Page 1

904-TWH12-D1-01

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

3

1

© 2014 Edge Lighting. All Rights Reserved.

1718 W. Fullerton Ave

Chicago, IL 60614

Tel: 773-770-1195

Fax: 773-935-5613

www.edgelighting.com

info@edgelighting.com

TWH12-D1-1RE-_

TWH12-D1-4SQ-_

Installation Instructions for Twiggy Hinged 12V AC, Direct Lens with 4"

Square Canopy or 1" Rectangular Canopy

IMPORTANT INFORMATION

- This instruction shows a typical installation.

- This product must be installed by a qualified electrician.

- The 1RE version mounts to the provided C-1RE-JBOX. The

4SQ version mounts to standard electrical box with plaster

ring or octagon box.

- Before beginning any electrical work, ensure that

the power to the installation is turned OFF!

SAVE THESE INSTRUCTIONS!

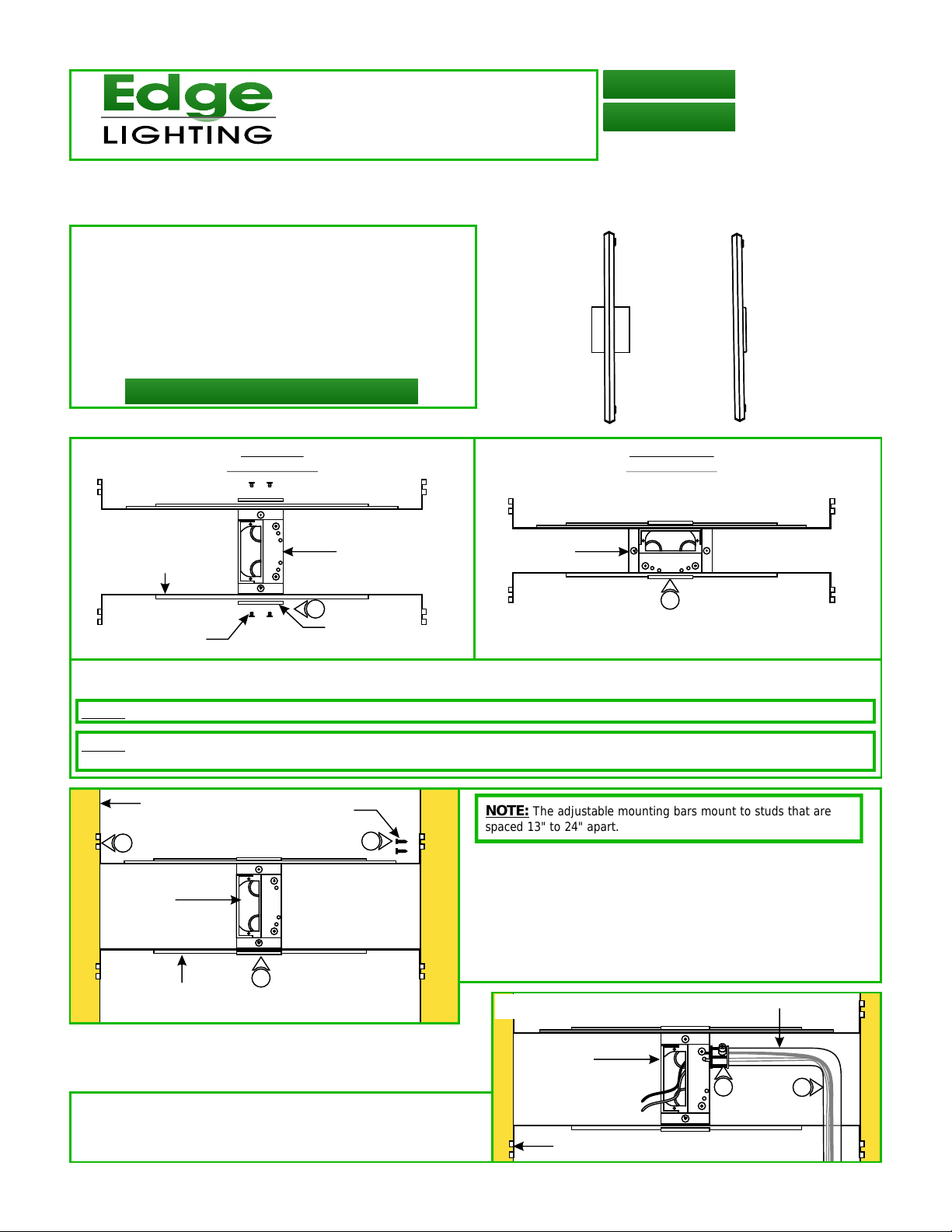

Section One: Steps for TWH12-D1-1RE

A

VERTICAL

ORIENTATION

HORIZONTAL

ORIENTATION

ADJUSTABLE

MOUNTING BAR

PHILLIPS

SCREW

JUNCTION

BOX

1

MOUNTING

BRACKET

JUNCTION

BOX

1

1: Mount each adjustable mounting bar to one side of the junction box (mounts to any side of the housing depending on the

orientation of the channel) and secure them with the mounting brackets and two Phillips screws provided.

NOTE: The adjustable mounting bars mount to studs that are spaced 13" to 24" apart.

NOTE: Ensure the opening of the junction box is alinged with the center of the desired fixture location. If necessary, adjust the junction box

location by loosening the screws and sliding the junction box to the proper location. Tighten the Phillips screws after adjusting.

B

STUD

#8 SCREW

NOTE: The adjustable mounting bars mount to studs that are

spaced 13" to 24" apart.

3

4

Select the location between the two studs for the junction

2:

box to be mounted.

JUNCTION

BOX

3: Place the adjustable mounting bars between the studs.

4: Make sure the lips on the adjustable mounting bars are

against the studs. Secure the adjustable bars to the studs

with the eight #8 screws.

C

CONDUIT

ADJUSTABLE

MOUNTING BAR

2

5: Remove a knockout to install the power line conduit.

6: Ensuring power to the junction box is off, install the conduit

and run the 120V power wires.

