Page 1

Rev. 1/07

mc

©2007 Edelbrock Corporation

Brochure No. 84-5496

Page 1 of 4

EDELBROCK SHOCK

INSTALLATION INSTRUCTIONS

Please study these instructions carefully before installing your new Edelbrock shocks. If you have any questions, please call our

Technical Hotline at: 1-800-416-8628

, 7:00 am to 5:00 pm, Monday - Friday, Pacific Standard Time or e-mail us at

Edelbrock@Edelbrock.com.

IMPORTANT NOTES:

• Any time you are working under a vehicle, be sure to use the proper jackstands and

tire chocks to prevent any shifting or slipping of the car. Never use a jack only to

support the vehicle while changing shocks.

• Inspect shock brackets or mounting points before installation to make sure they are not

broken or bent.

•

Do not attempt to disassemble these shocks.

Return damaged shocks to

Edelbrock for any necessary service or repairs.

• Upon initial inspection, some new shocks may have a small amount of oil in the area

of the seal. This is a normal occurrence following manufacture and does not

indicate

a problem with your shocks.

• For good ride quality, tire pressure should be at original equipment manufacturer’s

recommended PSI (Pounds per Square Inch). Failure to adhere to the recommended

pressure will affect the ride quality and void the Edelbrock Limited Warranty.

PLEASE READ THESE INSTRUCTIONS ENTIRELY BEFORE BEGINNING

• Proper installation is a must to realize the maximum performance improvements.

Follow these steps carefully.

USE THE RIGHT SHOCK FOR YOUR VEHICLE

• Use Edelbrock shocks only for the applications for which they are listed. Each shock

is specifically tuned for that vehicle’s weight, suspension geometry, and other

characteristics.

• Compare original shock mounting style and hardware with your new shocks before

starting installation. If original hardware is not reusable, it should be replaced with

OEM quality and style hardware.

• Shocks are tuned to vehicle manufacturer’s recommendation for tire pressure, not

necessarily the max inflation pressure listed on sidewall of tire.

