Page 1

Installation Instructions For

© 2014 Pure Lighting. All Rights Reserved.

IMPORTANT INFORMATION

- This fixture is wall or ceiling mount.

- This instruction shows a typical installation.

- Consult the configuration notes on Page 1 before

beginning any installation.

- This product is ETL listed for indoor use.

SAVE THESE INSTRUCTIONS!

TruLine .5A 24VDC

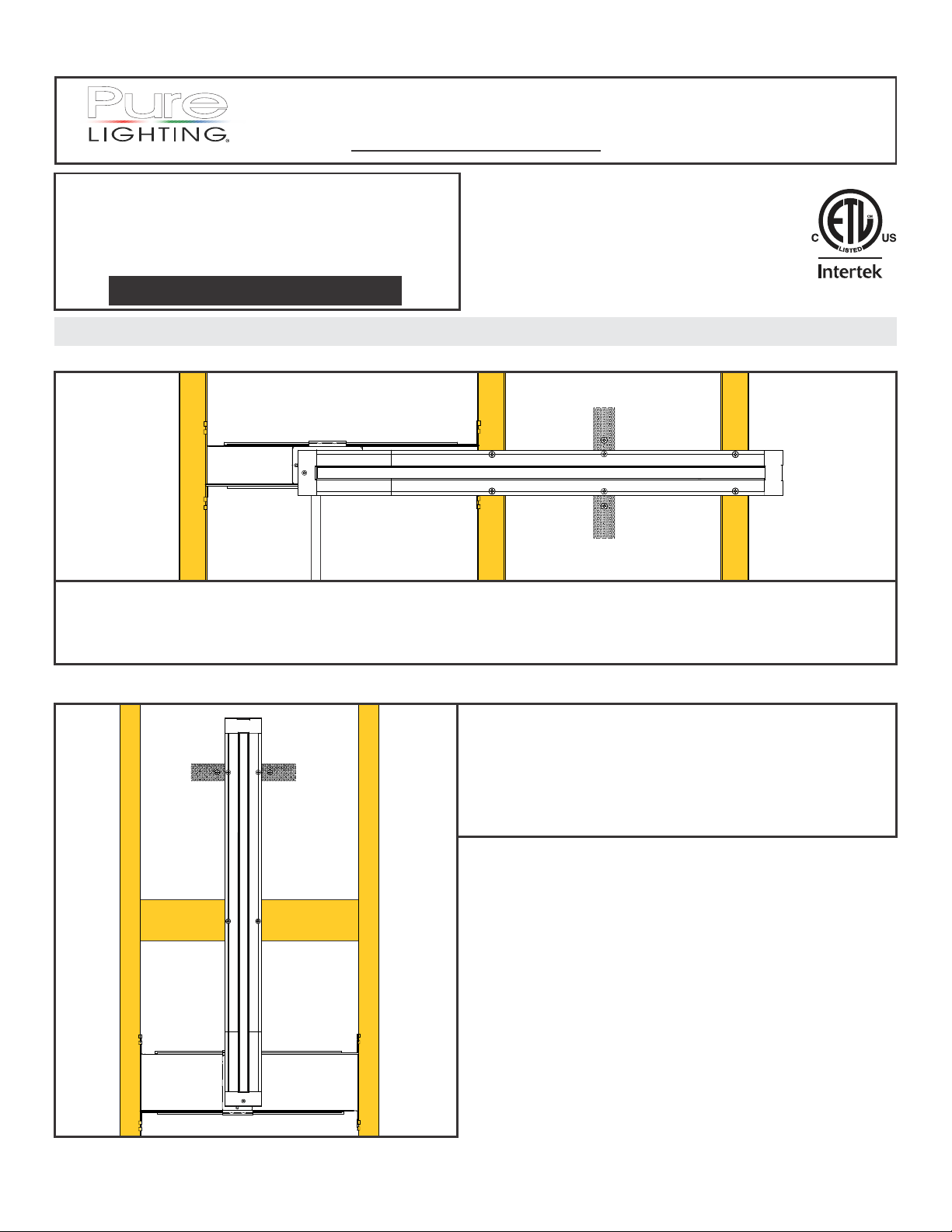

Section One: Basic Configuration Options

Horizontal Configuration

INS# 902-TL.5A-01

1718 W. Fullerton Ave

Chicago, IL 60614

Tel: 773-770-1195

Fax: 773-935-5613

www.purelighting.com

info@purelighting.com

Horizontal installations are linear runs of channel beginning and ending at an end cap and junction/take-up box on a single plane

surface. Runs can be up to 40' in length and the LED strip lays in the bottom of the channel.

Horizontal installations are typically installed perpendicular to wall studs or ceiling joists. Where no stud/joist is present (or in a

remodel installation) a mounting strap may be used to secure the channel to the drywall.

Vertical Configuration

Vertical installations are linear runs of channel beginning and

ending at an end cap and junction/take-up box on a single plane

surface. Runs can be up to 40' in length and the LED strip lays in

the bottom of the channel.

Horizontal installations are typically installed between wall studs

or ceiling joists. Cross-braced stud sections or mounting straps

are suggested to provide additional support every 32".