JUNCTION

BOX

STUD

5

6

1

Page 2

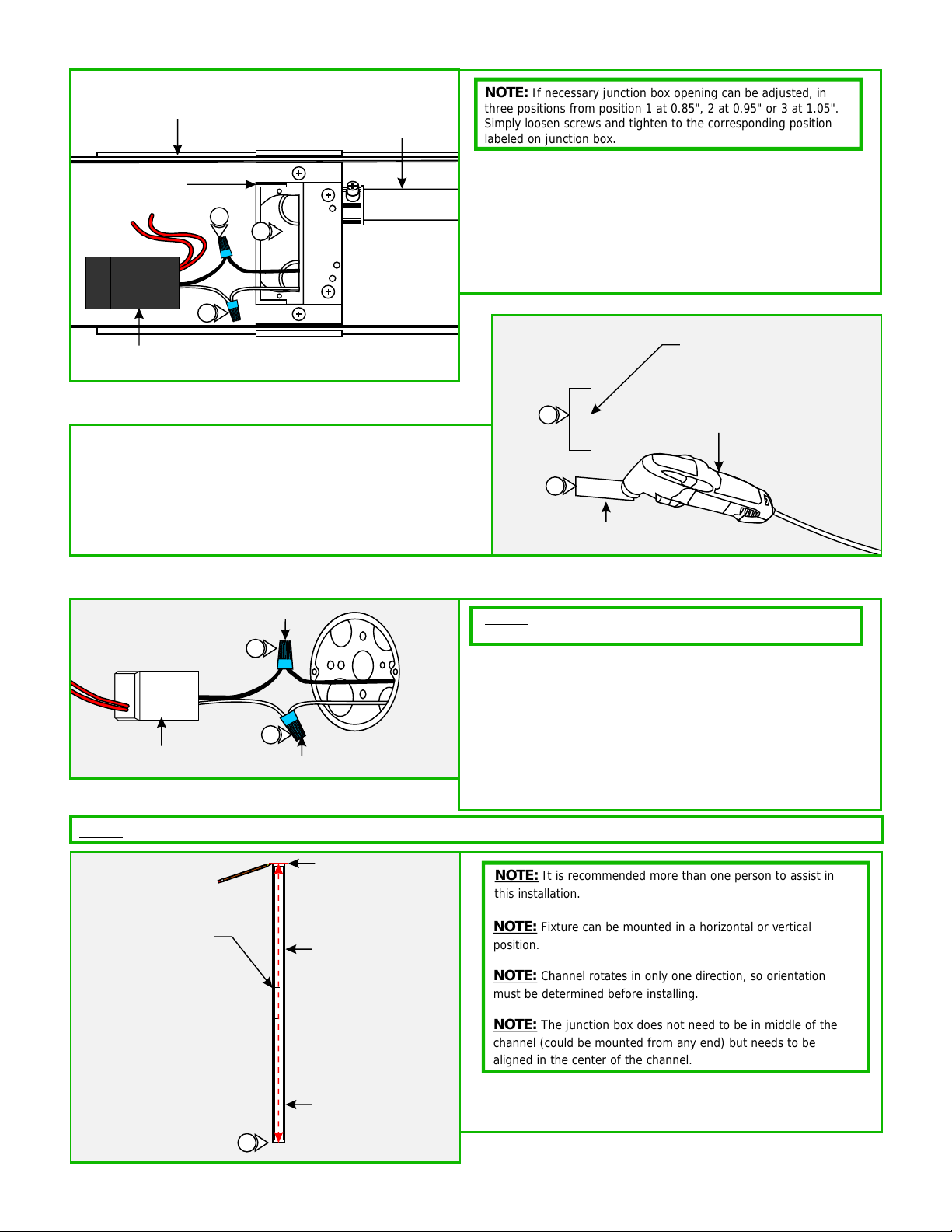

D

2

3

1

2

3

1

TRANSFORMER

ADJUSTABLE

MOUNTING BARS

JUNCTION

BOX

8

7

NOTE: If necessary junction box opening can be adjusted, in

three positions from position 1 at 0.85", 2 at 0.95" or 3 at 1.05".

CONDUIT

9

Simply loosen screws and tighten to the corresponding position

labeled on junction box.

7: Connect the white transformer wire to the neutral power

wire with a wire nut.

8: Connect the black transformer wire to the hot power wire

with a wire nut.

9: Place the transformer and transformer wires inside the

junction box.

E

RECTANGLE

OPENING

DRYWALL

10

Mark a rectangle shape on drywall where the junction box

10:

opening will be located depending on selected position.

11: Cut out the marked rectangle opening, using a "Dremel

Multi-Max" with the "wood & drywall" cutting bit.

12: Follow steps in Section Three to complete installation.

11

Section Two: Steps for TWH12-D1-4SQ

D

TRANSFORMER

Section Three: Install Fixture

NOTE: Twiggy Hinge w/rectangular junction box shown for illustration purposes.

WIRE NUT

2

1

WIRE NUT

NOTE: Low-voltage power wires should be present in the

junction box before completing the steps in this section.

1: Connect the white power supply wire to the neutral power

wire with a wire nut.

2: Connect the black power supply wire to the hot power wire

with a wire nut.

3: Place the power supply and wires inside the electrical box.

