Page 1

© 2014 Edge Lighting. All Rights Reserved.

1718 W. Fullerton Ave

Chicago, IL 60614

Tel: 773-770-1195

Fax: 773-935-5613

www.edgelighting.com

info@edgelighting.com

CCS-R1-_

Installation Instructions for Cirrus Channel Suspension R1,

Rectangular 1" Lens

IMPORTANT INFORMATION

- This product is suitable for indoor locations.

- This instruction shows a typical installation.

SAVE THESE INSTRUCTIONS!

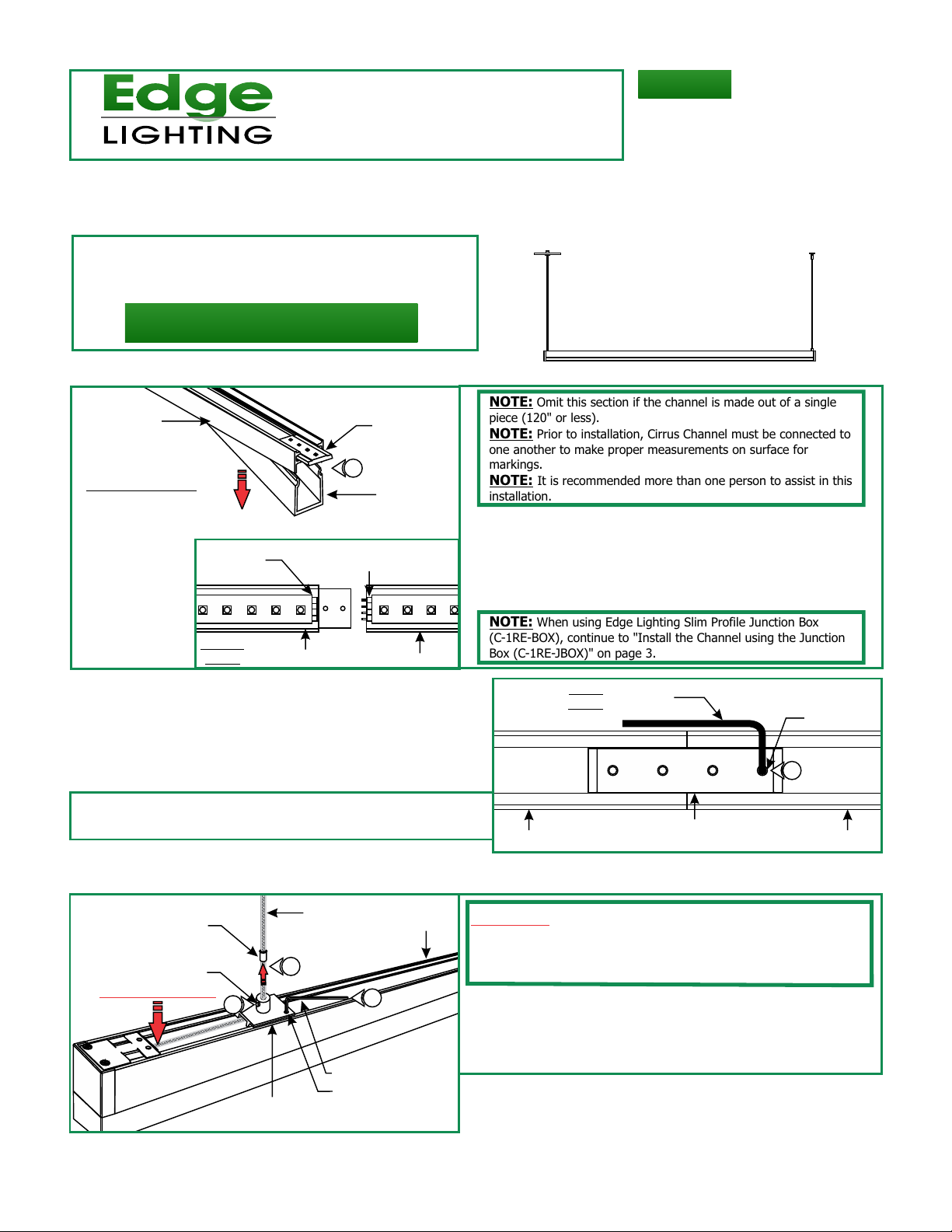

Connecting the Channel

904-CCS-R1-03

A

CHANNEL

TOP OF CHANNEL

FEMALE

CONNECTOR

FRONT

VIEW

3: Position the joiner bracket where the two channels meet.