1

Page 2

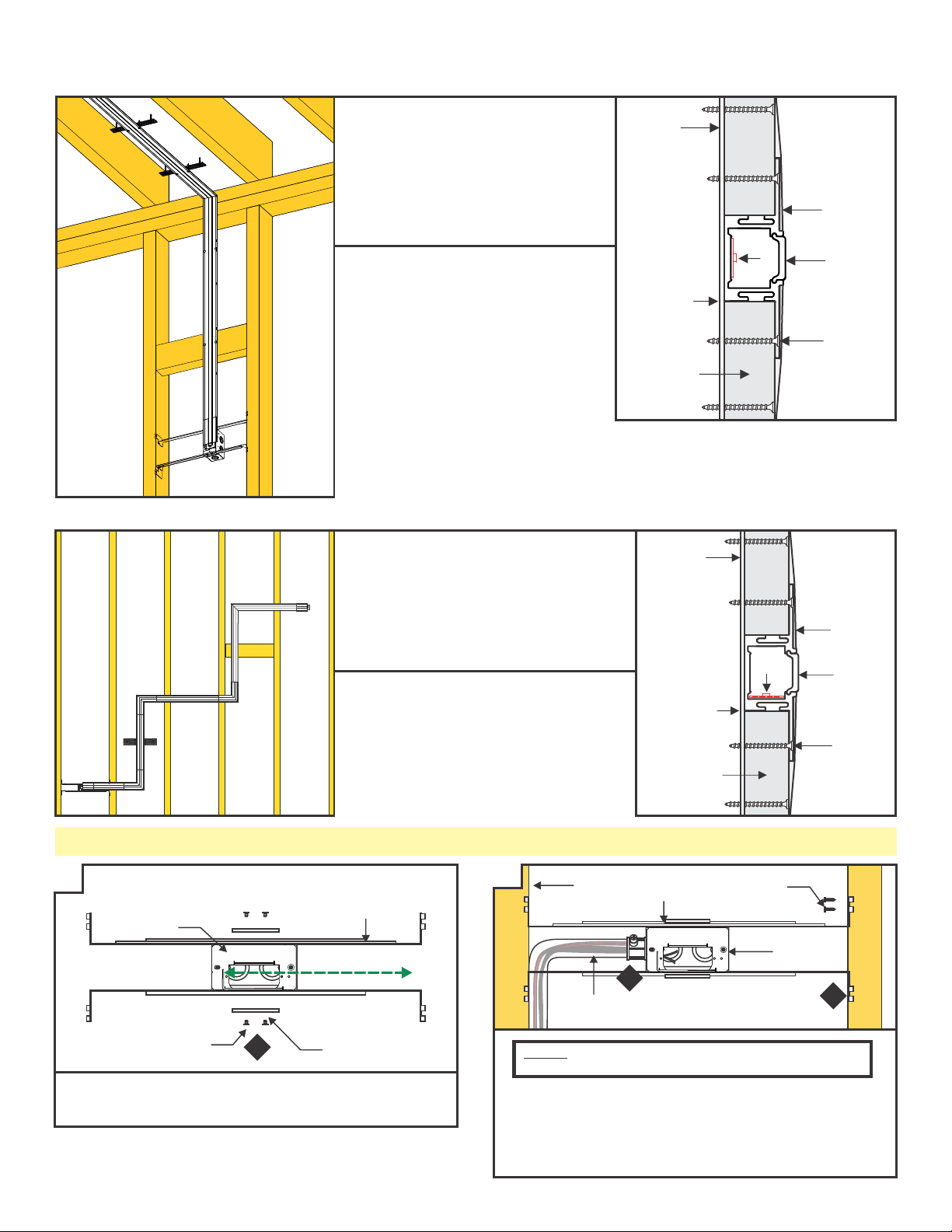

Room-Wrapping Configuration

LENS

PLASTER

MOUNTING

STRAP

CHANNEL

DRYWALL

DRYWALL

SCREW

LED

STRIP

Zig Zag Configuration

Room-wrapping configurations are used

for installations that join runs of TruLine

.5A on multiple planes (like a ceiling and a

wall) using miter-cut linear sections of

channel.

For room-wrapping installations, the LED

strip will be installed in the bottom of the

channel.

Zig Zag configurations are used for

installations that join runs of TruLine .5A on a

single plane (like a ceiling or a wall) using

sections of channel joined by L connections.

MOUNTING

STRAP

CHANNEL

DRYWALL

LED

STRIP

PLASTER

LENS

DRYWALL

SCREW

For Zig Zag installations, the LED strip will be

installed in the side of the channel to allow the

strip to follow the channel corners.

