Page 1

Catalog #68712, 68713

©2006 Edelbrock Corporation

Page 1 of 3

Brochure #63-68712

Rev. 6/06 - DA/mc

TUBULAR EXHAUST SYSTEM

For 1982-1987 Camaro & Firebird

with LG-4 (Low Output) 305 C.I.D. V8 Engine

Catalog #68712, #68713

INSTALLATION INSTRUCTIONS

Please study these instructions carefully before installing your new

Tubular Exhaust System

(TES). If you have any questions, please contact our

Technical Hotline at : 1-800-416-8628 from 7 am - 5pm, Monday-Friday, Pacific Standard Time or e-mail us at Edelbrock@Edelbrock.com.

TUBULAR EXHAUST SYSTEM: These components are designed as a system to improve the exhaust efficiency of the GM 305 LG-4 V8 engine. A

performance gain can be expected by the installation of the system. This system requires no welding for installation and retains all O.E.M.

emissions equipment.

Suggested Tools Needed for Installation: This vehicle has metric fasteners.

❑ 3/8” ratchet socket set with extensions and universal 13mm and 15mm swivel sockets

❑ Combination set of open-end wrenches

❑ Jackstands, screwdrivers, pliers, crescent wrench, etc.

❑ Liquid penetrant, (GM #1052627) anti-seize compound (GM #5613695)

SPECIAL NOTICE: This Edelbrock Tubular Exhaust System has received an Executive Order number (E.O.#) from the California Air Resources Board

(C.A.R.B.) making it legal for street use in all 50 states. To assist you with emission equipment certification, we have included a silver fan shroud

decal to help testing personnel verify the this part is a legal replacement on the vehicle for which it is cataloged. The adhesive-backed decal should

be affixed next to the existing emission and engine specifications decal. Do not cover any part of your original emission decal.

WARNING: The use of "Thermal Wrap" or any aftermarket coating process will void the warranty

on your Edelbrock Tubular Exhaust Systems.

Those products can cause excessive heat and moisture buildup resulting in corrosion and failure of the system.

NOTE: High temperature spark plug wires and boots are recommended to withstand heat from T.E.S.

IMPORTANT NOTE:

Proper installation is the responsibility of the installer. Improper installation will void warranty and may result in poor

performance and engine or vehicle damage.

