop computer to the same local area network

(LAN). This board also enables a wireless connection to the laptop computer.

Power Separation board. With the additional telemetry option only, the Power Separation board

combines downlink command signals and uplink data that are input on J3 from P4 of the VDSL

Modem board with 75 VDC tow vehicle power from J5 of the Power board for transmission to the

tow vehicle.

If the additional telemetry option is not included, the Power Separation board is used only to

route the 75 VDC tow vehicle power to the tow vehicle Commands and data are sent and received,

respectively, over a direct ETHERNET connection to the tow vehicle.

2

The specifications for the 4125 Tow Vehicle are shown below:

4125 SIDE SCAN SONAR SYSTEM 0004823_REV_C

Page 35

2-7

Size:

98.0 cm (39.0 in.) long; 9.6

diameter, w/o

telemetry

112.0 cm (44.0 in.) long; 9.6

diameter, w

telemetry

Weight in air:

16.7 kg (36.7 lbs.) w/o telemetry

20.4 kg (45.0 lbs.) w/ telemetry

Weight in salt water:

11.3 kg (24.9 lbs.) w/o telemetry

14.4 kg (31.6 lbs.) w/ telemetry

Construction:

Stainless steel

Depth rating:

200 m (656 ft.)

Maximum tow cable length:

150 m w/o telemetry

600 m w/ telemetry (loop resistance cannot exceed 14

ohms). Contact EdgeTech Customer Service for the

specific cable types.

Tow cable conductors:

(2) #18 and (2)

RG

Kevlar tow cable breaking load:

545 kg (1200 lbs.)

Input power:

7

Towing speed

1

Shear force:

420 kg (930 lbs.)

Frequencies:

400/900 kHz or 600/1600 kHz

Pulse type:

Chirp or CW

Data interface:

10/100BaseT TCP/IP

VDSL

Operating range:

150 m

75 m

120 m

35 m

Across track resolution:

2.3

1.5

1.5

0.6

4125 Tow Vehicle

cm (3.75 in.)

cm (3.75 in.)

-58 coax w/ telemetry

5 VDC, 50 watts maximum

–8 knots

w/ telemetry

twisted shielded pairs w/o telemetry

ETHERNET w/o telemetry

(400 kHz)

(900 kHz)

(600 kHz)

(1600 kHz)

cm (400 kHz)

cm (900 kHz)

cm (600 kHz)

cm (1600 kHz)

Page 36

2-8

Along track resolution:

80 cm @ 100 m (400 kHz)

58 cm @ 100 m (600 kHz)

40 cm @ 50 m (400 kHz)

29 cm @ 50 m (600 kHz)

24 cm @ 50 m (900 kHz)

20 cm @ 25 m (400 kHz)

14 cm @ 25 m (600 kHz)

12 cm @ 25 m (900 kHz)

.08 cm @ 25 m (1600 kH

.05 cm @ 15 m (1600 kHz)

Horizontal beam width:

0

0.28°

0.33°

0.20°

Vertical beam width:

50°

Side lobes:

<

Transducer array depression angle:

Factory set at 33

Operating temperature:

0–45°C (32–113°F)

Heading accuracy:

1.

Heading resolution:

0.1

Pitch and roll accuracy:

0.1

Pitch and roll resolution:

0.1°

Pressure sensor accuracy:

0.5% of depth when calibrated for 0 m

Pressure sensor working depth:

0–200 m

Pressure

>200 m

Navigation interfaces:

RS

Options:

Additional telemetry

Keel Weight Kit

Depressor Wing Kit

HullScan Kit, W/O Telemetry

HullScan Kit, W/ Telemetry

4125 Tow Vehicle

.46° (400 kHz)

(900 kHz)

(600 kHz)

(1600 kHz)

z)

sensor tolerance:

-36 dB

0° RMS

°

°

-232, NMEA0183

°, adjustable to 25°

Table 2-2: Tow Vehicle Specifications

4125 SIDE SCAN SONAR SYSTEM 0004823_REV_C

Page 37

2-9

2.3

Over the Side Mounting Option

2.4

Cables

2

EdgeTech also offers an over-the-side mounting option for the 4125 series tow vehicle. Contact EdgeTech

Customer Service for more information.