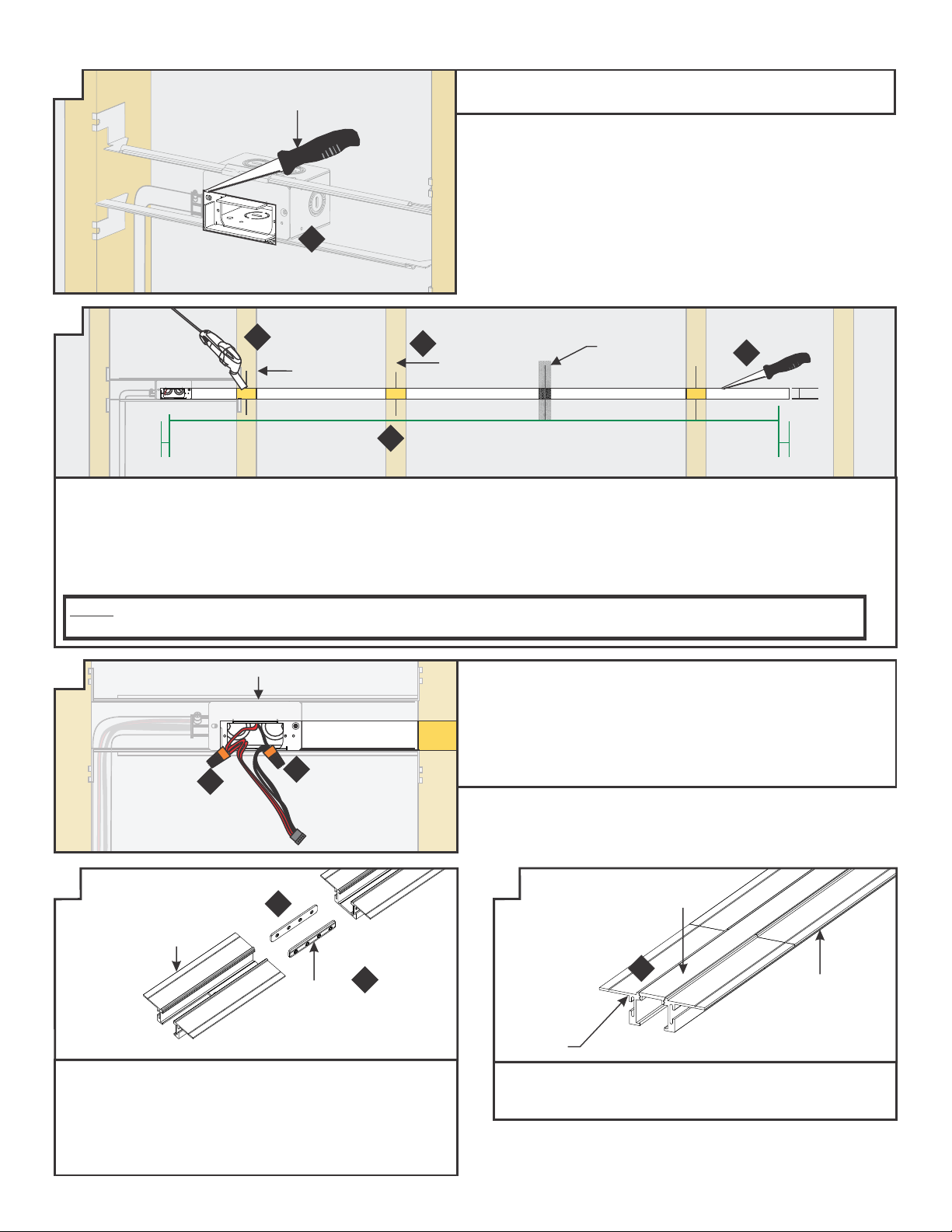

Section Two: Standard Horizontal Installation

A

ADJUSTABLE

JUNCTION

BOX

PHILLIPS

SCREW

1: Mount each adjustable mounting bar to one side of the

junction box and secure them with the mounting brackets

and two Phillips screws provided.

1

MOUNTING BAR

INSTALLATION

DIRECTION

MOUNTING

BRACKET

B

NOTE: The adjustable mounting bars mount to studs that

are spaced 13" to 24" apart.

2: Place the lips on the adjustable mounting bars against

the studs. Secure the adjustable bars to the studs with

the eight #8 screws.

3: Install conduit (if required by local electrial code) and run

low-voltage power wires to the junction box.

