Page 1

EdgeTech

3300 HULL MOUNT SUB-BOTTOM PROFILER

USER HARDWARE MANUAL

0016732_REV_C 5/1/2018

i

4 Little Brook Road

West Wareham, MA 02576

Tel: (508) 291-0057

Fax: (508) 291-2491

www.EdgeTech.com

Page 2

ii

The information, figures, and specifications in this manual are proprietary and are issued in strict

confidence on condition that they not be copied, reprinted, or disclosed to a third party, either wholly or

in part, without the prior, written consent of EdgeTech. Any reproduction of EdgeTech supplied software

or file sharing is strictly prohibited.

Copyright © 2015 – 2018 EdgeTech. All rights reserved.

Microsoft® and Windows® are registered trademarks of Microsoft Corporation.

Kevlar® is a registered trademark of the DuPont Company.

Intel® and Pentium® are registered trademarks of Intel Corporation.

Novagard G624® is a trademark of Novagard Solutions, Inc.

Storm Case™ is a trademark of Pelican.

Page 3

iii

ATTENTION – READ THIS FIRST!

All personnel involved with the installation, operation, or maintenance of the equipment described in this

manual should read and understand the warnings and cautions provided below.

CAUTION! This equipment contains devices that are extremely sensitive

to static electricity. Therefore, extreme care should be taken when

handling them. Normal handling precautions involve the use of anti-static

protection materials and grounding straps for personnel.

WARNING! High Voltage may be present in all parts of the system.

Therefore, use caution when the electronics are removed from their

containers for servicing.

CAUTION! Operation with improper line voltage may cause serious

damage to the equipment. Always ensure that the proper line voltage is

used.

Page 4

iv

HARDWARE VARIATIONS AND COMPATIBILITY

The 3300 Hull Mount Sub-Bottom Profiler contains both standard and proprietary hardware. At times,

EdgeTech may change the standard components due to their availability or performance improvements.

Although the component manufacturers—along with their models and styles—may change from unit to

unit, replacement parts will generally be interchangeable.

EdgeTech will make every effort to see that replacement components are interchangeable and use the

same software drivers (if applicable). At times, however, direct replacements may not exist. When this

happens, EdgeTech will provide the necessary drivers with the replacement part, if applicable.

EdgeTech may also change certain hardware per customer requirements. Therefore, portions of this

manual, such as parts lists and test features, are subject to change. These sections should be used for

reference only. When changes are made that affect system operation, they will be explicitly noted. Also,

some options and features may not be active in the customer’s unit at time of delivery. Upgrades will be

made available when these features are implemented.

Contact

EDGETECH CUSTOMER SERVICE with any questions relating to compatibility.

Page 5

v

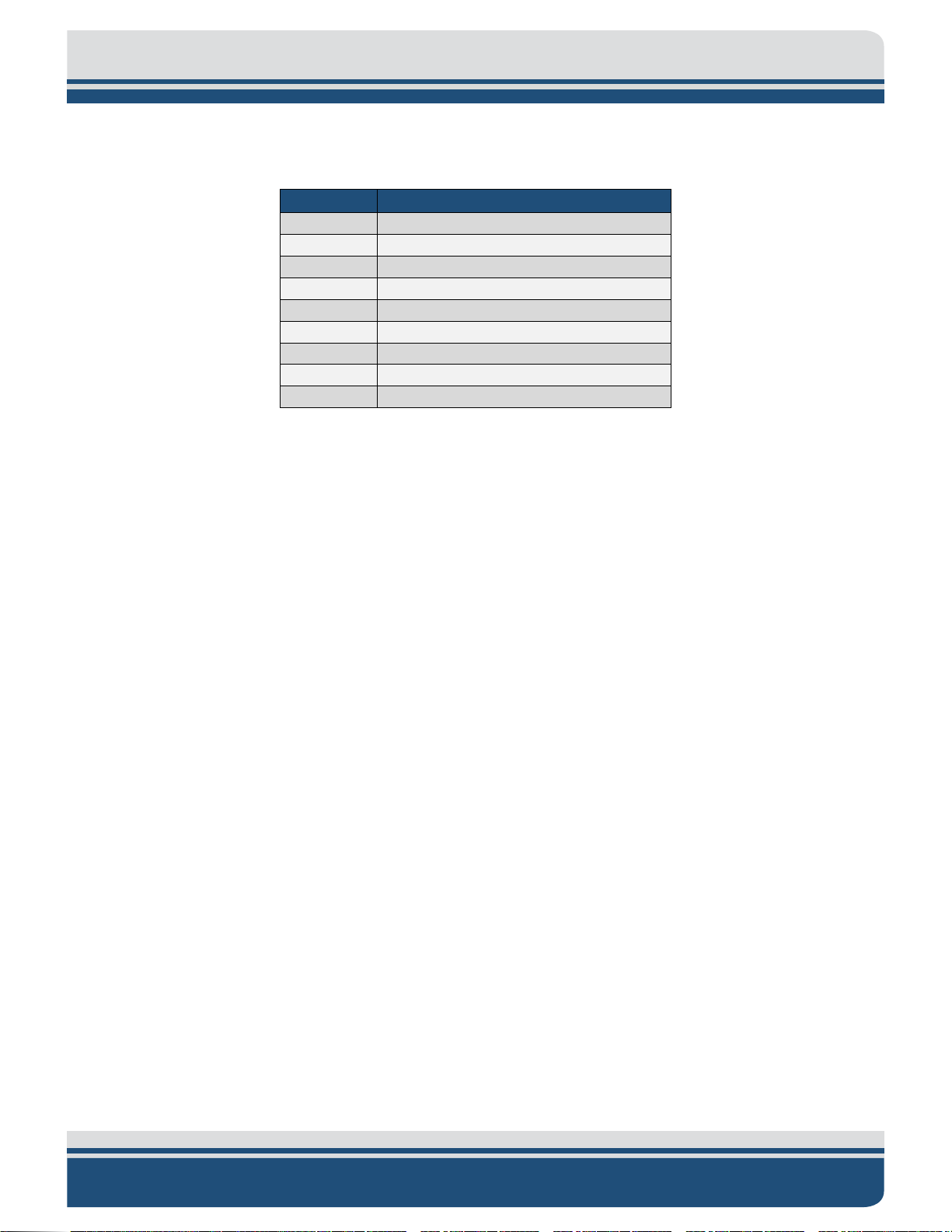

REVISION

DESCRIPTION

DATE

APPROVAL

A

Release to Production

03/09/2015

RM B Updates

08/25/2017

RM C Updates

05/01/2018

TS

ABOUT THIS DOCUMENT

We, the employees at EdgeTech, would like to thank you for purchasing 3300 Hull Mount Sub-Bottom

Profiler. At EdgeTech, it is our policy to provide high-quality, cost-effective products and support services

that meet or exceed your requirements. We also strive to deliver them on-time, and to continuously look

for ways to improve them. We take pride in the products we manufacture, and want you to be entirely

satisfied with your equipment.

Purpose of this Manual

The purpose of this manual is to provide the user with information on the setup and use of EdgeTech’s

3300 Hull Mount Sub-Bottom Profiler. Although this manual encompasses the latest operational features

of the 3300 Hull Mount Sub-Bottom Profiler, some features may be periodically upgraded. Therefore, the

information in this manual is subject to change and should be used for reference only.

Liability

EdgeTech has made every effort to document the 3300 Hull Mount Sub-Bottom Profiler in this manual

accurately and completely. However, EdgeTech assumes no liability for errors or for any damages that

result from the use of this manual or the equipment it documents. EdgeTech reserves the right to upgrade

features of this equipment, and to make changes to this manual, without notice at any time.

Warnings, Cautions, and Notes

Where applicable, warnings, cautions, and notes are provided in this manual as follows:

WARNING! Identifies a potential hazard that could cause injury or death.

CAUTION! Identifies a potential hazard that could damage equipment or

data.

NOTE: Recommendations or general information that is particular to the

material being presented.

Revision History

Page 6

vi

WARRANTY STATEMENT

All equipment manufactured by EdgeTech is warranted against defective components and workmanship

for a period of one year after shipment. Warranty repair will be done by EdgeTech free of charge.

Shipping costs are to be borne by the customer. Malfunction due to improper use is not covered in the

warranty, and EdgeTech disclaims any liability for consequential damage resulting from defects in the

performance of the equipment. No product is warranted as being fit for a particular purpose, and there is

no warranty of merchantability. This warranty applies only if:

i. The items are used solely under the operating conditions and in the manner recommended in

Seller's instruction manual, specifications, or other literature.

ii. The items have not been misused or abused in any manner, nor have repairs been attempted

thereon without the approval of EdgeTech Customer Service.

iii. Written notice of the failure within the warranty period is forwarded to Seller and the directions

received for properly identifying items returned under warranty are followed.

iv. The return notice authorizes Seller to examine and disassemble returned products to the extent

Seller deems necessary to ascertain the cause for failure.

The warranties expressed herein are exclusive. There are no other warranties, either expressed or implied,

beyond those set forth herein, and Seller does not assume any other obligation or liability in connection

with the sale or use of said products. Any product or service repaired under this warranty shall be

warranted for the remaining portion of the original warranty period only.

Equipment not manufactured by EdgeTech is supported only to the extent of the original manufacturer's

warranties.

Page 7

vii

SOFTWARE SERVICE OVERVIEW

EdgeTech provides software services free of charge. This software agreement does not address customerspecified modifications or enhancements. These services may be ordered separately. Furthermore,

EdgeTech software upgrades are meant for the sole use of EdgeTech customers. Any reproduction of

EdgeTech-supplied software or file sharing is strictly prohibited.

Software Updates and Enhancements

EdgeTech customers can download new software releases with all modifications and enhancements from

the EdgeTech ftp site. Major software issues, should they occur, will be reported directly to the customer.

New software releases consist of the following:

• Software enhancements that are not on the price list

• Software fixes and changes

• Product integration

• Documentation updates to on-line help

• Tests for compatibility with other modules

Software patches consist of software that has undergone the following:

• Minor software enhancements

• Software fixes and changes

EdgeTech customers are entitled to contact

to report a difficulty, to discuss a problem or to receive advice on the best way to perform a task. When

contacted, EdgeTech Customer Service will do the following:

• Respond within 24 hours via Telephone, Facsimile, and E-mail Support

• Immediately attend to serious problems affecting operations

• Attempt to find an immediate work-around

EDGETECH CUSTOMER SERVICE by telephone, facsimile, or e-mail

Page 8

viii

RETURNED MATERIAL AUTHORIZATION

Prior to returning any equipment to EdgeTech, a Returned Material

Authorization (RMA) Number must be obtained from CUSTOMER SERVICE.

RMA Purpose

The RMA Number identifies returned equipment when it arrives at our receiving dock and enables tracking

while at our facility. Refer to RMA number on all documentation and correspondences.

All returned materials must be shipped prepaid. Freight collect shipments will not be accepted. All

equipment should be adequately insured for shipping, but equipment belonging to EdgeTech must be

insured for full value.

If there is more than one item per consignment, include a packing with the shipment. An invoice can

double as a packing slip only when the contents are clearly numbered and identified on the invoice.

Shipper’s Oath:

"I, ______________________________, declare that the articles herein specified are the growth,

produce, or manufacture of the United States; that they were exported from the

United States from the port of _____________________, on or about _______________; that they

are returned without having been advanced in value or improved in condition by any

process of manufacture or any other means; and that no drawback, or allowance has

been paid or admitted hereof."

CAUTION! Never attempt to ship a Portable Topside in its Storm CaseTM

alone. Although rugged, these cases are not intended to be used as

shipping containers and the delicate internal components could be

damaged. Shipping in this manner will void any warranties.

NOTE: All shipping charges shall be the responsibility of the customer,

unless under warranty, as EdgeTech will pay for return shipping.

NOTE: For International Shipments valued over $1000, the following

Shipper's oath must be sent with the invoice.

Signed ______________________________

Page 9

ix

CUSTOMER SERVICE

Customer service personnel at EdgeTech are always eager to hear from users of our products. Your

feedback is welcome, and is a valuable source of information which we use to continually improve these

products. Therefore, we encourage you to contact EdgeTech Customer Service to offer any suggestions

or to request technical support:

E-mail: service@edgetech.com

Mail: 4 Little Brook Road

West Wareham, MA 02576

Telephone: (508) 291-0057

Facsimile: (508) 291-2491

24-Hour Emergency

Technical Support Line: (508) 942-8043

NOTE: Please have your system Serial Number available when contacting

Customer Service.

