Page 1

1718 W. Fullerton Ave

Chicago, IL 60614

Tel: 773-770-1195

Fax: 773-935-5613

www.edgelighting.com

© 2014 Edge Lighting. All Rights Reserved.

info@edgelighting.com

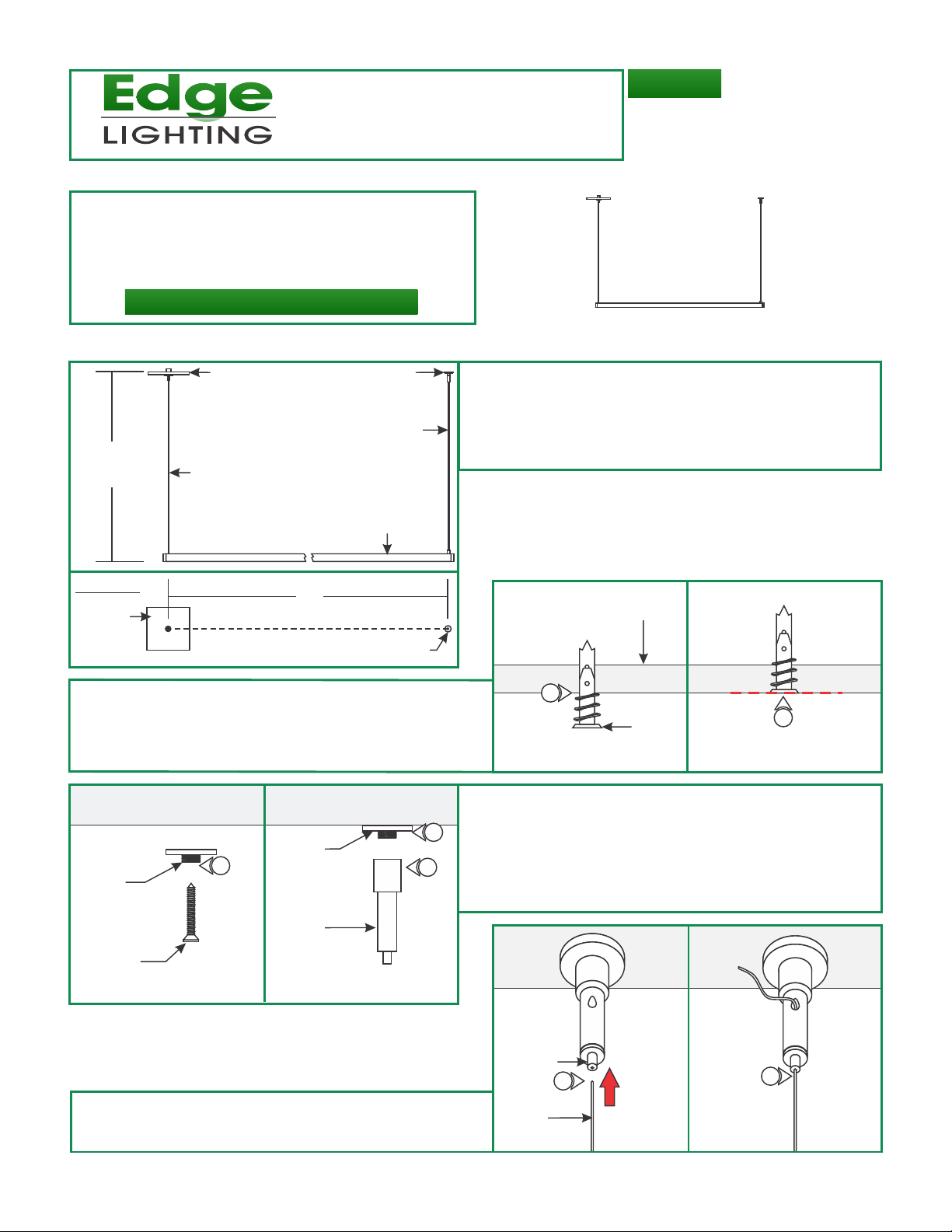

Installation Instructions for Cirrus Float End Feed

IMPORTANT INFORMATION

- This product is suitable for indoor locations.

- This instruction shows a typical installation.

- Ensure that power to the junction box is OFF before

beginning any electrical work.

SAVE THESE INSTRUCTIONS!

Install the Fixture

A

CANOPY

H

COAXIAL CABLE

STANDOFF

AIRCRAFT CABLE

1: Measure the distance between the coaxial cable and the

aircraft cable mounted on the channel. This measurement

varies on the fixture length.