2

ADJUSTABLE

STUD

MOUNTING BAR

3

CONDUIT W/

LOW-VOLTAGE WIRES

#8 SCREW

JUNCTION

BOX

2

Page 3

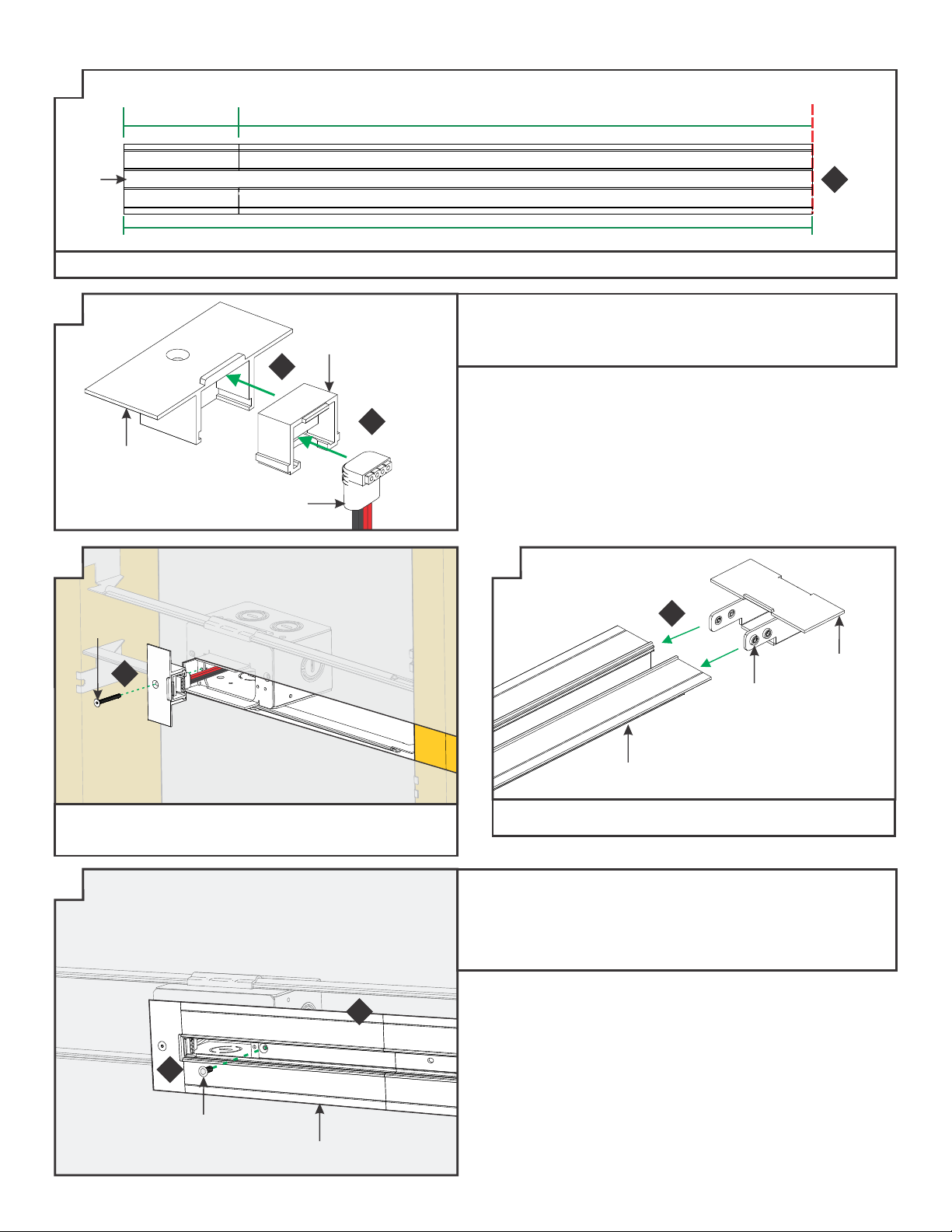

C

6" FIXED

JAB SAW

4

4: Cut a section of drywall using a 6" fixed jab saw or other

appropriate tool to expose the mounting plate area.

D

6

STUD

0.75"

5: Determine the desired length of lit installation area and mark on wall. The total installation length cut will need to be 1 3/4" longer

than the desired lit installation area to account for the fixture end caps. (For example, a desired 48" lit area will require a

drywall cut of 49 3/4" inches). Mark this length on the wall using the junction box mounting plate and a level as a guide.

6: Cut out the marked area using a "Dremel Multi-Max" or a 6" Fixed Jab Saw.

7: Mark the location of the studs to the drywall for future reference.

NOTE: To install channel in a wall without standard-spaced studs, install perforated mounting straps every 32" behind drywall

and secure using two drywall screws. Mark the location of any mounting straps to the drywall.

E

JUNCTION BOX

8

9

7

MARKING

DESIRED LIT LENGTH

5

8: Connect the red power supply (24VDC+) wire to the red

power connector wires with a wire nut.

9: Connect the black power supply (24VDC-) wire to the black

power connector wires with a wire nut.

10: Place the wire nut connections inside junction box.

MOUNTING

STRAP

6

1.05"

1.0"

F

11

TRAP DOOR

FRAME

JOINER

BAR

11: Insert the joiner bars halfway into the channel trap door

frame. Tighten the two #4-40 set screws on each joiner bar

with a 0.05" Allen wrench.

12: Slide the other section of channel onto the joining bars and

tighten the remaining #4-40 set screws with a 0.05" Allen

wrench.

12

G

LENS

13

CHANNEL

TRAP DOOR

FRAME

13: Snap the lens into the assembled trap door frame and

channel BEFORE cutting to length. This ensures a proper

fit after installation.

3

Page 4

H

TRAP DOOR

FRAME

CHANNEL

SECTION

LENS

DESIRED LIT LENGTH

14: Cut the assembled trap door frame, channel, and lens to match the desired lit installation length.

I

END CAP

INSERT

15: Place the power connector into the end cap insert.

16: Slide the assembled end cap insert and power connector into

the end cap.

16

15

END CAP

POWER

CONNECTOR

J K

#4-40

SCREW

14

18

17

17: Secure the assembled power connector end cap to the

junction box with the #4-40 screw using a 1.5mm Allen

wrench.

L

19

20

TAKE-UP

BOX

M4 SET

SCREW

CHANNEL

18: Slide the take-up box onto the non-power channel end and

tighten the M4 set screws.

19: Place the assembled channel to the cutout area on the wall

making sure to fully seat it against the power connector end

cap.

20: Attach the assembled trap door frame and channel to the

junction box using the #4-40 screw.

