Edgetec TF060-AH-50, TF075-AH-50-HF, TF110-AH-50, TF060-XH, ET Owners & Installation Manual

...

Owner's &

Installation Manual

TriFlo Spa Bath Pump

EDGETEC SYSTEMS PTY LTD Part # 9-2100 FEB2017 www.edgetec.net

2

Table of Contents

Pro-Tec Accessories .................................................................................................... 3

Correct Spa Bath Pump Installation ......................................................................... 4

Incorrect Spa Bath Pump Installation ...................................................................... 5

Correct Mounting on External Wall. ......................................................................... 6

Air Tube Connections – AH and XH Models ........................................................... 7

Touch Pad Connections ST and ET Models ............................................................. 7

Activating Air Bleed .................................................................................................... 8

AIR BLEED – INTERNAL INSTALLATION ........................................................................ 8

TriFlo Spa Bath Pump .................................................................................................. 9

Installation Instructions (refer page 4, 5 & 6) ........................................................ 11

Electrical Connection .............................................................................................. 12

Trouble Shooting Guide ........................................................................................... 14

TriFlo Technical Data ................................................................................................ 15

Edgetec Product Warranty ..................................................................................... 16

Terms & Conditions ................................................................................................... 16

Commercial Installation ........................................................................................... 16

TriFlo Pump Details

Model Number:

Serial Number:

Date of Purchase:

Invoice Number:

EDGETEC SYSTEMS PTY LTD Part # 9-2100 FEB2017 www.edgetec.net

3

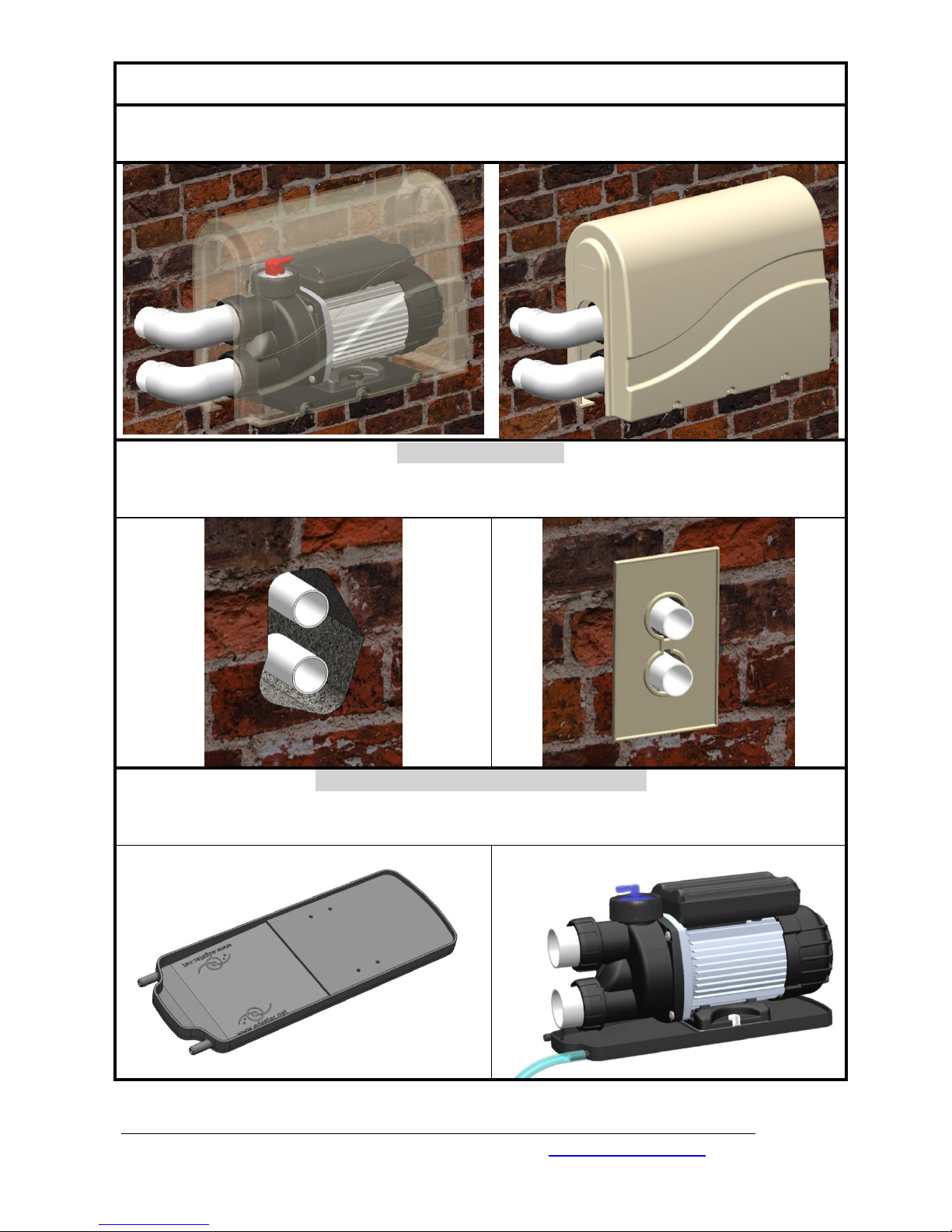

Pro-Tec Accessories

Easy To Install. Complete With Wall Brackets & Base. Pro-Tec Pump Cover Reduces Noise

Level. Left or Right Hand Mount – Neutral Merino Colour-Part #6400

Pro-Tec Cover Plate

Easy to Install. Can be fitted during installation or fitted after installation. Complements ProTec Pump Cover above and can be painted to match house décor -Part #6420

Pro-Tec Drain Tray – Internal Installation

Easy To Install. Protects indoor installations from water damage should any small drip from