Outline drawings of the supplied cables are listed below along with their corresponding figure numbers.

x Figure 2-4: Kevlar Reinforced Tow Cable

x Figure 2-5: Kevlar Reinforced Tow Cable, Telemetry

x Figure 2-6: AC Power Cable

x Figure 2-7: DC Power Cable

x Figure 2-8: ETHERNET Cable

Page 38

4125 SIDE SCAN SONAR SYSTEM 0004823_REV_C

2-10

Figure 2-4: Kevlar Reinforced Tow Cable

Page 39

2-11

Figure 2-5: Kevlar Reinforced Tow Cable, Telemetry

Page 40

4125 SIDE SCAN SONAR SYSTEM 0004823_REV_C

2-12

Figure 2-6: AC Power Cable

Page 41

2-13

Figure 2-7: DC Power Cable

Page 42

4125 SIDE SCAN SONAR SYSTEM 0004823_REV_C

2-14

Figure 2-8: ETHERNET Cable

Page 43

3-1

SECT I ON 3 : SETU P AND A CTIV ATION

3.1

Unpacking and Inspection

3.2

Power Requirements

S

Setup and test of the EdgeTech 4125 Series Dual-frequency Side Scan Sonar System encompasses

unpacking, inspecting, and connecting the system components (including an optional printer); connecting

a navigation system if required; activating the system; and verifying operation using the EdgeTech

DISCOVER 4125 Side Scan Sonar software. This section provides instructions on how to perform these

tasks, along with how to deploy, tow, and recover the tow vehicle.

The tow vehicle is shipped in a foam-lined Pelican Storm Case. The 4125-P Portable Topside Processor is

shipped in a cardboard box with its associated cables, including the tow cable, depending on its length.

Before unpacking the system components, inspect the shipping containers for any damage. Report any

damage to the carrier and to EdgeTech.

If the shipping containers appear free of damage, carefully unpack the components and inspect them for

damage as well. Also check the packing list, verifying that all the items on the list are included. Again, if

any damage is found, report it to the carrier and to EdgeTech. If any items are missing, immediately

contact EdgeTech Customer Service. Do not install or operate any equipment that appears to be damaged.

Although the items shipped will vary, depending on the customer requirements, the 4125 Series Dualfrequency Side Scan Sonar System typically includes the items listed below.

x 4125-P Portable Topside Processor

x 4125 Tow Vehicle

x Laptop computer

x Laptop computer power supply

x 50-meter tow cable

x AC power cable

x DC power cable

x ETHERNET cable

x Software CDs

x Spares kit

After unpacking the system components, store the shipping containers, including any packing materials,

in a safe place for later use. When transporting or storing the system, pack all items in their original

shipping containers in the same manner in which they were originally shipped. Store the system in a dry

environment when not in use.

The power requirements for the 4125-P Portable Topside Processor are 90–260 VAC, 50/60 Hz or 12–24

VDC.

Page 44

3-2

3.2.1

Use of an Uninterrupted Power Supply

3.2.2

Changing a Non-US Power Plug

3.3

Navigation Interface

3.4

Placement of the 4125-P Portable Topside Processor

3

The AC power source should be continuously free of high-amplitude, high-frequency transients, as this

type of interference could cause degraded performance or damage to the equipment. An uninterruptable

power supply (UPS) with power surge protection is recommended for powering the equipment.

However, whether or not a UPS is used, never use an AC power source that also powers electric motors

on the survey vessel, such as pumps and winches. In addition, do not use switching type battery chargers

or DC to AC converters with square wave outputs.

An AC power cord is provided for connecting the Deck Unit to a standard U.S. 3-pronged outlet. For nonU.S. power outlets, modify this cord by cutting off the 3-pronged plug and attaching the appropriate plug.

Refer to Table 3-1 for connection information.

AC POWER CORD

WIRE COLOR

Black

White

Green

FUNCTION

AC line

AC neutral

Earth ground

Table 3-1: AC Power Cord Wiring

NOTE: The 4125-P Portable Topside Processor is shipped configured for

the end user’s country voltage requirements.

