Page 1

Edelbrock 4.6L Mustang GT Supercharger

Part #1580 & #1585

Page 2

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 2

Edelbrock LLC, 2700 California Street, Torrance, CA 90503

Toll-Free Tech Line: 1-800-416-8628

Office: 310-781-2222

Thank you for purchasing the Edelbrock 4.6L Ford Supercharger System for the Mustang GT. The Edelbrock E-Force

Supercharger System for the 2005-2009 4.6L 3V Mustang utilizes Eaton’s new Gen VI TVS Supercharger rotors, featuring

a four lobe design with a full 160 deg. of twist for maximum flow, minimum temperature rise, quiet operation, and the

reliability for which Eaton is known. These rotors however, are merely the foundation of the system. The Edelbrock

Supercharger is a complete system that maximizes efficiency and performance by minimizing air restriction into, and out

of, the supercharger. This results in maximum airflow, with minimum temperature rise and minimum power consumption.

In addition, Edelbrock inverted the supercharger and packaged it down low in the valley, allowing for an incredible, industry

leading, 15 inches of runner length, maximizing low end torque. The supercharger housing itself is integrated into the

intake manifold for a seamless design with minimal components, eliminating the possibility of vacuum leaks between

gasket surfaces. The system also utilizes a front drive, front inlet configuration giving it the shortest, least restrictive inlet

path on the market. Further minimizing inlet restriction is the massive 85mm electronic throttle body that is included in

the kit. Sitting right above the supercharger and below the enormous runners is the largest air to water intercooler

available, measuring an astonishing 110 square inches. Last but not least, the E-Force supercharger is without a doubt

the best looking engine compartment upgrade imaginable. It features a uniquely styled plenum, and includes matching

side covers. In summation, the Edelbrock supercharger will provide you with the most power at the lowest amount of

boost resulting in neck snapping performance that is safe to operate on a completely stock engine. It is also pending 50

state emissions legality, and can be had with an optional 3 yr 36,000 mile warranty so that there are no worries when

installing it on your brand new car.

INTRODUCTION

TOOLS REQUIRED

Jack and Jack Stands

OR Service Lift

Panel Puller

Ratchet and Socket Set including

5.5mm (or 7/32”), 7mm, 8mm,

10mm, 12mm (deep), 13mm, 15mm

& a 9/16” Spark Plug Socket

12” Ratchet Extension Bar

1/2” Breaker Bar

Flat Blade & Philips Screwdrivers

Torx-20 Driver

1/8” Allen Wrench

5/8” Fuel Line Removal Tool

Torque Wrench

Vice

Needle Nose Pliers

Pliers

OR Hose Clamp Removal Tool

Hacksaw, Drill & File

OR Grinding & Cut-Off Wheels

Impact Wrench

24mm Allen Tool (‘09 Mustangs only)

Wire Stripper

Wire Crimper

Terminal Removal & De-Pinning Tools

OR Safety Pin

Heat Gun

Blue Loctite

O-ring Lube

Anti-sieze

Dielectric Grease

Masking Tape

Page 3

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 3

Due to the complexity of the Edelbrock E-Force Supercharging system, it is recommend that this system only be

installed by a qualified professional with access to a service lift, pneumatic tools, and a strong familiarity with

automotive service procedures. To qualify for the optional 3-year, 36,000 mile warranty, it is necessary to have this

system installed by a certified ASE technician, Ford dealership, or Edelbrock approved installer. Failure to have this

system installed by a properly certified service center may result in voiding of both the optional warranty offered with

this sytem, as well as the standard Edelbrock parts warranty. Please contact the Edelbrock Technical Support

department if you have any questions regarding how this sytem and/or your installer of choice will affect any warranty

coverage for which your vehicle may qualify.

Proper installation is the responsibility of the installer. Improper installation will void warranty and may

result in poor performance and engine or vehicle damage.

IMPORTANT WARNINGS

Any equipment that directly modifies the fuel mixture or ignition timing of the engine can cause severe engine damage

if used in conjunction with the Edelbrock E-Force Supercharger System. This includes, but is not limited to: ignition

boxes, air/fuel controllers, OBDII programmers, and any other device that modifies signals to and/or from the ECU.

Aftermarket bolt-on equipment such as underdrive pulleys or air intake kits will also conflict with the operation of the

supercharger and must be removed prior to installation. Use of any of these products with the E-Force Supercharger

could result in severe engine damage.

Any previously installed aftermarket tuning equipment must be removed and the vehicle returned to an as

stock condition before installing the supercharger.

91 octane or higher gasoline is required at all times. If your vehicle has been filled with anything less, it

must be run until dry and refilled with 91 or higher octane gasoline twice prior to installation.

This kit includes all the parts needed to install this system on ‘07 & ‘08 Mustang GTs only. ‘05 & ‘06

models will also need the 15804 Cooling Upgrade Kit, while ‘09 models will need the 15805 Hardware Kit.

Mustang GTs produced in 2005 and 2006 were equipped with a cooling system that mounted the thermostat on the

cold side of the radiator. The Edelbrock E-Force Supercharger was designed to take advantage of the improvements in

cooling efficiency that are offered by mounting the thermostat on the hot side as found in later models. Cooling

Upgrade Kit #15804 will allow owners of ‘05 & ‘06 model year Mustangs to retro-fit their cars with the later model

cooling systems, and is required before the supercharger can be installed. 2009 model year Mustangs recieved some

minor changes from previous model years and will require a different pulley nut and intake manifold gaskets, offered in

kit #15805, to operate correctly. It is strongly recommended that these parts be purchased, if needed, before beginning

installation of the supercharger.

Inspect all components for damage that may have occured in transit before beginning installation. If any

parts are missing or damaged, contact Edelbrock Technical Support, not your parts distributor.

Do not use a wibeband oxygen sensor in place of when dyno testing this supercharger system. The

voltage signal will cause the fuel system to run lean and possible engine damage.