the mechanical seal occur due to normal wear -Part #6450

Pro-Tec Drain Tray

Pump Mounted on Drain Tray

EDGETEC SYSTEMS PTY LTD Part # 9-2100 FEB2017 www.edgetec.net

4

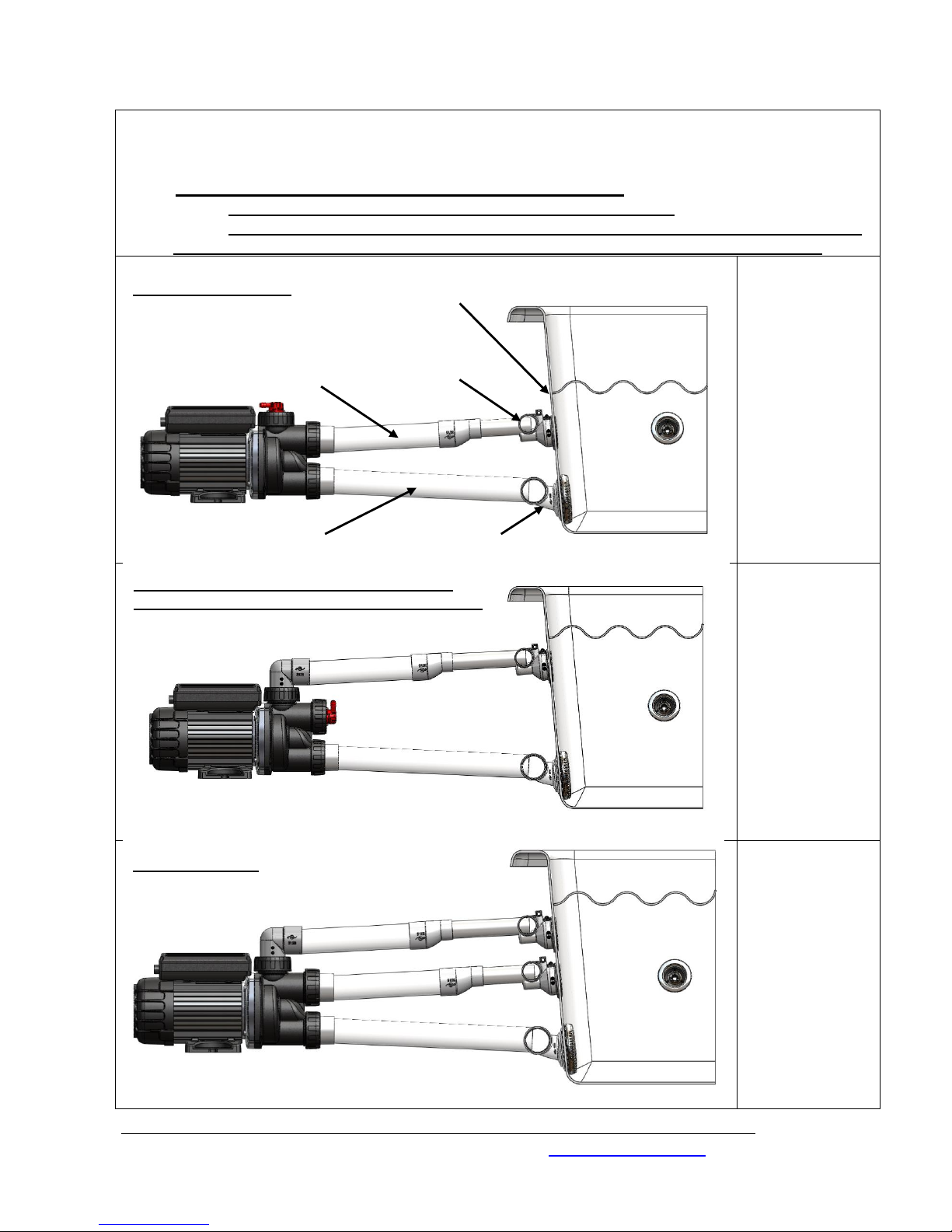

Correct Spa Bath Pump Installation

Use 40mm or 25mm UPVC Pressure Pipe for plumbing installation,

40mm pipe is preferred for both the suction and return lines.

IMPORTANT REQUIREMENT FOR PUMP SERVICE:

Pump installation must provide access for pump removal.

To allow for pump removal a serviceman must be able to reach the barrel unions.

For under the hob installation- an access panel must be provided on the installation

Return Line

Minimum 1:100 Gradient (0.5°)

Return Line

Minimum 1:100 Gradient (0.5°)

Return Line

Minimum 1:100 Gradient (0.5°)

Suction Line

Minimum 1:100 Gradient (0.5°)

Suction Line

Minimum 1:100 Gradient (0.5°)

Spa Jets

Water Level Minimum 50 mm Above Spa Jets

Suction

Standard Installation

Top Outlet Installation-Please note the Air

Bleed cannot be activated in this installation.

TriFlo Installation

Suction Line

Minimum 1:100 Gradient (0.5°)