For more information please go to www.EdgeTech.com.

Page 10

x

COMPANY BACKGROUND

EdgeTech (formerly EG&G Marine Instruments) traces its history in Underwater Data Acquisition and

Processing back to 1966. EdgeTech has designed, developed, and manufactured products, instruments,

and systems — for the acquisition of underwater data, including marine, estuarine, and coastal

applications — for over 50 years.

EdgeTech responds to the needs of the Scientific, Naval, and Offshore communities by providing industryleading equipment — such as Sub-Bottom Profilers, Side Scan Sonar, Acoustic Releases, USBL Positioning

Systems, and Bathymetric Systems — that have become standards in the industry.

EdgeTech consistently anticipates and responds to future needs with an active Research and Development

Program. Current efforts are focused on adapting new cutting-edge acoustic technology.

Page 11

xi

TABLE OF CONTENTS

ATTENTION – READ THIS FIRST! ......................................................................................................... iii

HARDWARE VARIATIONS AND COMPATIBILITY .................................................................................. iv

ABOUT THIS DOCUMENT .................................................................................................................... v

Purpose of this Manual ............................................................................................................................. v

Liability ...................................................................................................................................................... v

Warnings, Cautions, and Notes ................................................................................................................. v

Revision History ........................................................................................................................................ v

WARRANTY STATEMENT ................................................................................................................... vi

SOFTWARE SERVICE OVERVIEW ........................................................................................................ vii

Software Updates and Enhancements.................................................................................................... vii

RETURNED MATERIAL AUTHORIZATION .......................................................................................... viii

RMA Purpose ......................................................................................................................................... viii

CUSTOMER SERVICE .......................................................................................................................... ix

COMPANY BACKGROUND .................................................................................................................. x

TABLE OF CONTENTS ......................................................................................................................... xi

LIST OF FIGURES .............................................................................................................................. xiv

LIST OF TABLES ................................................................................................................................ xv

1.0: OVERVIEW ...............................................................................................................................1-1

1.1 Advantages of Full Spectrum CHIRP Technology .......................................................................... 1-1

1.1.1 Compared to Older Technology ............................................................................................. 1-1

1.1.2 Transducer Array .................................................................................................................... 1-2

1.1.3 Resolution ............................................................................................................................... 1-2

1.1.4 Processing Enhancements ...................................................................................................... 1-2

1.1.5 Reduction of Side Lobes and High Repeatability .................................................................... 1-3

1.2 Major Components ....................................................................................................................... 1-3

1.2.1 Deck Unit ................................................................................................................................ 1-5

1.2.2 T/R Box Assembly ................................................................................................................... 1-6

1.2.3 Transducer Array .................................................................................................................... 1-7

1.3 Applications .................................................................................................................................. 1-8

2.0: SPECIFICATIONS .......................................................................................................................2-1

2.1 Deck Unit Specifications................................................................................................................ 2-1

Page 12

xii

2.1.1 Processor Specifications ......................................................................................................... 2-1

2.1.2 Amplifier Specifications .......................................................................................................... 2-2

2.1.2.1 Power Output ............................................................................................................. 2-3

2.1.2.2 Performance ............................................................................................................... 2-3

2.1.2.3 Construction ............................................................................................................... 2-4

2.1.3 Display, Keyboard, and Mouse Specifications ........................................................................ 2-4

2.2 T/R Box Specifications ................................................................................................................... 2-4

2.3 Technical Drawings ....................................................................................................................... 2-4

2.4 Spider & Array Specifications ........................................................................................................ 2-7

2.5 Technical Drawings ....................................................................................................................... 2-7

KT-216H Specifications: ..................................................................................................................... 2-9

KT-106D Specifications:...................................................................................................................... 2-9

2.5.1 Array Sizes ............................................................................................................................ 2-11

2.6 Signal Cable Specifications .......................................................................................................... 2-18

3.0: CONTROLS & CONNECTIONS .....................................................................................................3-1

3.1 Deck Unit Controls and Indicators ................................................................................................ 3-1

3.2 Deck Unit Connections .................................................................................................................. 3-3

4.0: INSTALLATION ..........................................................................................................................4-1

4.1 Unpacking & Inspecting ................................................................................................................ 4-1

4.2 Topside Installation ....................................................................................................................... 4-2

4.2.1 Power Supply .......................................................................................................................... 4-2

4.2.2 Use of an Uninterruptable Power Supply............................................................................... 4-2

4.2.3 Selecting the Power Amplifier Input Power Voltage .............................................................. 4-2

4.2.4 Changing to a Non-US Power Plug ......................................................................................... 4-2

4.2.5 Navigation Interface ............................................................................................................... 4-3

4.2.6 Deck Unit Placement .............................................................................................................. 4-3

4.3 Hull Mount Array Installation ....................................................................................................... 4-3

4.4 Connecting the System ................................................................................................................. 4-5

5.0: OPERATION ..............................................................................................................................5-1

5.1 Activating the System ................................................................................................................... 5-1

5.2 File Format .................................................................................................................................... 5-1

5.2.1 EdgeTech’s Native JSF Format ................................................................................................ 5-1

Page 13

xiii

5.2.2 Standard SEG-Y Format .......................................................................................................... 5-1

5.2.3 Palette File Format ................................................................................................................. 5-2

5.3 Triggering and Coupling ................................................................................................................ 5-2

6.0: MAINTENANCE .........................................................................................................................6-1

6.1 Hard Drive Disk ............................................................................................................................. 6-1

6.2 Array Connectors .......................................................................................................................... 6-1

7.0: TROUBLESHOOTING .................................................................................................................7-1

7.1 Freq. Plots and Raw Data Time Series Analysis Using J-STAR ....................................................... 7-1

7.2 System Does Not Operate ............................................................................................................. 7-4

7.2.1 Symptom / Probable Cause .................................................................................................... 7-5

7.2.2 Poor Image Quality or Performance Issues ............................................................................ 7-6

7.3 Sonar Errors .................................................................................................................................. 7-6

A.0: SYSTEM RESTORE .................................................................................................................... A-1

B.0: FAQ: FREQUENTLY ASKED QUESTIONS ..................................................................................... B-1

C.0: NAVIGATION SYSTEMS ............................................................................................................ C-1

C.1 NMEA Approved Sentence Structure ........................................................................................... C-1

C.2 Port Parameters ............................................................................................................................ C-1

C.3 Port Selection ................................................................................................................................ C-2

C.4 Inputs ............................................................................................................................................ C-2

GLL – Geographic Position – Latitude/Longitude ................................................................... C-3

GXY Geographic Position X and Y Coordinates ....................................................................... C-3

GUU – Geographic Position – X and Y Coordinates ................................................................ C-4

GGA – Global Positioning System Fix Data ............................................................................. C-4

RMA – Recommended Minimum Specific Loran-C Data ........................................................ C-5

RMC – Recommended Minimum Specific GNSS Data ............................................................ C-5

VTG – Track Made Good and Ground Speed.......................................................................... C-5

ZDA – Time & Date ................................................................................................................. C-6

HDG - Heading, Deviation and Variation ................................................................................ C-6

EVT – Event * Annotation (EdgeTech Custom) ...................................................................... C-7

EMA: Event, Set Mark & Annotation (EdgeTech Custom) ...................................................... C-8

C.5 Serial Port Connections ................................................................................................................. C-9

C.6 Troubleshooting ............................................................................................................................ C-9

Page 14

xiv

LIST OF FIGURES

Figure 1-1: Overall System Diagram (2x2 Configuration) .......................................................................... 1-4

Figure 1-2: 3200 Rack Mount Processor .................................................................................................... 1-5

Figure 1-3: T/R Box (Interior & Exterior) .................................................................................................... 1-6

Figure 1-4: Spider Array ............................................................................................................................. 1-7

Figure 1-5: Single Transducer..................................................................................................................... 1-7

Figure 1-6: 2x2 Sea Chest Array ................................................................................................................. 1-7

Figure 2-1: Topside Processor Internals ..................................................................................................... 2-2

Figure 2-2: T/R Box Assembly Drawing - 0007914 ..................................................................................... 2-5

Figure 2-3: T/R Box Wiring Diagram - 0004638 ......................................................................................... 2-6

Figure 2-4: Spider Wiring Diagram - 0009969 ............................................................................................ 2-8

Figure 2-5 : KT-106 Non-Symmetrical Array Configurations .................................................................... 2-10

Figure 2-6: Deck Cable, T/R Box, and Spider Wiring Diagram (2x2 Configuration) ................................. 2-12

Figure 2-7: Single Transducer Drawing - 0013579 ................................................................................... 2-13

Figure 2-8: 2x2 Transducer Configuration - 0011720 .............................................................................. 2-14

Figure 2-9: 3x3 Transducer Configuration - 0015753 .............................................................................. 2-15

Figure 2-10: 4x4 Transducer Configuration - 0013960 ............................................................................ 2-16

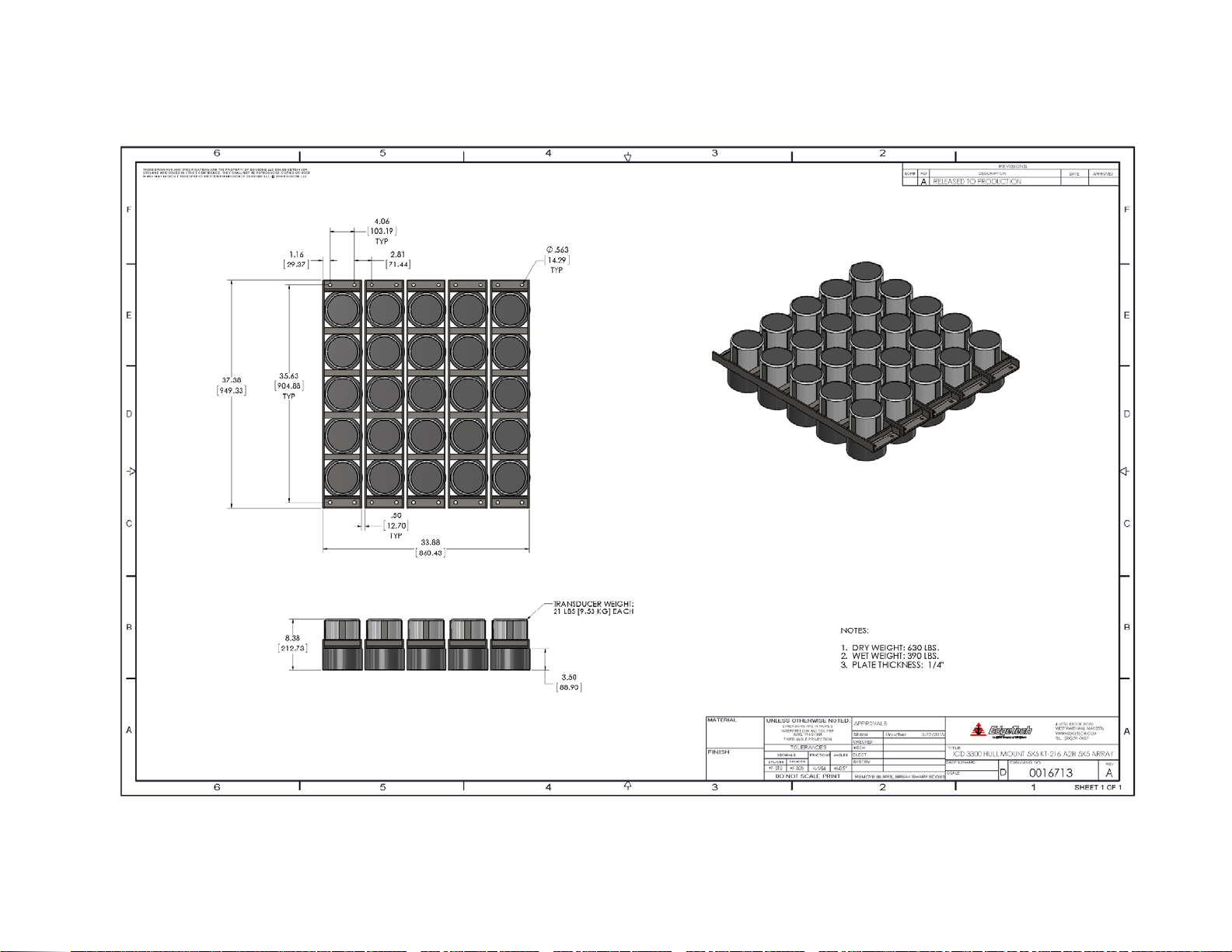

Figure 2-11: 5x5 Transducer Configuration - 0016713 ............................................................................ 2-17

