Page 1

Catalog #29085, #28095

Rev. 1/08 - AJ/mc

Page 1 of 2

©2008 Edelbrock Corporation

Brochure #63-0341

Victor Jr. LS1 EFI Intake Manifold

for GM 5.7L LS1 & LS6 V8 Engines

Catalog #29085 & #28095

INSTALLATION INSTRUCTIONS

PLEASE study these instructions carefully before installing your new Intake Manifold. If you have any questions or problems, do not

hesitate to contact our Technical Hotline at: 1-800-416-8628, from 7am-5pm PST, Mon-Fri, or via e-mail at:

Edelbrock@Edelbrock.com

CAUTION: Make sure the vehicle’s battery has been disconnected and that the vehicle is supported on a level surface to prevent any

possibility of the vehicle moving during the installation procedure.

MANIFOLD: The single plane Victor Jr. LS1 Intake Manifold is intended for racing and engine swap applications. A fuel rail kit

designed to work with this manifold may be purchased as part #3638.

EGR SYSTEM: This manifold has no provision for EGR (exhaust gas recirculation) equipment. EGR systems are used on most 1972

and later model vehicles, up to certain GVWs. Check local laws for requirements. This manifold is not considered to be a direct

replacement part.

ACCESSORIES & INSTALLATION ITEMS: Major recommendations are listed below. However, because this manifold system is

intended for engine swaps into a variety of vehicles, some customization may be required.

ITEM NOTES PART NUMBER AND DESCRIPTION

Throttle Body Standard Square-Bore Style Base P/N 3878 - With standard GM/Delphi IAC

P/N 38783 - With Mototron/Hitachi Linear Style IAC

Fuel Rail Kit Stock Injector Angles P/N 3638 - Includes Hold Down Brackets

Headers 1-3/4” - 1-7/8” Step, Victor Series Various. See Catalog For Details

Camshaft Developed for Carbureted Applications P/N 2215 - 220° Int./224° Exh. @ .050”, .510” Valve Lift

P/N 2216 - 230° Int./237° Exh. @ .050”, .540” Valve Lift

KIT CONTENTS: 29085 and 28095

QTY

. Description

❑ 1 Intake Manifold

❑ 1 MAP Sensor Bracket (For LS1 Style Sensor)

❑ 1 1/8”NPT to ¼” Hose Fitting (For MAP)

❑ .75 ft ¼” I.D. Vacuum Hose (For MAP)

❑ 2 Cable Bracket (Large Opening)

❑ 2 Cable Bracket (Small Opening)