EDGETEC SYSTEMS PTY LTD Part # 9-2100 FEB2017 www.edgetec.net

5

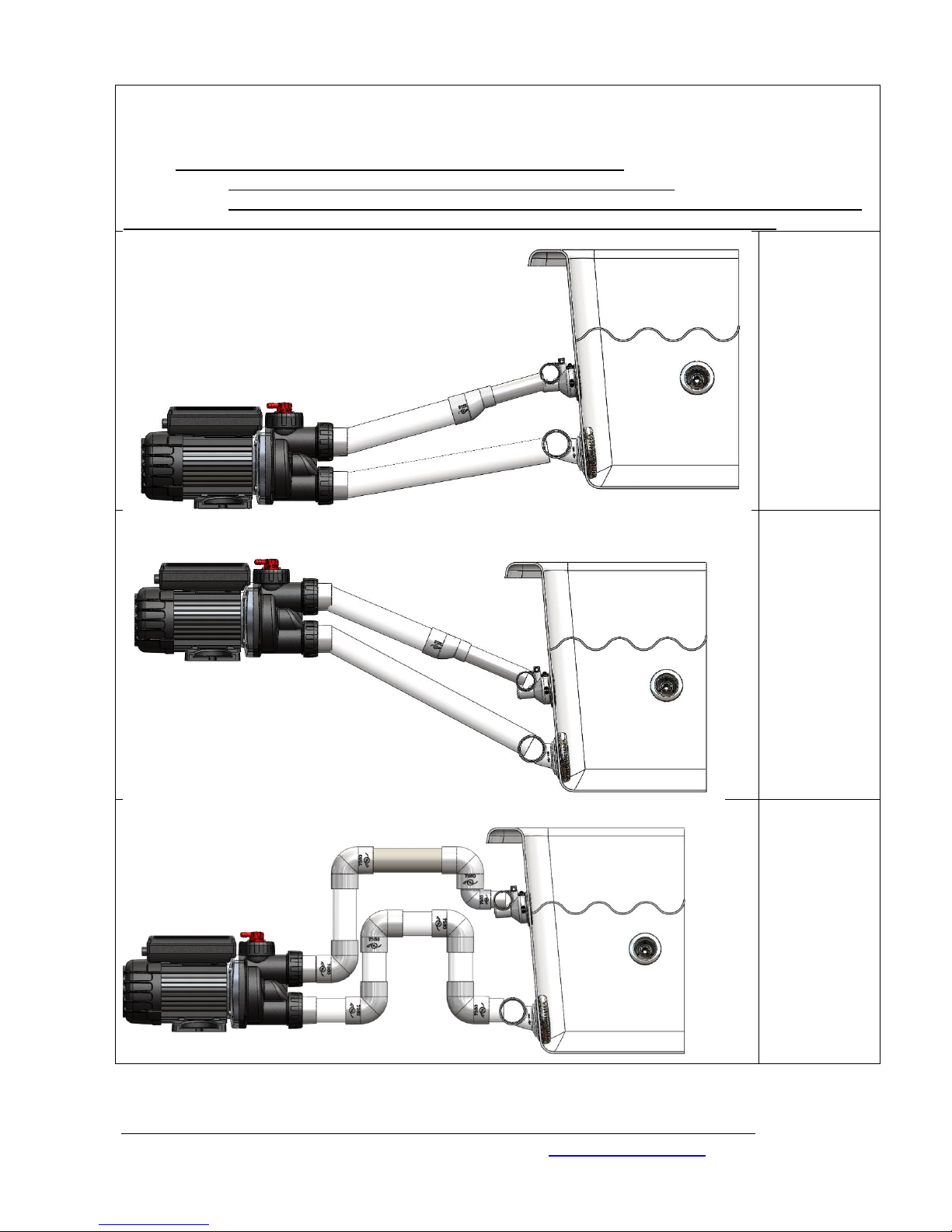

Incorrect Spa Bath Pump Installation

Use 40mm or 25mm UPVC Pressure Pipe for plumbing installation,

40mm pipe is preferred for both the suction and return lines.

IMPORTANT REQUIREMENT FOR PUMP SERVICE:

Pump installation must provide access for pump removal.

To allow for pump removal a serviceman must be able to reach the barrel unions.

For under the hob installation- an access panel must be provided on the installation.

X

X

INCORRECT PIPEWORK

LOOP-PUMP WILL AIRLOCK

PUMP CANNOT PRIME

PUMP MOUNTED TO HIGH

PUMP CANNOT PRIME

PUMP MOUNTED TO LOW

PUMP CANNOT DRAIN

X

EDGETEC SYSTEMS PTY LTD Part # 9-2100 FEB2017 www.edgetec.net

6

Correct Mounting on External Wall.

Incorrect Mounting on External Wall

– Pump too High

PUMP CAN NOT PRIME

Incorrect Mounting on External Wall –

Pump too Low

PUMP CAN NOT DRAIN

EXTERNAL WALL INSTALLATION WITH Pro-Tec Pump Cover and Pro-Tec Cover Plate

X

X

EDGETEC SYSTEMS PTY LTD Part # 9-2100 FEB2017 www.edgetec.net

7

Air Tube Connections – AH and XH Models

Touch Pad Connections ST and ET Models

1. Connect the touch pad cable into

the housing, the alignment is shown

above.

2. Push the connector into the housing

until it “clicks” into the fixed position.

3. Push the protective rubber cap on

the touch pad cable over the

circular housing (failure to do this will

void the warranty).

4. Do not wrap or loop excess cable

around frame work of the bath or

pipe work!

1. Attach 3mm flexible air tube (supplied with the pump) onto

the air switch nipple. Cut off excess tube, do not wrap or

loop excess tube around frame work of the bath or pipe

work as this may cause the air button not to operate

correctly.

EDGETEC SYSTEMS PTY LTD Part # 9-2100 FEB2017 www.edgetec.net

8

Activating Air Bleed

*Important - If pump does not prime - activating the air

bleed valve MAY improve priming (refer page 13)

AIR BLEED CAP (Clear or Blue)

To activate air bleed,

Drill out blind hole inside elbow

(Use 4 mm drill bit)

TWIST CAP AIR BLEED

Twist Cap Air Bleed - Rotate Fully

Anticlockwise to Open

AIR BLEED – INTERNAL INSTALLATION

Edgetec highly recommend a drain tray be fitted on ALL internal installation

Drain tray will protect indoor installations from water damage should any small drip

from the mechanical seal occur due to normal wear. Will also collect any minor

“squirt” from the air bleed.

NO DRAIN TRAY FITTED

Attach 10 mm Flexible drain tube (Not

Supplied). Loop Tube Above Bath

Maximum Waterline

DRAIN TRAY FITTED - AIR BLEED ACTIVATED

EDGETEC SYSTEMS PTY LTD Part # 9-2100 FEB2017 www.edgetec.net

9

TriFlo Spa Bath Pump

Congratulations on the purchase of your new TriFlo spa bath pump. The TriFlo spa bath

pump has been specifically designed for spa bath applications to ensure that you have

optimum spa jet performance and many years of trouble free operation.

The TriFlo pump internal design allows the water to self-drain so that there is minimal residue

water left in the pump when the spa is emptied in accordance with Local Health

Regulations when installed correctly.

TriFlo spa bath pumps are designed for spa bath operation only and should not be used in

chemically treated water or any other purpose without seeking written approval from

Edgetec Systems Pty Ltd for the application.