2: Mark the standoff location from the center of the electrical

box for the distant achieved on step 1.

CF-D1-E-_

904-CF-D1-E-02

CHANNEL

TOP VIEW

CANOPY

3: Tap the anchors onto the marked points up to the threaded

portion with a hammer.

4: Screw in the threaded portion of the anchors with a Phillips

screwdriver.

L

STANDOFF

C

6

7

WASHER

W/THREADED

NIPPLE

#8 SCREW

WASHER

5

W/THREADED

NIPPLE

STANDOFF

POST

B

3

5: Feed the #8 screw through the washer w/threaded

nipple into the anchor.

6: Tighten the #8-32 screw completely into the anchor.

7: Tighten the standoff posts completely onto the threaded

nipple.

CEILING

ANCHOR

4

ANCHOR MUST

BE FLUSH TO CEILING

D

8: Push the tab on standoff and feed the aircraft cable from

the channel into a standoff, to hold the one end of the fixture

in place.

STANDOFF

POST TAB

AIRCRAFT

CABLE

8

8

1

Page 2

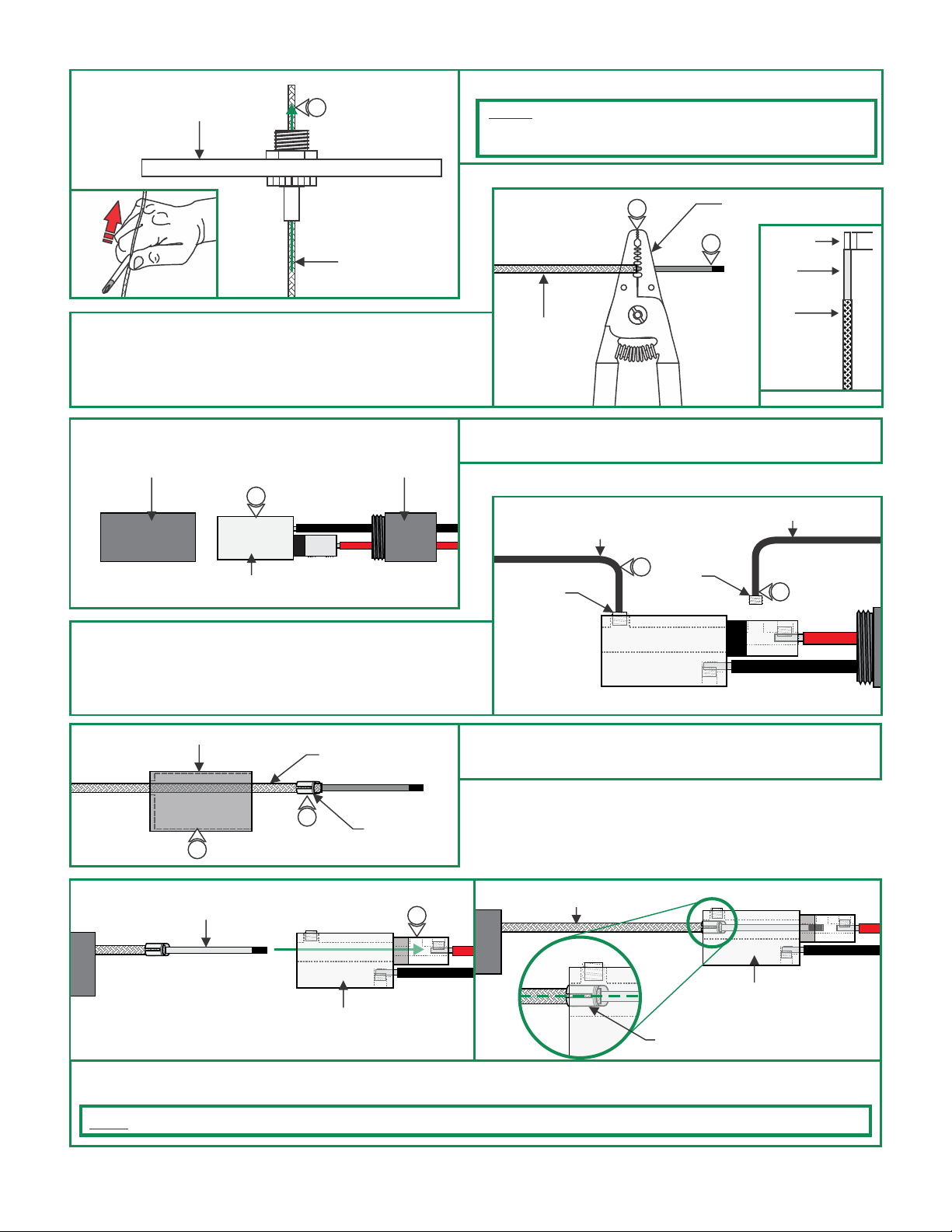

E

BRAIDED

WIRE

INNER

INSULATION

BARE WIRE

1/8"

COAXIAL CABLE

POWER

CANOPY

9: Feed the coaxial cable through the power feed canopy.

