Edgecraft Choice 2000 User Manual

INSTRUCTION MANUAL

Commercial

Diamond Hone® Knife Sharpener 2000

Read instructions before use.

It is essential that you follow these

instructions to achieve optimal results.

IMPORTANT SAFEGUARDS

When using electrical appliances, basic safety precautions should always be

followed including the following:

1. Read all instructions. Every user should read this manual.

2. To protect against electrical hazards, do not immerse the Chef’sChoice

section in water or other liquid.

3. Make sure only clean knife blades are inserted in the Chef’sChoice

4. Unplug from outlet when not in use, before putting on or taking off parts and

before cleaning.

5. Avoid contacting moving parts.

6. Do not operate any appliance with a damaged cord or plug or after the appliance

malfunctions, or is dropped or damaged in any manner.

U.S. customers: You can return your sharpener to EdgeCraft’s factory for service where

the cost of repair or electrical or mechanical adjustment can be estimated. When the

electrical cord on this appliance is damaged, it must be replaced by the Chef’sChoice

distributor or other qualified service to avoid the danger of electrical shock.

Outside U.S.: Please return your sharpener to your local distributor where the cost of

repair or electrical or mechanical adjustment can be estimated. If the supply cord of

this appliance is damaged, it must be replaced by a repair facility appointed by

the manufacturer because special tools are required. Please consult your local

Chef’sChoice

®

distributor.

7. CAUTION! “This appliance may be fitted with a polarized plug (one blade is wider than

the other). To reduce the risk of electric shock, this plug will fit in a polarized outlet only

one way. If the plug does not fit fully in the outlet, reverse the plug. If it still does not fit,

contact a qualified electrician. Do not modify the plug in anyway.”

8. The use of attachments not recommended or sold by EdgeCraft Corporation may cause

fire, electric shock or injury.

9. The Chef’sChoice

®

Model 2000 is designed to sharpen kitchen knives (including serrated knives), pocket knives and most sports knives. Do not attempt to sharpen “parrot

beak” knives, scissors, ax blades or any blade that does not fit freely in the slots.

10. Do not let the cord hang over edge of table or counter or touch hot surfaces.

11. When in the “ON” position (Red flash on switch is exposed when “on”) the

Chef’sChoice

®

should always be on a stable countertop or table.

12. WARNING: KNIVES PROPERLY SHARPENED ON YOUR CHEF’SCHOICE

THAN YOU EXPECT. TO AVOID INJURY, USE AND HANDLE THEM WITH EXTREME CARE.

DO NOT CUT TOWARD ANY PART OF YOUR FINGERS, HAND OR BODY. DO NOT RUN

FINGER ALONG EDGE. STORE IN A SAFE MANNER.

13. Do not use outdoors.

14. Close supervision is necessary when any appliance is used by or near children.

15. Do not use honing oils, water or any other lubricant with the Chef’sChoice

16.

SAVE THESE INSTRUCTIONS.

®

motor drive

®

Model 2000.

®

WILL BE SHARPER

®

.

®

2

Congratulations on your selection of

the Chef’sChoice® Commercial Knife

Sharpener Model 2000!

You will find this method of sharpening puts an exceptionally sharp and durable edge on all

of your knives. It is backed by EdgeCraft—World Leader in Cutting Edge Technology

The Chef‘sChoice

incorporates advanced diamond abrasive and honing technology to produce the sharpest

and most durable edges of any sharpener available today. With it you can develop a

shaving-sharp edge on all your knives. Once your knives have been sharpened on the

Model 2000, resharpening takes less than 1 minute.

Consequently, if the Model 2000 is conveniently located in your work area, you can

resharpen so rapidly that you need not rely on the sharpening steel to tune up the edge.