TriFlo Models and Operation Guide

Triflo pumps can be controlled by Air Switch (air tube operation), Electrical

touchpad (RJ45 cable), or radio remote control (Spa Key).

Auto-Heat: AH Model – air tube connect. The “Auto-Heat” TriFlo will help

maintain your spa bath water temperature during your spa by heat transfer. This

pump is activated by the air button installed on your bath.

Xtra-Heat: XH Model – air tube connect. The “Xtra-Heat” TriFlo has the integral

flat plate 700watt Stainless Steel heater built into the pump, this will maintain your

spa bath water temperature even in the largest spa baths. This pump is activated by

the air button installed on your bath.

EEZI-Touch: ET Model – RJ45 Cable. The “EEZI-Touch”

TriFlo has the integral flat plate 700watt Stainless Steel

heater built into the pump and a bath mounted touch

pad which allows you to control the pump from the baths

edge.

Depressing the touch pad button will turn your pump “on

or off”. When operating the Blue Led will light up.

The heating function will automatically come on once the pump has primed and

water is detected in the spa bath pump, if there is no water in the spa bath or

insufficient water in the pump the pump will automatically shut down to protect your

pump from running dry and causing potential damage to the mechanical seal.

The Green indicator light on the touch pad is showing that the communication

cable from the pump is fitted correctly and that there is power to the spa bath

pump.

Sensa-Touch: ST Model – RJ45 Cable. The “Sensa-

Touch” TriFlo has the integral flat plate 700watt Stainless

Steel heater built into the pump and a bath mounted

touch pad which allows you to control the Pump & Heater

function from the baths rim.

Depressing the Pump button will turn your pump “On or

Off”, if there is no water in the spa bath or insufficient

water in the pump the pump will automatically shut down to protect your pump

from running dry and causing potential damage to the mechanical seal.

The heating function will automatically come on once the pump has primed and

water is detected in the spa bath pump.

EDGETEC SYSTEMS PTY LTD Part # 9-2100 FEB2017 www.edgetec.net

10

The Red heater indicator lights will flash in sequence to indicate that the water is

now being heated. When the water temperature has reached the setting chosen or

the bath water is at the set temperature the red lights L, M or H will stay on

depending on the setting chosen. To turn the heating down press the heater button,

each time you press the heater button an indicator light will turn off and the set

temperature will be reduced, when all the lights are off the heater is no longer

active. To turn the heater back on, press the heater button and the heater will come

back on at the highest setting.

The Green indicator light in the centre of the touch pad is showing that the

communication cable from the pump is fitted correctly and that there is power to

the spa bath pump.

Spa-Key: SK Model – Radio Remote. The “Spa-Key” has the integral flat plate

700watt Stainless Steel heater built into the pump. The Spa-Key is a unique radio

operated remote control system which is housed in an immersible casing. The SpaKey operates the pump, and heater – and has additional buttons to switch on a Spa

Blower and Light – all in the one small casing. The Spa-Key is installed on the wall

near the door in a moulded housing, from where it can operate any of the four

functions of the highly sophisticated spa bath. The Spa-Key can be removed from

the housing and carried around the bathroom to

provide a hand held control function even while you

are relaxing inside the bath. The Spa-Key will even

function underwater – although we do not

encourage submersion. The Spa-Key has a

replaceable long life battery.

Depressing the Pump button will turn your pump “On

or Off”, if there is no water in the spa bath the pump

will automatically shut down to protect your pump

from running dry and causing potential damage to

the mechanical seal.

The heating function will automatically come on

once the pump has primed and water is detected in the spa bath.

To turn the heater “On or Off” depress the heater button on the remote control.

To control the Spa Blower (where fitted) depress the Spa Blower button on the

remote control.

To turn the Light (where fitted) “On or Off” depress the Light button on the remote

control.

Your hand set that is provided with your pump has already been synchronized

during assembly and is ready to use.

Extra or Replacement Hand Set. Can be synchronized by turning the pump power

off then on and pressing the PUMP key on the SPA-KEY handset within 15 seconds,

then the pump will give a little surge to tell you that the synch mode is finished. Refer

www.edgetec.net for further technical information.

Pump

Heater

Light

Air

This appliance is not intended for use by young children or

infirm persons without supervision

!

Never run your spa pump without water as this can cause

serious damage to the mechanical seal – which may

cause the spa pump to leak. Running the pump without

water will void your warranty.

!