Figure 2-12: Topside Unit Deck Cable for Hull Mount Systems (Female) Amphenol #97-3106A-20-33F2-18

Figure 2-13: Female Marshal Connector – 86-5FC (Deck Cable to T/R Box Connection) ........................ 2-19

Figure 2-14: Male Marshal Connector – 86-5MC (T/R Box to Deck Cable Connection) .......................... 2-19

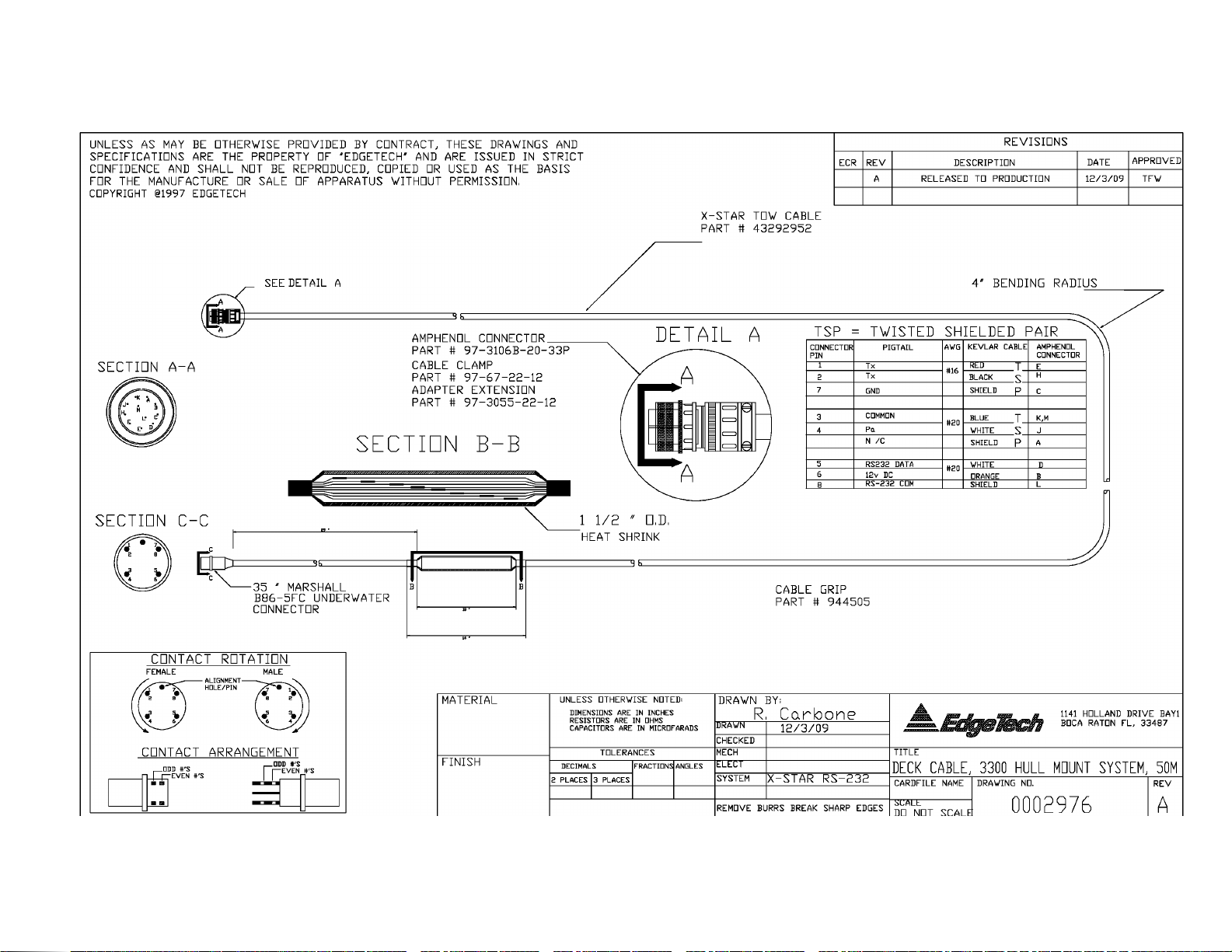

Figure 2-15: Deck Cable Schematic - 0002976 ......................................................................................... 2-20

Figure 3-1: Topside Front Panel Controls and Connections....................................................................... 3-2

Figure 3-2: Topside Rear Panel Controls and Connections ........................................................................ 3-4

Figure 3-3: Rear Panel Schematic - 0004957 ............................................................................................. 3-5

Figure 7-1: Graph Display Tab .................................................................................................................... 7-2

Page 15

xv

LIST OF TABLES

Table 2-1: Overall Physical Deck Unit Specs .............................................................................................. 2-1

Table 2-2: Processor Specifications ........................................................................................................... 2-1

Table 2-3: Power Amp Specifications: Power Output ................................................................................ 2-3

Table 2-4: Power Amp Specifications: Performance ................................................................................. 2-3

Table 2-5: Power Amp Specifications: Construction .................................................................................. 2-4

Table 2-6: Display, Keyboard, and Mouse Specifications .......................................................................... 2-4

Table 2-7: Physical Specifications of T/R Box ............................................................................................. 2-4

Table 2-8: General Array Specifications ..................................................................................................... 2-7

Table 2-9: KT-216A2H Array Specifications................................................................................................ 2-9

Table 2-10: KT-106D Array ......................................................................................................................... 2-9

Table 2-11: Array Size vs. Expected Signal-to-Noise Ratio (SNR) ............................................................. 2-11

Table 2-12: Signal Cable Specifications .................................................................................................... 2-18

Table 2-13: Deck Cable Pinouts................................................................................................................ 2-18

Table 2-15: Deck CABLE Connector Pinouts............................................................................................. 2-19

Table 4-1: AC Power Cord Wiring .............................................................................................................. 4-2

Table 7-1: Troubleshooting Causes and Solutions ..................................................................................... 7-5

Table 7-2: Image Quality or Performance Issues ....................................................................................... 7-6

Table 7-3: Troubleshooting Sonar Errors ................................................................................................... 7-6

Table C-1: NMEA Approved Sentence Structure ....................................................................................... C-1

Table C-2: Port Parameters ........................................................................................................................ C-1

Table C-3: GLL Geographic Position – Latitude/Longitude ........................................................................ C-3

Table C-4: GXY Geographic Position X and Y Coordinates ......................................................................... C-3

Table C-5: GUU – Geographic Position – X and Y Coordinates .................................................................. C-4

Table C-6: GGA – Global Positioning System Fix Data ............................................................................... C-4

Table C-7: VTG – Track Made Good and Ground Speed ............................................................................ C-5

Table C-8: ZDA – Time and Date ................................................................................................................ C-6

Table C-9: HDG: Heading, Deviation, and Variation .................................................................................. C-6

Table C-10: EVT – Event * Annotation (EdgeTech Custom) ....................................................................... C-7

Table C-11: EMA: Event, Set Mark & Annotation ...................................................................................... C-8

Table C-12: 9 Male Pin Out ........................................................................................................................ C-9

Page 16

Page 17

1-1

1.0: OVERVIEW

The 3300 Hull Mounted Sub-Bottom Profiler (3300-HM SBP) Full Spectrum Sonar is a versatile, wideband,

FM sub-bottom profiler that generates cross-sectional images of the seabed and collects digital normal

incidence reflection data over a wide variety of frequency ranges.

The system transmits an FM pulse that is linearly swept over a full spectrum frequency range (also called

a “CHIRP pulse”). The reflections, measured by the system, are displayed as shades of gray or color on a

computer monitor. Data is stored real-time into a large capacity hard drive, and can be archived to a

CD/DVD ROM or thumb drive.

1.1 Advantages of Full Spectrum CHIRP Technology

EdgeTech’s Full Spectrum Technology has several distinct advantages over conventional sub-bottom

systems, including increased penetration and higher resolution. The tapered wave form spectrum results

in images that have virtually constant resolution with depth.

The 3300-HM SBP system generates virtually no side lobes, due to the wide bandwidth of the sweep

frequency. This bandwidth has an effect of smearing the side lobes of the transducer, resulting in a beam

pattern with almost no side lobes.

Because the FM pulse is generated by a digital-to-analog converter with a wide dynamic range and a

transmitter with linear components, the energy, amplitude, and phase characteristics of the acoustic

pulse can be precisely controlled. This precision produces the high repeatability and signal definition

required for sediment classification.

The operating frequency range is determined by the acoustic characteristics and mounting schematic of

the transducers. EdgeTech offers various transducer configurations that can transmit acoustic pulses with

different center frequencies and bandwidths. Pulse selection is made by the operator while profiling to

achieve the best imagery.

For detailed information regarding configuration options, contact

EDGETECH CUSTOMER SERVICE.

1.1.1 Compared to Older Technology

EdgeTech’s 3300-HM SBP Full Spectrum sonar system transmits FM pulses. FM pulses have been used in

radar and sonar systems for over 40 years and are sometimes referred to as CHIRP or Swept-frequency

pulses. The advent of modern digital signal processing components has provided tools for realizing the

potential of these methods.

Full Spectrum signal processing technology does not use a conventional matched filter (the typical

correlation filter used to compress FM signals) to process wide band signals. It uses proprietary amplitude

and phase weighting functions for the transmitted pulse and a pulse compression filter that maximizes

the Signal-to-Noise Ratio (SNR) of the acoustic images over a wide band of operating frequencies. These

Page 18

1.0: OVERVIEW 1-2

functions provide a significant SNR improvement in the acoustic image over other impulse and CHIRP

sonar with band-limited components that are limited in dynamic range.

1.1.2 Transducer Array

Acoustic projectors in the 3300-HM SBP system are constructed from wideband, piston-type transducers

and the acoustic receivers are a discrete line array of PZT crystals. The acoustic hull-mounted transducers

are designed for profiling at ship speeds varying from zero (drifting) to 7 knots.

The transducer array receives the low amplitude sub-bottom reflections, while a 24-dB gain preamplifier

amplifies and drives the signal through a 50-meter cable. A software-controlled, programmable gain

amplifier provides a final amplification stage before the signal is digitized with a 16-bit Analog-to-Digital

(A/D) converter at a sampling rate of 24, 40, 50, and 66 kHz. To achieve the theoretical temporal resolution

predicted by the inverse of the bandwidth, the FM pulse is compressed using a digital compression filter.

The correlation process is implemented in real-time, with forward and inverse Fast Fourier Transforms.

The compressed pulse resulting from this signal processing procedure has a time duration approximately

equal to the inverse of the bandwidth of the FM pulse.

1.1.3 Resolution

High temporal resolution allows for the measurement of fine layering. Good resolution is an important

factor in sediment classification, as it provides a more precise impulse response of the sediment, and, in

turn, a realistic picture of the true geologic variability of the seafloor and accurate determination of the

depositional processes. When the time duration of the processed pulse is too large, individual reflections

will be lumped together with random phase causing constructive and destructive interference, thereby

making it difficult to estimate the impedance and examine the geologic processes.

1.1.4 Processing Enhancements

In addition to the resolution improvement, correlation processing achieves a signal processing gain over

the background noise. This gain is approximately ten times the log of the time-bandwidth product. This

improvement is due to the signal having a time duration longer than the inverse of the bandwidth, thus

increasing signal energy without increasing the power of the outgoing pulse. To equal the typical

performance of the Full Spectrum sonar pulse, conventional pulse sonar would have to operate at a peak

pulse power of 100 times greater than the Full Spectrum pulse with a time-bandwidth product of 100.

Another important feature of the Full Spectrum Sub-Bottom Sonar is that the computer generates a signal

that optimizes the performance of the system. The sonar contains many components, each with a unique

dynamic range and linearity characteristic, which are frequency dependent.

In addition to this, the amplitude spectrum of the outgoing pulse is chosen to be approximately Gaussian

in shape in order to limit the side lobe level and temporal resolution losses due to attenuation. As a

wavelet with a Gaussian-shaped spectrum is attenuated by the sediment, energy is lost but its bandwidth

Page 19

1-3

is nearly preserved. Thus, even after being attenuated by sand, the acoustic pulse has approximately the

same resolution as an un-attenuated pulse.