4: Follow steps in Section Three to complete installation.

DREMEL

MULTI-MAX

WOOD & DRYWALL

CUTTING BIT

F

WALL

1RE JUNCTION

BOX OPENING

MARK LOCATION

CENTER LINE

CHANNEL

1

NOTE: It is recommended more than one person to assist in

this installation.

NOTE: Fixture can be mounted in a horizontal or vertical

position.

NOTE: Channel rotates in only one direction, so orientation

must be determined before installing.

NOTE: The junction box does not need to be in middle of the

channel (could be mounted from any end) but needs to be

aligned in the center of the channel.

1: Center the channel to the junction box opening. Make

markings to each end of the channel and also make a center

line from end to end.

Page 3

HINGE

BACK OF CHANNEL

MOUNTING

HOLE

G

5

HINGE

CHANNEL

If the junction box is located at one end of the channel, then

NOTE:

loosen the #4-40 set screw with the 0.05 Allen wrench on one of the

back cover moving the opening hole to one end. Pull the wire out of

that end & retighten the #4-40 set screw with the 0.05 Allen wrench.

HINGE LINE (3/16" AWAY

FROM THE CENTER LINE)

2

CENTER LINE

2

HINGE

WALL

2: Unfold the channel hinges. Align the channel between the

marked lines and mark the hinge holes 3/16" away from the

center line.

E

#4-40

SET SCREW

CHANNEL

0.05 ALLEN

WRENCH

BACK COVER

WALL

H

3

CEILING

ANCHOR

4

ANCHOR MUST

BE FLUSH TO WALL

5: Line up the hinge to the anchors and secure it by tightening

the #8 screws to each hinge.

