Page 1

Edelbrock Nitrous Systems

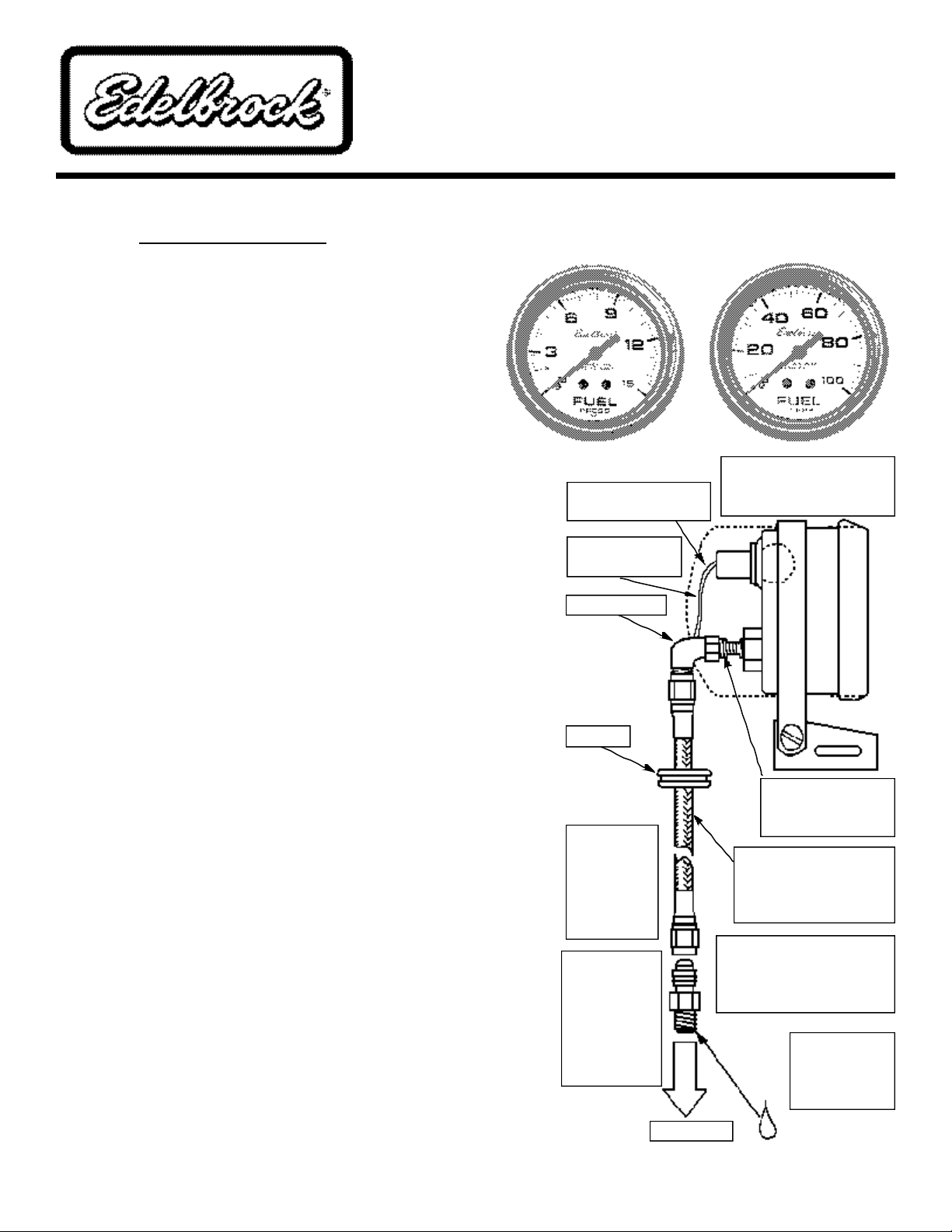

2-5/8” Glycerin-Filled Fuel Pressure Gauge

Catalog #73828 & #73830

INSTALLATION INSTRUCTIONS

Please study these instructions carefully before installing your new Fuel Pressure Gauge. If you have any questions or problems,

please contact our Technical Hotline at:1-800-416-8628, 7:00 am to 5:00 pm, Monday through Friday, Pacific Standard Time or

e-mail us at edelbrock@edelbrock.com . Please fill out and mail your warranty card.

