Page 1

2.Install supplied exhaust gasket in place between header

and cylinder head. Install one bolt to hold gasket in

place.

3.Install supplied header bolt s . T ighten all bolt s evenly.

4. Reinstall clutch cable bracket, sp ark plugs, plug wires,

and dipstick tube assembly. Do not tighten H-pipe.

NOTE: Bending of clutch cable bracket may be necessary for clearance.

Left side is complete.

NOTE: Use supplied Anti-Seize on all bolts . Apply liber ally to collector socket to ensure proper seal with H-pipe.

• RIGHT SIDE INSTALLATION

1. Remove lower motor mount nut (right side only) and

raise engine approximately 1".

2. Put right side T.E.S. header into position. Then lower

engine block into position and reinstall motor mount nut.

Put H-pipe into position (do not tighten).

3.Install supplied exhaust gasket in place between header

and cylinder head. Install one supplied header bolt to

hold gasket in place.

4.Install supplied header bolt s . T ighten all bolt s evenly.

• DISASSEMBLY

1. Raise front of vehicle using the front crossmember to

support the vehicle. Position jack stands under the crossmember. Drive up ramps may also be used to raise the

front of the vehicle. Make sure parking brake is on and

the rear wheels are blocked so vehicle cannot roll.

2. Loosen H-pipe from stock exhaust headers.

3. Remove the dipstick tube assembly, and clutch cable

bracket from the left side of the engine.

4. Remove air intake tube, air cleaner cover and air flow

sensor from the right side of the engine. Also remove the

smog hoses from the same side.

5. Remove the stock exhaust headers and gaskets. Make

sure the gasket surfaces are clean.

6. Take all the sp ark plugs out, remove plug wire holders

from bolt posts on the valve covers. Label all plug wires

for ease of reassembly.

• LEFT SIDE INSTALLATION

1. Put lef t side Bassani header into position. Jostle H-pipe

to allow header to drop into place. Set H-pipe in place do

not tighten.

© 1997 Edelbrock Corp. REV 1/97

TUBULAR EXHAUST SYSTEM

CATALOG #6883/#7983

1986-1993 Ford Mustang /Mark/Capri with 5.0L V8

Equal Length TES Headers

INSTRUCTIONS

• PLEASE study these instructions carefully before

inst alling your new Tubular Exhaust System (TES). If you

have any questions or problems, do not hesitate to con tact our Technical Hotline at : 1-800-416-8628.

• TUBULAR EXHAUST SYSTEM: These components are

designed as a system to improve the exhaust efficiency

of the Ford 5.0L V8 engine. A performance gain can be

expected by the installation of the system. This system

requires no welding for installation and ret ains all O.E.M.

emissions equipment.

• SUGGESTED TOOLS FOR INSTALLATION: This vehi -

cle has some metric fasteners

Sockets - 7/16", 1/2", 9/16", 5/8", 1 1/16"

Screwdriver- straight blade

Wrenches- 7/16", 1/2", 9/16", 11/16"

W ire cutters

Pliers

Ratchet- 3/8 drive

Extension- about 10"

Universal 3/8 drive

Ratchet- 1/4" drive

Extension- 3-6"

Jackstands, screwdrivers, pliers, crescent

wrench, hacksaw, etc.

Liquid penetrant, (GM #1052627) anti-seize com

pound (GM #5613695)

• WARNING: The use of "Thermal Wrap" materials will

void the warranty on your Tubular Exhaust System. Those

products can cause excessive heat and moisture buildup

resulting in corrosion of the system. If additional thermal

isolation is desired, use the Edelbrock Pro-Tech coated

TES #7983.

• NOTE: The paint used on non-coated T.E.S. (6800 &

6600 series) is for protection during shipping and storage and will burn off soon after the engine is st arted.

Those who desire a longer lasting finish should sand

blast the T .E.S. to remove the original p aint, then apply

high temperature header paint, such as VHT, a va il a bl e a t

most auto part s stores.

• CAUTION: Due to higher underhood temperatures gen-

erated by T.E.S., vehicles equipped with original spark

plug wires should have them replaced with high temperature plug wires for longer life.

• NOTE: When cleaning any Edelbrock Pro-Tech coated

TES, use only soap and warm water. The use of caustic

solvents (Gunk, etc.) will mar or damage the Pro-Tech

coating.

Page 2

• Please complete and mail your warranty card. Be sure to write the model number of this product in the Part #____

sp ace.

THANK YOU.

