Page 1

EQUAL LENGTH SHORTY HEADERS

For 1986-1993 Ford Mustang, Mark, Capri with 5.0L V8

Catalog #68832 (Ceramic-Coated)

Catalog #68833 (Ti-Tech Coated)

INSTALLATION INSTRUCTIONS

Please study these instructions carefully before installing your new Equal Length Shorty Headers. If you have any questions, please

call our Technical Hotline: 1-800-416-8628, 7am - 5pm, Monday-Friday, Pacific Standard Time or

e-mail us at: edelbrock@edelbrock.com. Please fill out and mail your warranty card.

DESCRIPTION: These components are designed as a system to improve the exhaust efficiency of the Ford 5.0L V8 engine. A

performance gain can be expected by the installation of the system. This system requires no welding for installation and retains all

O.E.M. emissions equipment.

SUGGESTED TOOLS FOR INSTALLATION: This vehicle has some metric fasteners.

❑ Sockets- 7/16", 1/2", 9/16", 5/8", 11/16" ❑ Universal 3/8 drive

❑ Screwdriver- straight blade ❑ Ratchet- 1/4" drive

❑ Wrenches- 7/16", 1/2", 9/16", 11/16" ❑ Extension- 3-6"

❑ Wire cutters ❑ Jackstands, screwdrivers, pliers, crescent wrench,

❑ Pliers hacksaw, etc.

❑ Ratchet- 3/8 drive ❑ Liquid penetrant, (GM #1052627) anti-seize

❑ Extension- about 10" compound (GM #5613695)

SPECIAL NOTICE: This Edelbrock part has received an Executive Order number (E.O.) from the California Air Resources Board

(C.A.R.B.) making it legal for street use on pollution-controlled motor vehicles in all 50 states. To assist you with emissions equipment

certification, we have included a silver fan shroud decal to verify that this part is a legal replacement part on the vehicle for which it

is cataloged. The adhesive-backed decal should be affixed to your fan shroud next to the existing emission and engine specification

decal. Do not cover your original equipment specification decal with the Edelbrock fan shroud decal.

WARNING: The use of “Thermal Wrap” or any aftermarket coating process will void the warranty on your headers. Those products

can cause excessive heat and moisture buildup resulting in corrosion and early failure of the system.

CAUTION: Due to higher underhood temperatures generated by headers, vehicles equipped with original spark plug wires should

have them replaced with high temperature plug wires for longer life.

INSTALLATION INSTRUCTIONS

DISASSEMBLY

1. Raise front of vehicle using the front crossmember to

support the vehicle. Position jackstands under the

crossmember. Drive up ramps may also be used to raise

the front of the vehicle. Make sure parking brake is on and

the rear wheels are blocked so vehicle cannot roll.

2. Loosen H-pipe from stock exhaust headers.

3. Remove the dipstick tube assembly, and clutch cable

bracket from the left side of the engine.

4. Remove air intake tube, air cleaner cover and air flow

sensor from the right side of the engine. Also remove the

smog hoses from the same side.

5. Remove the stock exhaust headers and gaskets. Make

sure the gasket surfaces are clean.

6. Take all the spark plugs out, remove plug wire holders

from bolt posts on the valve covers. Label all plug wires

for ease of re-assembly.

LEFT SIDE INSTALLATION

1. Put left side header into position. Jostle H-pipe to allow

header to drop into place. Set H-pipe in place do not

tighten.

2. Install supplied exhaust gasket in place between header

and cylinder head. Install one bolt to hold gasket in place.

3. Install supplied header bolts. Tighten all bolts evenly.

4. Re-install clutch cable bracket, spark plugs, plug wires,

and dipstick tube assembly. Do not tighten H-pipe.

©2005 Edelbrock Corporation

Catalog #68832 & #68833

Page 1 of 2

Brochure #63-0160

Rev. 9/05

Page 2

NOTE: Bending of clutch cable bracket may be necessary

for clearance.

Left side is complete.

NOTE: Use supplied anti-seize on all bolts. Apply liberally

to collector socket to ensure proper seal with H-pipe.

RIGHT SIDE INSTALLATION

1. Remove lower motor mount nut (right side only) and raise

engine approximately 1".

2. Put right side header into position. Then lower engine

block into position and re-install motor mount nut. Put

H-pipe into position (do not tighten).

3. Install supplied exhaust gasket in place between header

and cylinder head. Install one supplied header bolt to hold

gasket in place.