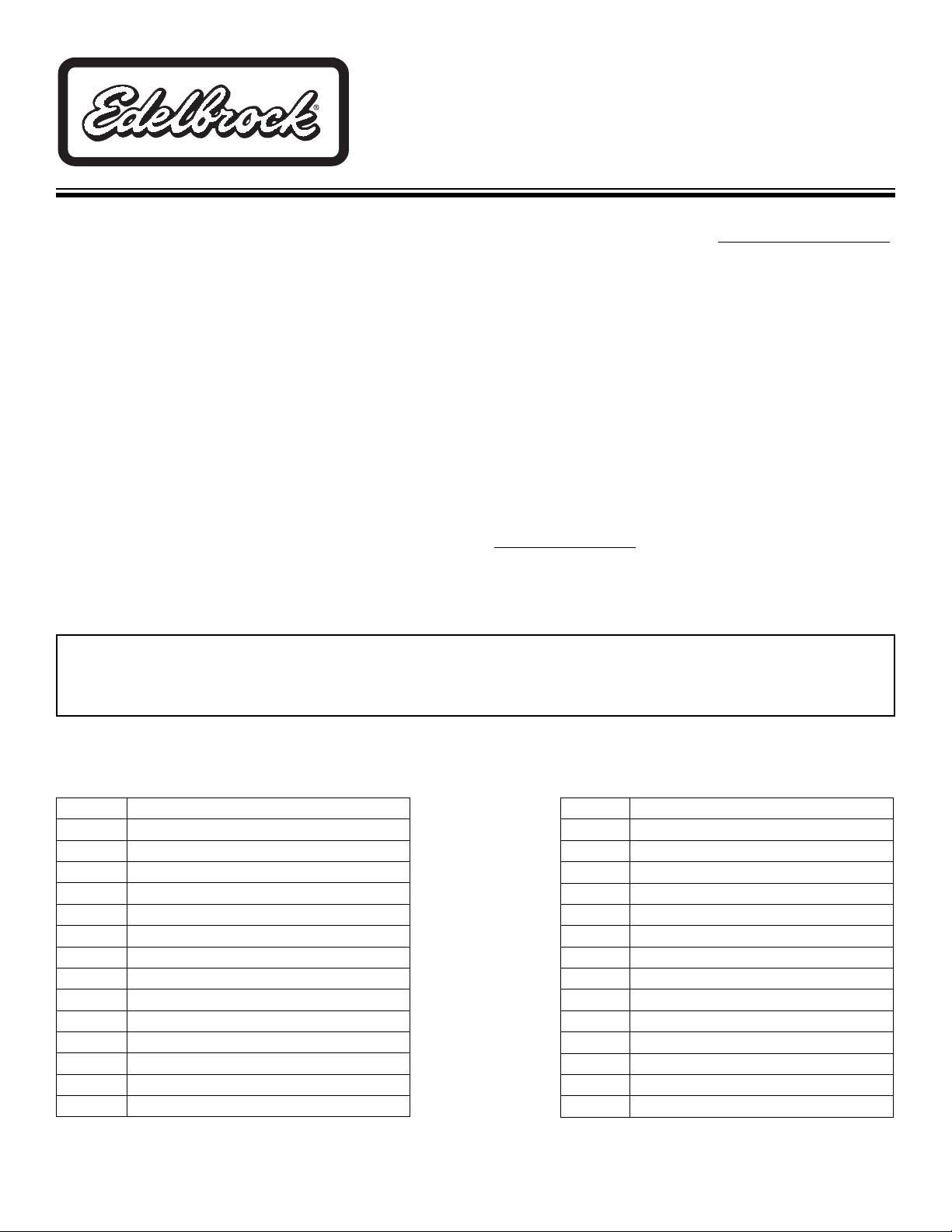

KIT CONTENTS

Catalog #68712 (Ceramic-Coated), #68713 (Ti-Tech Coated)

Qty. Description

❑ 1 Header left side #25-9331 (#68712)

❑ 1 Header right side #25-9332 (#68712)

❑ 1 Header left side #25-9003 (#68713)

❑ 1 Header right side #25-9004 (#68713)

❑ 1 Extension pipe left side #25-9503

❑ 1 Extension pipe right side #25-9504

❑ 1 Umpco clamp; 3/8” I.D.

❑ 1 Umpco clamp; 1-5/8” I.D.

❑ 1 Hex nut; 10-32

❑ 1 Hex capscrew; 10-32 x 1”

❑ 1 Star washer; 3/16” internal

❑ 2 Tube spacer; 5/8” x 1.53”

❑ 1 Tube spacer; 5/8” x .72

❑ 2 Donut gaskets; 2-1/4”

Qty. Description

❑ 1 Flange connector

❑ 1 U-Muffler clamp; 2-1/4”

❑ 1 O2 Sensor pigtail wire; 12”

❑ 2 Chevy V8 port gaskets

❑ 1 Thermo wrap; 2” x 6”

❑ 1 Safety wire; 8”

❑ 2 Hex capscrews; 3/8” 16 x 2”

❑ 2 Header bolts; 3/8” - 16 x 3”

❑ 16 Split lock washers; 3/8”

❑ 4 Flat washers; 3/8”

❑ 12 Header bolts; 3/8” - 16 x 1”

❑ 2 Hex cap screws; 3/8” - 16 x 3”

❑ 1 O2 Sensor plug (if needed)

❑ 4 Hardened washers; 3/8”

Page 2

Catalog #68712, 68713

©2006 Edelbrock Corporation

Page 2 of 3

Brochure #63-68712

Rev. 6/06 - DA/mc

• DISASSEMBLY

1. Disconnect battery negative cable from battery.

2. Raise vehicle and support with jackstands.

3. The use of penetrating oil when removing and the use of antiseize compound when installing nuts and bolts will prevent the

possibility of broken or stripped nuts and bolts.

4. Making sure converter is cool, remove the catalytic converter.

5. Lower vehicle to the ground.

• DISASSEMBLY LEFT SIDE

1. Remove air cleaner system (note position of line and hose

connections).

2. Disconnect A.I.R. (air injection reactor) hose from exhaust

manifold.

3. Remove air conditioner rear support bracket (if air conditioning

is applicable).

4. Remove power steering support bracket (if power steering is

applicable).

5. Disconnect spark plug wires and remove spark plugs.

6. Remove O2 sensor, being careful not to rupture or destroy the

unit.

WARNING: Do not clean this unit in any cleaning solvents and

do not rupture wire.

7. Disconnect temperature sensor wire at cylinder head.

8. Remove temperature sensor wire support bracket from valve

cover bolt and lay wire back over engine.

9. Remove bolts and exhaust manifold from top side.

10. Disconnect steering column connector and lower slip tube

down to steering box. CAUTION: Do not turn steering wheel or

front wheels while this system is disconnected.