1 Manifold left side #25-9107

1 Manifold right side #25-9108

2 Bracket; A.I.R. tube

16 Hex header bolts ; 3/8" x 1"

1 Hose clamp; 11/16" 1-1/4"

2 Ford V8 port gaskets

1 Hose; 3/4" x 5-1/2"

1 Hex nut; 1/4"-20

1 Hex bolt; 1/4"-20 x 3/4"

1 A.I.R. tube; zinc plated

1 Lock washer; 1/4"

16 Lock washers; 3/8"

4 Flat washers; 3/8"

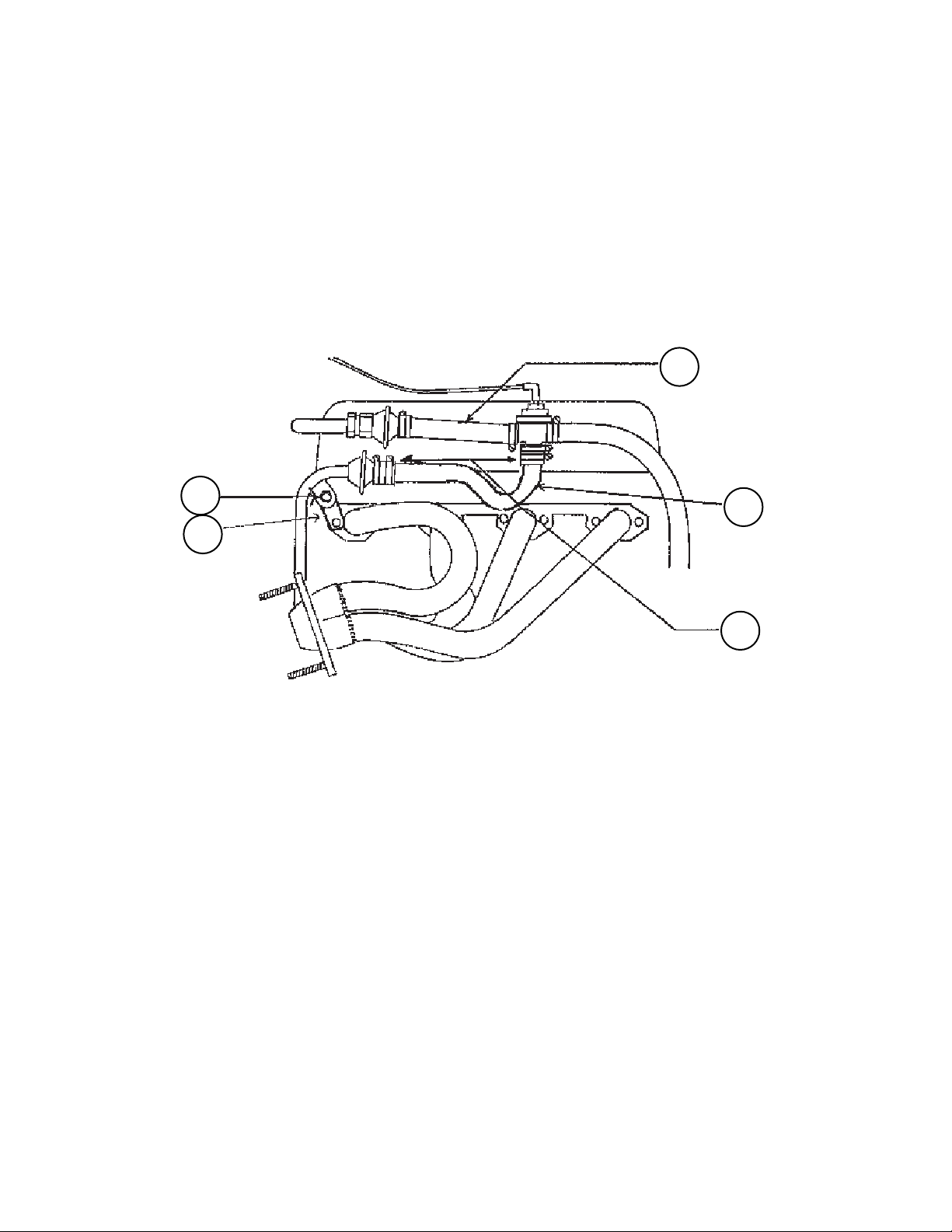

• SMOG HOSE ASSEMBLY

1. Use hardware supplied as shown in Figure 1 for smog

hose adaptation

#1 3/4" diameter extension hose, 5-1/2" long.

#2 3/4" diameter bent extension tube.

#3 2-#10 hose clamps.

#4 5/16" x 18 bolt. hex nut, and lock washer.

#5 3" smog tube support bracket.

2. Replace upper stock smog hose (#1) with the one supplied in kit (3/4" I.D. x 5 1/2") using stock clamp s .

3. Cut upper stock smog hose in half to use at each end to

accept (#2) 3/4" diameter bent extension tube (supplied

in kit ) to assemble bottom halt of smog pump. 2 addi-

HARDWARE SUPPLIED

FIGURE 1

tional hose clamps are needed.

4. Tighten clamps on smog hoses. Reinstall air intake tube,

air flow sensor and air cleaner cover.

5. T ighten H-pipe to T.E.S. headers.

6.Start engine and check for any exhaust leaks. If everything is satisfactory, you are ready to go.

7. Check tightness of all header hardware after one day of

operation.

1

2

3

4

5

Loading...

Loading...