The 4125 Series Dual-frequency Side Scan Sonar System accepts all standard National Marine Electronics

Association (NEMA) 0183 message sentence formats from a connected global positioning system (GPS) or

integrated navigation system.

The 4125-P Portable Topside Processor can be located in a wet environment if the cover is kept closed.

Otherwise it should be located and set up in a dry, sheltered area that is protected from weather and

water spray, and where the temperature is consistently between 0°C and 40°C (32°F and 104°F). However,

avoid areas of direct sunlight, especially in tropical environments, as heat build-up could occur.

4125 SIDE SCAN SONAR SYSTEM 0004823_REV_C

Page 45

3-3

3.5

Topside Controls and Indicators

The location should also enable direct communications with the deck crew that is handling the tow

vehicle. Secure the topside processor in place, using tie downs if necessary, near the required AC power

source.

3

The 4125-P Portable Topside Processor includes controls and indicators on the side panel as shown in

Figure 3-1.

Page 46

POWER

indicator

FISH POWER

indicator

POWER

switch

5A/250V

fuse

TOWCABLE

connector

ETHERNET

connector

AC INPUT

connector

DC INPUT

connector

LINK

indicator

CM

indicator

4125 SIDE SCAN SONAR SYSTEM 0004823_REV_C

3-4

Figure 3-1: 4125-P Portable Topside Processor Side Panel

Page 47

The 4125-P Portable Topside Processor controls and indicators are the following:

3.6

4125-P Portable Topside Processor Connections

POWER Toggle switch. Turns on the 4125-P Portable Topside Processor.

(Switch)

POWER Red indicator. Illuminated when the 4125-P Portable Topside

(Indicator) Processor is on.

FISH POWER: Red indicator. Illuminated when the 4125-P Portable Topside

Processor is on and the tow vehicle is properly connected to it. The

indicator is off if no power is being drawn by the tow vehicle.

NOTE: The 4125-P Portable Topside Processor will automatically switch

off power to the tow vehicle should the processor be disconnected from

the tow vehicle for an extended period. The power will also be turned off

if an over current or under current condition exists. To reactivate the

power to the tow vehicle, turn the POWER switch off and then on again.

3-5

LINK: Green indicator. Flashes when the 4125-P Portable Topside Processor

is connected to a tow vehicle that does not include the additional

telemetry option. For a tow vehicle that does include the additional

telemetry option, the indicator flashes while a reliable

communications link with the tow vehicle is being established and

then illuminates continuously when the link is found.

CM Red indicator Flashes at 1 HZ is an undercurrent condition exist and 2

(Current Memory) HZ if an over current condition exist between the topside and tow fish.

If flashing, check the tow cable for shorts or for non-continuity on pins

1 and 2.

3

The 4125-P Portable Topside Processor connections are made using connectors on the side panel as

shown in Figure 3-1.

The 4125-P Portable Topside Processor connections are the following:

TOWCABLE: 6-pin female bulkhead connector. Connects to the tow cable.

ETHERNET: 4-pin female bulkhead connector. Provides a 10/100BaseT ETHERNET

connection to the laptop computer.

DC INPUT: 2-pin male bulkhead connector. Connects to 12–24 VDC power.

Page 48

3-6

3.7

TCP/IP Address Settings

DEVICE

TCP/IP ADDRESS

Wireless bridge

192.9.0.225

DEVICE

TCP/IP ADDRESS

CPU board

192.9.0.101

3.8

Assembling the 4125 Tow Vehicle

AC INPUT: 3-pin male bulkhead connector. Connects to 90–260 VAC, 50/60 Hz

power.

3

The 4125 Series Dual-frequency Side Scan Sonar System includes a number of ETHERNET devices

connected on a common local area network (LAN), and each of these devices has a factory set TCP/IP

address which under normal circumstances does not require changing.