Tighten four #6-32 set screws using the 1/16 Allen wrench.

CHANNEL

JOINER

BRACKET

1

LENS

MALE

CONNECTOR

JOINER CHANNEL

NOTE: Omit this section if the channel is made out of a single

piece (120" or less).

NOTE: Prior to installation, Cirrus Channel must be connected to

one another to make proper measurements on surface for

markings.

NOTE: It is recommended more than one person to assist in this

installation.

1: Lift a section of the lens at the end of the channels where

the connectors are visible. Slide the channel over the joiner

bracket make sure that the male & female connectors mate

properly.

2: Push the lens back into the channel.

NOTE: When using Edge Lighting Slim Profile Junction Box

(C-1RE-BOX), continue to "Install the Channel using the Junction

Box (C-1RE-JBOX)" on page 3.

B

CHANNEL CHANNEL

BACK

VIEW

1/16 ALLEN

WRENCH

JOINER BRACKET

#6-32 SET

SCREW

3

Adjusting Cable Position

C

STRAIN RELIEF

#4-40 SET SCREW

HOLD CABLE HERE

4

SLIDING POST

COAXIAL CABLE

5

0.05" ALLEN WRENCH

#4-40 SET SCREW

4

CHANNEL

WARNING: To avoid damaging the coaxial cable electrical

connection, make sure that the end of the coaxial cable coming

out of the fixture is held with thumb before relocating sliding

posts.

1: Loosen (DO NOT REMOVE) the #4-40 set screw on the

sliding post bushing and bed with a 0.05" Allen wrench.

2: Slide the strain relief tube out of the sliding post using a pair

of needle-nose pliers.