Page 4

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 4

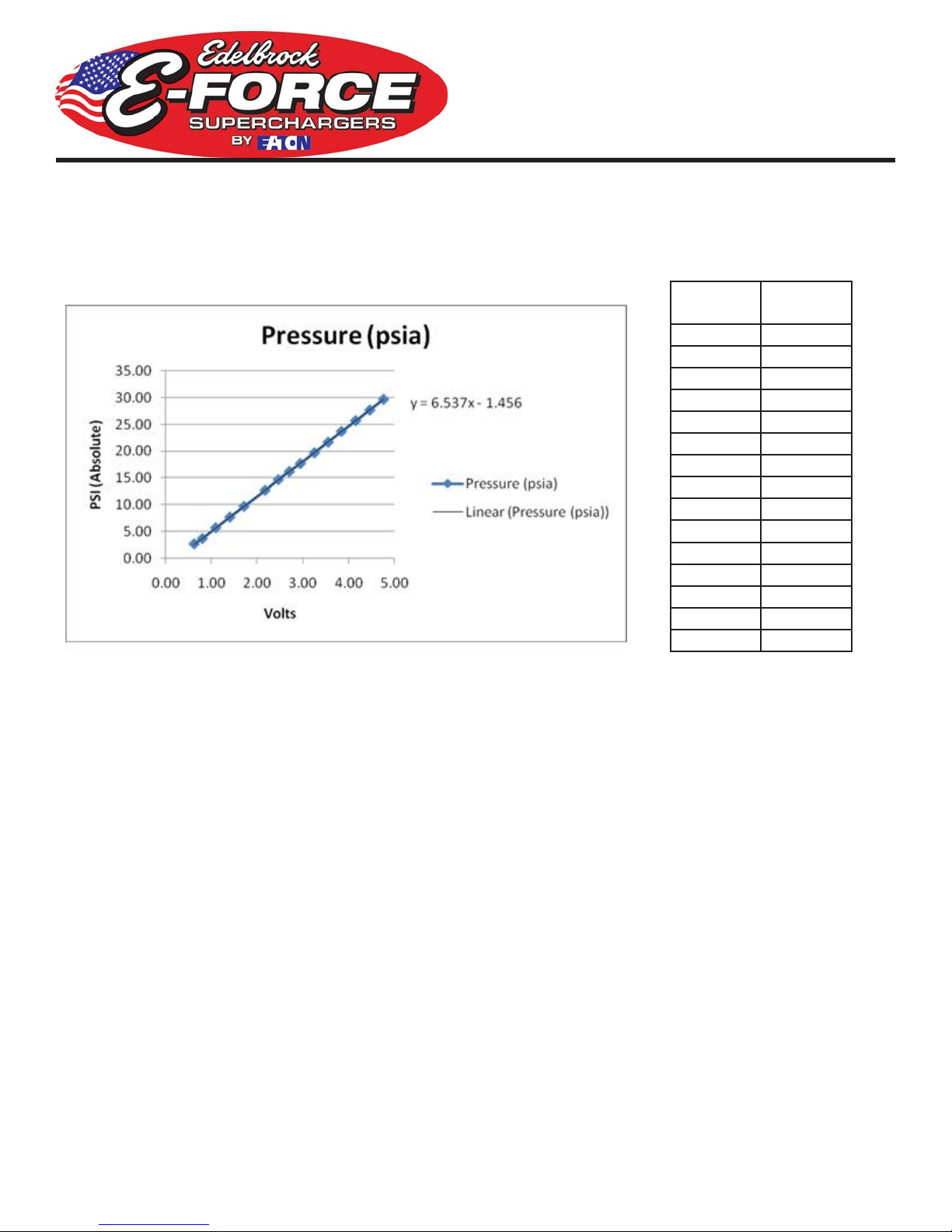

INSTALLING A BOOST GAUGE OR PRESSURE TRANSDUCER

Your E-Force supercharger is equipped with two options for measuring boost. The TMAP sensor mounted on top of the

manifold at the rear of the driver’s side, outputs a 0-5 volt signal through pins 1 & 2 (pin 1 is signal & pin 2 is signal

return,) that can be converted to an absolute pressure reading using the below calibration curve. Use of this signal

requires an ambient pressure correction for calculating boost pressure.

The second option is to utilize the pressure port at the rear of the passenger side intake runner flange. Your

supercharger has been pre-drilled and tapped for a 1/8” NPT fitting. There is currently a plug sealing the hole, which

can be removed, and replaced with a fitting to adapt to your sensor.

CAUTION: Never cut into the vacuum lines leading to the fuel rail pressure sensor and bypass actuator, on the driver’s

side of the manifold, for the purpose of tapping in a boost gauge. Interruption of the vacuum signal to the fuel rail

pressure sensor can affect the fuel pressure reading to the PCM, which can result in engine failure!

Voltage

Pressure

(psia)

0.62 2.70

0.80 3.69

1.09 5.70

1.40 7.69

1.71 9.70

2.17 12.70

2.46 14.70

2.70 16.21

2.94 17.70

3.25 19.71

3.55 21.70

3.84 23.71

4.15 25.70

4.46 27.70

4.76 29.70

SPECIAL NOTE REGARDING BULLITT AND SHELBY MUSTANGS

These limited edition Mustangs have been equipped from the factory with a larger diameter air inlet that alters

the signal provided by the Mass Air Flow Sensor supplied with this kit. Installation of the E-Force Supercharger on

these applications will require the use of a standard Mustang GT airbox or the Edelbrock Competition Air Intake #15808.

Please note that the Edelbrock Competition Air intake is not legal for emissions controlled applications and will require a

custom calibration. Please contact Edelbrock Technical Support for any questions regarding installation and tuning for

these applications.

Page 5

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 5

INSTALLATION HARDWARE PARTS LIST

Hardware Bag #1 Hardware Bag #2

Hardware Bag #3

(8x) - M6 x 1.0 x 30mm Hex Flange Bolt (Intake Manifold)

(4x) - M6 x 1.0 x 20mm Socket Flange Bolt (Fuel Rail)

(1x) - M8 x 1.25 x 75mm Hex Flange Bolt

(2x) - M8 x 1.25 x 65mm Hex Flange Bolt

(1x) - M8 x 1.25 x 60mm Hex Flange Bolt

(2x) - M8 x 1.25 x 40mm Hex Flange Bolt

(1x) - M8 x 1.25 x 35mm Hex Flange Bolt

(1x) - M6 x 1.0 x 20mm Hex Flange Bolt

(1x) - Alternator Strap Bracket

(1x) - M16 x 1.5 Hex Nut

Hardware Bag #4

(4x) - M6 x 1.0 x 35mm Hex Flange Bolt (Throttle Body)

Page 6

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 6

INSTALLATION HARDWARE PARTS LIST (Continued)

Hardware Bag #6

(2x) - M6 x 1.0 x 35mm Hex Flange Bolt (Water Crossover)

(2x) - M6 x 1.0 x 45mm Hex Flange Bolt (Water Crossover)

Hardware Bag #7

(1x) - M6 x 1.0 x 16mm Hex Flange Bolt (Water Pump)

(2x) - M6 x 1.0 Hex Nut (Water Pump)

Hardware Bag #5

(4x) - M8 x 1.25 x 30mm Hex Flange Bolt (Intercooler)

(6x) - M8 x 1.25 Hex Flange Nut (Intercooler)

(4x) - M8 Fender Washer (Intercooler)

(6x) - 10-32 x 0.5” Button Head Bolt (Coil Covers)