However, should any of these devices be replaced, or if upgrades are later installed, it may be required

that the TCP/IP addresses be reconfigured. In addition, any computer that is to be connected to the 4125P Portable Topside Processor must have its IP address set to 192.9.0.nnn, where nnn is any integer from

1 to 100, except for the following reserved addresses:

The factory IP address setting of the wired ETHERNET connection for the laptop computer included with

the 4125-P Portable Topside Processor is 192.9.0.99, and for the wireless ETHERNET connection, the

factory setting is 192.9.0.100. For a list of the topside processor ETHERNET devices and their TCP/IP

addresses, refer to Table 3-2, and for the tow vehicle, Table 3-3.

x 192.9.0.225

x 192.9.0.101

Table 3-2: Topside Processor or ETHERNET Devices TCP/IP Addresses

Table 3-3: Tow Vehicle ETHERNET Devices IP Addresses

To assemble the tow 4125 Tow Vehicle, refer to Figure 3-2 and the following instructions:

1. Insert the four tail fins into the tail fin slots in the tail cone.

2. While holding the tow vehicle vertically with the nose down, insert the tail cone with the installed

tail fins into the tow vehicle body.

3. Install the tail fin locking bolt with the urethane washer into the tow vehicle body and securely

tighten them.

4125 SIDE SCAN SONAR SYSTEM 0004823_REV_C

Page 49

3-7

3.9

Connecting the System Components

Tail fin (4)

Tow vehicle body

Tail cone

Tail fin

locking

bolt

Urethane

washer

Shear point

4. Check that the tail fins are inserted properly, with the shear point engaging on the tow vehicle

body. When installed correctly, the fins will align at 45 degrees off the vertical and horizontal

planes.

5. Insert the line provided through the hole in each of the tail fins, stringing them together, and then

tie each end of the line to the rear carrying handle.

Figure 3-2: 4125 Tow Vehicle Tail Fins Assembly

3

Most of the system components connect to the 4125-P Portable Topside Processor. Optional components,

such as a printer, navigation system, and cable counters connect to the supplied laptop.

Page 50

3-8

3.9.1

Connecting and Attaching the Tow Cable to the Tow Vehicle

WARNING!

Do not connect the tow cable to the topside processor before connecting

it to the tow vehicle, otherwise injury or death can occur if the exposed

connector on the tow cable is energized. Always connect the tow cable to

the tow vehicle first.

When connecting the system components, refer to sub-section 3.6: 4125-P Portable Topside Processor

Connections for the location and description of the connectors. The AC Power, DC Power, and ETHERNET

cables used with the 4125-P Portable Topside Processor are shown in Figure 3-3.