1

Page 2

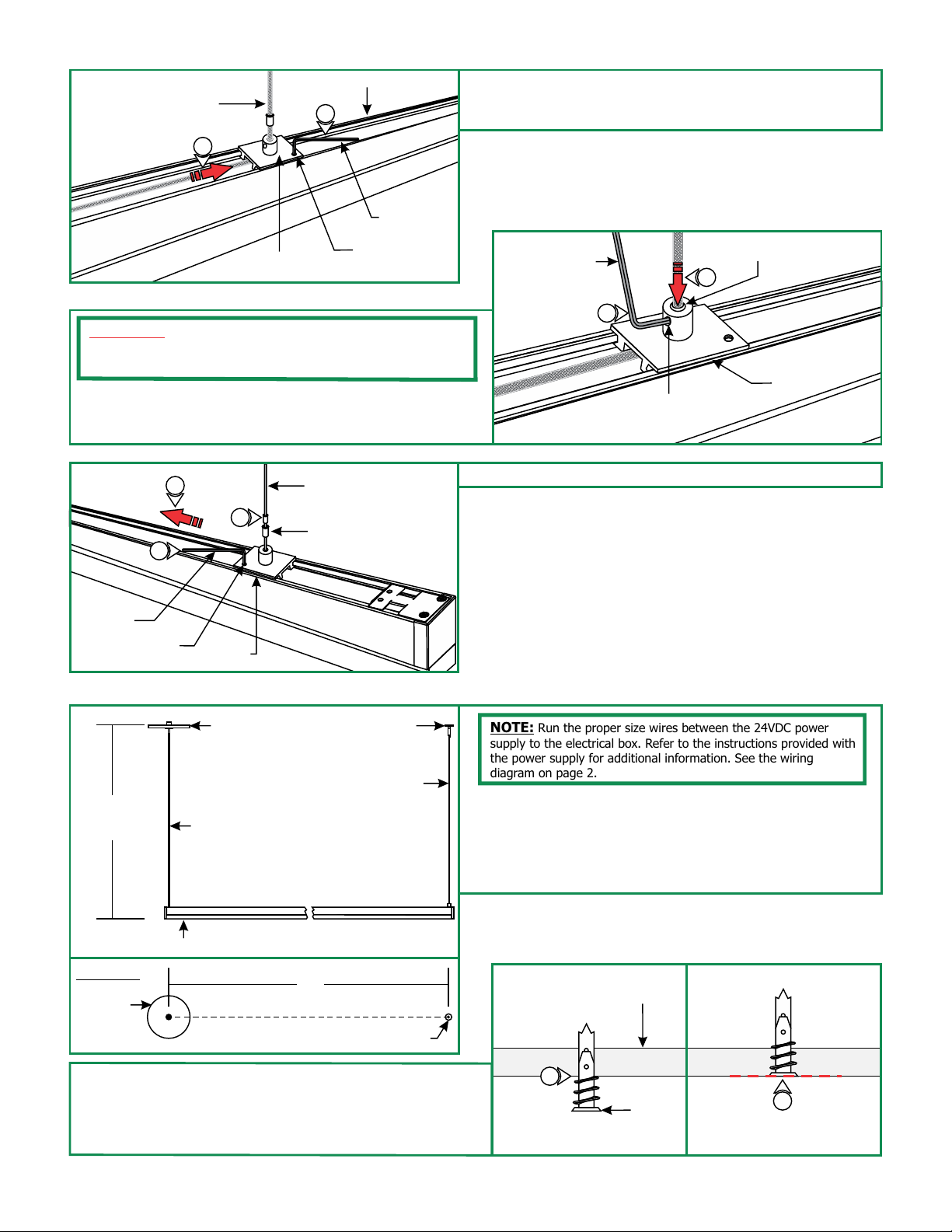

D

COAXIAL CABLE

3

SLIDING

POST

!CAUTION! Tightening the strain relief set screw CANNOT

BE REVERSED. Only tighten the set screw AFTER the cable

location is set properly.

4: Insert the strain relief tube back inside the sliding post

bushing and tighten the #4-40 set screw with the 0.05"

Allen wrench.

CHANNEL

3

0.05" ALLEN

WRENCH

#4-40 SET

SCREW

3: Carefully move the sliding post to the predetermined location

on channel and tighten the #4-40 set screw on the sliding

post bed with the 0.05" Allen wrench.

E

0.05" ALLEN

WRENCH

4

#4-40 SET

SCREW

STRAIN RELIEF

4

SLIDING

POST

F

0.05"ALLEN

WRENCH

#4-40 SET SCREW

5

5

5

SLIDING

POST

Install the Fixture

G

H

CANOPY

COAXIAL CABLE

AIRCRAFT CABLE

STRAIN RELIEF

STANDOFF

AIRCRAFT CABLE

5: Repeat Steps 1 through 4 for aircraft cable side.

NOTE: Run the proper size wires between the 24VDC power

supply to the electrical box. Refer to the instructions provided with

the power supply for additional information. See the wiring

diagram on page 2.

1: Measure the distance between the coaxial cable and the

aircraft cable mounted on the channel. This measurement

varies on the fixture length.

2: Mark the standoff location from the center of the electrical

box for the distant achieved on step 1.

CHANNEL

TOP VIEW

L

CANOPY

STANDOFF

3: Tap the anchors onto the marked points up to the threaded

portion with a hammer.

4: Screw in the threaded portion of the anchors with a Phillips

screwdriver.

H

CEILING

3

ANCHOR

BE FLUSH TO WALL

4

ANCHOR MUST

2

Page 3

I

BRAIDED

WIRE

INNER

INSULATION

BARE WIRE

1/8"

COAXIAL CABLE

WASHER

WASHER

5

W/THREADED

NIPPLE

#8 SCREW

W/THREADED

NIPPLE

STANDOFF

POST

8: Push the tab on standoff while feeding the aircraft cable

coming from the channel into a standoff so that it holds one

end of the fixture in place.

6

7

5: Feed the #8 screw through the washer w/threaded

nipple into the anchor.

6: Tighten the #8 screw completely into the anchor.

7: Tighten the standoff posts completely onto the threaded

nipple.

J

STANDOFF

POST TAB

8

AIRCRAFT

CABLE

8

K

POWER

CANOPY

9

COAXIAL

CABLE

K1

10: Using the 18 AWG hole of the wire strippers, remove 1" of

the outer braided wire.