#4-40

SCREW

TRAP DOOR

FRAME

4

Page 5

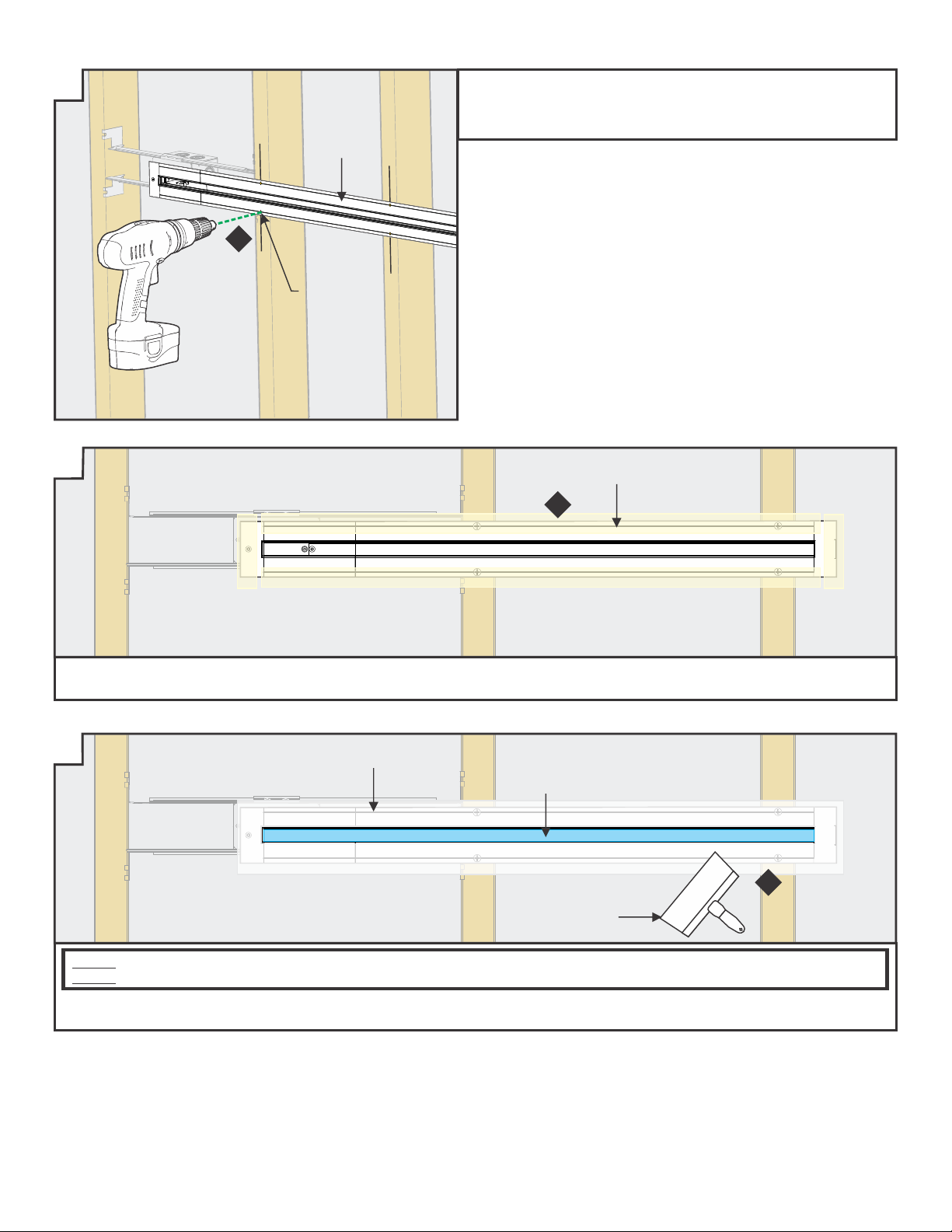

M

21: Drill and countersink the channel at stud markings.

22: Properly secure the channel to the wall using drywall screws.

Ensure all screw heads are flush with the channel surface.

CHANNEL

21

DRILL AND

COUNTERSINK

N

23: Apply ultra-thin drywall tape along edges of channel to prevent cracking of plaster after installation. DO NOT overlap strips of

drywall tape.

O

PLASTER

CONTRACTOR'S

TAPE

ULTRA-THIN

DRYWALL TAPE

23

24

12" COMPOUND

KNIFE

NOTE: Test the LED strip before any plaster work is done

NOTE: Cover the channel opening with contractor’s tape before plastering.

24: Use a 12" compound knife for a smooth compound spread. Sand, paint, and finish the plaster and drywall before removing the

blue contractor's tape.