4. Install supplied header bolts. Tighten all bolts evenly.

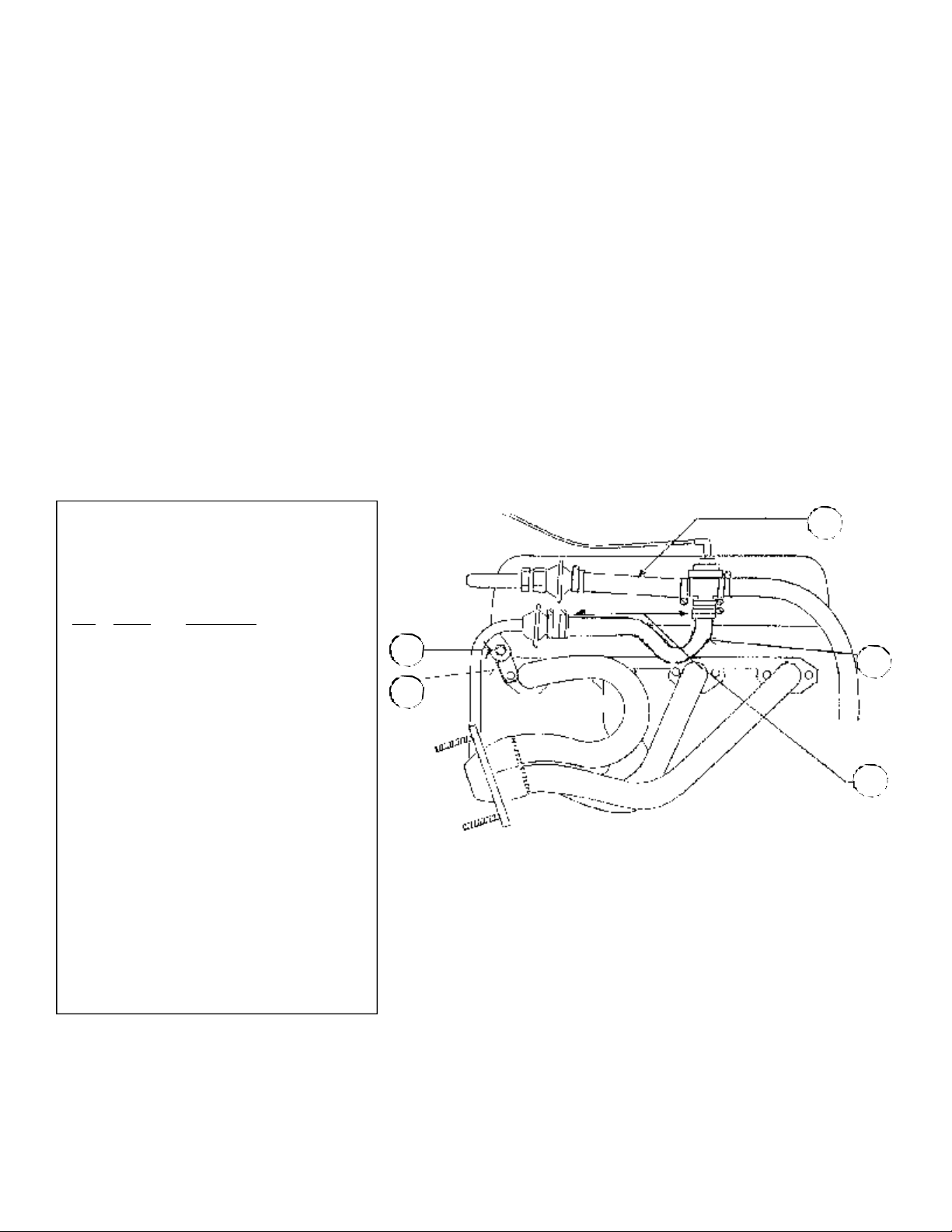

SMOG HOSE ASSEMBLY

1. Use hardware supplied as shown in Figure 1 for smog

hose adaptation:

#1 - 3/4" diameter extension hose, 5-1/2" long

#2 - 3/4" diameter bent extension tube

#3 - 2-#10 hose clamps

#4 - 5/16" x 18 bolt, hex nut, and lock washer

#5 - 3" smog tube support bracket

2. Replace upper stock smog hose (#1) with the one supplied

in kit (3/4" I.D. x 5 1/2") using stock clamps.

3. Cut upper stock smog hose in half to use at each end to

accept (#2) 3/4" diameter bent extension tube (supplied in

kit ) to assemble bottom half of smog pump. 2 additional

hose clamps are needed.

4. Tighten clamps on smog hoses. Re-install air intake tube,

air flow sensor and air cleaner cover.

5. Tighten H-pipe to headers.

6. Start engine and check for any exhaust leaks. If

everything is satisfactory, you are ready to go.

7. Check tightness of all header hardware after one day of

operation.

KIT CONTENTS

Catalog #68832 (Ceramic-Coated)

Catalog #68833 (Ti-Tech Coated)

Qty. Part # Description

1 25-9107 Manifold Left Side (Ceramic)

1 25-9278 Manifold Right Side (Ceramic)

1 25-9107 Manifold Left Side (Ti-Tech)

1 25-9108 Manifold Right Side (Ti-Tech)

2 - Bracket, A.I.R. tube

16 - Hex header bolts; 3/8” x 1”

1 - Hose clamp; 11/16” - 1-1/4”

2 - Ford V8 port gaskets

1 - Hose; 3/4” x 5-1/2”

1 - Hex nut; 1/4”-20

1 - Hex bolt; 1/4”-20 x 3/4”

1 - A.I.R. tube; zinc-plated

1 - Lock washer; 1/4”

16 - Lock washer; 3/8”

4 - Flat washers; 3/8”

1

4

2

5

3

©2005 Edelbrock Corporation

Catalog #68832 & #68833

Edelbrock Corporation, 2700 California St., Torrance, CA 90503

Tech Line: 1-800-416-8628

E-Mail: edelbrock@edelbrock.com

Page 2 of 2

Brochure #63-0160

Rev. 9/05

Loading...

Loading...