3: Tap the anchors onto the marked points up to the threaded

portion with a hammer.

4: Screw in the threaded portion of the anchors with a Phillips

screwdriver.

J

CHANNEL

HINGE

5

#8 SCREW

5

WALL

2

Page 4

INSULATION

BRAIDED

WIRE

INNER

INSULATION

BARE WIRE

1/8"

COAXIAL CABLE

1/4"

INSULATION

BRAIDED

WIRE

COAXIAL CABLE

1"

K

JUNCTION BOX

CHANNEL

7: Using the 16 AWG hole of a pair of wire strippers, remove 1"

of outer plastic insulation from the coaxial cable.

COVER

6

COAXIAL

CABLE

6: Pull the coaxial cable through center hole of junction box

cover.

L

7

WIRE STRIPPERS

M

8

COAXIAL

CABLE

WIRE STRIPPERS

9

10: Unscrew the coaxial connector covers and remove from the

connector assembly.

O

2MM ALLEN

WRENCH

M4 SET

SCREW

12

M3 SET

SCREW

1.5MM ALLEN WRENCH

11

8: Using the 18 AWG hole of the wire strippers, remove

braided wire leaving 1/4" from the outer plastic insulation.

9: Using the 20 AWG hole of the wire strippers, remove 1/8"

of inner plastic insulation from the end of the coaxial cable.

N

COAXIAL

CONNECTOR

COVER

10

CONNECTOR

ASSEMBLY

COAXIAL

CONNECTOR

COVER

11: Using the provided 1.5mm Allen Wrench, remove the M3

set screw from the coaxial connector assembly.

12: Using the provided 2mm Allen wrench to loosen (do not

remove) the M4 set screw.

13: Slide the connector cover over the coaxial cable.

14: Place the ferrule over the braided wire of the coaxial cable.

P

COAXIAL

CONNECTOR

COVER

13

BRAIDED

WIRE

FERRULE

14

3

Page 5

2

3

1

2

3

1

Q

COAXIAL

COAXIAL

CABLE

CONNECTOR

ASSEMBLY

15

15: Insert the coaxial cable into the coaxial connector until the wires of the center conductor are visible through the M3 set

screw hole.

NOTE: Ensure that the split in the ferrule is aligned 90° from the M4 set screw (see inset).

CABLE

CONNECTOR

ASSEMBLY

FERRULE

R

COAXIAL

CABLE

1.5MM ALLEN

WRENCH

CONNECTOR

ASSEMBLY

16

M3 SET

SCREW

17: Use the provided 2mm Allen wrench to securely tighten the

M4 set screw until it squeezes the wire ferrule tightly to the

coaxial cable.

T

COAXIAL

18

CONNECTOR

COVER

16: Use the provided 1.5mm Allen wrench to replace and

securely tighten the M3 set screw.

S

2MM ALLEN

WRENCH

COAXIAL

CABLE

17

M4 SET

SCREW

CONNECTOR

ASSEMBLY

18: Replace the coaxial connector cover and tighten into

place.

COAXIAL

CABLE

19: Connect the red wire from the coaxial connector to one of

the LED driver wires using a wire nut.

20: Connect the black wire to the remaining LED driver wire

using a wire nut.

21: Place all connections into the junction box.

U

COAXIAL

CONNECTOR

WIRE

NUT

WIRE

NUT

19

20

4

Page 6

ROTATES UP TO 90º

HINGE

BACK OF CHANNEL

TIGHTEN SET

SCREW TO

HOLD

POSITION

V

22

CHANNEL

JUNCTION

BOX

22: Attach the junction box cover to the junction box with the

provided hex screw.

HEX SCREW

COVER

23: If necessary channel can be rotated up to 90º degrees, and

to hold the position, tighten the M2 set screw to each the

hinge with a 0.9mm Allen wrench.

GENERAL WIRING DIAGRAM

INPUT

120VAC

WHITE (NEUTRAL)

BLACK (HOT)

ELECTRONIC LOW

VOLTAGE DIMMER

YELLOW

WHITE (NEUTRAL)

BLACK (HOT)

LED TRANSFORMER

W

RED (12VAC)

RED (12VAC)

COAXIAL

CONNECTOR

23

TWIGGY

COAXIAL

CABLE

5

Loading...

Loading...