®

Commercial Diamond Hone® Knife Sharpener Model 2000

UNPACKING AND PREPARING FOR OPERATION

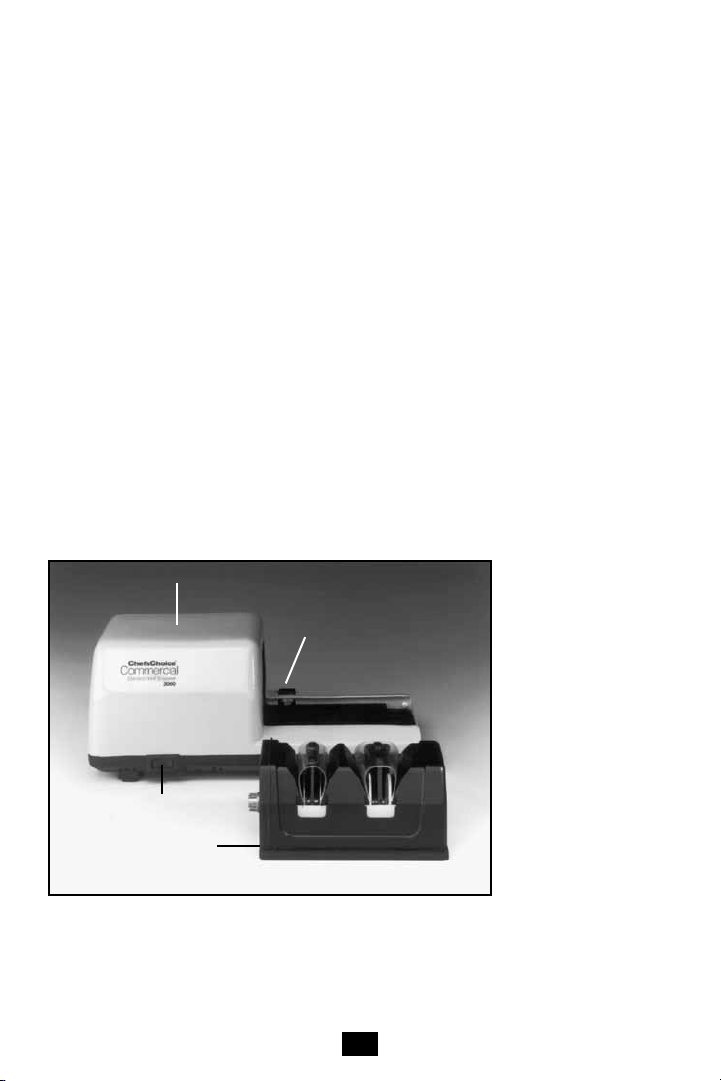

The Model 2000 has a motor-drive section and a detachable Sharpening Module that is

packed and shipped disassembled (see Figure 1).

To assemble the Model 2000, insert the Sharpening Module into the guide rails of the

motor section, (Figure 2) and slide the module toward the motor housing until it locks in

place. If the sections do not snap together easily & quickly, follow the instructions in the

“Inserting” section, (Page 8) of this manual.

Motor-drive Section

Release Button

Figure 1. Model 2000

sharpener - disassembled.

®

.

On/Off Switch

Sharpening Module

3

DESCRIPTION - MODEL 2000 SHARPENER

The Model 2000 sharpener uses a novel two-stage sharpening and honing process, where

the knife is first sharpened with a pair of conical diamond-coated wheels and then honed

with a pair of patented conical honing disks incorporating ultrafine abrasive particles. This

creates a unique edge geometry that gives the edge extraordinary “bite” and sharpness

and ensures it will stay sharp much longer than conventionally sharpened knives. The

Sharpening Module, incorporating both the sharpening and honing stages, is a self-contained unit that can be removed for washing and sanitizing in a dishwasher or at the sink. It

can be removed simply by depressing the release button (Figure 2) and sliding the module

off the motor-drive section.

A powerful 150 watt motor operating at 1700 RPM is enclosed in the motor housing.

Splined drive couplings attached to the shafts of the motor drive and the Sharpening

Module permit their rapid engagement or disengagement.