❑ 1 GEN III EFI Throttle Bracket Base

❑ 4 6mm x 1.0 x 12mm Serrated Flange Hex Bolt

❑ 4 6mm x 1.0 Serrated Flange Hex Nut

❑ 10 6mm x 50mm Hex Head Capscrew

❑ 10 ¼” AN Washer

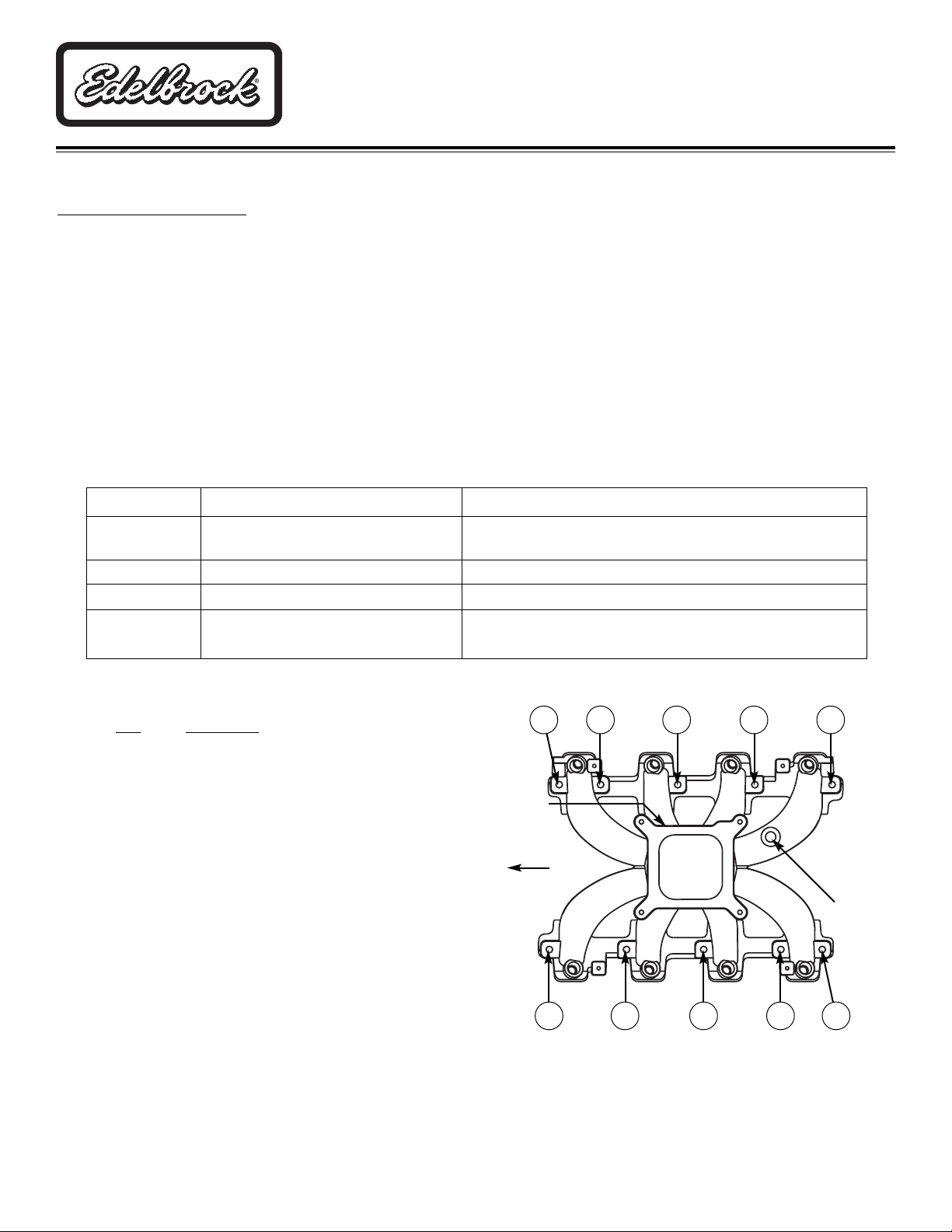

Figure 1 - Intake Manifold Tightening Sequence

10 4 1 5 8

93267

3/8” NPT

1/8” NPT

Front

Page 2

Catalog #29085, #28095

Rev. 1/08 - AJ/mc

Page 2 of 2

©2008 Edelbrock Corporation

Brochure #63-0341

INSTALLATION PROCEDURE:

1.

(Note: Manifold #29085 must use O-Ring type gaskets (GM P/N

12533587) when installing this intake manifold. Manifold #28095 uses a

conventional style gasket, Fel-Pro #1312-3).

Gasket sealer is not

required when using OEM type gaskets. Using the supplied 6mm x 50mm

hex head bolts and 1/4” AN washers, mount the manifold to the engine.

The Gen III throttle bracket mounts under the two left side rear intake

manifold bolts. Following the torque sequence in

Figure 1

, torque all

manifold bolts to 11 ft/lbs.