1.1.5 Reduction of Side Lobes and High Repeatability

Full Spectrum sonar has the unique ability to reduce side lobes in the effective transducer aperture. The

wide bandwidth of the sweep frequency has the effect of smearing the side lobes of the transducer and

thus achieving a beam pattern with virtually no side lobes. The effective spatial beam width obtained after

processing the 2-10 kHz signal is 20 degrees measured to -3db points.

Since the transmitted Full Spectrum pulse is highly repeatable, and its peak amplitude is precisely known,

the sediment reflectivity values can be estimated from the peak pulse amplitude measurements of the

bottom returns.

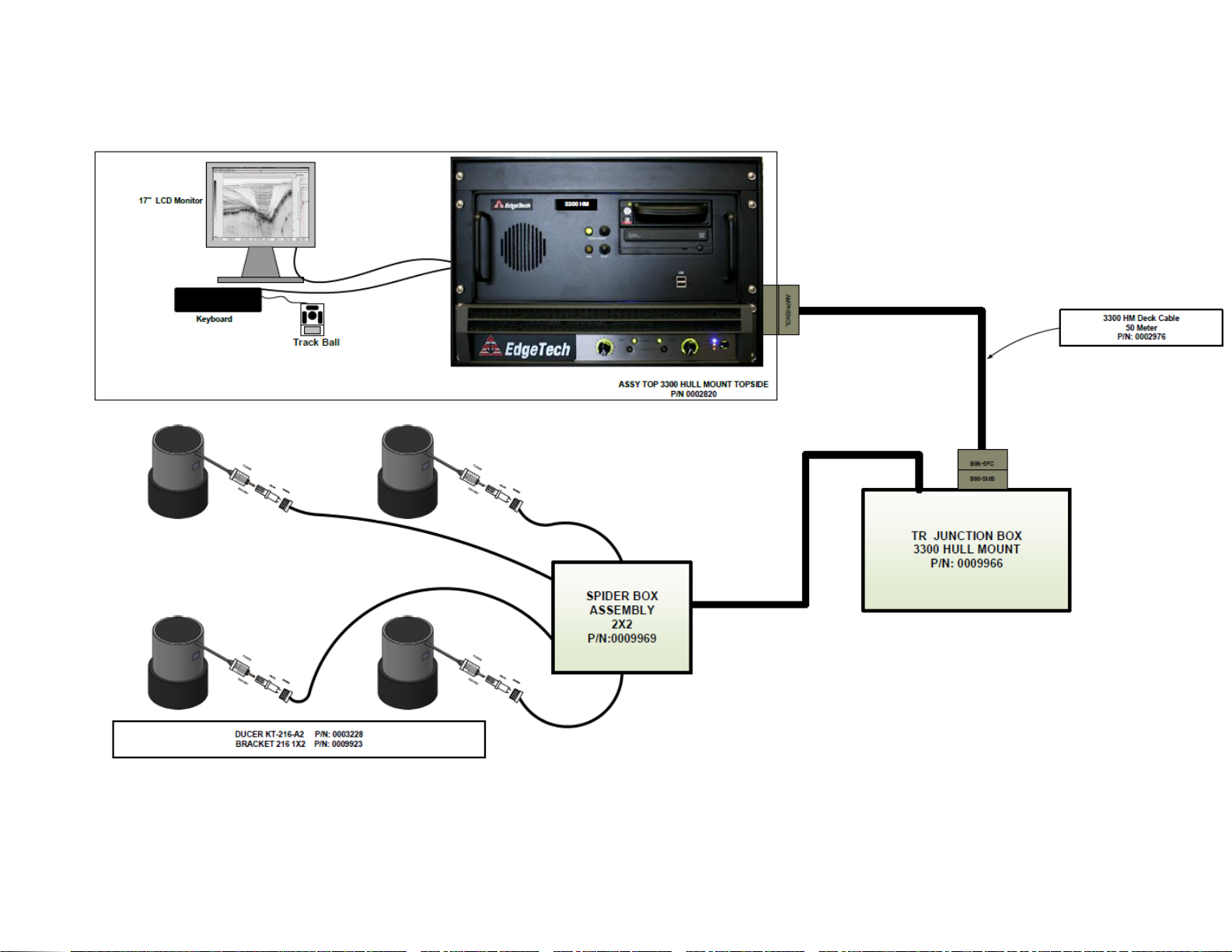

1.2 Major Components

The hull mounted configuration consists of the topside unit, deck cable, T-R box, spider box assembly, and

the transducer arrays (see an example of a 2x2 system configuration is shown in

FIGURE 1-1.

Page 20

1.0: OVERVIEW 1-4

Figure 1-1: Overall System Diagram (2x2 Configuration)

Page 21

1.2.1 Deck Unit

LCD Monitor

19-inch Rack

Power Amplifier

DISCOVER Software

Keyboard

Trackball

3200-XS Topside Processor

1-5

The Deck Unit consists of a processor, amplifier, and monitor as shown in

Mount enclosure consists of a computer-based controller containing a Sonar Interface Board (SIB). The

SIB stores the transmitted waveform and the correlation filter, and performs the correlation processing

and spherical range correction. At periodic intervals, the SIB sends the transmitted waveform to the 16bit digital-to-analog converter, which generates an analog pilot signal that is amplified by a 2 kW power

amplifier. This amplifier drives the transducer.

The acoustic signal returns from the seafloor are measured by the receiving arrays, and are then increased

by a preamplifier. The output of the preamplifier is connected via the underwater signal cable to a

digitally-controlled amplifier on the sub-bottom board (mounted on the SIB) before being sampled by a

16-bit analog-to-digital converter. The SIB board performs the correlation processing, corrects for

spherical spreading, and transfers the data to the system board.

Figure 1-2: 3200 Rack Mount Processor

FIGURE 1-2. The 19-inch Tack

Page 22

1.0: OVERVIEW 1-6

Connect to array T/R Box

The DISCOVER Sub-Bottom software is supported on Windows 7 OS. The data and control connections to

the DISCOVER Sub-Bottom program are entirely through TCP/IP connections.

EdgeTech’s Full Spectrum sonar systems employ advanced CHIRP technology to obtain high resolution,

low-noise data records. EdgeTech’s advanced CHIRP technology employs long-duration, wide-band,

frequency-modulated transmit pulses. Return sonar echo data is processed to remove the FM carrier, and

produce high-resolution images of the echo field. DISCOVER Sub-Bottom allows monitoring of this normal,

de-CHIRPed, sub-bottom data, as well as raw, CHIRPed data. This latter data type is often useful for

diagnostic purposes.

For compatibility with other EdgeTech products, the DISCOVER Sub-Bottom program interfaces to a

second program that is run in the background called sonar.exe. Sonar.exe interfaces with both the SIB and

the analog interface boards to generate and transmit CHIRP pulses. A startup file launches the sonar.exe

program automatically every time the system is booted.

The 3300-HM SBP interfaces with the ship’s Navigation (GPS, IMU, etc), triggers, motion and heave

sensors, echo sounder, and printers.

The 3300-HM SBP’s computer-based controller and amplifier components are mounted in a rugged

Optima Case. The computer-based controller and amplifier can be removed from Optima case and

installed in a 19-inch rack.

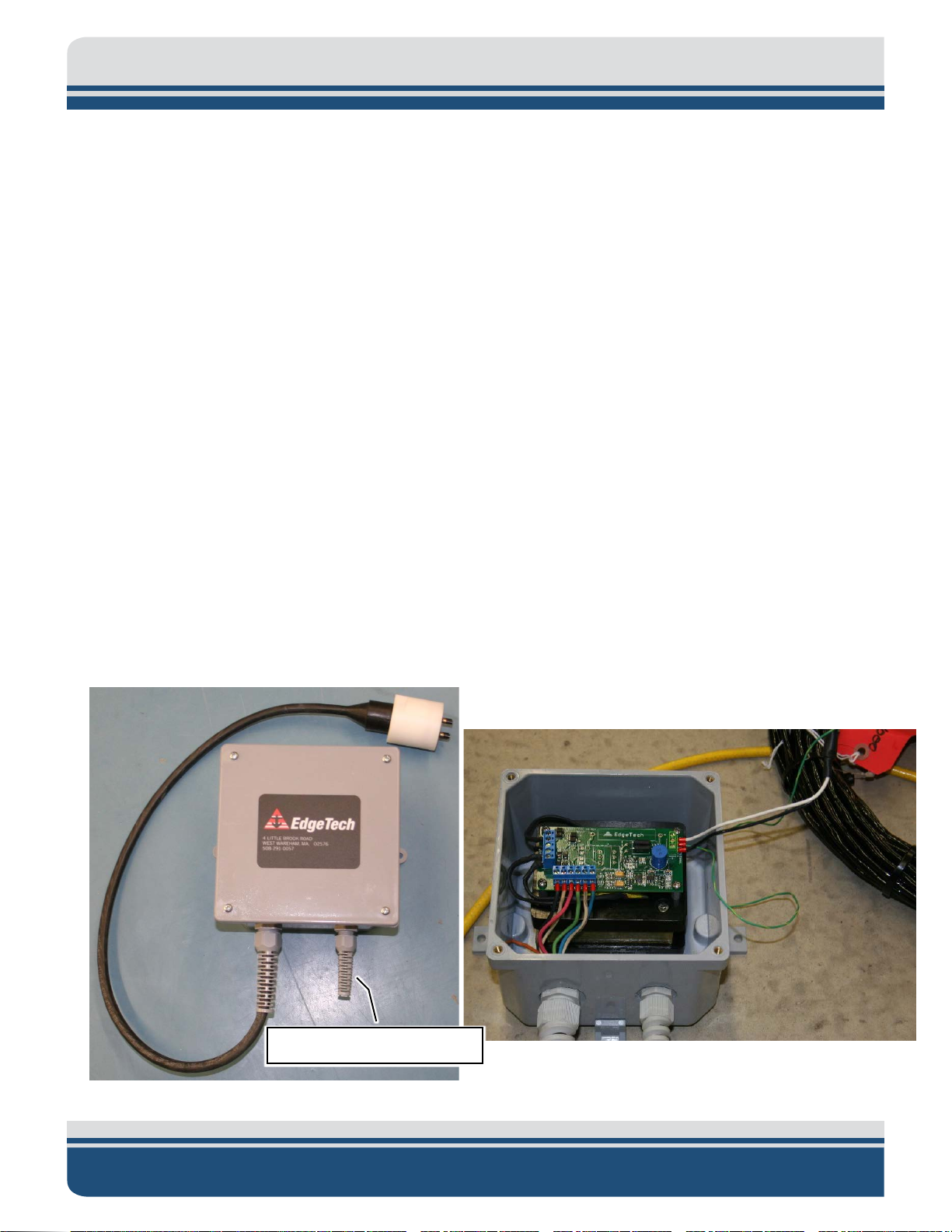

1.2.2 T/R Box Assembly

The T/R Box connects the topside to the transducers array. It contains a pre-amp, a matching transformer,

and the T/R switch. See

FIGURE 1-3 below:

3300 HULL MOUNT SUB-BOTTOM PROFILER 0016732_REV_C

Figure 1-3: T/R Box (Interior & Exterior)

Page 23

1-7

1.2.3 Transducer Array

The transducers for the 3300-HM SBP are mounted in a two-dimensional array inside a closed well on

board a survey vessel. These transducers act as both projectors and hydrophones.

EdgeTech offers a range of transducer arrays, each designed to provide various beam widths. In general,

lower operating frequencies require multiple receiving arrays and larger transducers, therefore requiring

different array sizes.

Figure 1-4: Spider Array

Figure 1-6: 2x2 Sea Chest Array

Figure 1-5: Single Transducer

Page 24

1.0: OVERVIEW 1-8

NOTE: Each transducer is fitted with an 81 cm (32 in.) pigtail with a single

pin (2 contacts) connectors. All Transducer Cables connect to a T/R Box.

1.3 Applications

The 3300-HM SBP has the unique ability to strip-away the world’s oceans during imaging and provide high

resolution sub-bottom images.