This glycerin-filled gauge instrument houses a special vibration

dampening fluid. The bourdon tube mechanism has been factory

calibrated for 2% full-scale accuracy. Your Edelbrock glycerin-filled

gauge will remain in top operating condition because of its unique

design. Please follow the installation instructions carefully to

ensure the prolonged life of your gauge.

IMPORTANT: DO NOT mount these gauges in the passenger

compartment of the vehicle. These fuel pressure gauges must be

mounted outside of the vehicle’s interior, such as on the cowling in

front of the windshield. This is required to prevent the possibility of

a dangerous explosion of gas fumes in the vehicle’s interior, which

could result from a leaky connection between the pressure line and

the gauge.

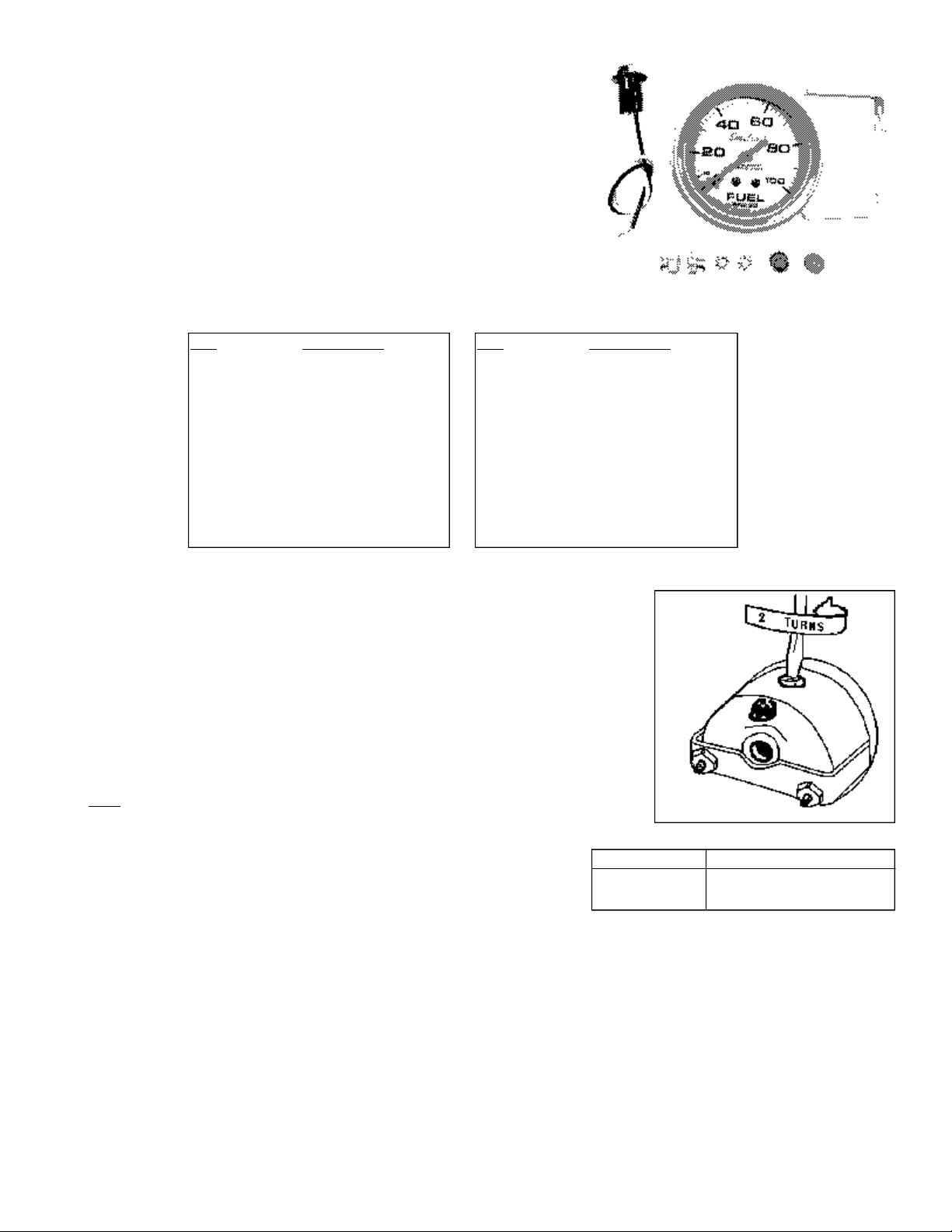

(White)

