Page 1

©2002 Edelbrock Corporation

Rev. 10/02

Brochure No. 63-0126

Catalog #70206

Page 1 of 4

150HP Upgrade System

for the 70205 80HP LT-1 Nitrous System

Catalog #70206

INSTALLATION INSTRUCTIONS

Please study all instructions carefully before you install your new 150HP Upgrade System. If you have any questions or problems,

please call our Technical Hotline at: 1-800-416-8628, 7:00 a.m. to 5:00 p.m., Monday through Friday, Pacific Standard Time or

e-mail us at edelbrock@edelbrock.com.

Jet Map Information: Edelbrock engineers have conducted extensive dyno testing with the Edelbrock LT-1 Performer EFI Nitrous

System to ensure the horsepower increase is as intended. On a typically stock LT-1 engine, you can expect the following approximate

power gain:

Nitrous/Fuel Jetting

Approx.

HP Gains Final Air/Fuel Ratio

.068 .042 150 13.5/1

The dyno tests were conducted at Edelbrock using a stock LT-1 engine. These tests were conducted with 950 psi nitrous bottle

pressure.

INSTALLATION INSTRUCTIONS

Fuel Pump Installation (Camaro, Firebird)

Warning: Before performing any of these steps, relieve the pressure in the fuel system.

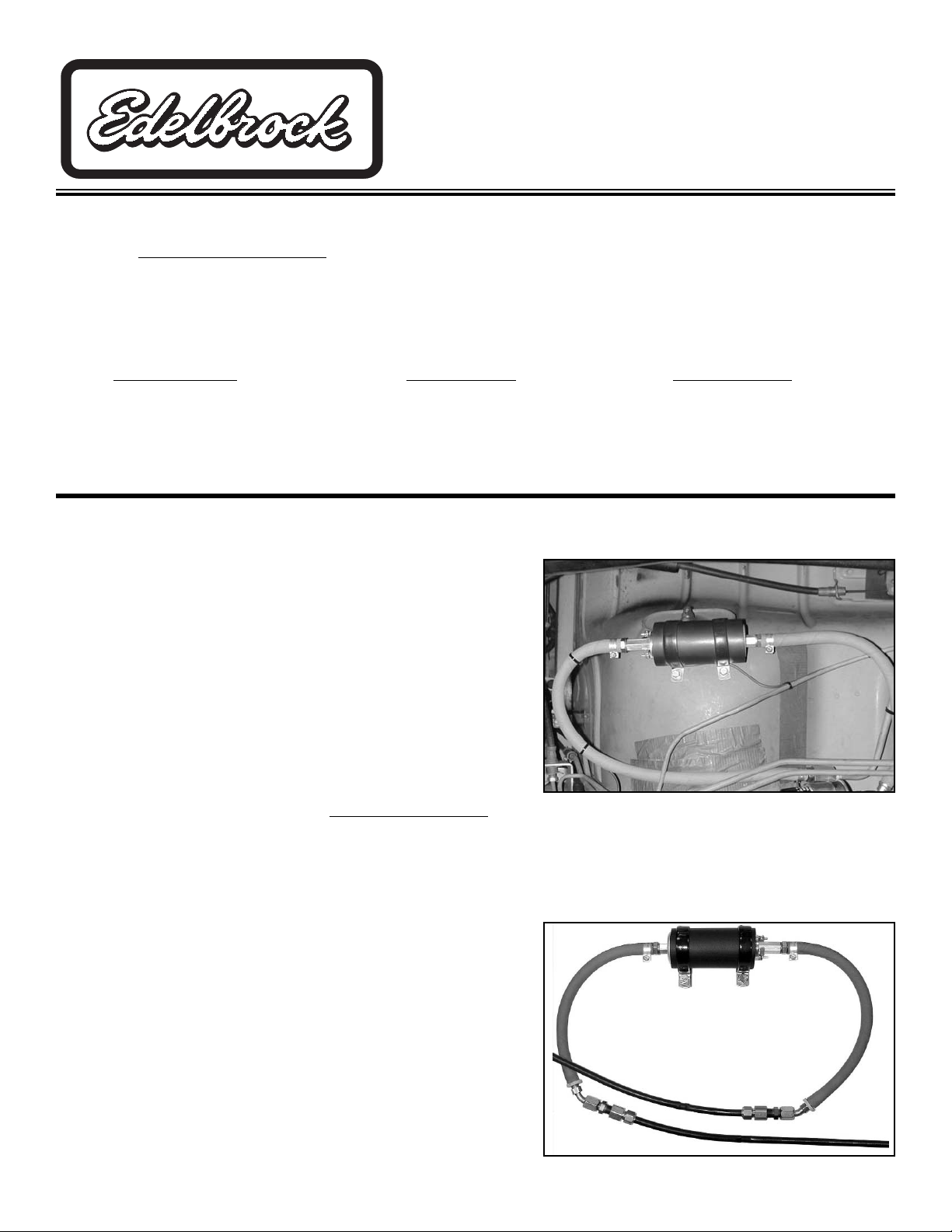

1. Locate the fuel filter on the under-carriage of the car. Disconnect the

hard fuel line from the filter.

2. Install the male O-Ring to -6AN male adapter fitting into the outlet of

the fuel filter.

3. Mount the fuel pump to the under-carriage of the vehicle. Cut the

supplied fuel line to size as pictured.

4. Install the hose fittings and tighten all hoses down with the supplied

hose clamps.

5. Install the female O-Ring to -6AN male adapter to the end of the steel

fuel line. Secure fitting to hose with supplied hose clamp and connect

hard fuel line to this fitting. Check the fuel system for leaks by turning

the ignition key to the “On” position. Do not start the engine

. Inspect all fittings and lines for leaks. Also check wires from

time to time for damage or leaks.

Fuel Pump Installation (Impala)

Warning: Before performing any of these steps, relieve the pressure in the fuel system.

1. Locate the fuel lines under the vehicle. These should be 2 black plastic

lines located on the driver’s side of the vehicle by the frame rails.

Determine which line is the main feed line by following them back to

the fuel filter.

2. Determine the mounting location of the fuel pump and mount the

pump. Be sure the pump will be mounted above the lowest parts of

the car and out of danger from road debris. The pump must be

mounted between the fuel filter and engine.

3. Be sure where you decide to cut the line is close to the booster pump.

Cut the plastic fuel line using a sharp razor blade or other similar

cutting tool.

