Page 1

©2008 Edelbrock Corporation

Brochure #63-770769

Catalog #770769

Rev. 1/08 - AJ/mc Page 1 of 3

GLIDDEN VICTOR SC-1 CYLINDER HEADS

For Ford Windsor Engines

Catalog #770769

INSTALLATION INSTRUCTIONS

PLEASE study these instructions carefully before beginning this installation. Most installations can be accomplished with common tools and

procedures. However, you should be familiar with and comfortable working on your vehicle. If you do not feel comfortable performing this installation,

it is recommended to have the installation completed by a qualified mechanic. If you have any questions, please call our Technical Hotline at:

1-800-416-8628, 7:00 am - 5:00 pm, Pacific Standard Time, Monday through Friday or e-mail us at Edelbrock@Edelbrock.com

.

IMPORTANT NOTE: Proper installation is the responsibility of the installer. Improper installation

will void your warranty and may result in poor performance and engine or vehicle damage.

DESCRIPTION: The Glidden Victor SC-1 cylinder head is designed for all out performance applications on Ford Windsor V8 blocks. It has a raised

intake port with an extended intake flange and a raised exhaust port designed to work with Yates headers. Water outlets are provided on the front and

rear of the head for external plumbing of a water crossover. For maximum head gasket retention, these heads include two auxiliary head bolt holes

per cylinder.

(Note: Provisions for these extra bolts are found only on aftermarket race blocks. Four of these bolt holes are partially drilled and will

need to be finished to be used.)

These heads have small ports and chambers that will require professional porting prior to installation. Valve guides

and seats are included but not installed, and the seat bores are undersized and shallow. Heli-coil thread inserts for valvetrain retention are also

included but not installed. We recommend Edelbrock intakes #2860, #2865 or #2868 for these heads.

NOTE: Prior to standard machining and heat treating procedures, this cylinder head was subjected to a process know as Hot Isostatic Pressing

(HIP). During this process the casting is exposed to heat in excess of 900° F and inert gas pressures of nearly 30,000 psi. This combination of

heat and pressure eliminates any gas pores remaining from when the head was orignially cast. By elevating the material density of the cylinder

head to nearly the level of billet aluminum, significantly increased durability and longevity under extreme conditions is achieved.

BEFORE BEGINNING INSTALLATION

IMPORTANT NOTES: READ BEFORE BEGINNING INSTALLATION!

For a successful installation, Glidden Victor SC-1 Cylinder Heads require

several specialized components. To complete your installation, you will

need the following items:

❑ Head gaskets (using ten head bolts per head only); Fel-Pro

#1134 (4.180” bore), or #1135 (4.210” bore).

❑ Intake manifold gaskets; these are currently in development by

Edelbrock, custom gaskets or other sealing solution will need

to be used until gaskets are available

❑ Exhaust gaskets; Fel-Pro #1433 or equivalent.

❑ Valve cover gaskets; Edelbrock #7569

❑ Head Bolts/Studs; when using the standard 10 bolt per head

pattern, you will need five (5) bolts or studs 5” long, and five (5)

that are 4.5” long.

❑ Valves; the valve guides supplied are sized for 5/16” stems on

the intake, and 11/32” on the exhaust.

❑ Spark Plugs; 14mm x 3/4” reach x 5/8” hex, gasketed seal

(heat range to be determined by specific application)

❑ Shaft mounted rocker assembly; Jesel and T&D have produced

application specific rockers for this head

❑ Pistons; custom pistons are preferred for use with this head

due to its unique chamber and valve angle configuration.

Pistons designed for a Yates head should also work with

minimal modifcations

CHECKING ENGINE CLEARANCES: As with any competition engine

build, it is highly recommended that valve-to-piston clearances are

checked prior to installation and corrected to minimum specs, if

necessary. Minimum intake valve clearance should be .080”.