This tool lends itself to various tasks that include:

• Imaging fluidized mud to a resolution of 8 cm

• Sediment classification

• Buried pipeline and cable location and routing

• Dredging studies for inlets

• Scour/erosion surveys in rivers and streams

• Marine geotechnical surveys

• Bridge erosion surveys

• Hazardous waste target location

• Geological surveys

• Archeological surveys

• Imaging biologics in water column

• Mapping shellfish populations

• Beach re-nourishment

• Military and Offshore Oil applications

• Full ocean depth sub-bottom imaging

3300 HULL MOUNT SUB-BOTTOM PROFILER 0016732_REV_C

Page 25

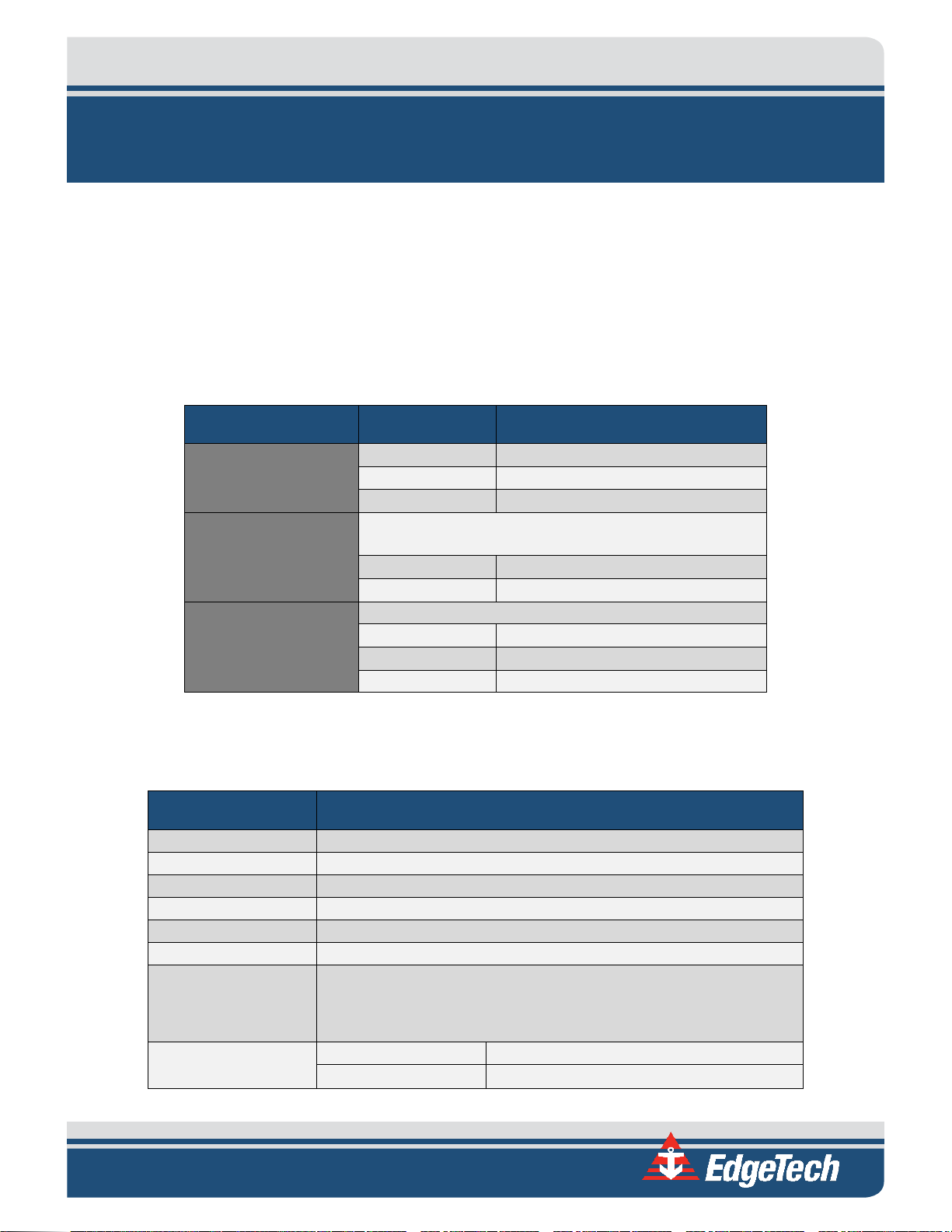

2-1

Temperature

0 to 40°C (32 to 104°F)

Portable aluminum case suitable for transit. Unit can be

Size

50W x 60D x 33H cm (19.5x23.5x13 in)

Weight

46 kg (102 lbs.)

Size

76L x 71W x 50H cm (30x28x20 in)

Weight

82 kg (330 lbs.)

Material

Sealed high impact polyurethane case

Main Processor

Intel I7 Quad Core 3.4GHz 8MB Cache

Memory

8GB DDR4 RAM

Hard drive

500GB capacity minimum (operating system)

CDRW

10x4x32 min speed

Operating System

Windows 7 64 bit

Input Power

120 or 220 VAC auto sense

Front Panel: (2) USB2

(4) port RS-232

Analog Input

16-bit resolution, 200 kHz max. sampling rate

Analog Output

16-bit resolution, 200 kHz max. sampling rate

2.0: SPECIFICATIONS

The 3300-HM SBP system is composed of a deck unit, T/R Box, and hull-mounted transducer array. This

section details the sub-components of the system and provides their specifications. For information

related to the provided DISCOVER software, refer to 0019800 in the Manual Folder.

2.1 Deck Unit Specifications

The Deck Unit is composed of a computer processor, trackball, keyboard, LCD monitor, and a power

amplifier, as shown in

2-1, and the minimum specifications for the individual parts are given in the sub-sections that follow.

SPEC TYPE SPECIFICATION VALUE

FIGURE 1-2. The physical specifications for the entire deck unit are provided in TABLE

Environment

Enclosure

Shipping Containers

Humidity 5% to 95% relative

Vibration Normal ship environment

removed from case and mounted in a 19” rack.

Deck Unit (No topside Processor)

Table 2-1: Overall Physical Deck Unit Specs

2.1.1 Processor Specifications

SPECIFICATION VALUE

I/O

Data Acquisition

SIB & A/D-D/A

Rear Panel: (2) USB2 (2) USB3.1

(2) USB3 (2) Ethernet

Table 2-2: Processor Specifications

Page 26

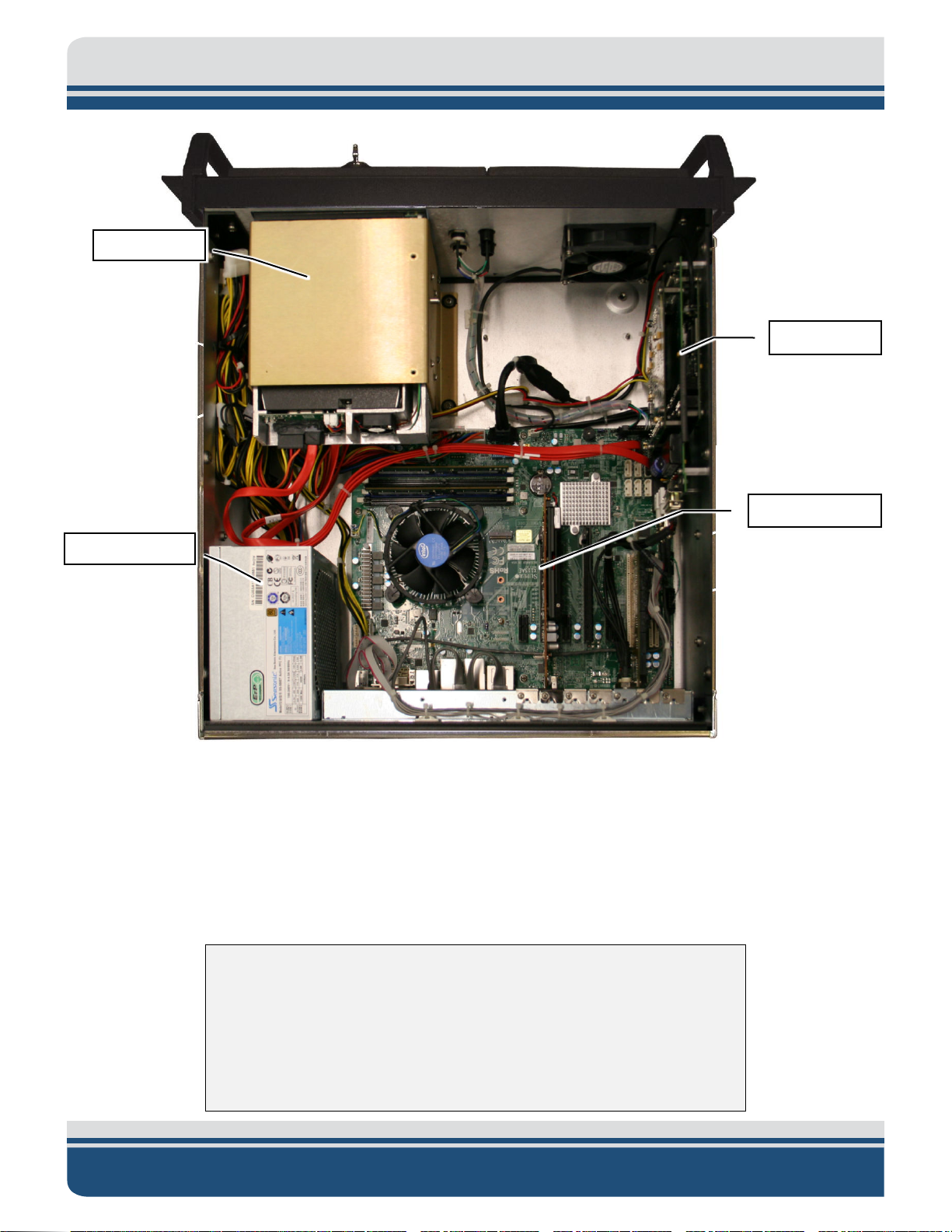

2.0: SPECIFICATIONS 2-2

Tiger Board

Mother Board

Power Supply

Hard Drive

Figure 2-1: Topside Processor Internals

2.1.2 Amplifier Specifications

The amplifier is designed for mounting in standard 19-inch Computer Rack. The power amplifier must stay

close to the topside processor due to the short cables connecting the two units. The amplifier requires at

least 10 cm (4 in.) of clearance behind the heat sink array to permit vertical air flow through the array. In

the rack mount, ensure the environmental operating temperature does not exceed 55°C (131°F).

CAUTION!

Inadequate ventilation can cause overheating. Should this occur, the

thermal protection circuit automatically protects the amplifier. If this

occurs, the system will stop transmitting and DISCOVER will display a

‘HOT’ error message. When a safe operating temperature is restored, the

amplifier will resume normal operation.

3300 HULL MOUNT SUB-BOTTOM PROFILER 0016732_REV_C

Page 27

2-3

4-ohm Bridge

5,600 W

8-ohm Bridge

6,000 W

Frequency Response (at 1 watt, 20 Hz – 20 kHz into

Signal to Noise Ratio

Total Harmonic Distortion (THD) (at 1 watt into 8

THD plus Noise (at full rated power)

< 0.35%, 20 Hz to 20 kHz

Intermodulation Distortion (60 Hz and 7kHz at 4:1,

Damping Factor (20 Hz to 100 Hz at 8 ohms)

> 5000

Crosstalk (below rated power, 20 Hz to 1 kHz)

> 80 dB

Common Mode Rejection (20 Hz to 1 kHz)

> 55 dB, typically > 70 dB

DC Output Offset (Shorted input)

< ± 3 mV

Input Impedance (Nominal)

10 kilohms balanced, 5 kilohms unbalanced

Maximum Input Level

+20 dBu typical

Stereo: 1/2/4/8/16 ohms Bridge

Input Sensitivity (Referenced to 8 ohm rated output)

1.4V, 32 dB gain, and 26 dB gain

Voltage Gain (Referenced to 8 ohm rated output)

37.9 dB to 23.0 dB

Universal AC input, 100-240VAC, 50/60 Hz (±10%).

The specifications for the Power Amplifier (PN 0010855) are shown in TABLE 2-3, TABLE 2-4, and TABLE 2-5.

2.1.2.1 Power Output

SPECIFICATION VALUE

Table 2-3: Power Amp Specifications: Power Output

2.1.2.2 Performance

SPECIFICATION VALUE

8 ohms)

(below rated full bandwidth power, A-weighted)

ohms)

from full rated output to -30 dB)

± 0.25 dB

> 108 dB

< 0.1%

< 0.35%

Load Impedance (Safe with All Types of Loads)

Required AC Mains

Table 2-4: Power Amp Specifications: Performance

Mono: 2/4/8 ohms

Maximum AC mains voltage 264VAC.