®

Page 2

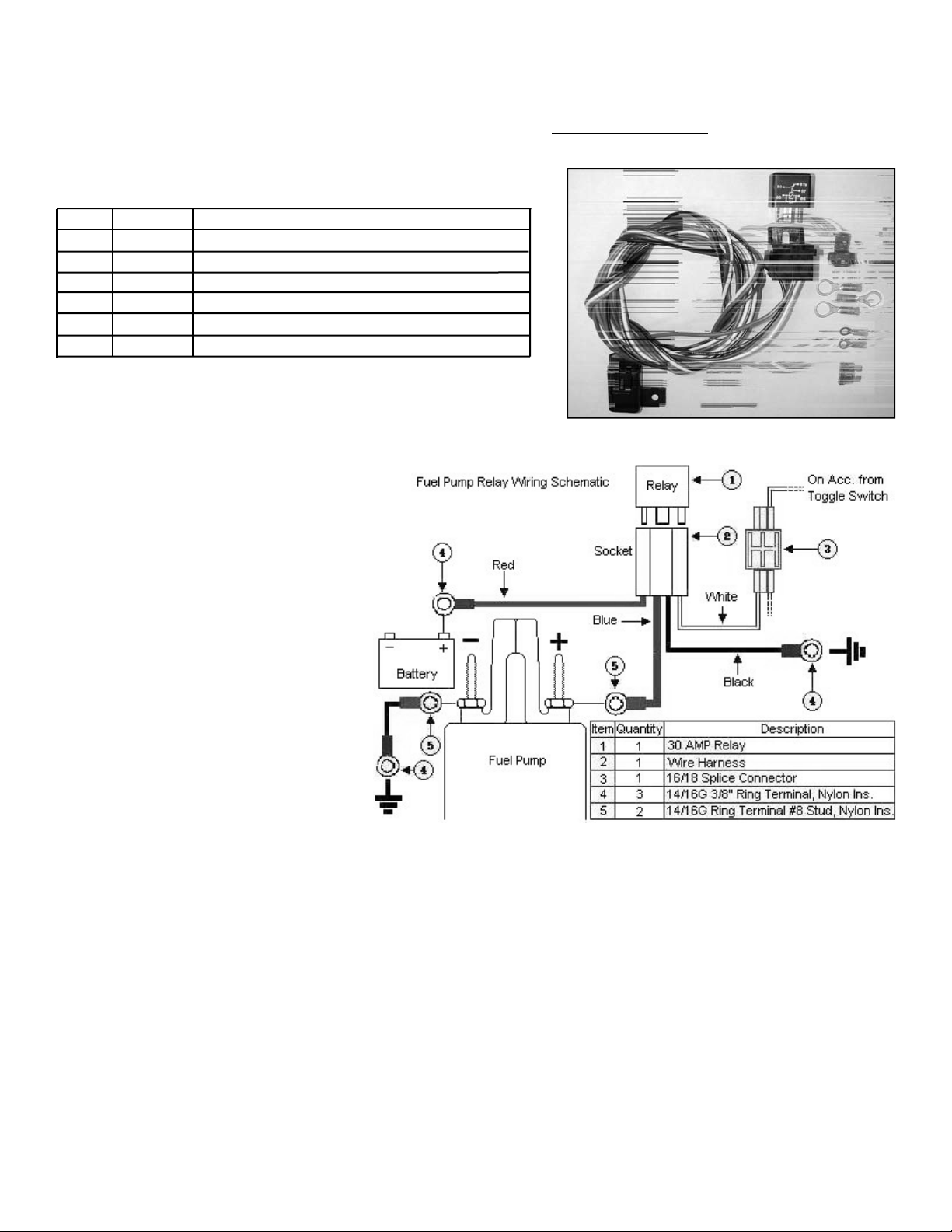

Fuel Booster Pump Electrical Components Bill of Materials

Item # Quantity Description

1 1 ea. 30 amp relay

2 1 ea. Wire harness with integral relay/fuse holder

3 1 ea. 16/18g splice connector

4 1 ea. 14/16g 3/8” ring terminal, Nylon insulated

5 1 ea. 14/16g ring terminal #8 stud, Nylon insulated

6 1 ea. 15 amp ATO blade fuse

©2002 Edelbrock Corporation

Rev. 10/02

Brochure No. 63-0126

Catalog #70206

Page 2 of 4

Fuel Booster Pump Electrical System Installation Procedures

1. Determine the location of the Fuel

Booster Relay and Fuse Holder Wire

Harness. Most common installations

locate these components inside the

driver’s compartment and close to the

fuse panel under the dash. You can also

mount the relay and fuse holder and

harness close to the battery. However,

these connectors are water-resistant, not

water-proof, so care is required when

mounting this assembly under the hood

of your vehicle.

2. The wire harness attached to the relay

and fuse holder includes 8 feet of colorcoded wires to make the electrical

system installation as easy as possible.

We recommend that you do not cut any

lengths of wires from the wire harness or complete the wiring of the fuel booster pump until all of the mechanical components

are securely mounted in their permanent locations.

3. Use the Fuel Pump Relay Wiring Schematic located above along with the Origin and Destination Map on next page to determine

the proper routing for the wires and their locations. Take caution as to not interfere with operating linkages, heat sources,

brackets, etc. Pay particular attention to sharp edges along the route of your wire harness as they can chafe the wire and cause

your system to fail.

4. Once all components have been securely mounted, decide the location of the relay and fuse holder. Secure them with fasteners

(not included with kit) such as sheet metal screws, nuts and bolts, etc. Allow for some slack in the red wire that connects the

relay and fuse holder together.