(2x) - Rear Coil Cover Bracket

(1x) - Front Coil Cover Bracket

(3x) - Coil Cover Thumbscrews

Hardware Bag #8

Page 7

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 7

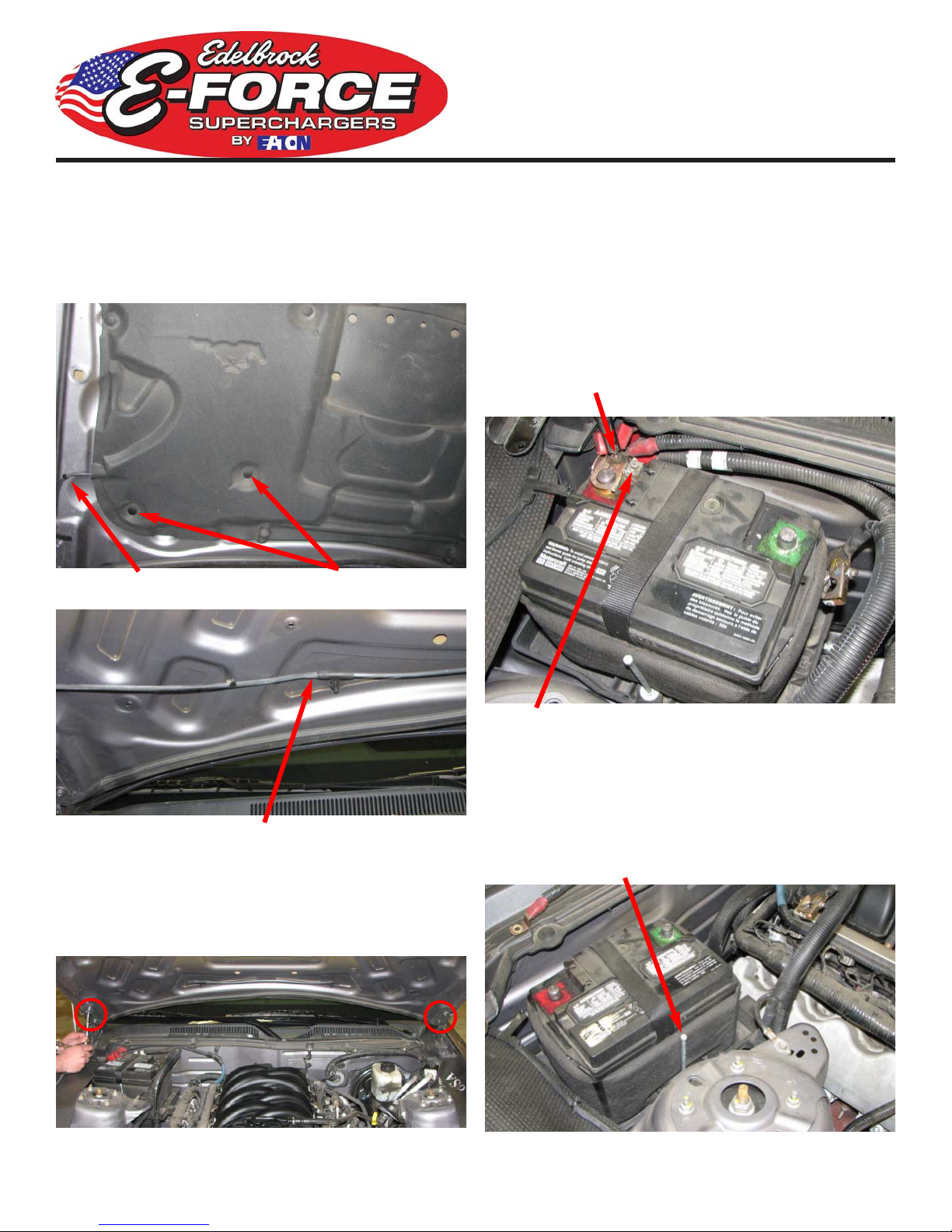

I. Hood Removal

1. Use a panel puller to pry off two of the push-pins

holding the hood insulator in place on the passenger side,

then reach behind the insulator to disconnect the washer

hose from the T-junction at the passenger side nozzle.

Detach hose retaining clip, then remove these two pins.

Pull hose off here.

(Insulator fully removed for illustrative purposes.)

2. Have an assistant support the hood while a 10mm

socket is used to remove the four bolts attaching it to its

hinges. Lift the hood off the vehicle and set it aside.

II. Battery Removal

3. Use an 8mm socket to loosen the negative battery

terminal clamp and remove it. Tuck it to the side to

prevent any accidental contact with the negative battery

terminal.

4. Use a 10mm socket to remove the nut on the positive

battery terminal that retains the alternator power wire.

Detach this wire from the terminal, then loosely reinstall

the nut.

5. Use an 8mm socket to loosen and remove the positive

battery terminal clamp, then tuck the wire over to the

side.

6. Pull the insulating sleeve off of the battery, then use an

8mm socket to loosen the long bolt that secures the

battery tie-down strap. The battery can then be removed

and set aside.

Page 8

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 8

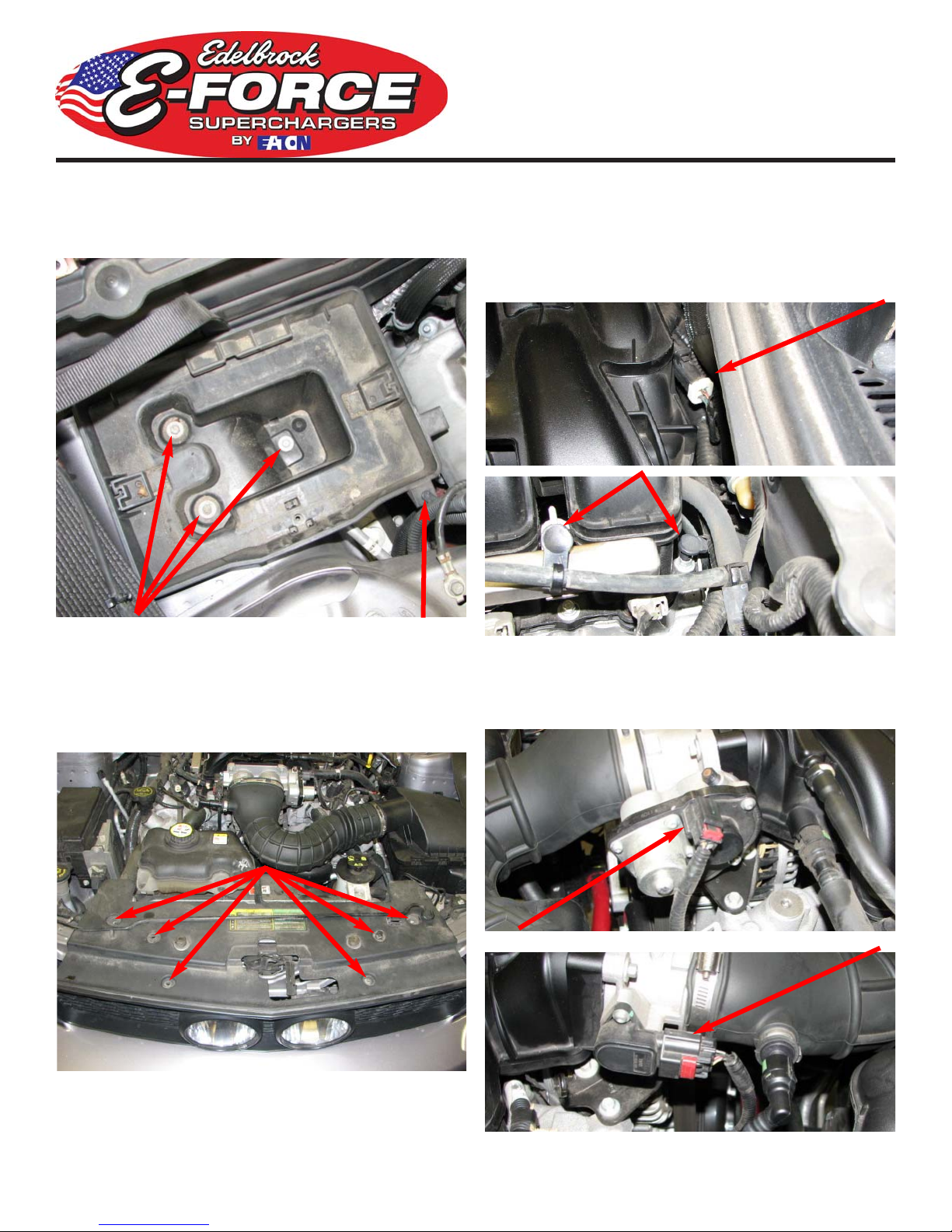

7. Use an 8mm socket with a 12” extension bar to

remove the three bolts holding the battery tray in place,

then use a panel puller to detach the wiring harness clip.

Remove and set aside the tray.

Bolts Wiring Harness Clip

8. Use a flat blade screwdriver to pry up the head of the

six push-pins that retain the radiator shroud, then use a

panel puller to fully remove the push-pins. Lift the shroud

off the car and set it and the push-pins aside.

III. Removing Engine Components

9. Detach the charge motion control valve (CMCV)

electrical connector at the rear of the manifold. Seperate

the wiring retainers from the intake manifold stud and the

CMCV bracket, then move the wiring harness to the side.

10. Detach the throttle position sensor (TPS) and

electronic throttle control (ETC) connectors from the

throttle body.