5

Page 6

P

TRAP DOOR

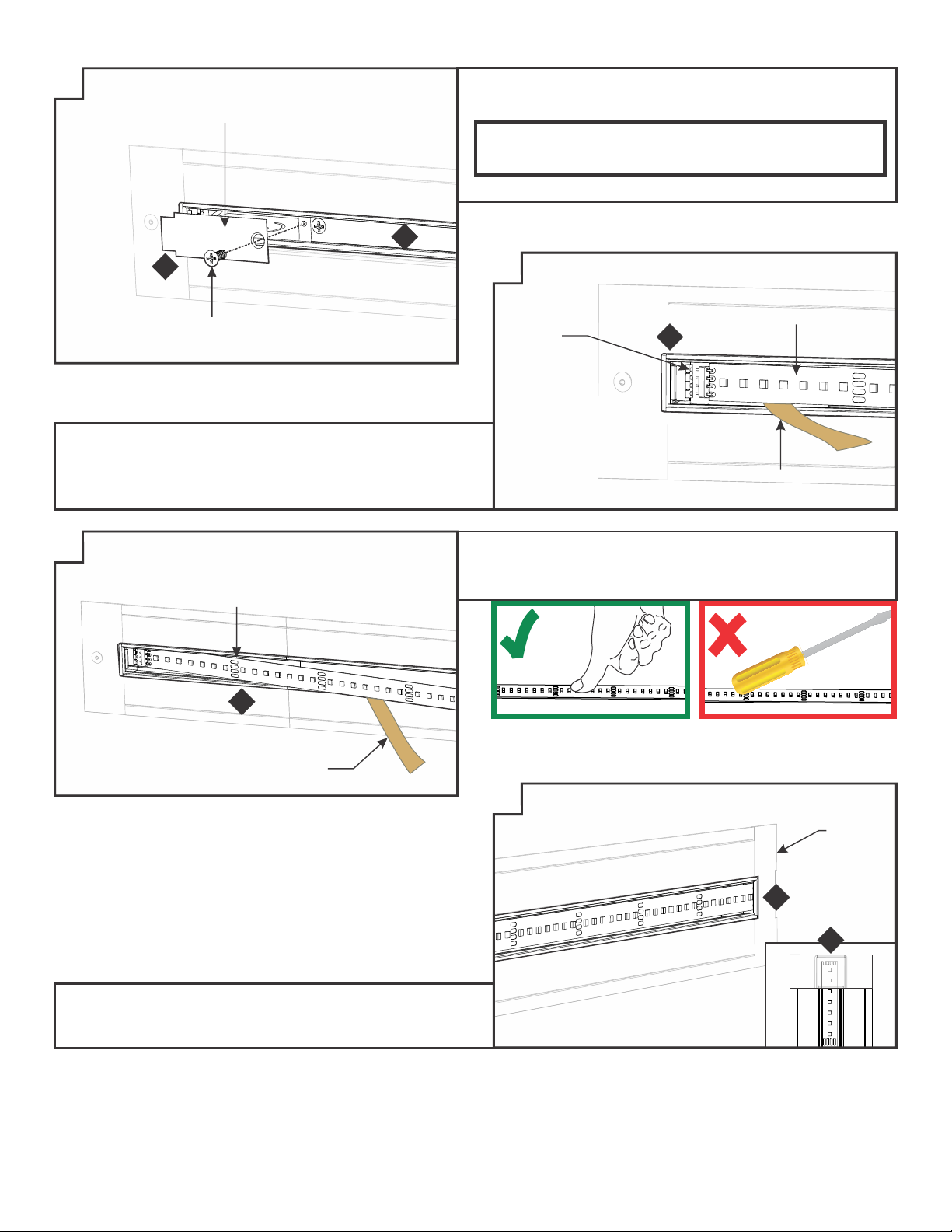

26: Remove the blue contractor’s tape from the inside of the

channel. Clean the channel surface with alcohol to remove

any dust or debris before continuing.

IMPORTANT: Soft strip may not properly adhere to channel

surface unless the channel is cleaned with alcohol prior to

application.

27: Attach the trap door to the junction box using the #6-32 screw.

26

27

#6-32

SCREW

28: Carefully remove the backing from the LED soft strip, making

sure not to remove the tape from the soft strip. Line up the red

wire side of the power connector with the “+24VDC” marking

on the Soft Strip. Push the male connector of the Soft Strip

into the female power connector.

R

LED STRIP

29

Q

POWER

CONNECTION

29: Firmly press down the adhesive portion of the soft strip onto

the channel surface while removing the rest of the backing,

making sure there are no air bubbles that can cause surface

irregularities.

28

LED STRIP

PAPER

BACKING

PAPER

BACKING

30: If required, trim the soft strip on the dashed cuttable section,

place the excess soft strip inside the take up box (see inset).

Ensure the entire length of the channel is covered with Soft

Strip to avoid unlit areas.

S

TAKE-UP

BOX

30

30

6

Page 7

T

31

31

CORRECT

31: Snap the lens back onto the channel. Ensure lens is fully seated.

Section Three: Vertical Installation

U

ADJUSTABLE

MOUNTING BAR

PHILLIPS

SCREW

1: Mount each adjustable mounting bar to one side of the

junction box and secure them with the mounting brackets

and two Phillips screws provided.

VERTICAL

ORIENTATION

INSTALLATION

DIRECTION

JUNCTION

BOX

1

MOUNTING

BRACKET

NOT INSTALLED

CORRECTLY

V

STUD

CONDUIT

3

2: Remove a knockout to install the power line conduit (if

required by local electrical code.

3: Install the conduit and run the low voltage 24V DC power

wires coming from the remote power supply to the

junction box.

JUNCTION

BOX

ADJUSTABLE

MOUNTING BAR

W

DRYWALL

4: Refer to the instruction provided with the power supply

along with the wiring diagram for proper wiring.

4: Cut a section of drywall using a 6" fixed jab saw or other

appropriate tool to expose the mounting plate area.

6" FIXED

JAB SAW

3

7

Page 8

X Y

1.0"

DREMEL

MULTI-MAX

DRYWALL

MOUNTING

STRAP

STUD

5

DESIRED LIT LENGTH

6

JUNCTION

BOX

0.75"

1.05"

5: Determine the desired length of lit installation area and

mark on wall. The total installation length cut will need to

be 1 3/4" taller than the desired lit installation area to

account for the fixture end caps. (For example, a desired

48" lit area will require a drywall cut of 49 3/4" inches)

Mark this length on the wall using the junction box

mounting plate and a level as a guide.

6: Cut out the marked area using a "Dremel Multi-Max" or a

6" Fixed Jab Saw.

6" FIXED

JAB SAW

9

10

JUNCTION

BOX

8: Install mounting straps behind the drywall (suggested

spacing is every 32") by threading a drywall screw into

the perforated material.

9: Place the mounting strap behind the cut drywall and rotate

into place using the drywall screw as a handle.

10: Secure the mounting strap to the drywall using two

drywall screws. Mark the location on the drywall.

DRYWALL

SCREW

10

Complete cutting, mounting,

plastering,painting, and LED strip

installation by following Steps 8

through 31 on Pages 3 through 7.

Z

STUD

11

SUPPORT

BRACE

11

ALTERNATE VERTICAL INSTALLATION OPTION:

11: Install 2x4 support braces (suggested spacing is every

32") before installing and finishing drywall.

Section Four: Room-Wrapping

Configuration

Z1

ASSEMBLED

CUTAWAY VIEW

OUTSIDE CORNER

INSIDE CORNER

INSTALLATION NOTES

Room-wrapping installations use LED strip bent 90° for inside

or outside corner configurations. Channel sections will be

miter cut on-site.