• DISASSEMBLY RIGHT SIDE

1. Disconnect A.I.R. injection hose from exhaust manifold and

catalytic converter tube.

2. Disconnect electrical connector and vacuum hoses from A.I.R.

diverter valve assembly (note position of hose and electrical

connections).

3. Remove A.I.R. pump feed hose from diverter valve assembly.

4. Remove nut from diverter valve support bracket at exhaust

manifold and loosen lower alternator pivot bolt, then remove

diverter valve assembly.

5. Disconnect spark plug wires and remove spark plugs.

6. Remove dipstick and tube from engine.

CAUTION: Do not damage tube.

7. Remove bolts and exhaust manifold from top side.

8. At this time, clean exhaust flange surfaces on cylinder heads.

• ASSEMBLY LEFT SIDE

1. Install T.E.S. flange gasket and one 3/8-16 x 1" bolt and lock

washer at rearmost bolt hole (leave bolt loose enough to accept

T.E.S.).

2. Install left side T.E.S. manifold from top side.

3. Install all but the front two bolts and washers on left side (do

not tighten at this time).

4. Re-install rear power steering support bracket. Do not tighten

at this time.

5. Re-install rear A/C support bracket with bolts, lock washers and

spacers supplied.

6. Align all parts and tighten left side bolts and nuts at this time.

7. Re-connect steering column coupler.

INSTALLATION INSTRUCTIONS

WARNING: Make sure coupler bolt is tight and check to see

that steering wheel is in same orientation as prior to

disassembly.

8. Form brake lines to clear T.E.S. pipes.

9. Re-install spark plugs and reconnect wires left side.

10. Re-install temperature sensor wire support bracket and

reconnect wire to temperature sensor.

11. Re-install O2 sensor. Use anti-seize on threads of sensor and

torque to 30 ft./lbs. Re-route O2 sensor wire from wire loom to

O2 sensor (use O2 sensor extension lead supplied) making sure

all wires are clear of exhaust system.

• ASSEMBLY RIGHT SIDE

1. Remove fuel line bracket bolts on side and top of frame (two

bolts) right side.

2. Pull lines away from frame approximately 1" and place any

spacer between lines and frame to hold away.

3. Soak thermo wrap supplied in water, this will make it easy to

form.

4. Form thermo wrap around fuel lines as shown in

Figure 1.

5. With thermo wrap in place, wrap wire around at each end to

hold in place.

6. Remove spacer.

7. Replace bolts and tighten both clamps.

8. Install T.E.S. flange gasket and one 3/8" - 16 x 1" bolt, lock

washer and flat washer at rearmost bolt hole (leave bolt loose

enough to accept T.E.S).

9. Install right side T.E.S. manifold from top side concurrently with

dipstick tube.

10. Install remaining bolts, lockwashers, dipstick and tube clamps

(see Figure 2)

. Do not tighten bolts at this time.

11. Re-install O.E.M. front stud bolt with spacer (supplied). Align all

parts and tighten all right side bolts at this time.

12. Re-install spark plugs and reconnect wires.

13. Re-install diverter valve assembly in front O.E.M. stud bolt and

tighten.

14. Re-connect electrical connections and vacuum lines to diverter

valve assembly.

15. Remove A.I.R. Check valves from O.E. manifolds and re-install

them on T.E.S. Re-connect all injection hoses.

16. Raise vehicle and support with jackstands.

• CROSSOVER PIPE ASSEMBLY

1. Assemble both lower pipes. Do not clamp tight at this point.

2. Rotate E.F.E. valve 180° from its original position (the

diaphragm will now be facing to the rear of vehicle).

3. Install crossover pipe assembly on vehicle with four 3/8" bolts,

lock and flat washers and gaskets supplied. Do not tighten at

this time.

4. Form A.I.R. injection tube to catalytic converter. Align and

tighten all bolts and clamps at this time.

• LOWER VEHICLE TO THE GROUND

1. Connect negative cable to battery. At this point, it would be a

good idea to look everything over and make sure nothing was

missed in assembly.

2. Start vehicle, bring up to normal operating temperature and

check for possible leaks.

3. Turn engine off and let cool. Tighten all bolts again.

Page 3

Catalog #68712, 68713

©2006 Edelbrock Corporation

Page 3 of 3

Brochure #63-68712

Rev. 6/06 - DA/mc

Edelbrock Corporation, 2700 California St., Torrance, CA 90503

Tech Line: 1-800-416-8628

E-Mail: Edelbrock@Edelbrock.com

Small Umpco Clamp

10-32 Capscrew, Nut, and Washer

Large Umpco Clamp

.720” Spacer

Fig. 2

Fig. 1

Loading...

Loading...