Page 28

2.0: SPECIFICATIONS 2-4

Cooling

Dual-zone, microprocessor controlled, continuously variable speed fans, front-to-back airflow

Front Panel

Cast aluminum with integrated handles

Weight

28 pounds (12.7 kg) net, 36 pounds (16.3 kg) shipping.

Dimensions

19 in. (48.3 cm) W x 3.5 in. (8.9 cm) H x 16.2 in. (41.1 cm) D.

Amplifier is protected against reactive loads, faults and shorts. If one channel experiences a

catastrophic failure, the entire amplifier will shut down.

SPECIFICATION

VALUE

Video Display

One High resolution 17” flat panel monitor

Keyboard

High impact industrial keyboard

Trackball

High impact industrial trackball

SPECIFICATION

VALUE

Dimensions (WxDxH):

18 cm x 18 cm x 12 cm

2.1.2.3 Construction

SPECIFICATION VALUE

Protection

Table 2-5: Power Amp Specifications: Construction

2.1.3 Display, Keyboard, and Mouse Specifications

Table 2-6: Display, Keyboard, and Mouse Specifications

2.2 T/R Box Specifications

Weight: 1.8 kg

Table 2-7: Physical Specifications of T/R Box

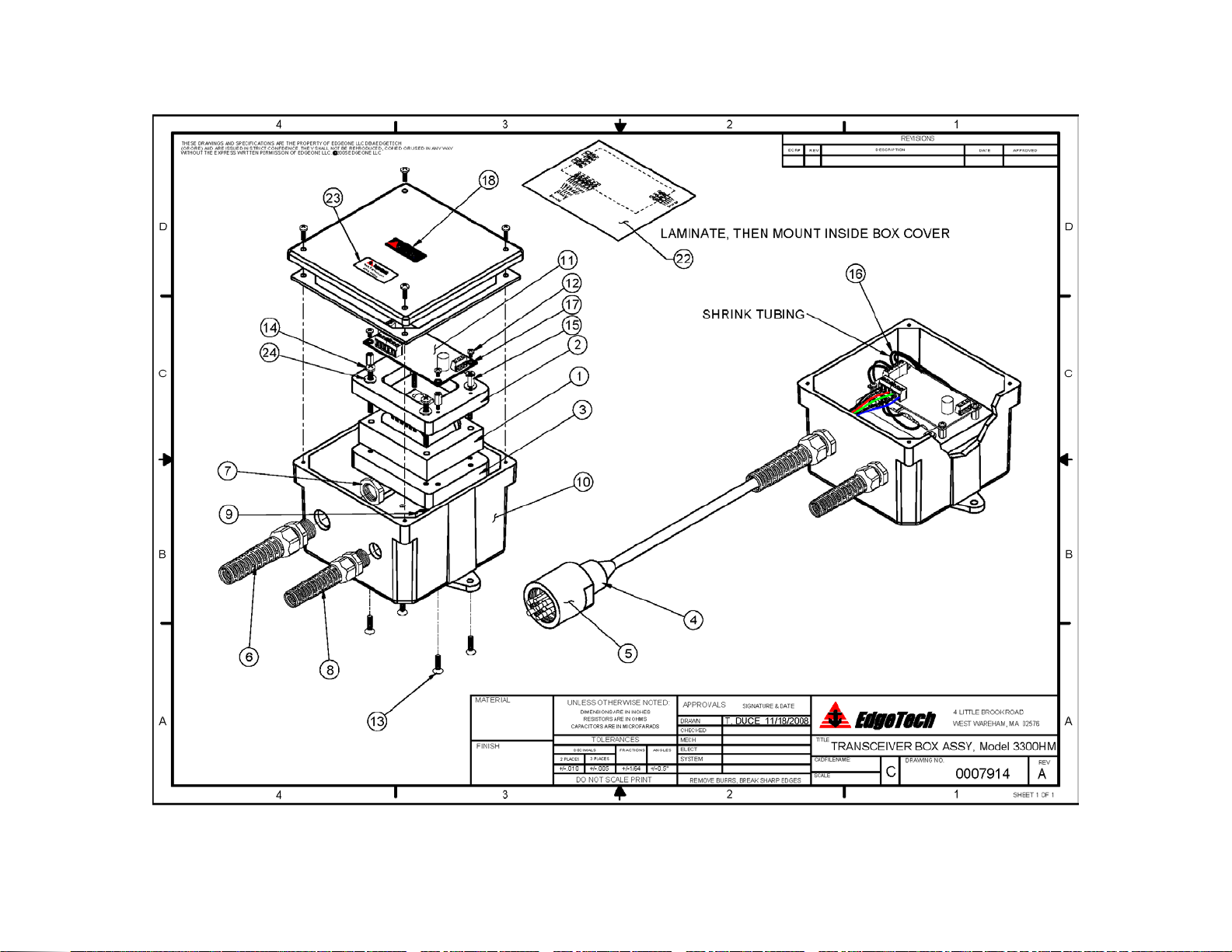

2.3 Technical Drawings

An assembly drawing of the T/R Box is provided in FIGURE 2-2.

A wiring diagram of the T/R Box is provided in

FIGURE 2-3.

3300 HULL MOUNT SUB-BOTTOM PROFILER 0016732_REV_C

Page 29

2-5

Figure 2-2: T/R Box Assembly Drawing - 0007914

Page 30

2-6

Figure 2-3: T/R Box Wiring Diagram - 0004638

Page 31

2-7

SPECIFICATION

VALUE

2.4 Spider & Array Specifications

The standard transducers for the 3300-HM SBP system have a good frequency response from 2 kHz to 16

kHz. Multiple transducers are mounted to give various beam width options. Specifications for the array

are given in

TABLE 2-6 and a wiring diagram for the spider box is provided in FIGURE 2-4.

Pulse Type Full Spectrum CHIRP FM

Pulse Length From 5 to 100 ms

Bandwidth From 500Hz to 12kHz depending on application

Trigger In TTL negative edge triggered

Trigger Out TTL negative edge triggered. Minimum 5ms long pulse (Lower BNC)

Sampling Rate 20, 25, 40,50 kHz depending on the pulse upper frequency

Acoustic Power

Resolution

Beam width 20 to 40 degrees depending on transducer configuration

Minimum array height 5 meters above seafloor

Table 2-8: General Array Specifications

NOTE: The 3300-HM SBP system is an application-specific unit; using it

for purposes other than sonar data acquisition is strongly discouraged.

The above information is for documentation purposes only.

Specifications are subject to change without notice.

2.5 Technical Drawings

About 212 dB ref 1µPa peak at center frequency of system

From 4 to 50 cm of vertical resolution depending on pulse vehicle

and pulse bandwidth

A wiring diagram of the spider box in a 2x2 configuration is shown in FIGURE 2-4.

Page 32

2.0: SPECIFICATIONS 2-8

_C

Figure 2-4: Spider Wiring Diagram - 0009969

Page 33

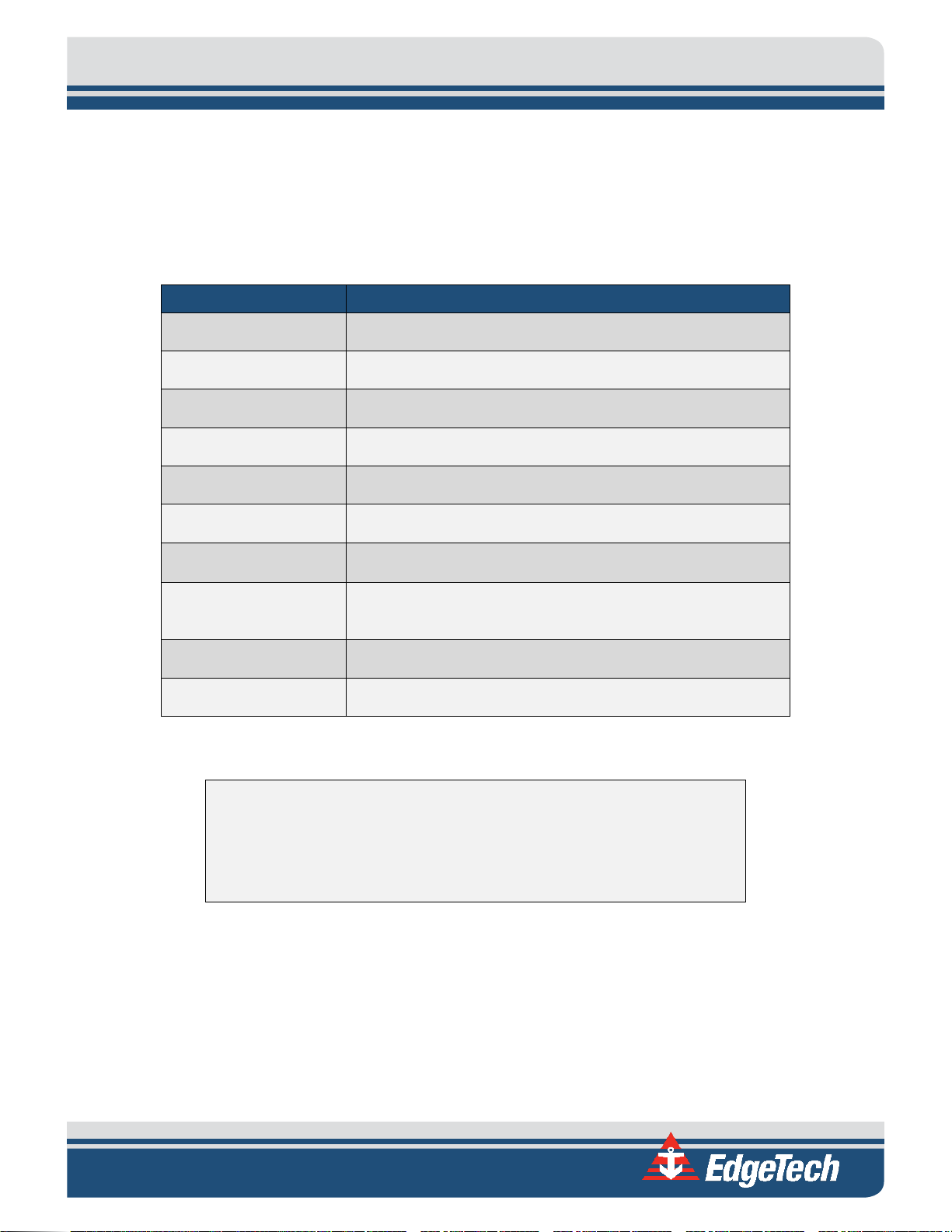

TABLE 2-7 and TABLE 2-8 show the specifications for the KT-216H and KT-106D arrays, respectively:

SPECIFICATION

VALUE

Frequency Range:

2 - 12 kHz

2 - 5 kHz, 100 ms

2 - 12 kHz, 3 ms

Vertical Resolution

(depends on pulse selected):

In Course Calcareous Sand:

6 m

In Clay:

80 m

Directivity Index

(per Array Size):

2 X 2

15 dB

3 X 3

18 dB

4 X 4

21 dB

5 X 5

23 dB

Beam Width (per Array Size):

Beam Width (per Array Size):

6 kHz Center Frequency

2 X 2

33°

3 X 3

25°

4 X 4

20°

5 X 5

17°

SPECIFICATION

VALUE

Frequency Range:

1 - 6 kHz

1.2 - 5.0 kHz, 66 ms

1.5 - 6.5 kHz, 12 ms

Vertical Resolution

(depends on pulse selected):

In Course Calcareous Sand:

6 m

In Clay:

80 m

Directivity Index

(per Array Size):

2 X 2

13 dB

5†

15 dB

7†

16 dB

3 X 3

17 dB

4 X 4

20 dB

Beam Width

3.75 kHz Center Frequency

KT-216H Specifications:

2 - 6 kHz, 40 ms

Pulses (user selected):

Penetration (typical):

2 - 8 kHz2 - 8 kHz, 40 ms, Wide Band (WB)

2 - 10 kHz, 20 ms

2 - 12 kHz, 20 ms

6 - 10 cm

2-9

4.5 kHz Center Frequency

KT-106D Specifications:

Pulses

(user selected):

Penetration

(typical):

2 X 2

40°

3 X 3

30°

4 X 4

24°

Table 2-9: KT-216A2H Array Specifications

1.5 - 4.5 kHz, 33 ms

1.5 - 4.5 kHz, 12 ms

1.5 - 5.5 kHz, 12 ms

1.5 - 6.0 kHz, 20 ms

6 - 10 cm

5 X 5

20°

† See FIGURE 2-5

(per Array Size):

2 X 2

38°

5†

26°

Table 2-10: KT-106D Array

7†

29°

3 X 3

24°

4 X 4

18°

Page 34

2.0: SPECIFICATIONS 2-10

2

1

3

5 4

6 7

7x Kt-106

2

1

3

5 4

5x Kt-106

NOTES: Vertical resolution is the smallest distinguishable distance

between the peaks of two reflections that can be displayed on the screen

as separate reflectors. Sound energy is reflected to the sonar system

when the transmitted pulse encounters a change in density, and the

resolution of a sonar system is measured by its ability to distinguish

between two adjacent targets. The vertical resolution is dependent on

the transmitted CHIRP pulse bandwidth. It is theoretically calculated by

the product of the transmitted pulse length (inverse of the bandwidth)

and half the speed of sound in water (approximately 750m/s).