EDGETEC SYSTEMS PTY LTD Part # 9-2100 FEB2017 www.edgetec.net

11

#6450

Installation Instructions (refer page 4, 5 & 6)

1. To ensure optimum performance of your spa bath the TriFlo pump should be

located as close as possible to your spa bath (maximum 3 Metres). To ensure

high efficiency of your TriFlo pump, use the minimum amount of pipe fittings

during your pump to spa bath installation. Correct installation allows water to

drain from pipe work to pump and from pump to the self-drain suction fitting

in the bath.

2. The pump can be located internally or externally. If the pump is fitted

externally, Edgetec recommends to fit the Pro-Tec pump cover as shown on

page 4 (not supplied).

3. Internal installation must have adequate

ventilation (minimum area 50cm²) for the

pump motor. Inadequate ventilation may

cause the motor to cut out on thermal

over load. If this occurs the thermal will

reset when the motor cools down.

4. A suitable drain tray (Edgetec #6450) on

internal installations should be installed to

avoid water damage to property should

any leaks occur from mechanical seal due

to normal wear.

5. Install the TriFlo pump as per page 3(using

the least amount of elbows. It is most

important that the suction line be installed

with a minimum of 1:100 gradient (0.5°)

(refer page 3) as this allows the water to

drain from the pump and pipe work when

the bath is emptied.

6. The pump should never be installed as shown in page 6 & 7.

If the pump does not prime – check the pump height and pipework

installation. If the pump is installed as shown in any of the images in page 5,

the pipework will airlock and prevent the pump from priming. Activating the

air bleed valve MAY improve priming.

7. The pump to be fixed to the frame or support through the pump mounting

points in the pump base with appropriate fasteners. Two anti-vibration

isolation washer buttons are provided with the pump for the fasteners.

8. Before connecting the pump to the pipe work, check pipe alignment to

barrel unions. The pump is not a pipework alignment tool! Pipe misalignment

will stress the barrel union nuts and may cause a leak!

9. Ensure that all the pipe work is clear of any debris as small particles can

cause blockage to spa jets or the pump impeller causing serious damage

10. Barrel unions only require to be hand tightened, over tightening may cause

damage to the unions and or o rings. Do not use Stillsons or any other

mechanical leverage.

11. IMPORTANT REQUIREMENT FOR PUMP SERVICE:

Pump installation must provide access for pump removal.

To allow for pump removal a serviceman must be able to reach the

barrel unions.

For under the hob installation- an access panel must be provided on

the installation.

EDGETEC SYSTEMS PTY LTD Part # 9-2100 FEB2017 www.edgetec.net

12

Electrical Connection

1. Spa bath pumps must be fitted in accord with AS3000 electrical wiring rules

2. AS3000 requires all 240 V pumps installed in Spa Bath to be supplied from a

circuit protected by a residual current device (RCD) with a maximum rated

residual current 30 mA.

3. The TriFlo spa bath pump is fitted with a standard lead and three pin plug for

240-220V 50Hz power supply.

4. The spa bath pump power connection must be accessible so that it can be

independently switched off in case of an emergency but must not be

accessible by the bath user.

5. If damage occurs to the power cord it must be replaced by Edgetec or an

authorised service agent or suitably qualified person.

Air Tube Connection AH & XH Models (refer page 7)

1. Supplied with your spa pump is a 4 metre roll of 3mm clear air tube, fit one

end of the air tube to the air button (supplied with the spa bath) on the spa

bath.

2. Uncoil the air tube so that you can connect it to the air switch located on the

pump (refer page 7) at the rear of the pump motor on the capacitor cover.

3. Cut off excess tube and ensure that the tube is not kinked, do not wrap or

loop excess tube around frame work of the bath or pipe work as this may

cause the air button not to operate correctly.

Touch Pad Cable Connection ST & ET Models (refer page 7)

1. Supplied on your spa bath is the Sensa Touch Pad, connected to the touch

pad will be a 4 metre RJ45 cable.

2. Uncoil the RJ45 cable and you will see that one end is already connected to

the touch pad on the spa bath.

3. Connect the other end to the pump as per page 6, ensuring that the RJ45

cable connection clip is fully inserted. Push the RJ45 connector until you hear

it “click” into the lock position. Do not wrap or loop excess cable around

frame work of the bath or pipe work!

4. Push the protective rubber cap that is on the cable over the circular housing

(refer page 6) to protect the touch pad cable connection. Failure to do this

will void your warranty.

5. When power is activated there will be a “Green” indicator light activated on

the touch pad to show that the connection is fitted correctly from the pump

to the touch pad.

Start Up – TEST ALL PIPEWORK AND PUMP OPERATION – PRIOR to TILING!