ETC TPS

Page 9

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 9

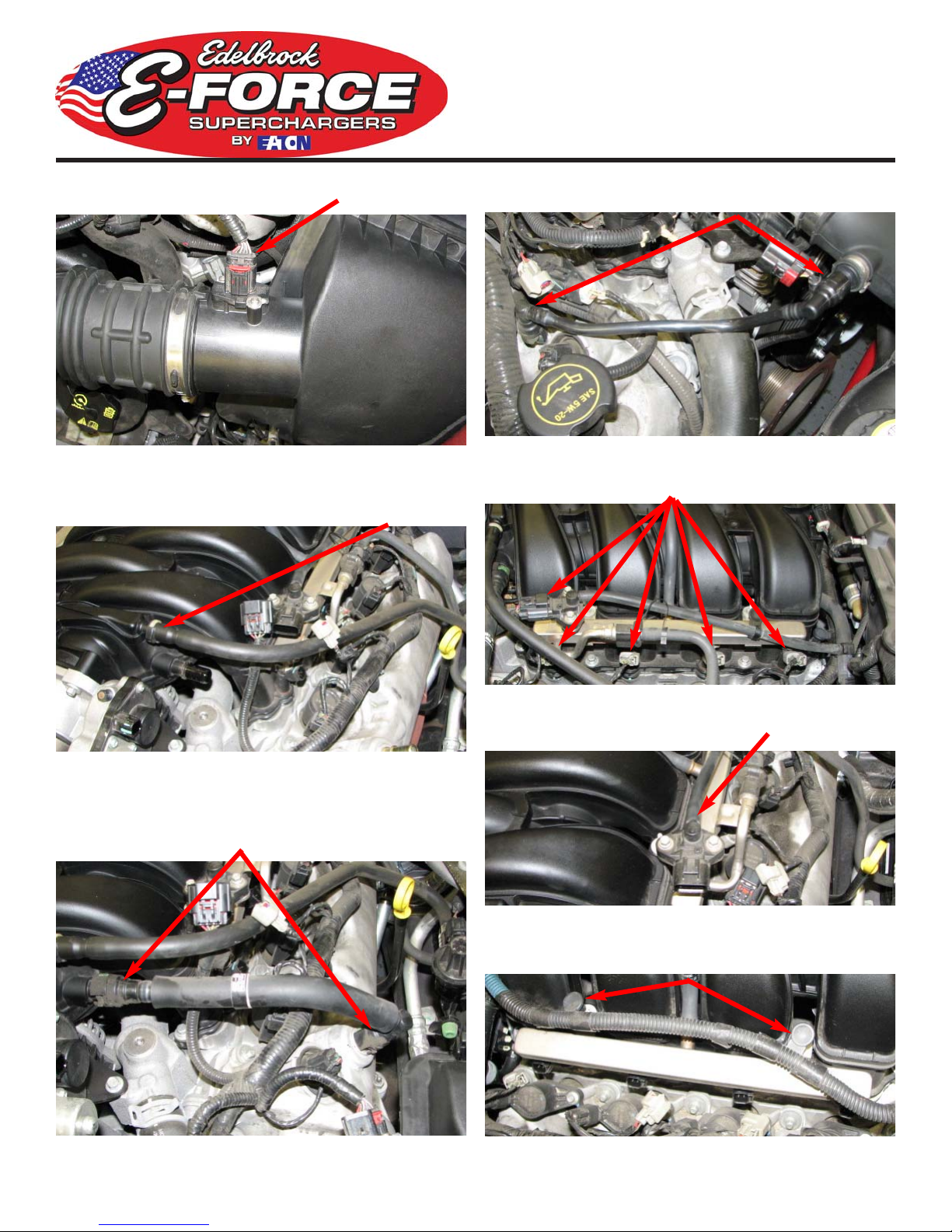

11. Detach the mass airflow sensor electrical connector

from the air filter outlet tube.

12. Disconnect the evaporative emissions tube from the

intake manifold and move it to the side.

13. Disconnect the PCV line from where it is connected to

the driver side valve cover, then disconnect it from the

intake manifold and remove it. This hose will not be

reused.

14. Disconnect and remove the passenger side PCV hose.

This hose will not be reused.

15. Detach the electrical connectors from all eight fuel

injectors and the fuel pressure sensor.

16. Disconnect the vacuum hose from the fuel pressure

sensor.

17. Detach the battery cable anchors from the fuel rail

bolts by pulling upward firmly.

Page 10

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 10

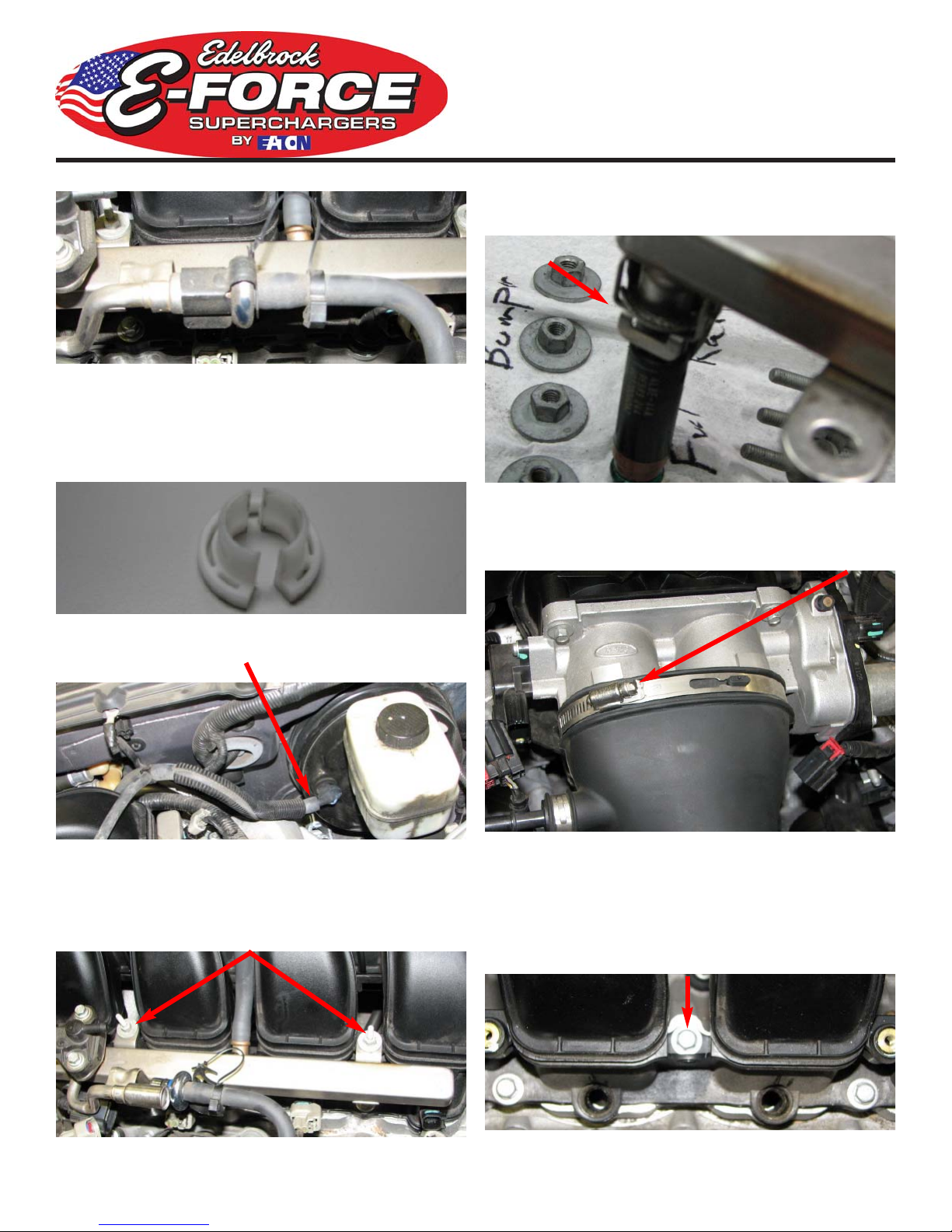

18. Remove the fuel line lock clip and let it dangle.

19. Use a 5/8” fuel line removal tool to disconnect the

fuel supply line from the fuel rails. Use a shop rag

wrapped over the connection to absorb the fuel remaining

in the system.

20. Disconnect the vacuum hose connected to the brake

booster.

Pull hose off nipple, do not remove fitting from booster.

21. Loosen the four studs that hold down the fuel rails.

The rails and injectors can then be removed together and

set aside.

22. Remove the retaining clips that hold in the injectors

and set them aside for reinstallation later, along with the

rails. The stock injectors will not be reused.

23. Use a flat head screwdriver to loosen the worm

clamps that retain the air inlet tube between the throttle

body and air filter cover, then remove the tube.

24. The manifold bolts may now be removed with a

10mm socket and the intake lifted off the engine. There

is no need to detach the throttle body as it will not be

reused. Use an extension bar to reach the two center

bolts hidden between the runners.

Page 11

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 11

25. 2005-2008 applications should remove the o-ring

seals from the intake manifold and inspect them for

damage. Any damaged seals must be replaced; the rest

will be retained for reuse with the supercharger runners.

2009 and later applications will use the o-rings supplied

in the 15805 Hardware Kit.

26. Use a soft cloth to clean any irregularities on the

sealing surfaces of the cylinder heads. Use two strips of

masking tape to prevent any debris from entering the

exposed ports.