The value for sub-bottom penetration is the maximum distance beneath

the sea floor that a step change of 10% in density can be seen on the subbottom display. This assumes the sediment is gas-free (without organic

materials), and the lowest frequency of the pulse spectrum is

transmitted. Lower frequencies reduce attenuation (sound absorption).

Many factors contribute to the penetration performance of a Hull

Mounted system. However, one of the essential factors in determining

the performance of a CHIRP pulse, along with the expected penetration

and resolution, is the center frequency of the CHIRP pulse? Therefore, for

example if you have a pulse of 1-8 kHz then you use the center frequency

(4.5 kHz) to determine resolution and penetration. The size of the array

is another contributing factor, as low frequency efficiency goes up as the

side of the array is increased due to increased directivity.

Figure 2-5 : KT-106 Non-Symmetrical Array Configurations

3300 HULL MOUNT SUB-BOTTOM PROFILER 0016732_REV_C

Page 35

2-11

ARRAY SIZE

EXPECTED SNR

2 X 2

28 dB

3 X 3

31 dB

4 X 4

34 dB

5 X 5

37 dB

2.5.1 Array Sizes

Selection of array size depends on transducer type (KT-216 or KT-106) and the geological survey

application. The important decision parameter is the water depth in which the system is to be used. For

most deployments to 3000 meters, a 4 x 4 array will provide the needed performance. A 2 x 2 array should

be considered only for coastal application and water depths to 300 meters. Only a 5 x 5 array can be used

for full ocean depth.

The following is a matrix of Signal to Noise Ratio for each array size. It assumes sea state 5, flow noise of

70 dB (about 10-knots), a loss in typical seafloor sediments of 10 dB, a 20 ms pulse length, and a bandwidth

of 5 kHz. Several other variables are not included in this matrix. They include hull type and thickness, selfnoise, variations in flow noise, other ship’s speeds, other sea states, and roll and pitch. Nor does it consider

other conditions that could affect the performance, such as a bubble screen.

Table 2-11: Array Size vs. Expected Signal-to-Noise Ratio (SNR)

NOTE: The 2-way transmission coefficient for a 4 kHz center frequency

over a 0.5 inch steel acoustic window is 0.5 (i.e. 50% of the acoustic pulse

amplitude is lost due to the 2-way travel of sound through the plate). The

coefficient reduces with higher frequencies and thicker steel hull.

See the following figures for images of the various array configurations:

FIGURE 2-6: DECK CABLE, T/R BOX, AND SPIDER WIRING DIAGRAM (2X2 CONFIGURATION)

•

• FIGURE 2-7: SINGLE TRANSDUCER DRAWING

• FIGURE 2-8: 2X2 TRANSDUCER CONFIGURATION

• FIGURE 2-9: 3X3 TRANSDUCER CONFIGURATION

• FIGURE 2-10: 4X4 TRANSDUCER CONFIGURATION

• FIGURE 2-11: 5X5 TRANSDUCER CONFIGURATION

Page 36

2-12

Figure 2-6: Deck Cable, T/R Box, and Spider Wiring Diagram (2x2 Configuration)

Page 37

2-13

Figure 2-7: Single Transducer Drawing - 0013579

Page 38

2-14

Figure 2-8: 2x2 Transducer Configuration - 0011720

Page 39

2-15

Figure 2-9: 3x3 Transducer Configuration - 0015753

Page 40

2-16

Figure 2-10: 4x4 Transducer Configuration - 0013960

Page 41

2-17

Figure 2-11: 5x5 Transducer Configuration - 0016713

Page 42

2.0: SPECIFICATIONS 2-18

SPECIFICATION

VALUE

Nominal Cable Weight:

30.8 kg per 100 m (207 lb/1000 ft.)

Voltage Rating:

600 Volts.

Bending Radius:

10 cm (4 in)

Length:

50, 60, or 75 meters (164, 197, or 245 ft.)

PIN

FUNCTION

A

AMPLIFIER OUTPUT SHIELD

B

+12 VDC

C

SEA GROUND

D

DF1000 SHIELD (SUBSCAN ONLY)

E

AMPLIFIER OUTPUT 1

F

DF1000 DATA (SUBSCAN ONLY)

H

AMPLIFIER OUTPUT 2

J

PRE-AMPLIFIER INPUT CHANNEL A

K

PRE-AMPLIFIER COMMON

L

NC M NC

K

J

H

F

E

D

C

B

A

M

L

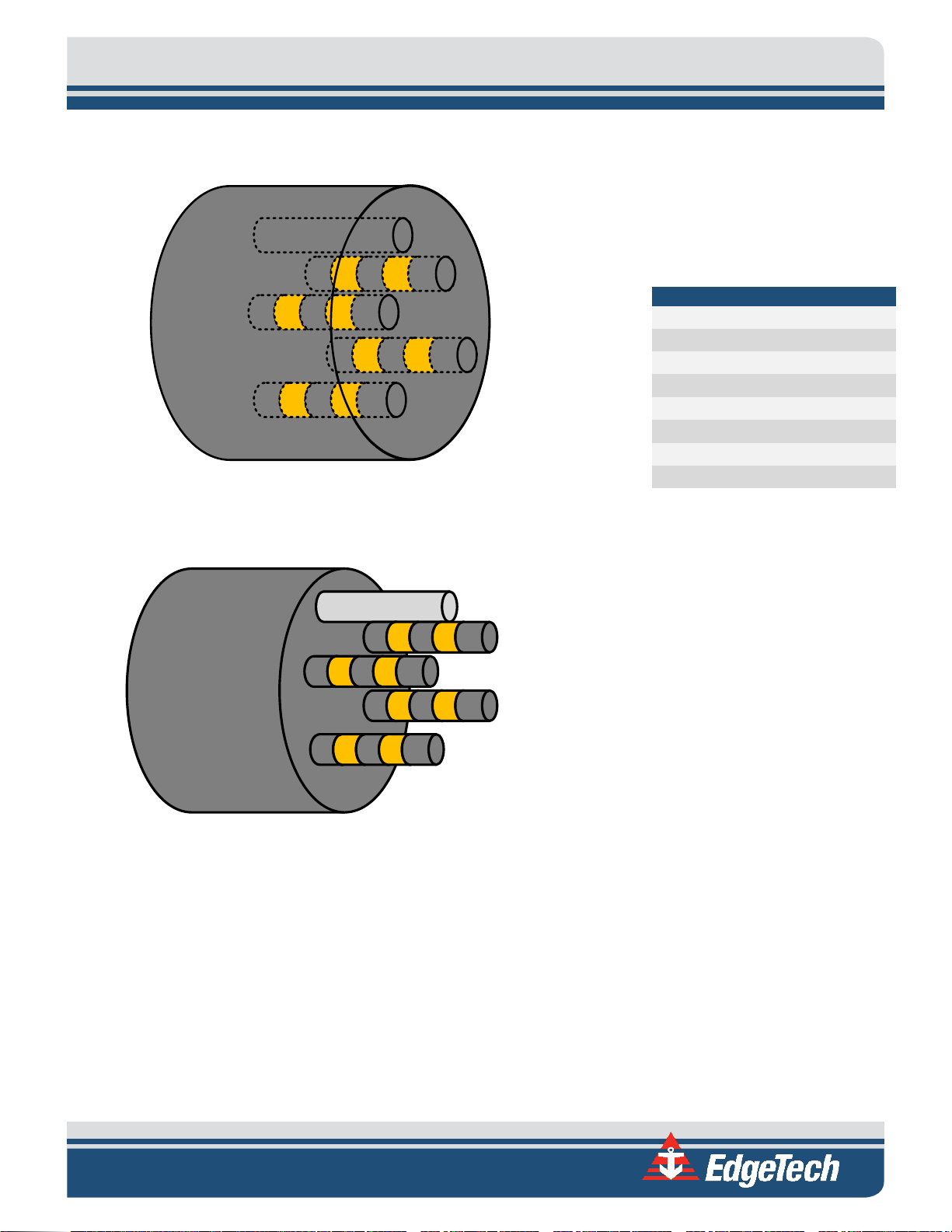

2.6 Signal Cable Specifications

The deck cable is made of six wires twisted and shielded in pairs. The cable has a Kevlar strength member

that provides a 1600 kg (3500 lb.) minimum breaking strength and 295 kg (650 lb.) working strength. See

TABLE 2-12:

Table 2-12: Signal Cable Specifications

The deck cable is terminated at the topside with a military type Amphenol connector and at the T/R Box

with a Marshal underwater wet pluggable connector. The Pinout Diagrams for the signal cable can be

found in

FIGURE 2-12, FIGURE 2-13, and FIGURE 2-14.

FIGURE 2-15 provides the wiring diagram for the signal cable.

Table 2-13: Deck Cable Pinouts

Figure 2-12: Topside Unit Deck Cable for Hull Mount Systems (Female) Amphenol #97-3106A-20-33F

3300 HULL MOUNT SUB-BOTTOM PROFILER 0016732_REV_C

Page 43

PIN

FUNCTION

1

AMPLIFIER OUTPUT 1

2

AMPLIFIER OUTPUT 2

3

PREAMPLIFER COMMON

4

PRE-AMPLIFIER SIGNAL

5

RS-232 DATA

6

+ 12 VDC

7

SEA GROUND

8

RS-232 COMMON

3

1

87

5 6

2

4

4

3

2 1

8 7

56

Figure 2-13: Female Marshal Connector – 86-5FC

(Deck Cable to T/R Box Connection)

2-19

Table 2-14: Deck CABLE Connector Pinouts

Figure 2-14: Male Marshal Connector – 86-5MC

(T/R Box to Deck Cable Connection)

Page 44

2-20

Figure 2-15: Deck Cable Schematic - 0002976

Page 45

3.0: CONTROLS & CONNECTIONS

This section describes the controls and indicators, along with the connections for the 3300-HM SBP.

3.1 Deck Unit Controls and Indicators

The deck unit controls and indicators are as follows, and are shown in FIGURE 3-1:

POWER SUPPLY: Rocker switch. Turns on the power supply in the 3300-HM SBP Topside

Processor. This switch can be left in the on position at all times.

SYSTEM POWER: Push button toggle switch. Turns the 3300-HM SBP Topside Processor on.

POWER: A blue indicator lights up when amplifier is on.

RESET: Momentary push button switch. Resets 3300-HM SBP Topside Processor.

HARD DISK: Red indicator. Indicates when a hard drive on the 3300-HM SBP Topside

3-1

Processor is active.

SYSTEM: Green indicator. Illuminated when 3300-HM SBP Topside Processor is on.

POWER AMP OUT TX1: Red indicator. Flashes when Channel 1 of the Power Amplifier transmits.

POWER AMP OUT TX2: Red indicator. Flashes when Channel 2 of Power Amplifier transmits.

READY: Green indicators. Illuminate when the system is ready to transmit. Upon

power up it will take one to two minutes for indicator to illuminate.

12 VDC OUT TO PREAMP: Test point. Used to measure the 12 VDC voltage applied to the

preamplifier in the T/R Box.

PREAMP 5 VDC: Test point. Used to measure the 5 VDC voltage preamplifier feedback

voltage from the T/R Box.

PREAMP COMMON: Test point. Common ground for the preamplifier.