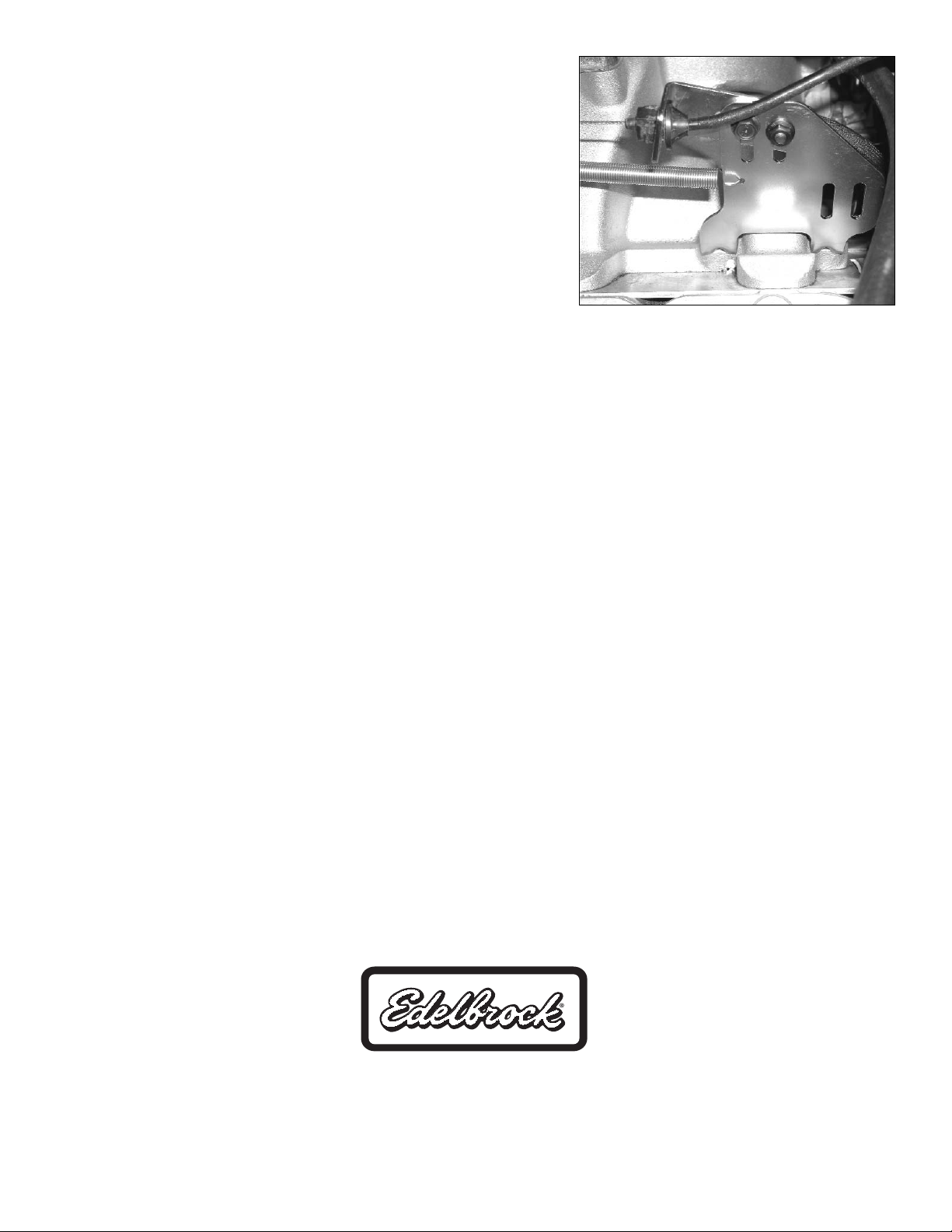

2. Select the appropriate cable brackets for your application (large or small

opening brackets) and attach them to the GEN III throttle bracket base

with the appropriate number of 6mm x 1.0 x 12mm serrated flange hex

bolts.

(Note: In our retrofit of the LS1 into a 1974 Camaro, using a

TH400R automatic transmission, we only needed one of the small opening cable brackets for the throttle cable, since a kickdown

cable is not used. See Figure 2 for example.)

INJECTOR SELECTION AND INSTALLATION: It is important to select the appropriate electronic injectors for optimum performance.

The injectors must not only match the fuel demands of an engine, but they must also match the electronic capability of the engine

control unit (ECU). When installing the injectors onto the manifold, make sure that the O-rings of the injectors create a complete seal

to prevent any air or fuel leaks. The same precaution should be applied when assembling the injectors to the fuel rails. Use assembly

lube on O-rings when installing injectors. Brake assembly lube works well.

FINAL CHECKS: After assembling the injectors, fuel rails, support brackets, throttle body, spacer (if needed), gaskets, and air cleaner,

check the following:

❑ Have an assistant depress and release the gas pedal. Check for full open throttle at the throttle body. Check for any possible

interference of the throttle with other components. Make sure the throttle can return without binding.

❑ Check the fit of each injector. They should be able to rotate freely. The O-rings should be fully inside their respective bores.

❑ Activate the fuel pump and fully check the system for any leaks prior to starting the engine.

Figure 2 - Throttle Cable Bracket

Edelbrock Corporation • 2700 California St. • Torrance, CA 90503

Tech-Line: 800-416-8628 • E-Mail: Edelbrock@Edelbrock.com

Loading...

Loading...