Minimum exhaust valve clearance should be .110”. The point of

minimum intake valve to piston clearance will usually occur

somewhere between 5° and 20° After Top Dead Center during valve

overlap. The point of minimum exhaust valve to piston clearance will

usually occur 20° to 5° Before Top Dead Center during valve overlap.

Some pistons may require notching depending upon the valves

selected for your application. Also make sure that there is adequate

clearance between the valves and the cylinder wall, as well as the

rocker arms to the valve cover and the rocker arm to the valve cover

rail (intake only).

REQUIRED MACHINE WORK: The intake and exhaust ports as

supplied are deliberately undersized to allow sizing and shaping to the

preference of the head porter. The valve seat provisions are also

undersized (2.180” intake and 1.600” exhaust from the factory) and

can be machined out to a maximum of 2.300” on the intake and 1.75”

on the exhaust. The valve seats can be sunk into the head by up to

.250” in order to increase chamber volume. The valve guide bores

have already been finished to .500” and the supplied guides simply

need to be installed.

COOLING REQUIREMENTS: Numerous water holes are cast and/or

drilled in this head. Three (3) 8-32 x 1/4” long set screws should be

installed with red Locktite in each tapped hole between the water core

and head bolt. Two (2) 5/16”-18 x 1/2” long set screws will plug the

appropriate holes on either end of the head. Use red Locktite on those

screws as well. A 3/4” and 1” NPT threaded hole is provided on each

end of the head to allow a variety of cooling solutions. Any hole that is

not plumbed, must be plugged.

®

Page 2

©2008 Edelbrock Corporation

Brochure #63-770769

Catalog #770769

Rev. 1/08 - AJ/mc Page 2 of 3

ACCESSORIES

• HEAD BOLTS OR STUDS: High quality 1/2” head studs or head

bolts with hardened washers must be used to prevent galling of the

aluminum bolt bosses. The head bolt boss heights and required bolt

lengths are listed in the “Specifications” section on Page 3.

See

Figure 1

for the cylinder head bolt tightening sequence. Bolt

threads, underside of bolt heads, and washers should be lubricated

with an oil/moly mix prior to installation and torquing. Apply liquid

Teflon PST or suitable thread sealant on any bolt threads that go into

coolant passages.

NOTE: This head has provisions for eight (8) auxiliary fasteners

per head. These provisions are located adjacent to each

exhaust port and directly below each intake port. A hole will

need to be drilled through both the roof and the floor of the

intake ports, and a plug installed to prevent oil seepage. Head

bolt length for these provisions will vary by application and

should be determined by the engine builder.

• GASKETS: Fel-Pro head gaskets can be used with any

application utilizing the standard ten (10) bolt per head pattern.

#1134 will work with engines having a bore diameter up to

4.180”, and #1135 will work with bore diameters up to 4.210”.

Applications using the eight auxiliary head bolt provisions

should use the head gasket recommend by the manufacturer of

the engine block.

ROCKER ASSEMBLIES: Shaft mounted rocker arms are required.

Edelbrock recommends the use of Jesel or T&D rocker shaft

assemblies. Eight (8) 7/16”-14 heli-coils have been supplied to

ensure the stability of the rocker system. These will need to be

installed by the engine builder. Significant thread depth has been

added to these holes to improve bolt retention and the longevity of

valvetrain components under the extreme conditions generated in a

racing enviroment.

• PISTONS: The unique chamber and valve placement of the SC1 cylinder head are ideally complimented by custom pistons,

however several manufacturers have compatible shelf pistons.

Valve angles are 7.3° by 0.3° cant intake and 6.9° by 0.6° cant

exhaust. Pistons designed for a Ford Yates type head or for the

Ford SC-1 are generally compatible, or can be made to work

with minimal machine work. Check with your preferred piston

manufacturer to see if they carry an application specific part

number.