GND: System ground connection.

DATA: Amp Indicator lights up and blinks when data is being transmitted

CH1 & 2: Defunct dials on the amplifier. Turning these will not affect the

performance or function of the 3300-HM SBP system in any way

Page 46

3.0: CONTROLS & CONNECTIONS 3-2

System Indicator

System Power

Hard Disk

Indicator

Hard Disk

Reset Button

USB

DVD R/RW

Removable 1-TB HDD

Ready

Power, Bridge, &

Data Indicators

CH2 Dial

(defunct)

CH1 Dial

(defunct)

Drive

3300 HULL MOUNT SUB-BOTTOM PROFILER 0016732_REV_C

Connectors

Indicators

Figure 3-1: Topside Front Panel Controls and Connections

Page 47

3-3

3.2 Deck Unit Connections

The topside deck unit connections are as follows, and are shown in FIGURE 3-2 . The wiring diagram can be

seen in

FIGURE 3-3:

TRACKBALL: USB on front or rear panel connects to the trackball.

KEYBOARD: USB on front or rear panel connects to the keyboard.

SEA CABLE: 11-Pin female bulkhead connector. Connects to the deck cable.

MONITOR: Mini display port on rear panel connects to the LCD monitor.

COM 1-NAV: DB-9 female connector. RS-232 serial port connects to the navigation system.

COM 3, 5, 6: DB-9 female connectors. RS-232 serial ports can be used to connect to the navigation

system.

TRIGGER IN: BNC connector. Connects to an external trigger source to enable and disable the sonar.

TRIGGER OUT: BNC connector. Connects to an external sonar system to trigger it.

ETHERNET: (2) RJ-45 connector. Available for connection to a local area network (LAN) and/or

printer.

USB: Front Panel:

(2) USB2

Rear Panel:

(2) USB2

(2) USB3

(2) USB3.1

AC POWER: CEE-type AC input and output connectors. The AC input connector connects to the AC

power source, and the AC output connectors are available for powering LCD monitor

and other equipment, if required.

Page 48

3-4

Power Supply

COM 1-NAV

Connector

COM 3

Connector

Ethernet1

Connectors

Ethernet2

Connectors

TRIGGER IN

Connector

TRIGGER OUT

Connector

USB3 Ports

GND

SEA CABLE Connector

Sonar Data Main I/O

Connector

POWER AMP OUT

TX2 indicator

12 VDC OUT TO

PREAMP test point

TOWFISH PREAMP

5 VDC test point

PREAMP COMMON

POWER AMP OUT

TX1 indicator

AC POWER input

USB 3.1 Ports

Mini Display Port Video

Connectors

Figure 3-2: Topside Rear Panel Controls and Connections

Test point

Page 49

3-5

Figure 3-3: Rear Panel Schematic - 0004957

Page 50

Page 51

4-1

4.0: INSTALLATION

This section explains how to unpack, inspect, and install the 3300-HM SBP system. It describes placement

considerations for the topside and transducer arrays, along with power requirements.

Refer to the PN 0016695 for a more detailed explanation of 3300-HM SBP installation.

For information on connecting a navigation device or printer, please refer to

B.0: NAVIGATION SYSTEMS.

4.1 Unpacking & Inspecting

The EdgeTech 3300-HM SBP system is supplied complete with all necessary cables. The system

components are individually packed in reusable shipping containers.

Before unpacking the system components, inspect the shipping containers for any damage. Report any

damage to the carrier and to

If the shipping containers appear free of damage, carefully unpack the components and inspect them for

damage. Again, if any damage is found, report it to the carrier and to

check the packing list and verify that all the items on the list are included. If any items are missing,

immediately contact

be damaged.

Although the items shipped may vary, depending on the customer requirements, the 3300-HM SBP

typically includes the following:

• Topside Unit

• Hull Mount Transducer Arrays

EDGETECH CUSTOMER SERVICE. Do not install or operate any equipment that appears to

EDGETECH CUSTOMER SERVICE, who will provide additional guidance.

EDGETECH CUSTOMER SERVICE. Also

• Connection Cable

• AC power cords (2)

• Software USB

• Manuals

After unpacking the system components, be sure to safely store the shipping containers – including any

packing materials – for later use. When transporting or storing the system, all items should be packed in

their original shipping containers in the same manner in which they were originally shipped, and always

store the system in a dry environment when not in use.

Page 52

4.0: INSTALLATION 4-2

4.2 Topside Installation

Once unpacked, the topside unit could be installed in a standard 19-inch rack, but can be set on any level

surface, as in the Optima case. Several requirements are necessary for proper placement of the unit, and

are addressed below:

4.2.1 Power Supply

The system power requirements are 120–220 VAC, 50/60 Hz. For the 3300-HM SBP Topside Processor,

the input voltage is auto sensing. For the Power Amplifier, you must select 120 VAC or 220 VAC operation

manually.

4.2.2 Use of an Uninterruptable Power Supply

The AC power source should be continuously free of high-amplitude, high-frequency transients, as this

type of interference could cause degraded performance or damage to the equipment. An uninterruptable

power supply (UPS) with power surge protection is recommended for powering the equipment.

However, whether or not a UPS is used, the AC power source should never be the same as that being used

to power electric motors, such as pumps and winches, on the survey vessel.

4.2.3 Selecting the Power Amplifier Input Power Voltage

To select the Power Amplifier input power voltage, first remove the amplifier from the rack. Then remove

the top cover, locate the board at the lower right corner, and switch it to the required input power voltage

as indicated by the arrow.

4.2.4 Changing to a Non-US Power Plug

An AC power cord is provided for connecting the Deck Unit to a standard U.S. 3-pronged outlet. For nonU.S. power outlets, you can modify this cord by cutting off the 3-pronged plug and attaching the

appropriate plug. For connection information, refer to

AC POWER CORD WIRE COLOR FUNCTION

Black AC line

White AC neutral

TABLE 4-1.

Green Earth ground

Table 4-1: AC Power Cord Wiring

3300 HULL MOUNT SUB-BOTTOM PROFILER 0016732_REV_C

Page 53

4-3

NOTE: Each Deck Unit is shipped configured to country voltage

requirements per each end-user.

4.2.5 Navigation Interface

The 3300-HM SBP system accepts all standard National Marine Electronics Association (NEMA) 0183

message sentence formats from a connected Global Positioning System (GPS) or Integrated Navigation

System.

4.2.6 Deck Unit Placement

The Deck Unit should be set up and situated in a dry, sheltered area that is protected from weather and

water spray. The placement area should also have a temperature that is consistently between 0°C and

40°C (32°F and 104°F). Avoid areas of direct sunlight, especially in tropical environments, as heat buildup

could occur and viewing the LCD monitor and status indicators could prove difficult. The 3300-HM SBP

Topside Unit should be placed in on a surface that is flat and free from vibrational interference.

Secure the Deck Unit in place, using tie-downs if necessary, near the required AC power source. If you are

mounting the 3300-HM SBP Topside Processor and the Power Amplifier in a 19-inch rack other than the

supplied rack mount enclosure, ensure that there is ample room behind the rack for connecting the cables.

Support the components inside the rack using appropriate mounting brackets and secure the front panels

using standard 19-inch rack front panel mounting hardware.

4.3 Hull Mount Array Installation

NOTE: This section is a summarized version of the full installation guide,

provided in EdgeTech document PN 0016695.

The transducer arrays for the 3300-HM SBP system are mounted to the bottom of the survey vessel in a

“Sea Chest.” This chest is filled with fresh water in order to protect the array from corrosion, while

providing a medium for the sub-bottom sonar signal to travel through.

A hatch on the top of the chest allows the deck crew to access the array in order to inspect or remove it

between surveys. The bottom of the Sea Chest (facing the sea floor) is an “acoustic window,” which is

made of a material that allows the signal to pass through it while still protecting the array.

Stainless steel trays are available from EdgeTech for mounting the transducers inside the user-provided

Sea Chest. However, the user may also construct the trays themselves by following the proper spacing

requirements listed below (for transducer array specifications, see sub-section

• Install the transducer array parallel to the sea surface within a flooded steel enclosure

2.3):

Page 54

4.0: INSTALLATION 4-4

• For best results, use an acoustic window made of a material such as a high-quality fiberglass with

no air pockets (e.g., 'G10' glass board), 'Lexan', or a polycarbonate material. Construct the Sea

Chest so the acoustic window can be bolted to the sea chest using a bezel to secure it in place.

• The steel enclosure is a steel box welded to a section of the hull that is flat and parallel to the sea

surface. The sides of the enclosure should be high enough to allow inspection of the array;

EdgeTech recommends the sides of the box be at least 30 cm higher than the top of the

transducers. There should be a minimum of 5 cm between the sides of the transducers and the

sides of the sea chest.

• A sea chest for a 4 x 4 array (of KT-216 transducers) will have the following minimum inside

dimensions:

Inside height: 22 inches / 56 cm

Inside width: 28.25 inches / 72 cm

Inside length: 31.25 inches / 80 cm

• Locate the steel box away from vibrating equipment and sufficiently deep below the water line to

prevent air bubbles passing along the hull and under the array during high sea states.

• Line all four vertical sides and the removable cover plate with a foam material such as ¼ inch (0.64

cm - minimum) diver’s wetsuit neoprene. Attach it with a good neoprene cement (such as 3M

5200 moisture cured) to the sides and top of the Sea Chest.

• Bolt the transducer array to an angle bracket that is welded to the inside of the box so that the

faces of the transducers are within 2 cm of the hull plate, but not touching it. The array is installed

in the box one row (rack) of transducers at a time.

• The steel box should have a removable cover to allow installation and removal of the transducer

array. The cover should bolt to the top of the box and have a gasket to prevent leakage. The Cover

Plate should have a fill pipe to fill the Sea Chest with fluid and a bleeder valve to exit the air from

the Sea Chest. The Sea Chest must be free of any air pockets or bubbles for the transducers to

properly operate.

• Fill the tank with fresh water (preferably distilled) from the ship’s fresh water supply. If the system

will be operated at temperatures near or below fresh water’s freezing point, antifreeze may be

added so that the freezing point is below that of sea water. EdgeTech recommends Propylene

Glycol antifreeze or an equivalent.

• Drain the tank and pipes when the ship is in dry dock if there is a risk of freezing weather. Vent all

air from pipes and tank after filling and before operating the sonar to prevent signal degradation.

• Install a stuffing tube and gland nut to allow a 0.8 cm diameter electrical cable to pass through

the tank. This cable connects the transducer array to a water-resistant T/R Box that is mounted

3300 HULL MOUNT SUB-BOTTOM PROFILER 0016732_REV_C

Page 55

4-5

to a bulkhead within 3 meters of the tank. The T/R Box contains a pre-amp, matching transformer,

and T/R switch. The T/R Box enclosure is plastic and approximately 18 cm high by 18 cm wide by

12 cm deep. A standard 50-meter 3300-HM SBP deck cable connects the T/R Box to the 3300-HM

SBP Topside Processor.

4.4 Connecting the System

WARNING!

Do not attach any cables or wires while the system is connected to the

ship's power, as severe electrical shock may occur.

Once the transducer arrays have been mounted, the Sea Chest has been filled and vented of air, and the

topside unit has been unpacked and secured, the user may proceed with connecting the 3300-HM SBP

system components in preparation for use:

1. Ensure the AC voltage selection switch in the amplifier is set to the proper voltage.

2. Connect the deck cable to the Hull Mount.

3. Connect the underwater cable to the Amphenol connector at the back of the amplifier unit.

4. Connect the video monitor.

5. Connect the keyboard and trackball to the front panel of the system.

6. [Optional] Connect a thermal printer

CAUTION!

Always connect the T/R box end connector before connecting the cable

to the deck unit to prevent connecting an energized connector. This may

cause damage to components in the T/R box.

Page 56

Page 57

5-1

5.0: OPERATION

The purpose of this section is to provide general information on the interface between the 3300-HM SBP

transducers and the 3300-HM SBP topside unit. The interface between the 3300-HM SBP and the

DISCOVER Sub-Bottom software can be found in the DISCOVER Sub-Bottom Software Manual.

5.1 Activating the System

1. Turn on the POWER SUPPLY switch on the back of the Deck Unit. This switch can be left in the on

position at all times if desired.

2. Turn on the POWER switch on the Power Amplifier.

3. Turn on the SYSTEM POWER switch on the 3300-HM SBP Topside Processor.