Connect to 12V lighting

(Black)

Connect to Ground

Fuel Pressure Gauge is

shown in the recommended

Auto Meter Mounting Cup

Temperature Compensation

With the vent screw in the upright position, turn the vent screw two turns

counterclockwise to equal the gauge case pressure. This allows the gauge

to breathe through the thread clearances and to self-adjust to the changes

in altitude, barometric pressure, and temperature. Note: Extreme vibration

and shock may cause the gauge fluid to leak through the vent screw. DO

NOTover tighten. If the vent screw is tight, consult the chart on the following

page. If necessary, bleed the gauge after altitude or temperature change.

In some cases, inside fluid may be splashed on the vent screw causing self

sealing of the threads. When this happens, it may be necessary to

completely remove the vent screw and re-install to equalize the gauge.

Mechanical Section

1. Determine the best location for mounting the fuel pressure gauge

outside of the vehicle’s interior. A mounting cup kit (Auto Meter

#3203 or #3204) is recommended for mounting on the vehicle’s

cowling in front of the windshield. Drill the necessary holes and

install the rubber grommets provided where the pressure line

passes through any sheet metal.

2. Because all fuels are flammable, it is recommended that a premium

braided stainless steel pressure line -4AN be used.

Use 90° Fitting

Grommet

DO NOT USE

NYLON OR

COPPER

TUBING WITH

COMPRESSION

FITTINGS

FOR FUEL

PRESSURE, IT IS

STRONGLY

RECOMMENDED

THAT BRAIDED

STAINLESS LINE

BE USED.

1/8”NPT x #4 Adapter

(not included)

Do not over tighten

Recommended Quality

Braided Stainless Steel

Hose Shown. See

Mechanical Section #2.

NOTE: TIE DOWN LINE TO

AVOID EXCESSIVE VIBRATION

THAT MAY CAUSE DAMAGE

TO THE GAUGE OR LINE.

Use Teflon

Sealing

compound where

symbol indicates.

©2000 Edelbrock Corporation

Rev. 7/00

Page 1 of 2

To T-Fitting

Catalog #73828 & #73830

Brochure No. 70-4687

Page 2

3. Route the pressure line through the grommets to the engine compartment.

Connect the line to a tee fitting plumbed in line with the fuel line. Be sure

to use liquid Teflon sealant on all tapered pipe threads for a good seal. No

sealant is required on AN flare fittings. Also make sure that the pressure

line is routed away from any sources of heat or moving components.

4. If you choose to use either the green or red light bulb cover, install this over

the bulb in the light fixture for the gauge and install the fixture into the

gauge by simply pushing the light fixture into the hole on the back of the

gauge until the fixture snaps into place.

Bill of Materials

Qty. Description

1 0-15 psi Fuel Pressure Gauge

1 Gauge Light with Harness

2 Star Washers

2 Attaching Screws

1 Gauge Bracket

1 Red Light Cover

1 Green Light Cover

Qty. Description

1 0-100 psi Fuel Pressure Gauge

1 Gauge Light with Harness

2 Star Washers

2 Attaching Screws

1 Gauge Bracket

1 Red Light Cover

1 Green Light Cover

Note: Test all fittings and hoses for any leakage. If any leaks are detected, determine the

cause of the leak and repair. Do not operate the vehicle if any leaks are detected.

Electrical Section

For maximum electro-luminescent life, do not wire lighting to direct igntion switched 12volt source. The lighting power source should be routed through OEM dash controls, or a

separate rheostat. Power can be achieved by tapping into the factory dash lighting through

either the fuse panel or from a 12-volt dash light wire. This will allow you to control the

light intensity. Use the appropriate connectors for your particular application. The white

wire mustbe connected to the power source and the black wire to a good ground. Damage

to electronic circuits could occur if connected incorrectly.

©2000 Edelbrock Corporation

Rev. 7/00

Gauge Reading

Edelbrock Corporation

2700 California Street

Torrance, CA 90503

Toll-Free Tech Line: 1-800-416-8628

Office: 310-781-2222

Tech E-Mail: edelbrock@edelbrock.com

Page 2 of 2

1 PSI Low

1 PSI High

Description

30° F. Temp. Rise

2000ft. Altitude Increase

Catalog #73828 & #73830

Brochure No. 70-4687

Loading...

Loading...