9

NOTE: If cable is curled or kinked, straighten by holding

between the shaft of a screwdriver and thumb and pulling the

cable through (see inset K1)

COAXIAL

CABLE

K1

10: Using the 18 AWG hole of the wire strippers, remove 1" of

the outer braided wire.

11: Using the 20 AWG hole of the wire strippers, remove 1/8"

of inner plastic insulation from the end of the coaxial cable.

G

COAXIAL

CONNECTOR

COVER

12

CONNECTOR

ASSEMBLY

13: Using the provided 1.5mm Allen Wrench, remove the M3

set screw from the coaxial connector assembly.

COAXIAL

CONNECTOR

COVER

F

10

COAXIAL

CABLE

WIRE STRIPPERS

11

12: Unscrew the coaxial connector covers and remove from the

connector assembly.

H

M4 SET

SCREW

2MM ALLEN

WRENCH

13

M3 SET

SCREW

1.5MM ALLEN WRENCH

14

14: Using the provided 2mm Allen wrench to loosen (do not

remove) the M4 set screw.

I

J

COAXIAL CONNECTOR COVER

15

COAXIAL

CABLE

17: Insert the coaxial cable into the coaxial connector until the wires of the center conductor are visible through the M3 set

BRAIDED

WIRE

16

CONNECTOR

ASSEMBLY

FERRULE

17

15: Slide the connector cover over the coaxial cable.

16: Place the ferrule over the braided wire of the coaxial cable.

COAXIAL

CABLE

CONNECTOR

ASSEMBLY

FERRULE

screw hole.

NOTE: Ensure that the split in the ferrule is aligned 90° from the M4 set screw (see inset).

2

Page 3

K

1.5MM ALLEN

WRENCH

18

M3 SET

SCREW

18: Use the provided 1.5mm Allen wrench to replace and

securely tighten the M3 set screw.

L

19

COAXIAL

CABLE

19: Use the provided 2mm Allen wrench to securely tighten the

M4 set screw until it squeezes the wire ferrule tightly to the

coaxial cable.

M

COAXIAL

CABLE

NOTE: Ensure that power to the junction box is OFF before

beginning any electrical work.

21: Connect the white transformer wire to the neutral power

wire with a wire nut.

CONNECTOR

ASSEMBLY

COAXIAL CONNECTOR

COVER

20

2MM ALLEN

WRENCH

COAXIAL

CABLE

CONNECTOR

ASSEMBLY

20: Replace the coaxial connector cover and tighten into

place.

M4 SET

SCREW

N

22

21

22: Connect the black transformer wire to the hot power wire

with a wire nut.

23: Place the transformer and transformer wires inside the

junction box.

O

25

24

26: Place all connections into the junction box.

24: Connect one red transformer wire (either one) to the black

coaxial connector wire using a wire nut

25: Connect the other red transformer wire to the red coaxial

connector wire using a wire nut.

P

POWER

CANOPY

27

CANOPY POST

#8-32

SCREWS

27: Secure the power canopy to the junction box using two #8 32 screws.

3

Page 4

Height Adjustments

Q

CANOPY

COAXIAL CABLE

GENERAL WIRING DIAGRAM

INPUT

120VAC

WHITE (NEUTRAL)

BLACK (HOT)

1

ELECTRONIC LOW

VOLTAGE DIMMER

CANOPY

POST TAB

STANDOFF

POST TAB

AIRCRAFT

CABLE

YELLOW

WHITE (NEUTRAL)

BLACK (HOT)

1: Adjust the fixture height by pushing the aircraft cable &

coaxial cable in to the standoff posts & canopy post.

2: If necessary push the tab on the standoffs & canopy post

to release the wire.

1

CHANNEL

COAXIAL

COAXIAL

CABLE

LED TRANSFORMER

RED (24VAC)

RED (24VAC)

CONNECTOR

4

Loading...

Loading...