5. When mounting your relay and fuse holder, make sure the mounting surface is strong enough to support servicing the relay and

fuse. Also, ensure you allow for some slack in the wire that joins the fuse holder to the relay mount. This will avoid any potential

loss of power due to stress on the wire harness. Be sure to cover the fuse with the fuse mount housing.

4. Install the supplied compression fitting adapters to the cut plastic fuel line. Using the supplied fuel line, cut lengths that will

reach from the booster pump to the hose barbs on the compression fittings.

5. Install cut fuel lines and secure using the supplied hose clamps.

6. Check the fuel system for leaks by turning the key to the “On” position. Do not start the engine

. Inspect all fittings and lines

for leaks. Also check wires from time to time for damage or leaks.

Page 3

©2002 Edelbrock Corporation

Rev. 10/02

Brochure No. 63-0126

Catalog #70206

Page 3 of 4

Knock Sensor By-Pass Relay Installation

1. Determine the location of the Knock Sensor By-Pass Relay. This should be as close to the ECM as possible. Since the connectors

are water-resistant, not waterproof, mount the relay in a location with minimal chance of exposure to water.

2. The wire harness attached to the relay includes 4 feet of color-coded wires to make the electrical system installation as easy as

possible. We recommend that you do not cut any lengths of wires from the wire harness or complete the wiring of the nitrous

system until all of the mechanical components are securely mounted in their permanent locations. Do not exceed the 4 feet of

wire to the ECM and the knock sensor, this could send a faulty signal and the system would not work at optimal power. You can

extend the white and black wires beyond the 4 feet if necessary.

3. Once all of the system components have been mounted, route the un-cut wires from the harness to each location allowing

enough wire length on each circuit to not interfere with operating linkages, heat sources, brackets, etc. Pay particular attention

to sharp edges along the route of your wire harness as they can chafe the wires and cause your system to fail.

4. After you have accounted for the routing of your wires, follow the Knock Sensor By-Pass Relay Wiring Schematic above and use

the Wire Schematic Origin and Destination Map below as a guide for which electrical connectors are used in each circuit. Note

that the one wire from the ECM to the Knock Sensor needs to be cut and intercepted with the relay. This wire on 1994-1997

Camaros, Firebirds, and Impalas is located on the BLUE terminal in pin location #22. It is a blue wire. On 1993 Camaros and

Firebirds, this wire in located on the GREEN ECM connector C terminal in pin location C8. It is a dark blue wire. Try to keep the

Knock Sensor By-Pass Relay as close to this wire as possible.

5. Once you have decided the location of the relay, secure them with fasteners (not included with kit) such as sheet metal screws,

nuts and bolts, etc.

Wire Color System Origin Destination Terminal Used

Red Main Booster Relay Harness Bat. Volt. Signal 3/8” Ring

Pump Bat. Volt.

Blue Fuel Pump Power Relay Harness Fuel Booster Pump #8 Ring

Black Fuel Pump Ground Fuel Booster Pump Chassis Ground #8 Ring / 3/8” Ring

White Relay Power Relay Harness Arming Switch Splice Conn.

Black Relay Ground Relay Narness Chassis Ground 3/8” Ring

Knock Sensor By-Pass Relay Components Bill of Material

Page 4

©2002 Edelbrock Corporation

Rev. 10/02

Brochure No. 63-0126

Catalog #70206

Page 4 of 4

Wire System Origin Destination Terminal

Red K.S. By-Pass Output of ECM Relay Harness Butt Conn.

Blue K.S. By-Pass Relay Harness Knock Sensor Butt Conn.

Black Sensor Ground Relay Harness Non-Grounded Splice Conn.

Side of Microswitch

White Relay Ground Relay Harness Arming Switch Splice Conn.

Edelbrock Corporation

2700 California Street

Torrance, CA 90503

Tech Line: (800) 416-8628

Tech Fax: (310) 972-2730

Tech E-Mail: edelbrock@edelbrock.com

Loading...

Loading...