Page 1

INSTRUCTION SUPPLEMENT FOR

2004-Later Yamaha Rhino 660

Removing stock carburetor and cables

1. Remove engine cover and tunnel

(center of floor board).

2. Remove throttle cable from throttle

pedal and chassis. See fig 1.

3. Remove choke cable from dash.

See figure 2.

Figure 1. Throttle cable

Figure 2. Choke cable

4. Remove stock carburetor, cables

and all vent hoses attached to

carburetor. NOTE: Carburetor can

be removed without disconnecting

cables. Unplug black and yellow

wires from carb and tape ends with

electrical tape as they will not be

use d with the Edelbrock carburetor.

5. Stuff a dry, clean rag into the

intake manifold to keep debris from

entering engine.

6. Remove oil line directly a bove oil

filter. See fig 3. Disconnect rubber

hose at bottom where it connects

to hard tube. See fig 4.

NOTE: Clean oil and dirt off of flange and

case before removing oil line.

Figure 3.

Figure 4.

7. Remove stock fuel line from fuel

pump. Save insulating material as

it will be reused on new fuel line.

Installing the Edelbrock Carburetor

1. Attach new fuel line to fuel pump

reusing stock clamp and insulating

material.

2. Install new throttle cable into bracket

and throttle pedal. Do not route

throttle cable in stock position. Cable

will need to be routed to passenger

side of vehicle. See figure 5 for cable

routing.

NOTE: Apply a small amount of grease to

O-ring on pedal end of cable for easier

installation into throttle pedal.

Figure 5.

Page 2

3. Remove the h ex pipe plug from the

carb cap using a 11mm or 7/16 wrench.

Do not discard plug, as it will be

needed later. Install the metering

adjustment tool included in the

hardware kit. Do not over-tighten as

damage may occur to cap.

4. Attach fuel line onto fuel inlet banjo

and secure with stock pinch clamp.

Fuel line may need to be trimmed to

prop er length.

5. Place Edelbrock carburetor into

manifold. Do not tighten clamp yet.

6. Remove the cable bracket en d from

cable bracket using #2 phillips.

7. Insert cable end into cable wheel in the

8:00 o’clock position. Place elbow into

bottom slot of cable bracket and secure

by reinstalling cables bracket end and

screw. See figure 6.

Figure 6.

8. Align carburetor as close to vertical as

possible and tighten manifold clamp.

9. Adjust cable until wide-open throttle is

achieved.

10. Secure clamp around air boot onto

back of carburetor.

11. Use supplied vacuum cap to cover

elbow on right side (passenger side) of

air boot. Secure with supplied zip tie.