8

Page 9

45°

45°

Z2 Z3

1.0"

DESIRED LIT LENGTH

CEILING

WALL

2

DESIRED LIT LENGTH

1

JUNCTION

0.75"

1: Install junction box and low-voltage power.

2: Measure and mark installation length, allowing for 0.75"

extra space at junction box for power end cap and 1.0" inch

at the end of the installation for the take-up box. Cut

out marked areas using appropriate tools.

BOX

3: Insert the joiner bars halfway into the channel trap door

frame. Tighten the two #4-40 set screws on each joiner bar

with a 0.05" Allen wrench.

4: Slide the other section of channel onto the joining bars and

tighten the remaining #4-40 set screws with a 0.05" Allen

wrench.

TRAP DOOR

FRAME

TRAP DOOR

FRAME

5

3

JOINER

BAR

4

LENS

CHANNEL

Z4

MARK DESIRED LIT LENGTH

ASSEMBLED LENS AND CHANNEL w/TRAP DOOR FRAME

ADDITIONAL CHANNEL AND LENS SECTIONS AS REQUIRED

6: Mark the desired lit length on the assembled channel and lens lengths.

Z5

SIDE VIEW

5: Snap the lens into all channel sections BEFORE cutting to

length. This ensures a proper fit after installation.

6

7: Miter cut each section of assembled channel and lens to

match the corner angle. In a 90° inside corner installation

as shown, each channel section is cut at a 45° angle to

form a complete corner.

ANGLE VIEW

7

7

9

Page 10

Z6 Z7

MOUNTING

STRAP

9

JUNCTION

BOX

8

8: Connect the red power supply (24VDC+) wire to the red

power connector wires with a wire nut.

9: Connect the black power supply (24VDC-) wire to the

black power connector wires with a wire nut.

10: Place the wire nut connections inside junction box.

12

13

JUNCTION

BOX

DRYWALL

SCREW

13

11: Install mounting straps behind the drywall (suggested

spacing is every 32") by threading a drywall screw into

the perforated material.

12: Place the mounting strap behind the cut drywall and

rotate into place using the drywall screw as a handle.

13: Secure the mounting strap to the drywall using two

drywall screws. Mark the location on the drywall.

Z8 Z9

END CAP

INSERT

15

END CAP

POWER

CONNECTOR

14: Place the power connector into the end cap insert.

15: Slide the assembled end cap insert and power connector

into the end cap.

14

16: Secure the assembled power connector end cap to the

junction box with the #4-40 screw.

JUNCTION

BOX

#4-40

SCREW

16

10

Page 11

Z10 Z11

CHANNEL

DRYWALL

SCREWS

23

CONTRACTOR'S

TAPE

24

ULTRA-THIN

DRYWALL TAPE

22: Using the marked locations on the drywall, carefully make

holes in the channel flange using the provided square drill

with counter sink bit.

23: Secure the channel using drywall screws. Ensure all

screws are flush to the channel.

24: Apply ultra-thin drywall tape along edges of channel to

prevent cracking of plaster after installation.

Z12 Z13

CONTRACTOR'S

TAPE

12"

COMPOUND

KNIFE

25

PLASTER

NOTE: Test the LED strip before any plaster work is done.

NOTE: Cover the channel opening with contractor’s tape

before plastering.

TRAP

DOOR

FRAME

26

27

#4-40

SCREW

28

TRAP

DOOR

25: Use a 12" compound knife for a smooth compound spread.

Sand, paint, and finish the plaster and drywall before

removing the contractor’s tape.

26: Remove the blue contractor’s tape from the inside of the

channel. Clean the channel surface with alcohol to remove

any dust or debris before continuing.

IMPORTANT: Soft strip may not properly adhere to channel

surface unless the channel is cleaned with alcohol prior to

application.

27: Attach the trap door frame to the junction box using a #4 40 screw.

28: Attach the trap door to the junction box using a #4-40 screw.

11

Page 12

Z14

LED SOFT

STRIP

31

30

PAPER

BACKING

29: Line up the red wire side of the power connector with the

“+24VDC” marking on the Soft Strip. Push the male connector

of the Soft Strip into the female connector of the power cables.

30: Carefully remove the backing from the LED soft strip, making

sure not to remove the tape from the soft strip.

31: Firmly press down the adhesive portion of the soft strip onto

the channel surface while removing the rest of the backing,

making sure there are no air bubbles that can cause surface

irregularities.

POWER

CONNECTOR

29

Z15 Z16

32

BEND SOFT

STRIP TO

FOLLOW

CORNER

33

34

32: Continue removing the paper backing from the soft strip

and installing along channel, pressing adhesive into

place using ONLY a finger.

33: Bend the soft strip to match the installation corner.

34

TAKE-UP

BOX

34: If required, trim the soft strip on the dashed cutting lines

ONLY. Ensure the entire length of the channel is covered

with Soft Strip to avoid unlit areas. Place any excess soft

strip inside the take-up box.

12

Page 13

Z17

35

CORRECT

35: Snap the lens back onto the channel sections. Ensure lens is fully seated.

Section Five: Zig Zag Installation

Z18

JUNCTION

BOX

PHILLIPS

SCREW

1: Mount each adjustable mounting bar to one side of the

junction box and secure them with the mounting brackets

and two Phillips screws provided.

1

ADJUSTABLE

MOUNTING BAR

INSTALLATION

DIRECTION

MOUNTING

BRACKET

35

NOT INSTALLED

CORRECTLY

Z19

STUD

ADJUSTABLE

MOUNTING BAR

#8 SCREW

JUNCTION

BOX

3

CONDUIT W/

LOW-VOLTAGE WIRES

NOTE: The adjustable mounting bars mount to studs that

are spaced 13" to 24" apart.