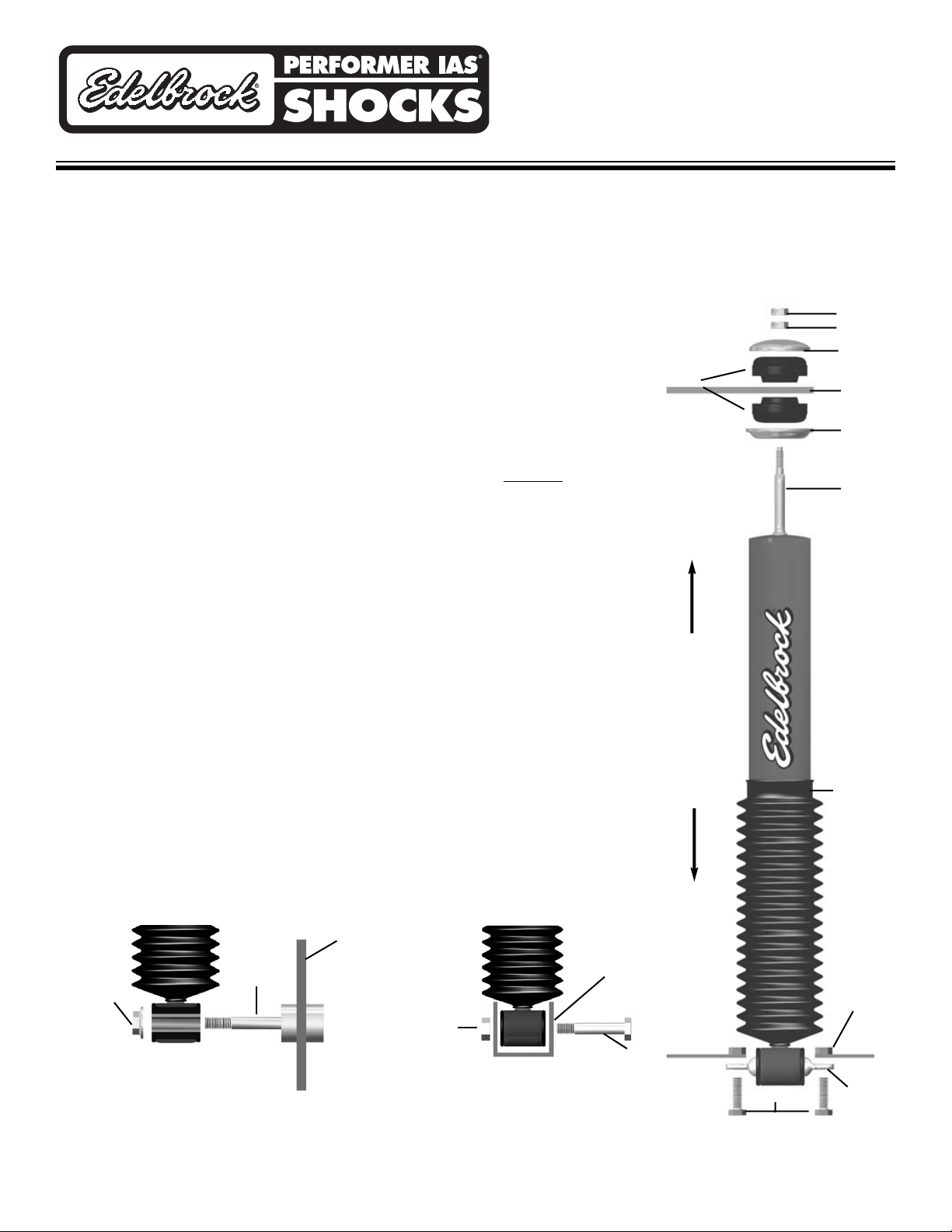

Nut/washer

Mounting Pin

Part of Vehicle

Part of Vehicle

Bolt

Nut

Stud Mount

Standard Bolt Mount

Shock Post Mount

Bushings

Some

shocks

will mount

rod up or

rod down

depending

on

hardware.

Jam Nut

Nut

Retaining

Washer

Part of Vehicle

Retaining

Washer

Post on Shock

Put Tie Wrap

Around Boot

Here

Part of Vehicle

Crossbar

Crossbar Mount

Bolts

Page 2

Rev. 1/07

mc

©2007 Edelbrock Corporation

Brochure No. 84-5496

Page 2 of 4

• Edelbrock Corporation guarantees for a limited

lifetime each new Edelbrock IAS Strut & Shock

Absorber (including Xtreme Travel units with remote

and piggyback reservoir) to be free from factory

defects (except for finish and shock boot) from date

of purchase, provided that the product is properly

installed, subjected to normal use and service and

that the product is not modified or changed in any

way, negligence by customer or installer, or used for

racing or competition purposes. Should a part

become defective, it should be returned to the

original selling dealer or shipped freight prepaid to

Edelbrock Corporation. It must be accompanied

with the sales receipt and a clear description of the

problem. This warranty is void on shocks used in

racing applications except for known, proven defects

in material or workmanship.

• Edelbrock Corporation reserves the right to replace

or repair the defective part and return said part

freight prepaid. This warranty covers the

replacement or repair of the product only and does

not cover the cost of removal and installation.

• Damage or defects resulting from collision,

improper installation, off-road use, road hazards or

racing, are not covered by this warranty. The

warranty for Edelbrock IAS Struts & Shock

Absorbers (including Xtreme Travel units with

remote and piggyback reservoir) extends only to the

original purchaser only for the lifetime of the

original vehicle in which it is installed.

PERFORMER IAS®STRUT & SHOCK ABSORBER

(INCLUDING XTREME TRAVEL UNITS WITH REMOTE AND PIGGYBACK RESERVOIR)

LIMITED LIFETIME WARRANTY

Edelbrock Corporation shall not be liable for any and

all consequential damages occasioned by the

breach of any written or implied warranty pertaining

to this sale in excess of the purchase price of the

product sold.