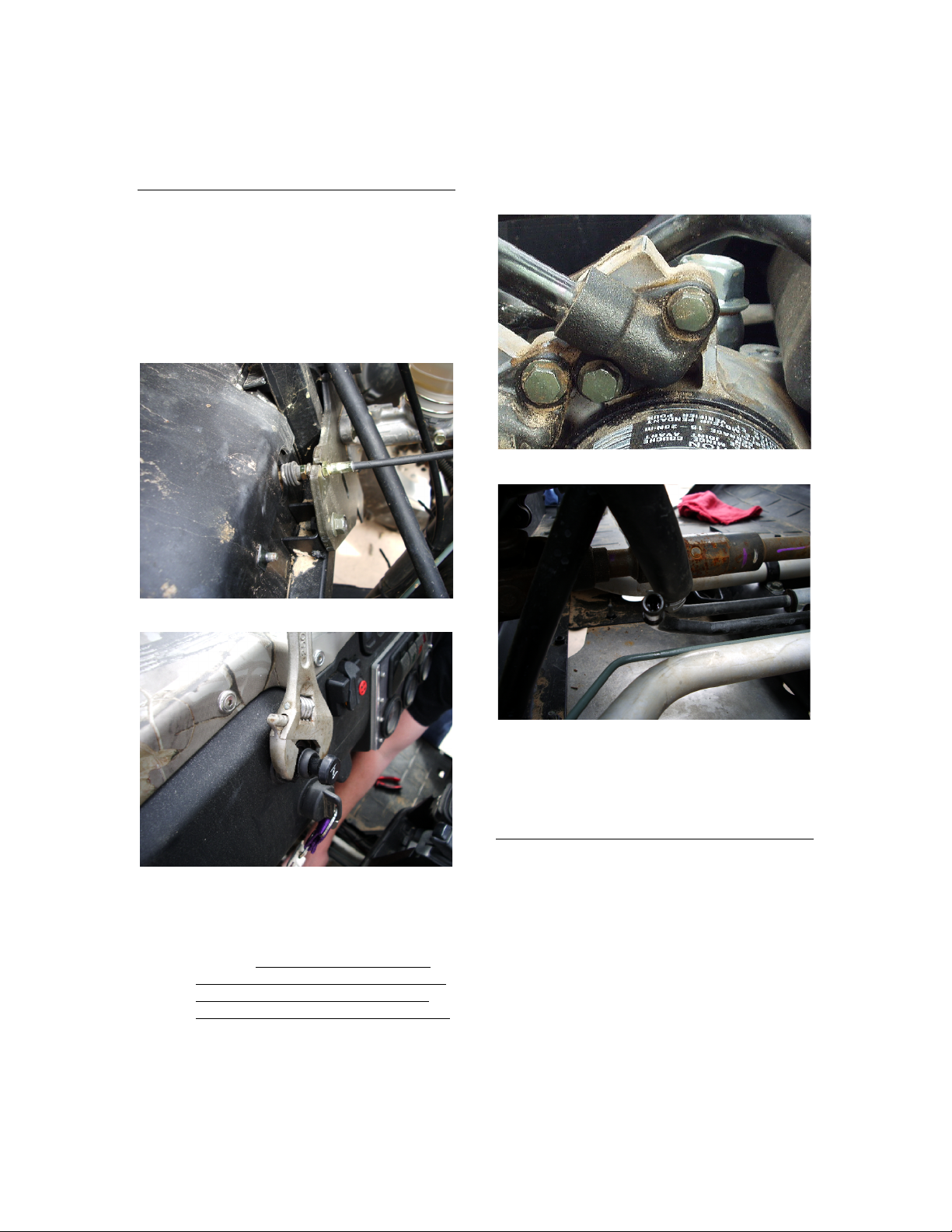

12. Carefully remove O-ring from stock oil

line flange and place it onto new oil line

flan ge as shown in figure 7.

Figure 7.