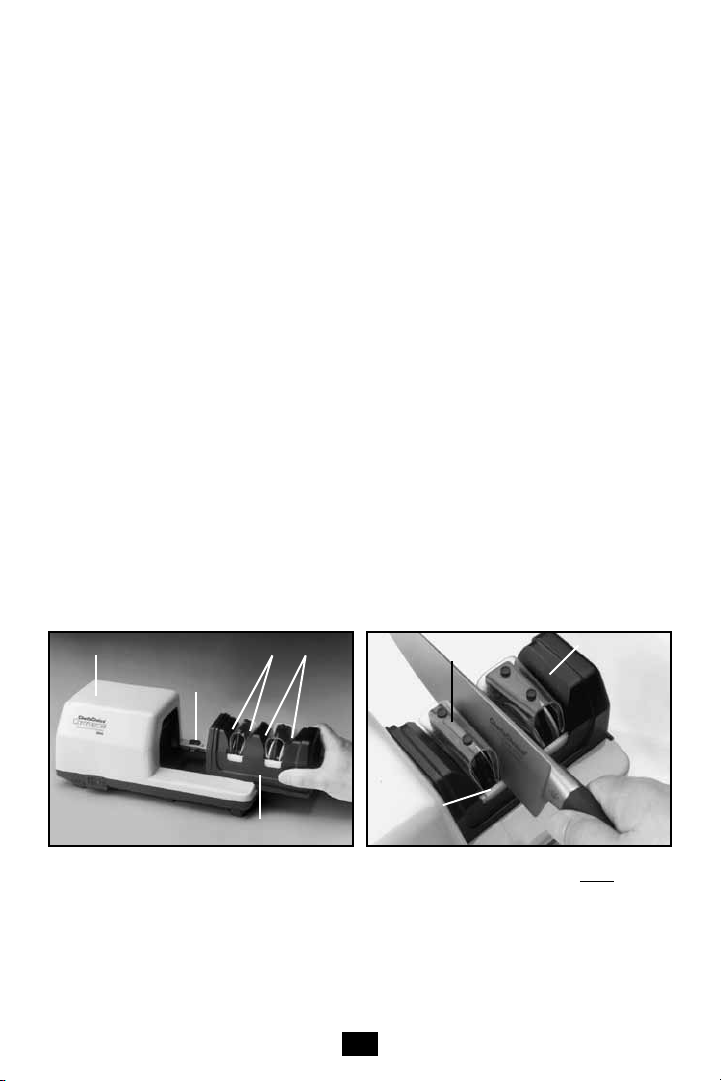

In both the sharpening and honing stages, the edge must be sharpened on alternate

strokes in the right and left slots (see Figure 3). Precise “Blade Guides” position and align

the knife at the correct angle while plastic hold-down springs stabilize and secure the

blade as it is pulled through each slot and makes contact with the abrasive wheels. The

downward movement of the blade in each of the slots is limited and controlled by an Edge

Stop Plate (Figure 3), made of a high-density polymer that serves both as a stop and as

a micro-guide “slot” for the edge, without damaging the sharp edge being formed. There

are Edge Stop Plates at the front and rear of the sharpening and honing stages. For best

results, the knife edge should only just touch or lightly rest on the front Edge Stop Plate.

Excessive downward pressure is unnecessary and will result in excessive cutting of the

Edge Stop Plate. The edge need not rest on the rear Stop Plate for the entire sharpening

and honing stroke.

Motor-drive Section

Release Button

Figure 2. Sharpening module is inserted on rails

and slid toward the motor-drive section to engage

motor-drive. To disengage, press release button and

slide away from the motor-drive. See text.

Knife Blade Guides

Sharpening Module

Plastic Spring

Edge

Stop Plate

Figure 3. Knife is inserted between the Blade Guide

and the plastic spring until edge rests lightly on Edge

Stop Plate.

Knife Blade

Guide

4

Loading...

Loading...