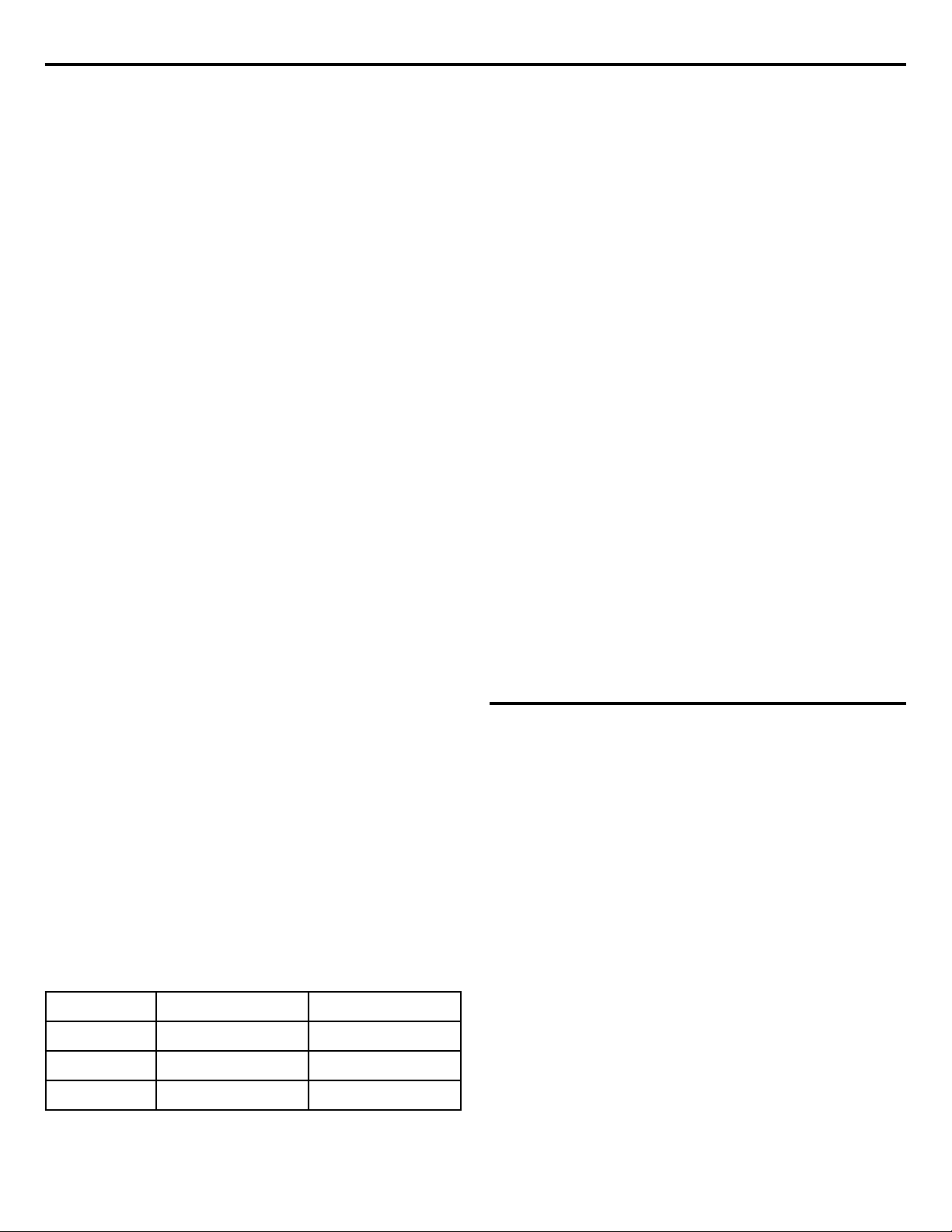

• INTAKE MANIFOLD: Edelbrock has developed several Super

Victor manifolds for use with the Glidden Victor SC-1 cylinder heads.