27. Unlatch the air cleaner cover, then use a Torx-20

driver to remove the MAF sensor from the outlet tube.

Apply a small strip of tape to the MAF sensor to

distinguish it from the modified unit supplied with this kit.

28. Use a 10mm socket to unbolt the air cleaner housing

and remove it.

29. Loosen the tensioner arm by using a 1/2” drive

breaker bar, and remove the serpentine belt. This belt can

be discarded as it will not be reused.

30. Use a 13mm socket to remove the two nuts at the

bottom of the alternator.

Page 12

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 12

31. Use a 10mm socket to remove the two outer

alternator bracket bolts, and an 8mm socket to remove

the two inner alternator bracket bolts.

8mm

10mm

32. Use a panel puller to remove the harness locating pin

from the alternator bracket, remove the bracket, then

disconnect the alternator electrical connector. Trace the

alternator harness back to where it clips into the main

harness and detach it. This wire may now be discarded.

33. Push aside the protective boot to access and remove

the nut retaining the alternator power wire. The power

wire will not be reused and can be discarded. The

alternator can now be lifted out and set aside.

IV. Front Fascia

34. Use a 10mm socket to remove the two upper front

bumper cover bolts, located between the grille and

headlights.

35. Use a jack and jack stands or a service lift to raise

the front of the vehicle. Use a 5.5mm (or 7/32”) socket to

remove the seven bolts that retain the lower splash shield,

then set the shield and bolts aside.

36. Remove the five push-pins and three screws that

secure each of the front inner fender wells. Note that the

front inner fender wells are divided in two sections, but

you will only need to remove the forward half. Turn the

head of push-pins that have a philips head recess on

them about a quarter turn or until the head pops up, then

fully remove the pin with a panel puller. Remove and set

aside the forward half of both front inner fender wells.

Page 13

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 13

37. Reach through the fender well with a 10mm socket to

loosen the two nuts on each side that attach the front

bumper cover to the body.

38. Pull the front bumper cover down off the studs, then

forward slightly to access the fog lamp, turn signal and

running light electrical connectors. Once these have been

detached, the entire front cover can be removed with the

lights and indicators in place.

39. Use a panel puller to remove the four pins retaining

the foam insulator, then set them and the insulator aside.

V. Cooling System

40. To avoid injury be sure the engine has fully cooled

before draining the cooling system. Release any excess

pressure in the system by using a cloth to rotate the

radiator cap counterclockwise. Step away from the

vehicle if any hot vapor is vented, then remove the cap.

41. Place a drain pan below the radiator petcock on the

passenger side, then use a 19mm wrench to open the

petcock and drain the coolant.

NOTE: If this system is being installed on an ‘05 or ‘06

Mustang GT, you will need to have purchased the

Cooling Sysem Upgrade Kit #15804 before proceeding

with the installation. Otherwise, 2007 and later vehicles

should skip ahead to step 48.

Page 14

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 14

42. Use large pliers or a clamp removal tool to detach

both upper radiator hoses from the water crossover.

43. Place shop rags in the engine valley to catch excess

coolant, then disconnect the heater hose connected to the

bottom of the crossover. Use a 10mm socket to unbolt

and remove the water crossover. Remove and save the orings for reuse later.

44. Disconnect the lower hoses joining the thermostat

housing to the radiator, engine block and the bottom of

the coolant recovery tank. Seperate the hose clamps from

the end of the hoses and save them for reuse later.

45. Disassemble the thermostat housing and remove the

thermostat. The thermostat itself can be discarded but

the o-ring will be reused.

46. Use a 15mm socket to remove the hose bracket.

47. Connect the radiator hose assembly supplied in the

15804 kit to the driver side radiator fitting and the engine

block fitting behind the power steering pump using the

stock hose clamps. The long segment should be

connected to the bottom of the coolant recovery tank, also

reusing the stock hose clamp.

Radiator Engine Block Coolant Recovery Tank

NOTE: ‘05-’06 applications can skip ahead to step 51,

the following steps only apply to ‘07 and later Mustangs.

Page 15

55. Hang the water pump on the passenger side outer

bumper bolts while pushing the outlet hose onto the inlet

nipple of the heat exchanger. Secure the hose with a

clamp, and the water pump bracket with two of the M8

flange nuts supplied.

56. Install the long 3/4” hose onto the driver side barb of

the heat exchanger and secure it with a clamp.

VII. Wiring

57. Locate the large multi-pin connector (C110) secured

to the driver side of the PCM bracket. This connector has

12 pins in ‘05 Mustangs, while ‘06 and later cars have a

16-pin connector in this location.

58. Seperate the harness connectors. ‘05 and ‘06

applications should trim enough electrical tape from the

harness behind the chassis side connector (closest to the

radiator) to pull out 2” of wire from the convoluted tubing.

‘07 and later applications will trim the electrical tape from

behind the engine connector (closest to the firewall) to

pull out 2” of wire from the convoluted tubing.

Chassis Side for Engine Side for

‘05 & ‘06 Mustangs ‘07 & Later Mustangs

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 15

48. Disconnect the upper radiator hose from the

thermostat housing and radiator, then set it aside.

49. Remove and save the thermostat, its housing and the

o-ring for later reuse.

50. Unbolt and remove the water crossover from the front

of the engine block and unclip the heater hose from the

bottom. Save the o-ring seals for later reuse.

VI. Installing Intercooler Accessories

51. Replace the two upper inside bumper bolts with two

of the M8 x 30mm long hex flange bolts and the two of

the M8 washers included in hardware bag #5.

52. Replace both outer bumper bolts on the passenger

side with two of the M8 x 30mm hex flange bolts and two

of the M8 washers supplied in hardware bag #5.

53. Hang the heat exchanger behind the bumper

reinforcement on the inner bumper bolts replaced in step

51 and secure it with the four M8 flange nuts supplied in

hardware bag #5.

54. Install the supplied 5” piece of 3/4” hose onto the

outlet of the intercooler water pump, secure it with the

supplied hose clamp, then slide a second clamp onto the

hose to secure it on the heat exchanger.

Page 16

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 16

59. ‘05 applications should locate the red wire in pin 10,

near the bottom of the connector. ‘06 applications should

locate the red wire in pin 2, at the top left of the

connector. ‘07 and later applications should locate the

red wire with the yellow stripe in pin 16.

‘06 Model Year Example

60. Once you have located the appropriate wire for your

model year application, cut the wire 1.5” back from the

connector and strip the end on the harness side.

61. Insert the the exposed end of the stripped harness

wire into the butt connector pre-installed on the yellow

wire with the red stripe of the intercooler water pump

harness. Secure the connection by crimping the butt

connector with an appropriate crimp tool, then use a heat

gun on the connection until it shrinks.

62. Remove the relay from the relay socket on the

supplied intercooler water pump wiring harness.

63. Mount the pump relay on the lower passenger side

fascia bracket bolt. Apply a light coat of blue loctite to the

bolt threads, then secure the relay holder with an M6 nut

supplied in hardware bag #7. Reinstall the relay.

64. Route the ground wire to the upper fascia bracket

bolt and secure it with an M6 nut from hardware bag #7.

65. Route wires under the fuse box and attach the fuse

holder to the passenger side strut tower with a 10mm

socket and the M6 bolt supplied in hardware bag #7. This

bolt hole is threaded on ‘07 and later Mustangs, but ‘05

and ‘06 will need to use an M6 nyloc nut supplied in the

#15804 Cooling Upgrade Kit.

Page 17

66. Use a 10mm socket to attach the power wire to the

power terminal on the fuse box

67. Route the water pump electrical connector below the

fuse box and around the washer fluid reservoir and plug it

into the intercooler water pump.

68. Install the short ETC harness extension onto the ETC

connector on the main engine wiring harness, previously

removed from the driver side of the throttle body.

69. Install the TPS/Alternator extension harness onto the

TPS connector on the passenger side of the main engine

wiring harness.

70. Locate the electrical connector on the main wiring

harness previously occupied by the alternator control

wiring harness.

71. Attach the round alternator connector on the supplied

TPS/Alternator harness into this connector and route the

harness around the back of the engine bay, then forward

along the driver side cylinder head.