Figure 3-3: AC Power, DC Power, and ETHERNET Cables

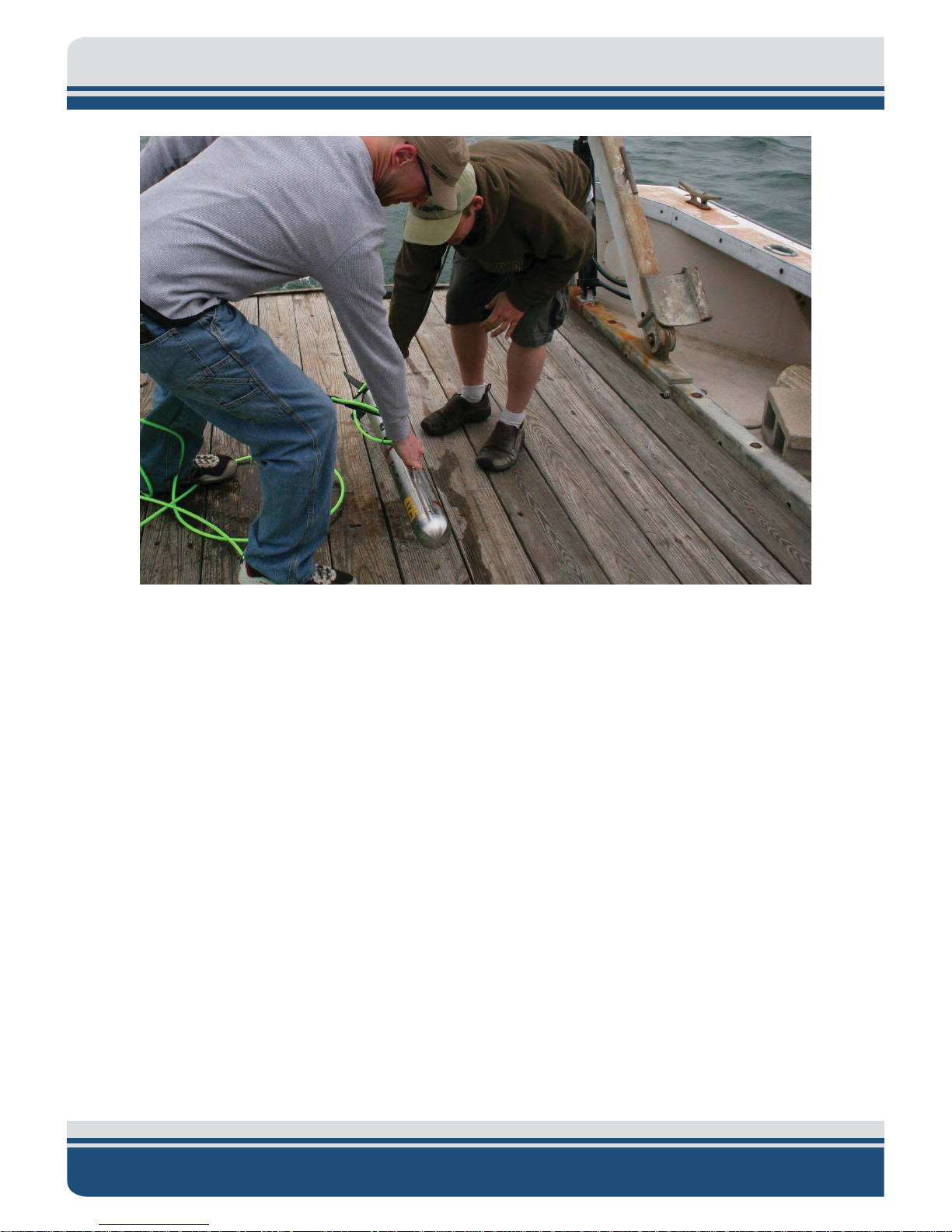

3

A tow cable is shown connected and attached to a tow vehicle in Figure 3-4.

4125 SIDE SCAN SONAR SYSTEM 0004823_REV_C

Page 51

3-9

3.9.2

Connecting the 4125-P Portable Topside Processor

Kellems grip

Tow cable

Safety cable

Tow cable

connector

Tie wraps

Waterproof

splice

Shackle

Shear pin

Figure 3-4: Tow Vehicle with Tow Cable Connected and Attached

To connect and attach the tow cable to the tow vehicle:

1. Verify that the tow cable is not connected to the 4125 Portable Topside Processor.

2. Verify that the tow cable connector on the tow vehicle and the mating female connector on the

tow cable are free of corrosion or dirt. If dirty, clean them with contact cleaner.

3. Apply a thin film of silicone grease to the pins of the tow cable connector on the tow vehicle.

4. Mate the connectors by pressing them firmly together. Do not wiggle the connectors.

5. Secure the locking sleeve.

6. Attach the loop of the Kellems grip to the shackle on the towing arm and secure the shackle bolt

with seizing wire or a tie wrap.

3

To connect the 4125-P Portable Topside Processor:

1. Verify that the 4125-P Portable Topside Processor is not connected to AC power.

2. Verify that the tow cable is properly connected and attached to the tow vehicle, and then connect

the tow cable to the TOW CABLE connector.

3. If using the wired ETHERNET connection, connect the ETHERNET cable to the ETHERNET connector

of the laptop computer. The ETHERNET cable may be extended up to 100 feet using a Category 5

ETHERNET crossover or straight patch cable.

Page 52

3-10

3.10 System Activation and Test

3.10.1 Preparing a Wired ETHERNET LAN Connection

4. Do not make this connection if the wireless ETHERNET connection will be used, as only one

ETHERNET connection can be connected or enabled at the same time.

5. If a printer will be used, connect the printer to the laptop computer through an USB ETHERNET