1. Fill the spa bath to approximately 50mm above the spa jets, check the pump

and pipe connection for any leaks.

2. Ensure that the pump power outlet is switched to the “on” position.

3. Auto-Heat & Xtra-Heat pumps. (AH & XH Model) Press the air button on the

spa bath, the pump will start and purge the air from the system and your spa

will start to operate. To stop the spa, simply press the air button again.

4. Sensa/Eezi-Touch pump. (ST & ET Model) Press the pump symbol on the touch

pad, the pump will start and purge the air from the system and your spa will

start to operate. To stop the spa, simply press the pump symbol on the touch

pad again.

5. Spa-Key. (SK Model) Press the pump symbol on the hand set, the pump will

start and purge the air from the system and your spa will start to operate. To

stop the spa, simply press the pump symbol on the hand set again.

6. If the pump fails to prime you may have an air lock, please refer to activating

air bleed. If after activating the air bleed - the pump will still not prime –

check the height of the pump and adjust to the correct level.

EDGETEC SYSTEMS PTY LTD Part # 9-2100 FEB2017 www.edgetec.net

13

Activating Air Bleed- (refer page 8)

Note: If after Activating Air Bleed the pump does not prime – check pump height

and pipework installation – refer page 3.

Blue or clear Air Bleed Cap

1. The air bleed valve is manufactured in the closed position and if your pump is

installed as per page 3 - there is no need to activate this valve.

2. If your spa pump is not priming, activating the air bleed valve MAY improve

priming. To do this you will require a 4mm or 3/16 drill bit. Carefully drill out the

blank in the air bleed elbow ensuring that you do not drill through the outer wall

(refer page 7).

3. It is common for air bleed valves to “Squirt” water when sealing, this will occur

every time the pump is switched on. Once the internal valve is seated, the

water “squirt” will stop.

4. INTERNAL INSTALLATION - to avoid water damage, FIT PRO- TEC DRAIN TRAY.

ATTACH 10 MM FLEXIBLE DRAIN TUBE (NOT SUPPLIED) AND CONNECT TO DRAIN

TRAY. FIT 10 MM FLEXIBLE DRAIN TUBE TO WASTE. REFER DRAIN TRAY INSTALLATION

INSTRUCTIONS.

Twist Air Bleed Cap (No Drilling Required)

The Twist Air Bleed has a Twist Cap which will activate when Cap is rotated Fully

Anticlockwise. Rotating the Twist Cap Fully Clockwise will close the air Bleed.

The pump is shipped with the air bleed in the closed position.

1. If your pump is installed as per page 3 - no need to activate this valve.

2. If your spa pump is not priming, activating the air bleed valve MAY improve

priming. To do this Rotate the Red Cap air Bleed valve Fully Anticlockwise.

3. It is common for air bleed valves to “Squirt” water when sealing, this will occur

every time the pump is switched on. Once the internal valve is seated, the

water “squirt” will stop.

4. INTERNAL INSTALLATION - to avoid water damage, FIT PRO- TEC DRAIN TRAY.

ATTACH 10 MM FLEXIBLE DRAIN TUBE (NOT SUPPLIED) AND CONNECT TO DRAIN

TRAY. FIT 10 MM FLEXIBLE DRAIN TUBE TO WASTE. REFER DRAIN TRAY INSTALLATION

INSTRUCTIONS.

Pro-Tec Drain Tray

DRAIN TRAY FITTED

Your spa bath pump should be installed on a well-drained

location or on a suitable drain tray on internal installations

to avoid water damage to property should any leaks

occur from pipe work, connections or normal wear.

!

EDGETEC SYSTEMS PTY LTD Part # 9-2100 FEB2017 www.edgetec.net

14

Trouble Shooting Guide

Auto-Heat & Xtra-Heat - Spa Pump will not start

Possible Cause

Suggested Action

Air tube is not

connected

Check the air tube is connected to the air button on the spa bath and the

air switch on the pump

Air Tube is kinked

Check the air tube is not kinked or wrapped around the frame work as this

will stop the pulse of air required to activate the pump

Air button is not

operating

Check the air button is clear of debris (i.e. tile grout) and that the air button

plunger moves freely.

Mains Power to

pump is not

switched on

Check the power point is in the “on” position

Check the Power Point has 240V Power

Pump Air switch

Contact service technician or spa installer.

Pump is not Priming - No water coming from jets

No water from Jets

Check the height of pump

Check that adjustable spa jets are in the open position

Activate Air Bleed-Refer to activating Air Bleed- page12

Eezi & Sensa-Touch - Spa Pump will not start

Possible Cause

Suggested Action

Mains Power to

pump is not

switched on

Check the Power Point has 240V Power

Check that the power point is “on”. Green indicator light should be glowing

on the touch pad to indicate power.