2: Place the lips on the adjustable mounting bars against

the studs. Secure the adjustable bars to the studs with

the eight #8 screws.

2

Z20

6" FIXED

JAB SAW

4

4: Cut a section of drywall using a 6" fixed jab saw or other

appropriate tool to expose the mounting plate area.

3: Install conduit (if required by local electrial code) and run

low-voltage power wires to the junction box.

Z21

5

TRAP DOOR

FRAME

JOINER

BAR

6

5: Insert the joiner bars halfway into the channel trap door

frame. Tighten the two #4-40 set screws on each joiner bar

with a 0.05" Allen wrench.

6: Slide the other section of channel onto the joining bars and

tighten the remaining #4-40 set screws with a 0.05" Allen

wrench.

13

Page 14

45°

Z22

LENS

7

CHANNEL

TRAP DOOR

FRAME

7: Snap the lens into the assembled trap door frame and

channel BEFORE cutting to length. This ensures a proper

fit after installation.

Z23

LENS

TRAP DOOR

FRAME

DESIRED LIT LENGTH

CHANNEL

SECTION

8: Determine the channel length and cut channel and lens at a 45° angle from the outer corner.

9: Cut additional lens/channel assembly for the opposing 45° angle and any other corners as required for the installation.

Z24

10: Measure and mark installation length, allowing for 0.75"

extra space at junction box for power end cap and 1.0" inch

at the end of the installation for the take-up box. Cut

out marked areas using appropriate tools.

11: Mark the location of the studs to the drywall for future

MARKING

10

reference.

NOTE: To install channel vertically or in a wall without standardspaced studs, install perforated mounting straps every 32"

behind drywall and secure using two drywall screws. Mark the

location of any mounting straps to the drywall.

1.05"

10

1.05"

11

STUD

8

Z25

JUNCTION BOX

12

13

12: Connect the red power supply (24VDC+) wire to the red

power connector wires with a wire nut.

13: Connect the black power supply (24VDC-) wire to the black

power connector wires with a wire nut.

14: Place the wire nut connections inside junction box.

14

Page 15

Z26

TAKE-UP

BOX

15

M4 SET

SCREWS

CHANNEL

15: Slide the take-up box onto the non-power channel end and

tighten the M4 set screws with a 1.5MM Allen wrench.

Z28

90° JOINING

BRACKET

Z27

16

CHANNEL

90° JOINER

BRACKET

16: Insert the 90° joiner bracket halfway into the mitered

channel corner. Tighten the two M4 set screws on each

joiner bar with a 1.5MM Allen wrench.

Z29

19

17

CHANNEL

CHANNEL

17: Slide the other section of mitered channel onto the 90°

joining brackets and tighten the remaining M4 set screws.

Z30

20

#4-40

SCREW

18

18: Rotate the connector and bend power connection wires

to place the power connector into the end cap insert.

19: Slide the assembled end cap insert and power connector

into the end cap.

Z31

#6 SCREW

CHANNEL

TRAP DOOR

21: Using the mark locations on the drywall, carefully make

a hole to channel using the provided square drill with

counter sink bit.

20: Secure the assembled power connector end cap to the

junction box with the #4-40 screw.

22: Secure the channel to the studs/mounting straps through

the drywall with the #6 screws using the provided square

recess bit.

23: Secure the Trap Door frame to the junction box with the

#4-40 screw.

15

Page 16

Z32 Z33

24: Apply ultra-thin drywall tape along edges of channel to

prevent cracking of plaster after installation. DO NOT

overlap strips of drywall tape.

Z34

TRAP DOOR

26

27

#6-32

SCREW

NOTE: Test the LED strip before any plaster work is done.

NOTE: Cover the channel opening with blue contractor’s

tape before plastering.

25: Use a 12" compound knife for a smooth compound spread.

Sand, paint, and finish the plaster and drywall before

removing the blue contractors tape.

26: Remove the blue contractor’s tape from the inside of the

channel. Clean the channel surface with alcohol to remove any

dust or debris before continuing.

IMPORTANT: Soft strip may not properly adhere to channel

surface unless the channel is cleaned with alcohol prior to

application.

27: Attach the trap door to the junction box using a #4-40 screw.

28: Line up the red wire side of the power connector with the

“+24VDC” marking on the Soft Strip. Push the male

connector of the Soft Strip into the female connector of

the power cables.

29: Carefully remove the backing from the LED soft strip, making

sure not to remove the tape from the soft strip. Firmly press

down the adhesive portion of the soft strip onto the channel

surface while removing the rest of the backing, making sure

there are no air bubbles that can cause surface irregularities.

16

Z35

POWER

CONNECTION

28

LED STRIP

PAPER

BACKING

29

Page 17

Z36

30

LED SOFT

STRIP

Z37

31

TAKE-UP

BOX

LED SOFT

STRIP

31

30: Continue applying LED soft strip in the side of channel.

Carefully bend the LED soft strip 90° to match the channel

corner.

Z38

32

CORRECT

32: Snap the lens back onto the channel. Ensure lens is fully seated.

31: If required, trim the soft strip on the dashed cuttable

section, place the excess soft strip inside the take up box

(see inset). Ensure the entire length of the channel is

covered with Soft Strip to avoid unlit areas.

32

NOT INSTALLED

CORRECTLY

17

Loading...

Loading...