72. Install the TMAP wiring harness extension onto the

MAF sensor connector on the driver side of the main

engine wiring harness. Route the longer segment of the

extension harness toward the back of the engine bay.

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 17

VIII. Cooling System Modifications

73. Route the molded hose under the fuse box and onto

the inlet at the top of the water pump. Secure it with a

clamp.

74. Remove the two inner passenger side strut tower

nuts and hang the recovery tank bracket from the

exposed bolts. Do not reinstall strut nuts at this time.

Bend the A/C service port slightly so that it is positioned

between the recovery tank and the passenger side fender.

75. Slide the molded hose onto the bottom barb of the

tank and secure it with a clamp.

Page 18

76. Reinstall the foam bumper insulator and secure it in

place with the stock body pins.

77. Reconnect the fog lights and indicators, then replace

the fascia onto the front of the car. Reach through the

fender wells to reattach the nuts that secure it.

78. Reinstall the screws and push in rivets that secure

the inner fender wells, then reinstall the upper front fascia

bolts.

79. Replace the lower splash shield and the radiator

shroud and secure them with the stock fasteners. The

vehicle can now be lowered.

80. Two hard coolant lines are held in place in the engine

valley by a bracket bolted to the rear of the passenger

side cylinder head. Remove the bolt holding this bracket

in place, then unclip the lower hose from the firewall.

81. Unclamp the upper hose from the hard line, then

remove both hard lines, being careful not to damage the

nipple in the bottom of engine valley.

82. Place the coolant pipes in cloth wrapped vice jaws to

avoid damaging them, then use a hacksaw or cut-off

wheel to seperate the tubes by cutting the two brackets,

as shown below.

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 18

83. Once the coolant pipes have been separated, reinstall

the smaller diameter of the two by gently sliding it onto

the nipple in the engine valley and securing it onto the

back of the head with the stock bolt. The lower hose and

larger diameter hard line can be discarded.

84. Reattach the upper heater hose to the hard line with

the stock hose clamp.

IX. Installing New Components.

85. Use a 13mm socket to remove the two idler pulleys

on the driver’s side of the engine, but save one of the

mounting bolts for later.

Page 19

86. Install the smaller of the two Edelbrock supplied idler

pulleys onto the alternator bracket with the open end

facing the bracket. Secure it with a small amount of blue

Loctite applied to the bolt saved in the previous step, then

use a 13mm socket to torque it down to 18 ft/lbs.

87. Remove the alternator mounting stud on the driver’s

side of the engine using a 5.5mm socket, or thread a

second nut onto the stud as shown, and use a 13mm

wrench on the nut closest to the block to remove the stud.

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 19

88. Use 13, 15 & 18mm sockets to remove the driver

side front cover nuts, bolts and studs, as shown below.

89. Slide the larger of the two Edelbrock supplied idler

pulleys onto the lower idler boss of the front cover with

the open side facing the engine block.

90. Use a 12mm deep socket and a small amount of blue

loctite to install the alternator bracket using the bolts

supplied in hardware bag #3. The upper two provisions

will use the 65mm bolts, while the bottom provision will

use the 75mm bolt. The center hole will use a 35mm bolt

that will pass through both the bracket and pulley, and

then thread into the front cover.

65mm 35mm 75mm

13mm Nut

15mm Stud

13mm

18mm

Page 20

X. Installing Spark Plugs (Not Included In 1585)

NOTE: The following steps only apply to Mustangs built

prior to December, ‘07. Later applications have the

proper heat range spark plug installed from the factory

and will not use the supplied plugs. These Mustangs

should skip ahead to ‘Installing the Supercharger’.

Early model spark plugs that need to be replaced have a

ground strap that extends all the way around the

electrode, while late models have a standard ‘L’ shape.

Mustangs with the late model spark plug have a brown

spark plug boot, while early models had a black boot.

Early Model Plug

91. Use a 7mm socket to remove the bolt that secures

each ignition coil, then use a slight twisting motion to

remove the coils.

92. Use compressed air to clean out the spark plug well,

then remove the stock spark plugs with a 9/16” spark

plug socket.

93. Coat the threads of the Edelbrock supplied spark

plugs with anti-sieze, and torque them to 25 ft/lbs.

94. Apply a thin layer of dielectric grease to the inside of

the coil boots, then reinstall them onto the plugs.

95. Tighten the coil retaining bolts to 44 in/lbs.

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 20

XI. Installing the Supercharger

96. Install the Edelbrock supplied heater hose on the

firewall connector, and lay it to the side for now.

97. Remove the supercharger assembly from its packing

container and install the o-ring seals, removed from the

stock manifold on early applications and supplied in the

#15805 Hardware Kit for 2009 applications, into the

grooves on the bottom of the runners. Be sure to line up

the tab on the o-rings with the notches provided.

98. Be sure that the engine bay and environs are clean

and free of debris, then remove the masking tape used to

protect the intake ports from contamination.

99. Install the o-ring gaskets removed from the stock

water crossover into the supplied crossover.

Page 21

100. Insert the water crossover into the gap between the

intercooler manifold and the and the supercharger drive

pulley. There are no bolts that directly attach the

crossover to the manifold, so it will need to be held steady

as the supercharger is installed.

101. With the help of an assistant or a cherry picker,

carefully lower the supercharger assembly onto the

cylinder heads. Be especially careful not to pinch any

wires between the supercharger and the cylinder heads.

Orient the attached 3/8” hose around the back of the

manifold in the direction of the brake booster as the

supercharger is lowered.

102. Push the supercharger as far to the rear of the

engine bay as space allows so that the bolts supplied in

hardware bag #6 can be inserted into the provisions on

the crossover. Pull the crossover forward against the

bolts, then torque them to 7-1/2 ft/lbs with a 10mm

socket.

103. Ensure correct alignment of the supercharger by

looking through the injector holes to verify that they are

aligned with the injector provisions of the cylinder head

and that the manifold is centered left to right as well as

front to back on the engine block.

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 21

104. Use a 10 mm socket to install the intake bolts

supplied in hardware bag #1 then torque them to 8 ft/lbs

in the sequence shown below.

105. Install the new fuel injectors (not included in 1585)

into the stock fuel rails by applying a bit of o-ring lube to

both o-rings of each injector, sliding the stock retaining

clips onto the injectors, then pushing each injector into the

rail until the clips snap into place.

106. Align each of the fuel injectors with its prospective

well, then pull the top of the rail outboard so that the the

brackets will clear the runner flanges as you push the rail

down. Make sure that the TMAP wiring harness is routed

below the driver side rail. The rails and injectors are fully

seated once the rail brackets contact the runner bosses.

Use a 5mm allen tool to secure the rails with the M6

socket head bolts supplied in hardware bag #2.

Page 22

107. Install the 3/8” vacuum hose attached to the rear of

the manifold onto the brake booster nipple and secure it

with the spring clamp provided.

108. Install the 1/4” vacuum hose attached to the rear of

the manifold onto the fuel pressure sensor.

109. Connect each of the fuel injectors to the appropriate

terminal on the main wiring harness, then reconnect the

fuel line to the fuel rail and secure it with the lock clip.

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 22

110. Connect the EVAP hose to the hard line at the front

of the manifold.

111. Reconnect the fuel pressure sensor to the main

wiring harness. Be sure to use the connector that does

not have a red locking tab, the connector with a red

locking tab is for the TPS.

112. Plug wiring harness extension into TMAP sensor.

XII. Modifying Stock Components

113. Use a 10mm socket to loosen the three bolts that

hold the tensioner in place and remove the arm.

Page 23

114. Place the tensioner in a cloth wrapped vice and use

a grinding wheel or hacksaw to remove the stop.

115. Use a grinding wheel or file to ensure that the area

that was ground down is smooth and free of burrs.

116. Use a 10mm socket to install the three tensioner

brace bolts, making sure to line up the square holes.

117. Use a 10mm socket to reinstall the tensioner.

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 23

118. Use a flat head screwdriver to pop off the bearing

cover on the alternator pulley. ‘05-’08 applications should

use the supplied tool with an impact wrench to remove

the stock pulley. ‘09 and later applications must

refer to the instructions supplied with #15805 kit

before proceeding.

