Page 1

Edelbrock Qwikdata Shaft Speed Sensor Kit

Catalog # 91195 & 91196

INSTALLATION INSTRUCTIONS

• PLEASE study these instructions carefully before installing your new Edelbrock Qwikdata Shaft Speed Sensor Kit. If you have any

questions or problems, do not hesitate to contact our Technical Hotline at: 1-800-416-8628, from 7am-5pm, Monday through

Friday, Pacific Standard Time, or via e-mail at: Edelbrock@Edelbrock.com.

• DESCRIPTION

The Edelbrock Qwikdata Shaft Speed Sensor Kit allows users

of the Qwikdata data aquisition system or other data

aquisition systems to mount up to 4 magnets in an aluminum

ring to the rear end pinion yoke on a Ford 9” housing.

Part #91195 will mount to most standard Ford 9” rear

housings with a 1.875” diameter pinion yoke. Part #91196

will fit 2.187” diameter, 35 spline yokes.

Installation Procedure

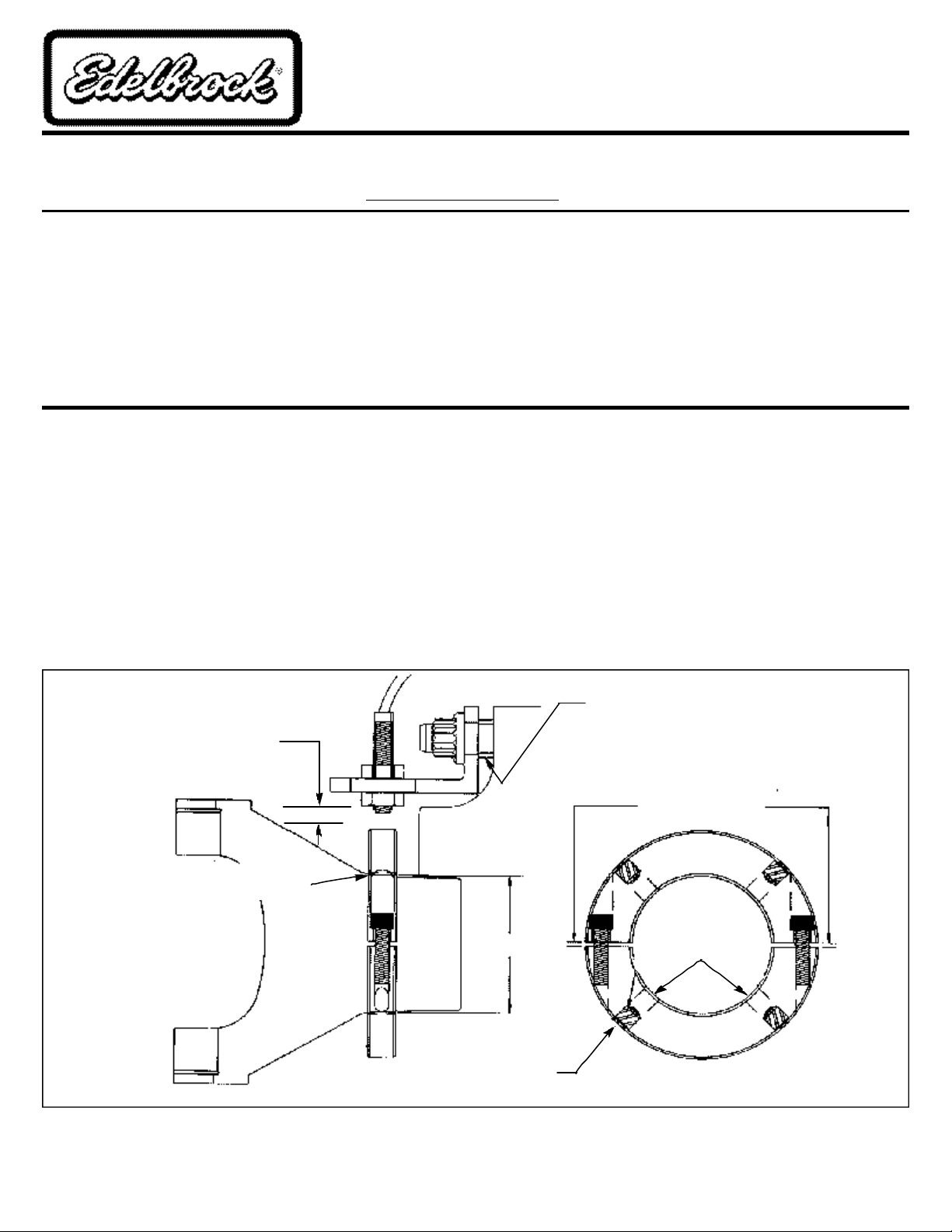

• Note: Refer to Figure 1 below for reference on all steps.

1. Install the number of magnets you require for your data

aquisition system into the ring assembly.

2. The magnets are to be seated against the shoulder (towards

the outside diameter of the ring), then glued with an adhesive

such as epoxy, RTV silicone, hot glue, etc. (Note: Some

computers are sensitive to the magnet’s north and south

poles. Install magnets per requirements for your data

aquisition system.)

3. Install the ring halves around the pinion coupler and tighten

the 10-32 x 3/4” cap screws tightly. The beveled edge of the

• Kit Contents:

1 - Two-Piece Aluminum Mounting Ring

2 - 10-32 x 3/4” Cap Screws

4 - Magnets

1 - Sensor Switch Bracket

1 - Sensor Switch

inside of the ring should face the pinion U-joint. The gap on

each side of the ring should be even to ensure correct timing

on multiple magnet use.

4. Attach the Sensor Switch Bracket to a bolt or stud on the rear

end housing as shown in Figure 1. Attach Sensor Switch and

adjust gap to .060”-.100” for Qwikdata use, or to your data

aquisition system specification.

• Note: Periodically, make sure the magnets and mounting ring

are secure.

• Caution: Excessive heat can cause the magnets to lose

power.

Set gap at .060”-.100” for

Qwikdata use

OR

Set gap per data aquisition system

per manufacturer’s instructions

Beveled edge should

face Pinion U-Joint

FIGURE 1

©2003 Edelbrock Corporation

Use a washer .060”-.080” thick to prevent

interference with the pinion support radius

Tighten so that the

gaps are even

Fill cavities with

Grip Diameter

Be sure the magnets are

seated against the outside

shoulder of the ring

Note: Some multi-magnet sensors are pole-sensitive

and must be installed in correct +/- sequence.

epoxy or silicone

to secure magnets

Edelbrock Corporation, 2700 California Street, Torrance, CA 90503

Tech Line: 800-416-8628; Office: 310-781-2222

Brochure No. 63-0192

Rev. 6/03

Loading...

Loading...