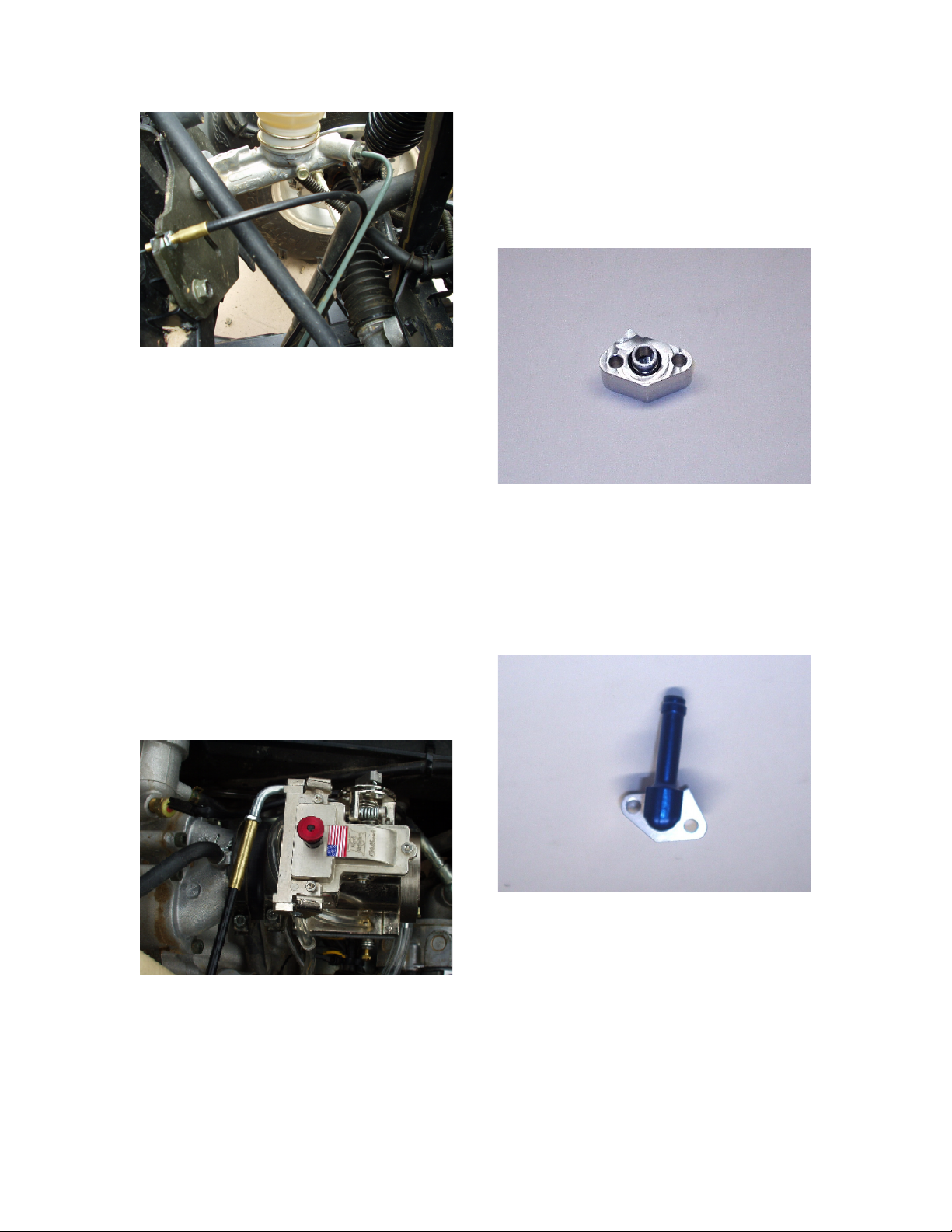

13. Wrap the threaded portion of the elbow

with Teflon tape and thread into billet

oil block until th e barb is 90 degrees to

the two holes as shown in figure 8. Do

not tighten completely as bolts need

too be installed.

Figure 8.

14. Install block onto engine with the elbow

and plug facing up. Secure to motor

with two M6 X1X30 bolts (supplied). Be

sure no to over tighten as damage

can occur to engine case. Se e

manual for recommended torque

specs.

15. Once bolts have b een tightened, use a

wrench to turn the elbow ¼ forward to

tighten as shown in figure 9.

Figure 9.

Page 3

NOTE: Turn elbow until it is just below three

o’clock position as shown in picture above.

16. Install hose clamps on each end of

sup plied 3/8 hose (blue). Lube the

inside of both ends of hose with a light

oil (WD-40 or similar). Push hose onto

oil fitting on engin e an d the opposite

end onto the factory hard tube coming

from the front of vehicle. See figures

10 and 11.

Figure 10.

Figure 11.

17. After each end of hose has been

installed tighten clamps.

18. Engage starter without opening

throttle. NOTE: The stock fuel pump is

vacuum operated, so it is

recommend ed that the starter be

engaged for at least 10 seconds.

19. After fuel has entered float bowl, pump

the throttle 3-5 times to prime the

accelerator pump.

20. Once pump is primed, start engine.

NOTE: The Edelbrock c arburetor

does not have a choke system. Cold

starts will require 2-3 pumps of the

throttle pedal to activate the

accelerator pump.

For any questions regarding

tuning or installation of Edelbrock

products, please call our toll free

tech line M-F 8:00am-12: 30pm,

1:30pm-5:00pm PST.

877-888-7504 ext.2.

Edelbrock #3119 Yamaha

Rhino 660 Carburetor

Specifications

Bore Size: 40mm round

Needle: 18E @ 14 clicks

Accelerator Pump Bypass: 1.5

turns out.

Alternate Needles: 16E, 20E

Main Jet: 74

Alternate Jets: 72, 76

Replacement Throttle Cables:

#9353

Loading...

Loading...