Page 1

Brochure #63-0067

© 2003 Edelbrock Corporation

Rev. 1/03

SQUARE-BORE CARB TO SPREAD-BORE MANIFOLD

ADAPTER #2696 AND UNIVERSAL FUEL LINE KIT #2697

(for OEM Spread-bore manifolds with 3/8" or 5/16" fuel line)

INSTALLATION INSTRUCTIONS

1—Square-bore carburetor adapter (#2696) #

4—Carb studs; 5/16" x 1-1/2” (Carb to adapter) #

4—Nuts; 5/16"-24 #

4—Lock Washers; 5/16" #

1—Gasket; Square-bore #

1—Gasket; Spread-bore #

4—Fillister Head Bolts 5/16” x 3/4” (Adapter to intake) #

KIT CONTENTS

1—Brass Compression Nut/Sleeve; 3/8" *

1—Brass Compression Sleeve/Nut; 5/16" *

1—3/8" Rubber Fuel Line; 24" long *

4—Stainless Steel Worm-type Hose Clamps *

1—Fuel Filter; 3/8" Inlet and Outlet *

1—Special Brass Adapter; 5/16" *

1—Special Brass Adapter Fitting; 3/8" *

DESCRIPTION: The Edelbrock Square-bore Carb to Spread-bore Manifold Adapters are designed to allow installation of

the Edelbrock Performer Series carburetor on vehicles with the OEM (original equipment) spread-bore intake manifold

(typically GM vehicles that were originally equipped with the Rochester Quadrajet carburetor). These kits will also work on

Chrysler manifolds designed for the Thermo-Quad carburetor. It contains the necessary items to adapt the EPS carb to the

OEM manifold. A high-capacity fuel filter is also incorporated in the 2697 fuel line kit to ensure that clean fuel is supplied

to the carburetor.

INSTALLATION: Before removing the old carburetor, make a note of any special or unusual linkage or mounting

requirements. EGR valves, kickdown linkages, cruise control linkages, air cleaner heat stove ducting, etc., all may require

extra parts, adapters, or extensions to complete your installation. Consult your Edelbrock Performer Series carburetor

Owner’s Manual and installation instructions for recommendations or call our Technical Hotline at:1-800-416-8628,

Monday-Friday, weekdays.

Note: The carb adapter will raise the carburetor by over 3/4" and some air cleaners will require additional spacers for

carburetor clearance, especially on carbs with electric chokes. The total height (carb spacer plus air cleaner spacer) must

be calculated and hood clearance checked before proceeding with your installation. Check air cleaner-to-hood clearance by

placing several large clay posts at various points on top of your air cleaner, then close the hood to compress the posts.

Measure the thickness of the clay posts to ensure that adequate clearance exists.

Note: All items marked with asterisk (*) refer to #2697 kits only. Items marked with (#) are included

in both Kits.

1. Remove OEM air cleaner and check for fit on your new

EPS carburetor. If additional clearance is required, use air

cleaner spacer #8092 (3/8" thick) or #8093 (1/2" thick).

You may want to use a new air cleaner designed

specifically for EPS carbs (including those with electric

chokes): Order Edelbrock Signature Series Air Cleaner

#1221 (chrome-plated steel) or Elite Series Air Cleaner

#4221 (polished aluminum).

2. Before removing vacuum lines, note whether each is

connected to a “full-time” or “timed” vacuum port on the

old carburetor. “Full-time” ports will have vacuum at idle,

and “timed” ports will not show any vacuum until the

engine rpm is increased; usually to about 1500 rpm. Mark

each vacuum line with masking tape so that it may be reconnected to the appropriate port on the new carburetor.

3. Disconnect all fuel lines, linkages, choke mechanisms, etc.

Remove old carburetor, gasket, and carb mounting studs.

Place clean rags or towels in the manifold throttle bore

openings to prevent debris from falling into engine. Clean

the gasket surface and surrounding area.

4. Remove rags or towels from the manifold and place

matching (spread bore) gasket on intake manifold and

secure spacer with fillister bolts. Install the four new carb

studs. “Double-nutting” the studs is preferred over

gripping with pliers. Place matching (square bore) gasket

on carb spacer. Install carburetor with new lock washers

and nuts and hand tighten lightly and evenly in a “crisscross” pattern.

Note: These adapters have a 1/4" NPT hole in the

back, which can be drilled if an additional vacuum

source is needed.

Adapter

Plate

Squarebore

Gasket

Spreadbore

Gasket

®

Page 2

Brochure #63-0067

© 2003 Edelbrock Corporation

Rev. 1/03

6. Attach all vacuum lines, linkages, and return springs.

Check for smooth throttle operation from idle to WOT

(Wide Open Throttle) and for a positive return to idle.

Note: When testing electric choke carburetors, make

sure to hold choke to full open position.