Communication

Cable is not

connected

Check the communication cable is connected to the Touch Pad and the

communication port on the pump. Green indicator light should glow on the

touch pad to indicate power

Touch Pads Lights

are all flashing

The touch pad may have entered fault mode, switch the power off at the

power point, wait 15 seconds and then switch the power back on. Only the

Green light on the touch pad should now be illuminated.

Mains Power to

pump is not

switched on

Check the power point is in the “on” position

Check the Power Point has 240V Power

Pump is not Priming - No water coming from jets

Pump runs but

stops after 10

seconds

Check the height of pump

Check that adjustable spa jets are in the open position

Activate Air Bleed-Refer to activating Air Bleed- page12

No water from Jets

Contact service technician or spa installer.

Spa-Key - Spa Pump will not start - www.spakey.com.au

Possible Cause

Suggested Action

Mains Power to

Spa pump

switched off

Check the Power Point has 240V Power

No Red LED glow

on handset.

Check the batteries are installed in your handset. Press any button on the

handset, if the Red LED glows-battery is OK. Dim or No Red glow replace

battery.

Mains Power to

Spa pump

switched off

Check the power point is in the “on” position

Check the Power Point has 240V Power

Pump is not Priming - No water from jets

Pump runs but

stops after 10

seconds

Check the height of pump

Check that adjustable spa jets are in the open position

Activate Air Bleed-Refer to activating Air Bleed- page12

No water from Jets

Contact service technician or spa installer.

EDGETEC SYSTEMS PTY LTD Part # 9-2100 FEB2017 www.edgetec.net

15

TriFlo Technical Data

Pump Model

Supply

Voltage

Power

(watts)

Heater

(watts)

Current

(amps)

Width

(mm)

Height

(mm)

Length

(mm)

dB

Rating

IP

Rated

TF060-AH-50

230-240

600 0 3.7

148

198

384

65

55

TF075-AH-50-HF

230-240

750 0 4.4

148

198

384

65

55

TF110-AH-50

230-240

1100 0 5.4

148

198

406

65

55

TF060-XH, ET, ST, SK-50

230-240

600

700

6.8

148

198

384

65

55

TF075-XH, ET,ST, SK-50-HF

230-240

750

700

7.5

148

198

384

65

55

TF110-XH, ET,ST, SK-50

230-240

1100

700

8.6

148

198

406

65

55

This appliance is not intended for use by persons (including children)

with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a person

responsible for their safety.

!

Never run your spa pump without water as this can cause serious

damage to the mechanical seal – which may cause the spa pump to

leak. Running the pump without water will void your warranty.

!

EDGETEC SYSTEMS PTY LTD Part # 9-2100 FEB2017 www.edgetec.net

16

Edgetec Product Warranty

Edgetec Systems Pty Ltd warrants that the items sold hereunder shall be free from

defects in material and workmanship for a period of one (1) year at the time of the

original purchase date and to the original purchaser.

Terms & Conditions

1. This product is to be installed in accordance with the installation and operating

instructions provided failure to do so will void your warranty.

2. The product warranty does not cover:

fair wear and tear, negligence, misuse or abuse,

incorrect installation or running the pump dry,

water damage from external sources or inadequate ventilation,

cement or other building debris blocking the pipe work or impeller,

chemically treated water,

high voltage spikes or acts of nature,

repairs by unauthorised persons,

Incorrect voltage.

Edgetec Systems Pty Ltd has service agents throughout Australia, should you require

warranty service please contact our service department for your nearest service

agent.

Edgetec Systems Pty Ltd goods come with guarantees that cannot be excluded

under the Australian Consumer Law. You are entitled to a replacement or refund for

a major failure and compensation for any other reasonably foreseeable loss or

damage. You are entitled to have the goods repaired or replaced if goods fail to

be of acceptable quality and the failure does not amount to a major failure. No

unauthorized personnel can make any warranty representation on the behalf of

Edgetec Systems Pty Ltd without written permission.

Commercial Installation

Commercial Warranty: Has a limited warranty of (6) months from the date of

purchase to these commercial installations including (but not limited to) hotels,

motels, caravan parks and health clubs installations etc.

13 Lieber Grove

Carrum Downs

Victoria 3201 Australia

Tel: (613) 9775 0882

Fax: (613) 9775 0881

Email:sales@edgetec.net

Web: www.edgetec.net

Proudly Australian Owned

Loading...

Loading...