119. Use an impact gun to install the new alternator pulley

with the nut supplied in hardware bag #3 (with kit #15805

for ‘09 Mustangs) and red LocTite.

WARNING: Failure to install the nut in the manner

described above will result in the nut loosening, causing

catastrophic damage to the engine’s front cover.

120. Attach the stock protective boot to the new

alternator power wire and fasten it to the alternator

terminal with a 10mm socket. Route the wire around the

back of the engine towards the battery, then attach the

new alternator control wiring harness connector from the

TPS/Alternator extension harness to the alternator.

Page 24

121. Unbolt the power steering reservoir so that it can be

pushed out of the way while installing the alternator.

122. Thread the serpentine belt through the alternator

bracket and over the alternator pulley before securing the

alternator to the bracket with the two M8 x 40mm bolts

supplied in hardware bag #3. Verify that the alternator is

fully seated on the bolts before torquing them to 18 ft/lb.

123. Use a 12mm socket to fasten the alternator strap to

the front cover using the M8 x 60mm long bolt supplied in

hardware bag #3, then tighten it to 18 ft/lbs. Place the

electrical noise isolating capacitor (not shown) in front of

the strap, then secure the strap to the alternator with the

M6 x 20mm bolt from hardware bag #3 and tighten it to 8

ft/lbs.

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 24

124. Route the supplied serpentine belt according to the

diagram provided below by using a 1/2” breaker bar to

twist the belt tensioner enough to allow the belt to slide

into place.

XIII. Installing the Throttle Body

125. Use 8mm and 10mm sockets to unbolt the OEM

throttle body from the stock intake manifold, using care

not to damage the motor housing.

126. Use a T20 Torx driver to remove the motor housing,

plastic capped spring and TPS from the OEM throttle body.

WARNING: Rotating the TPS when removing or installing

it may damage the internals beyond repair.

Plastic Capped Spring ETC TPS

Page 25

127. Carefully remove the motor housing cap.

128. Install the plastic capped spring into the new

Edelbrock supplied throttle body so that the pigtail end is

hooked into the catch slot of the gear on the end of the

throttle shaft.

129. Install the ETC motor over the plastic capped spring

and tighten the screws that hold it in place.

130. Use needle nose pliers to rotate the plastic spring

cap roughly half a turn counter-clockwise until the two

tabs line up with the notches in the motor housing. Pull

up on the cap until it snaps into place.

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 25

131. Reinstall the motor housing cap by lining up the tabs

and applying light pressure.

132. Reuse the stock bolts to install the TPS on the new

throttle body by lining up the locating tab and pushing it

straight on. Be careful to avoid rotating the TPS during

installation.

133. Verify correct installation by pushing the butterfly

open and closed a few times, making sure that it doesn’t

stick or bind in a particular position. Be sure that the

throttle blade returns to the closed position when released

before proceeding.

134. Align the throttle body gasket on the flange, then

install the throttle body onto the inlet elbow with the bolts

supplied in hardware bag #4. Open the throttle blade and

align the two parts so that there is a smooth transition

before tightening the bolts.

135. Use a cut off wheel or hacksaw and drill to cut the

base of the airbox off as shown, then reinstall the airbox.

Page 26

136. Install the new high flow air filter in the airbox.

137. Use a T20 Torx driver to install the new MAF sensor

in the air cover outlet tube, torque the two screws that

retain it to 18 in/lbs., then reinstall the cover.

138. Install the throttle body elbow onto the throttle body

and secure it with the provided hose clamps. The flexible

elbow should be oriented so that it can be easily mated to

the air cleaner cover outlet tube. Install the air box cover,

clamp it down and attach the MAF connector to the sensor.

139. Route the new driver side PCV hose between the

valve cover and intake elbow, then install the passenger

side PCV hose between the fitting on the throttle body and

valve cover.

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 26

140. Install the ETC extension harness and attach the

electrical connectors for the TPS and ETC stepper motor.

141. Install the 12” piece of 3/4” hose from the recovery

tank to the intercooler manifold fitting. Secure each end

with a clamp.

142. Route the other end of the hose up to the intercooler

manifold outboard of the A/C line, avoiding close proximity

to the exhaust manifold and power steering pump, and

attach it to the manifold fitting with a clamp.

143. Install the thermostat, o-ring & housing (thermostat

and housing supplied in #15804 for ‘05-’06 applications,

all model years reuse stock o-ring) onto the driver side of

the water crossover. Torque the thermostat housing bolts

to 7-1/2” ft/lbs. Install the stock molded hose onto the

thermostat housing and line the other end up with the

passenger side radiator fitting. Trim 1-1/2” from the

radiator side of the hose to achieve the best fit.

Page 27

144. Install the supplied heater hose onto the heater tube

on the passenger side of the water crossover.

145. Verify that the coolant petcock is closed, then refill

the coolant system.

146. Fill the intercooler system with a 50/50 blend of

water and coolant poured into the recovery tank. Fill the

tank until the water level is roughly 1” from the top of the

threaded neck.

XIV. Installing Coil Covers (Does Not Apply To 1585)

147. Lift the recovery tank off the strut tower bolts and

fold it forward.

148. ‘05 & ‘06 applications should tape off the strut

tower brackets to prevent damaging the covers during

installation. On some ‘05 & ‘06 vehicles, it may be

necessary to clearance the flange on the bottom of the

strut tower brackets in order for the covers to fit properly.

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 27

149. Install the coil cover brackets onto the coil covers

with the raised portion of the bracket facing towards the

top of the cover, while the lower ‘L’ portion faces in

towards the center of the cover, as shown below.

150 Apply a small amount of blue loctite to the thread of

each bolt supplied in hardware bag #8, then tighten them

into the threaded holes of the coil covers.

151. Remove the engine oil dipstick, then pull the main

wiring harnesses off the valve cover studs on both sides

of the engine bay.

152. Lube the grommet supplied with the driver side

cover with silicone spray, then slide it over the dipstick

tube and wiggle it into place with your thumbs as you

lower the driver side cover into place.

Page 28

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 28

153. Lower the driver side coil cover into place, orienting

the bracket so that it lines up with the bolt provision

below the TMAP sensor. Use caution not to pinch the

TMAP wire harness as you are fastening the cover bracket

to the runner with the supplied thumb screws. Verify that

the cover stands are flush on the valve cover and not

pinching any wires or hoses. Install the oil dipstick.

154. Install the passenger side cover by lowering it into

place and fastening the thumbscrews. Use caution not to

pinch any wire harnesses or heater hoses.

155. Replace the recovery tank on the strut tower bolts,

then install and torque the strut tower nuts to 26 ft/lbs.

156. Reinstall the battery tray, battery, protective sleeve

and tie down strap, then secure the battery. Reconnect

the positive and negative clamps to their respective

terminals, and connect the new alternator power wire to

the positive battery terminal.

157. Turn the ignition key to the ‘ON’ position.

158. Verify that water is flowing briskly through the

recovery tank, then install the cap.

159. Have an assistant support the hood while you

tighten the four bolts that secure it to its hinges. Be

careful to verify that it is properly aligned and that the

supercharger has nothing on top of it before you attempt

to close the hood.

160. Reattach the washer nozzle hose and replace any

hood insulator body pins that were removed.

XV. Flashing the ECU

161. Plug the supplied programming module into the

OBD-II port of the car, located below the steering column.

162. Once the main menu has loaded, press the central

‘select’ button on the controller to access the

‘Performance Tune’ option.

163. Read the discalimer carefully, then choose ‘Agree’

and press select.

164. Use the arrow buttons to select your transmission,

then press select to confirm your selection.

165. Select ‘Edelbrock E-Force 5psi’ from the menu.

Page 29

166. Read the description and press select.

167. The programmer will automatically save a copy of

your existing engine tune. Press select to continue.

168. Turn the ignition key to the ‘OFF’ position when

prompted, but do not remove it.

169. Turn the ignition key to the ‘ON’ position when

prompted, but do not attempt to start the car. The

programmer will automatically start saving the stock

calibration.