7. Locate the fuel filter in a position that does not interfere

with the air cleaner or any linkage parts and can be

supported using the shortest length of fuel hose

possible.(*)

8. Cut OEM fuel line in the selected location using either a

hacksaw or tubing cutter. It is easier to make the cut if

you first remove the fuel line from the vehicle (after

marking the place to be cut).(*)

9. Make sure that you file and remove the burrs from the

rough cut end of the steel line. Also be sure to

thoroughly clean out all filings and metal particles from

the line.(*)

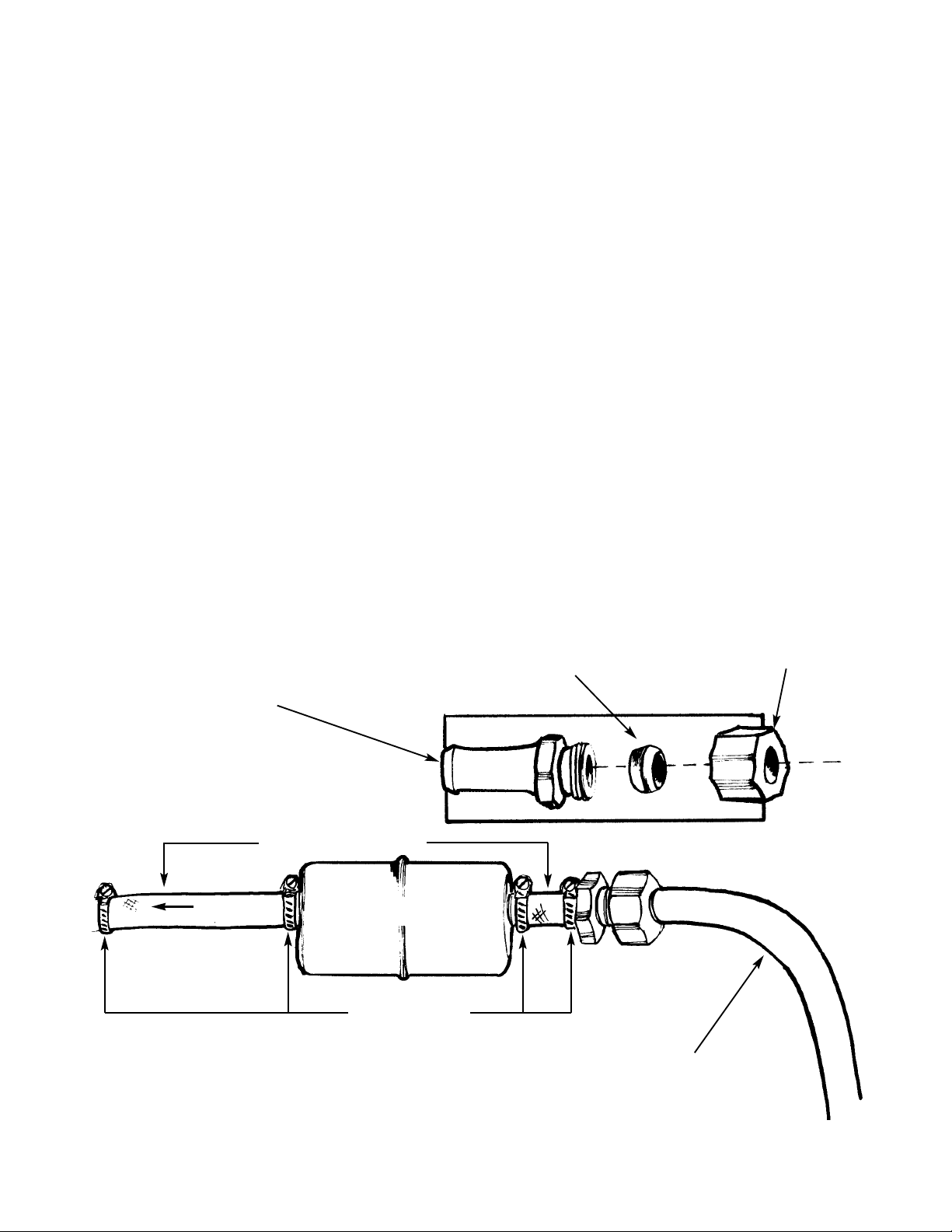

10. Install the Edelbrock special brass hose fitting

completely over the OEM steel fuel line (see

illustration) and securely tighten the compression

unit. Use tubing wrenches if possible to avoid rounding

the hex nut.(*)

11. Position the fuel filter as close as possible to the above

noted special brass fuel line fitting. Note: The filter

must face the correct direction. The filter end marked

“IN” must face the fuel pump.(*)

12. Cut the proper length of the fuel hose supplied in this

kit to connect the filter to the brass adapter fitting.

13. Install one clamp on each end of this hose and securely

push the fuel hose onto the filter and fuel line. Make

certain that the hose is completely installed on each

fitting before tightening the screw-type worm clamp.

CAUTION: Do not over-tighten the clamps or you may

cut into the fuel line and cause a leak.(*)

14. Correctly route the attaching hose from the outlet end

of the fuel filter to the inlet fitting of your Edelbrock

Performer Series carburetor. Make certain that there

are no sharp bends or kinks in this fuel line. Also, check

to make certain that when the carburetor air cleaner is

installed, it does not pinch or interfere with the fuel line

hose. If the straight inlet fitting on your carburetor

creates an interference problem, use Air Cleaner Spacer

#8092 to raise the air cleaner 3/8" for clearance, or

replace this fitting with an Edelbrock #8089 Banjo

fitting. This will allow the fuel hose to be located tightly

along the side of the carburetor to obtain the necessary

clearance beneath the air cleaner.(*)

15. Cut the fuel hose to the proper length between the fuel

filter and the carburetor. Install this hose using the

remaining two worm-type hose clamps.

CAUTION: Do not over-tighten the clamps or you may

cut into the fuel line and cause a leak.(*)

16. Start the engine and check for any fuel leaks

before installing the air cleaner. Correct any

leaks and re-install the air cleaner before

operating vehicle.

Special brass adapter fitting

Brass compression nut

Brass compression sleeve

Fuel Filter

To Carb

4 Hose clamps

3/8” Rubber fuel line

From fuel pump

Original steel fuel line

Edelbrock Corporation

2700 California St.

Torrance, CA 90503

Tech Line: 1-800-416-8628

E-Mail: edelbrock@edelbrock.com

Loading...

Loading...