11: Using the 20 AWG hole of the wire strippers, remove 1/8"

of inner plastic insulation from the end of the coaxial cable.

M

COAXIAL

CONNECTOR

COVER

12

COAXIAL

CONNECTOR

COVER

9: Feed the coaxial cable through the power feed canopy.

NOTE: If cable is curled or kinked, straighten by holding

between the shaft of a screwdriver and thumb and pulling the

cable through (see inset K1)

L

10

COAXIAL

CABLE

WIRE STRIPPERS

11

12: Unscrew the coaxial connector covers and remove from the

connector assembly.

N

2MM ALLEN

WRENCH

1.5MM ALLEN WRENCH

CONNECTOR

ASSEMBLY

13: Using the provided 1.5mm Allen Wrench, remove the M3

set screw from the coaxial connector assembly.

14: Using the provided 2mm Allen wrench to loosen (do not

remove) the M4 set screw.

M4 SET

SCREW

13

M3 SET

SCREW

14

3

Page 4

O

COAXIAL

CONNECTOR

COVER

15

BRAIDED

WIRE

FERRULE

15: Slide the connector cover over the coaxial cable.

16: Place the ferrule over the braided wire of the coaxial cable.

16

P

COAXIAL

COAXIAL

CABLE

CONNECTOR

ASSEMBLY

17: Insert the coaxial cable into the coaxial connector until the wires of the center conductor are visible through the M3 set

screw hole.

NOTE: Ensure that the split in the ferrule is aligned 90° from the M4 set screw (see inset).

Q

1.5MM ALLEN

WRENCH

18

17

18: Use the provided 1.5mm Allen wrench to replace and

securely tighten the M3 set screw.

M3 SET

SCREW

R

COAXIAL

CABLE

CONNECTOR

ASSEMBLY

CABLE

2MM ALLEN

WRENCH

CONNECTOR

ASSEMBLY

FERRULE

19

M4 SET

SCREW

19: Use the provided 2mm Allen wrench to securely tighten the

M4 set screw until it squeezes the wire ferrule tightly to the

coaxial cable.

S

COAXIAL

20

COAXIAL

CABLE

CONNECTOR

COVER

COAXIAL

CABLE

CONNECTOR

ASSEMBLY

20: Replace the coaxial connector cover and tighten into

place.

4

Page 5

T

NOTE: Ensure remote DC power supply wires are present in

the junction box before continuing.

21: Connect the black remote power supply wire to the black

coaxial connector wire using a wire nut.

21

22

23: Place all connections into the junction box.

24: Secure the power canopy to the junction box using two #8-

32 screws.

Height Adjustments

V

1

CANOPY

CANOPY

POST TAB

22: Connect the black remote power supply wire to the black

coaxial connector wire using a wire nut.

U

POWER

CANOPY

24

1: Adjust the fixture height by pushing the aircraft cable &

coaxial cable in to the standoff posts & canopy post.

2: If necessary push the tab on the standoffs & canopy post

to release the wire.

CANOPY POST

#8-32

SCREWS

COAXIAL CABLE

GENERAL WIRING DIAGRAM

WHITE (NEUTRAL)

INPUT

120VAC

RED 120VAC (HOT)

PURPLE 1-10V

GRAY 1-10V

DIMMING

BLACK (HOT)

GND

PHILIPS:

SUNRISE

SR1200ZTUNV

STANDOFF

POST TAB

VOLTAGE

DROP

AIRCRAFT

CABLE

1

96W, 24VDC LOW VOLTAGE WIRE SIZE CHART

WIRE LENGTH

IN FT

WIRE SIZE 14 AWG

VOLTAGE AT END

OF THE WIRE

UP TO 33FT3%34FT-52FT

12 AWG 10 AWG 8 AWG

23.28 VDC 23.29 VDC 23.28 VDC

53FT-86FT 87FT-130FT

PSB-96W-010-24VDC

input 120VAC

WH (N)

BK (L)

input 0-10V

PUR

GRY

RED (24VDC+)

BLUE (RETURN-)

YELLOW (DIM RETURN-)

RED 24VDC+

BLACK 24VDC-

24VDC

23.28 VDC

COAXIAL

CONNECTOR

COAXIAL

CABLE

CHANNEL

5

Loading...

Loading...