If you have any questions regarding a product or

installation, please contact our Technical Department

at 1-800-416-8628 between 7:00 am to 5:00 pm,

Pacific time, Monday to Friday.

IMPORTANT INSTALLATION NOTES

• If you are uncertain of proper shock installation procedure,

please consult appropriate service manual

. Torque all fasteners

to vehicle manufacturer’s specs.

Note:

On Post Mount shocks, finger tighten nut to achieve zero clearance between the retaining

washers and the bushings, then continue to tighten approximately 5-6 turns to achieve proper pre-load. Bushings should be slightly

bulged. Secure with Jam Nut. On some vehicles, nut may bottom out on stud before 5-6 turns, which is proper for those applications.

• OEM mounting hardware may be either standard or metric.

Make sure you have the proper tools before starting.

Do not

interchange hardware.

Use new mounting hardware provided with your shocks

, and re-use original mounting hardware in

all other locations.

• Edelbrock shocks have a high pressure nitrogen gas charge and may come with a restraining strap which holds the shock in a

compressed position. To ease most installations, l

eave the strap on until you have secured one end of the shock,

then cut

the strap and quickly guide the other end of the shock into position as it expands. Strap must be cut bef

ore some installations, such

as when strap goes around post.

• Wire ties are provided to secure the shock boot to the shock body. On some installations (especially where the shock must pass

through a hole in the lower control arm),

it is necessary to put the wire tie on after

the shock is installed.

• After installing shocks and before driving vehicle,

check for clearance of exhaust, brake or gas lines, electrical wiring, etc.

• After installation,

drive the vehicle cautiously for the first few miles

to develop a feel for the improved handling and ride

quality. After 10 miles, inspect installation, re-check torque on all fasteners, and verify adequate component clearance.