170. Once complete, follow the on-screen prompts

regarding key position until you are given the option to

‘Install Tune’ or ‘Modify Tune’. Choose ‘Modify Tune’ and

press select.

171. Read the disclaimer and press select.

172. Select ‘Modify Parameters’ and press select.

173. Press select to choose ‘Axle Ratio’.

174. Press select to choose ‘Axle Ratio’, again.

175. Use the directional buttons to choose the number

closest to your axle ratio (printed on the differential cover)

and press select.

176. Press select to confirm your choice.

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 29

177. An asterisk will appear next to the ‘Axle Ratio’ option

to signify that your changes have been saved. If your

Mustang is equipped with non-stock tires, choose the ‘Tire

Revs per Mile’ option and press select; otherwise, proceed

to step 198.

178. You will need to check your tire manufacturer’s

website to determine the tire revolutions per mile for your

tires. The stock tires get 771 revs per mile.

179. Use the directional buttons to select the number

closest to the tire revs per mile figure provided by your

tire manufacturer. Press select again to confirm your

selection.

180. Press escape twice to return to the Performance

Tune menu. Choose ‘Install Tune’ and press select.

181. Confirm your choice by pressing select.

182. Follow the on-screen prompts regarding key position

until you recieve notification that the tune installation is

complete.

183. When the download is complete you will be

prompted to disconnect the DiabloSport Performance

Tuner from the OBD-II port of your vehicle.

184. If you have access to a diagnostic scan tool, run a

‘Key On, Engine Off’ test to verify that all connectors are

properly installed, otherwise move on to the next step.

185. Start the car and verify a smooth idle. If you are

using a diagnostic scan tool, run a ‘Key On, Engine Run’

test.

Page 30

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 30

Additional Supporting Components

Now that the horsepower potential of your Mustang has been substantially increased, Edelbrock strongly recommends

upgrading the suspension and exhaust systems in order to fully utilize these gains. The following components have

been designed specifically to enhance the handling and acceleration capabilities of your Mustang when used in

conjunction with the E-Force Supercharger.

Exhaust Components

Edelbrock shorty headers have outstanding performance

features such as mandrel-bent tubes and laser-cut or

stamped flanges. They are direct replacements for stock

manifolds, so installation is simple using the factory

crossover pipe. Headers are made of durable 16-gauge

mild steel and are 50-state street legal. Two finishes are

available: Ti-Tech or ceramic coating.

Shorty Headers for ‘05-’09 Mustang GTs:

Ti-Tech Coated.....................................#65053

Ceramic Coated...................................#65052

Increase performance and improve driveability with an

Edelbrock Axle-Back Exhaust System. Built in the USA by

Edelbrock from 16-gauge aluminized or 17-gauge

stainless steel tubing, each system includes an Edelbrock

SDT muffler with Sound Deflection Technology for a

throaty performance sound. Polished, 304 stainless steel

tailpipes are included with both kits. Tips are available

separately to complete any exhaust system with a round

or flat oval design. Finally, all Edelbrock Exhaust Systems

are designed as a direct replacement for stock making

them emissions legal in all 50-states.

Axle-Back Exhaust for ‘05-’09 Mustang GTs:

Aluminized Steel...................................#5644

Stainless Steel......................................#5654

Page 31

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 31

Complete Suspension Kits

Edelbrock Touring Suspension Kits include the best combination of components needed to upgrade your stock

suspension and improve handling. Edelbrock Touring Kits are the entry level and most economical upgrade in our line

of kits. This kit includes all of the hardware and instructions needed for installation and uses the stock mounting

locations for a simple install. See the following page for a complete list of components.

Touring Suspension Kit for ‘05-’09 Mustang..........................................................................................#52207

Edelbrock Competition Suspension Kits include all of the best suspension components to help keep your high

performance muscle car or sportsman race car in straight line down the track. This kit is packaged with the right

combination of parts designed to work together for optimal torque transfer for a maximized launch. This kit includes all

of the hardware and instructions needed for a complete installation. See the following page for a complete list of

components.

Competition Suspension Kit for ‘05-’09 Mustang...................................................................................#52206

Page 32

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 32

Suspension Components

Suspension Kit Contents

Tubular

Lower

Trailing Arm

#5276

Adjustable

Upper

Trailing Arm

#5253

Adjustable

Panhard Rod

#5220

Trailing Arm

Relocation

Bracket

#52103

Lowering Coil

Spring Set

#5287

Front

Sway Bar

#52887

Rear

Sway Bar

#52888

Touring Kit #52207 Included Included Included - Included Included Included

Competition Kit #52206 Included Included Included Included - - -

Front Sway Bars are manufactured from lightweight

hollow-core (4130) Chromoly steel for maximum strength

and durability. The CNC forming ensures precision fitment

for a true bolt-on installation. A gloss black powder

coated finish is applied for great looks, lasting durability

and corrosion resistance. They also include greasable

graphite polyurethane bushings and high quality zinc

plated hardware.

Front Sway Bar...............................................#52887

Rear Sway Bars are manufactured from heavy duty solidcore (1045) high strength steel for maximum durability.

The CNC forming ensures precision fitment for a true bolton installation. Edelbrock engineers have designed these

to allow removal of the vehicle's rear differential cover

with the sway bar fully installed. They include greasable

graphite polyurethane bushings on most applications, ubolts and high quality zinc plated hardware.

Rear Sway Bar................................................#52888

Complete Sway Bar Set...........................................................................................................................#52889

Edelbrock weld-in sub-frame connectors are designed to

improve handling and straight line performance by

eliminating chassis twist and improving weight transfer.

Made with 1-5/8" diameter .120" wall steel tubing, laser

cut and formed end brackets fit the contours of the subframe. Get the performance benefits of a more rigid

chassis without reduced ground clearance.

Sub-Frame Connectors.....................................#5292

These Panhard Rods feature an improved design that

resists unwanted flex and twisting, keeping the axle

properly located under the chassis for improved cornering

and driveability under all conditions. They include our

fluted, greasable, graphite/polyurethane bushings for a

long trouble free life and are intended to center the rear

end on vehicles that have been lowered for improved

handling as well as tire-to-wheel clearance.

Panhard Rod.....................................................#5220

Page 33

©2011 Edelbrock LLC

Part #1580 & 1585

Brochure #63-1580

Rev. 1/11 - AJ/mc

Edelbrock 4.6L Ford Supercharger System

for 2005 and later Mustang GTs

Installation Instructions

Page 33

Tubular Trailing Arms are constructed of 1-1/4"

diameter.120" wall steel tubing which offers increased

strength over other designs, and have the added

advantage of lighter weight.

Tubular Lower Trailing Arm...............................#5276

Tubular Upper Trailing Arm...............................#5266

Heavy-duty Adjustable Trailing Arms allow easy rear

suspension adjustments for optimum handling and

traction. They can be adjusted without removing the arms

from the vehicle. Simply loosen the jam nuts and adjust

pinion angle. Spherical ball assembly with Delrin bushings

allows the rear suspension to move more freely. Includes

graphite/polyurethane differential bushings to replace soft

OE bushings. Sold in pairs.

Adjustable Upper Trailing Arm......................... #5253

Eibach produces springs with unparalleled precision and

quality, using Hi-Ten spring steel produced to exacting

tolerances. Custom CNC coilers yield race quality springs

with street-friendly performance and great looks. The

progressive rate design produces excellent ride quality

and aggressive handling characteristics. These springs

combined with Edelbrock suspension components will

improve your vehicles handling performance, cornering

ability, and braking stability.

Eibach Coil Spring Set......................................#5287

These brackets lower the mounting point of the rear

trailing arms. A must for lowered vehicles; they correct the

trailing arm angle while lowering the instant center of the

vehicle, which improves forward bite and eliminates rear

squat during hard acceleration. Two non-stock mounting

locations are available as well as the stock location and

they will accept Edelbrock, OEM, or any other aftermarket

lower trailing arm on the market. Grade 8 hardware is

included; welding is required for installation.

Trailing Arm Relocation Bracket.....................#52103

Loading...

Loading...