Refer to the table below to determine the best match for your

application:

• EXHAUST HEADERS: Any header designed for Yates heads will fit

the Edelbrock Glidden Victor SC-1 cylinder head. Fel-Pro exhaust

gaskets #1433 or equivalent are recommended. Check in-car

fitment, as these ports are raised significantly from the stock

location.

• VALVE COVERS: The valve cover flange is designed to work with

Cleveland style valve covers, though the shaft rocker assembly will

often require greater clearance than stock. Edelbrock Cast

Aluminum covers #4267 have been designed specifically for use on

SC-1 heads.

• SPARK PLUGS: Use 14mm x 3/4” reach gasketed spark plugs

with a 5/8” hex. Heat range for competition engines will vary by

application. Use anti-seize compound on the plug threads to

prevent galling in the cylinder head, and torque to the spark plug

manufacturers specification for aluminum heads; usually 10 ft./lbs.

DO NOT OVERTIGHTEN!

• VALVES AND VALVESPRINGS: Edelbrock Glidden Victor SC-1

cylinder heads will accept an intake valve with a diameter up to

2.25” and an exhaust valve diameter up to 1.70”. The supplied

valve guides are deigned to work with an intake valve stem diameter

of 5/16” and exhaust valve stem diameter of 11/32”. Length will

need to be determined by the engine builder once the valve seats

have been installed in their desired location. These cylinder heads

are equipped with a 1.760” valve spring pocket diameter. Edelbrock

strongly recommends the use of a hardened steel cup or shim below

the valve spring to prevent damage to the head. Refer to cam

manufacturer for recommended spring pressures.

We highly recommend that premium quality hardware be used with your new heads.

Manifold Part # Intended Deck Height Carburetor Pad Flange

2860 9.5 4150

2865 9.2, 9.5* 4500

2868 9.5 4500

INSTALLATION PROCEDURE

Installation is the same as for original equipment cylinder heads. Consult

service manual for specific procedures, if necessary. Be sure that the

surface of the block and the surface of the head are thoroughly cleaned

to remove any oily film before installation. Use alcohol or lacquer thinner

on a lint-free rag to clean. Apply oil or suitable thread lubricant to head

bolt threads and the underside of bolt heads and washers to prevent

galling and improper torque readings. Apply liquid Teflon PST or other

suitable thread sealant on any bolt threads that go into coolant passages.

Torque 1/2” bolts or stud nuts to 100-110 ft./lbs. in three step

increments, following the tightening sequence shown in Figure 1. A retorque is recommended after the initial star-up and cool-down (allow 23 hours for adequate cooling).

Other Assembly Tips: When installing the sparkplugs and exhaust

manifolds, be sure to use a high temperature anti-seize compound on the

threads to reduce the possibility of thread damage in the future. Do not

exceed a torque of 25 ft./lbs. on the intake manifold bolts and lubricate

the bolt threads prior to assembly.

NOTE: Torque sparkplugs to 10 ft./lbs. Do not over tighten

sparkplugs! If short reach plug is used, poor performance and

possible engine damage may occur.

*End seal spacers #2864 will be required to use #2865 on a 9.5” deck.

Page 3

©2008 Edelbrock Corporation

Brochure #63-770769

Catalog #770769

Rev. 1/08 - AJ/mc Page 3 of 3

5

1

3

7

10

6

2

4

8

9

Early production heads will need to be drilled at these locations if the

auxiliary head bolt provisions are to be used. Later model heads have these

holes pre-drilled, and must use the supplied plugs

FIGURE 1 - CONVENTIONAL TEN (10) BOLT TORQUE SEQUENCE

Bolts should be tightened to 100-110 ft/lbs in three intermediate steps.

Applications using the eight (8) auxiliary bolt provisions should consult their

engine block manufacturers instructions for the correct torque sequence.

Edelbrock Corporation • 2700 California St. • Torrance, CA 90503

Tech-Line: 1-800-416-8628 • E-Mail: Edelbrock@Edelbrock.com

®

Loading...

Loading...