Page 3

Rev. 1/07

mc

©2007 Edelbrock Corporation

Brochure No. 84-5496

Page 3 of 4

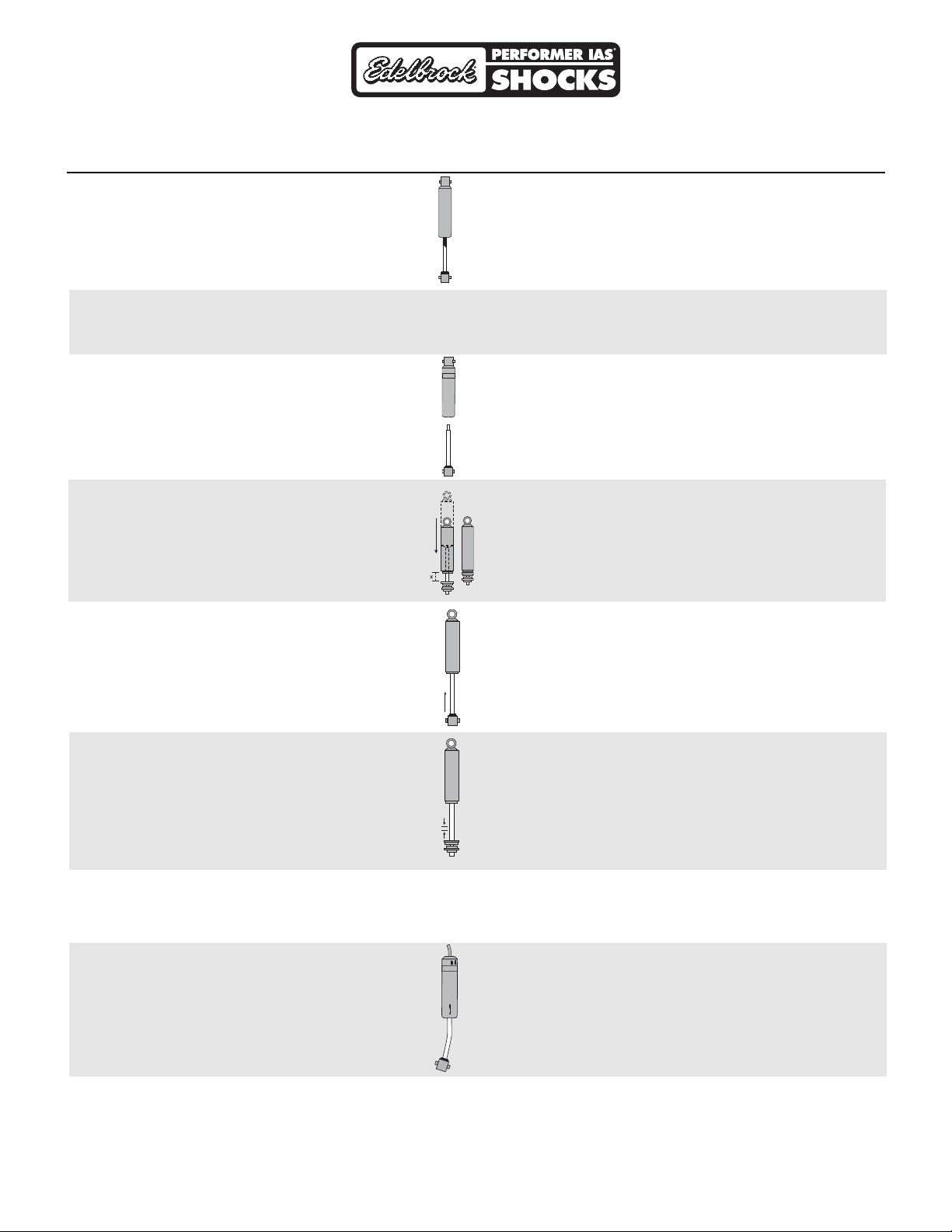

Warranty Inspection and Procedure

Condition

A slight amount of oil

on the piston rod and/or

shock body.

Oil dripping off shock.

Piston rod broken at

piston assembly and

separated from shock

body.

Compression depth

not correct.

Clicking noise and

significant endplay.

Bubbling noise inside.

Rod end missing or

separated from piston

rod.

Bent piston rod,

deformed mounting

loop or stem.

Kinked hoses, nitrogen

port is tampered/open/

missing.

Inspection Procedure

Visual inspection for slight

amount of oil film.

Visual inspection for oil

dripping off the bottom

mount of the shock.

Visual inspection for

conditions.

Check by fully compressing

shock and checking the

distance “x”. If the distance

“x” exceeds 1/2", the shock

is defective.

Shock is held rod down,

compressed halfway, then

quickly moved up and down

an inch in each direction.

When shock is inverted,

compressed and released,

listen for noise.

Visual inspection for

conditions.

Visual inspection for

conditions.

Visual inspection for

conditions.

Possible Cause

Normal occurrence when

the shock is dyno-tested.

Damaged seal.

Piston rod not properly

attached to piston.

• Divider cup seal failure.

• Leaking.

Loose piston.

Oil and gas have mixed.

Rod end worked loose.

• Abuse.

• Incorrect installation.

• Damaged in collision.

• Used in racing.

Customer tampering.

Action

✓ Not defective. Shock will

perform as intended.

✓ No replacement necessary.

✓ Place a warranty tag on shock

and return.

✓ Will be replaced.

✓ Place a warranty tag on shock

and return.

✓ Will be replaced.

✓ Place a warranty tag on shock

and return.

✓ Will be replaced.

✓ Place a warranty tag on shock

and return.

✓ Will be replaced.

✓ Place a warranty tag on shock

and return.

✓ Will be replaced.

✓ Place a warranty tag on shock

and return.

✓ Will be replaced.

✓ Warranty no longer valid.

✓ No replacement.

✓ No replacement.

Page 4

Rev. 1/07

mc

©2007 Edelbrock Corporation

Brochure No. 84-5496

Page 4 of 4

Edelbrock Corporation, 2700 California Street, Torrance, CA 90503

Tech Line: 1-800-416-8628

E-mail: Edelbrock@Edelbrock.com

Loading...

Loading...