Page 1

©

2007 Edelbrock Corporation

Rev. 6/07 - DA/mc

Catalog #5221

Brochure #63-5221

Page 1 of 2

Edelbrock Trailing Arm

for 1979-2004 Ford Mustang

Catalog #5221

INSTALLATION INSTRUCTIONS

Please study these instructions carefully before installing your new Adjustable Trailing Arm. If you have any questions, contact our

Technical Hotline at: 1-800-416-8628, 7 am to 5 pm, Monday-Friday, Pacific Standard Time or

e-mail us at Edelbrock@Edelbrock.com.

Tools and Supplies Required:

❑ Floorjack ❑ 15mm & 18mm sockets (1/2” drive) and combination wrenches

❑ (4) Jackstands ❑ Torque wrench, 1/2” drive 14”-16” extension

❑ Tire chocks ❑ Grease gun

❑ Lug wrench ❑ Blue Loctite™

❑ Edelbrock trailing arm hardware kit #5216

for ‘79-’98 - optional; stock hardware may

be used if in good condition.

REMOVAL OF STOCK TRAILING ARMS

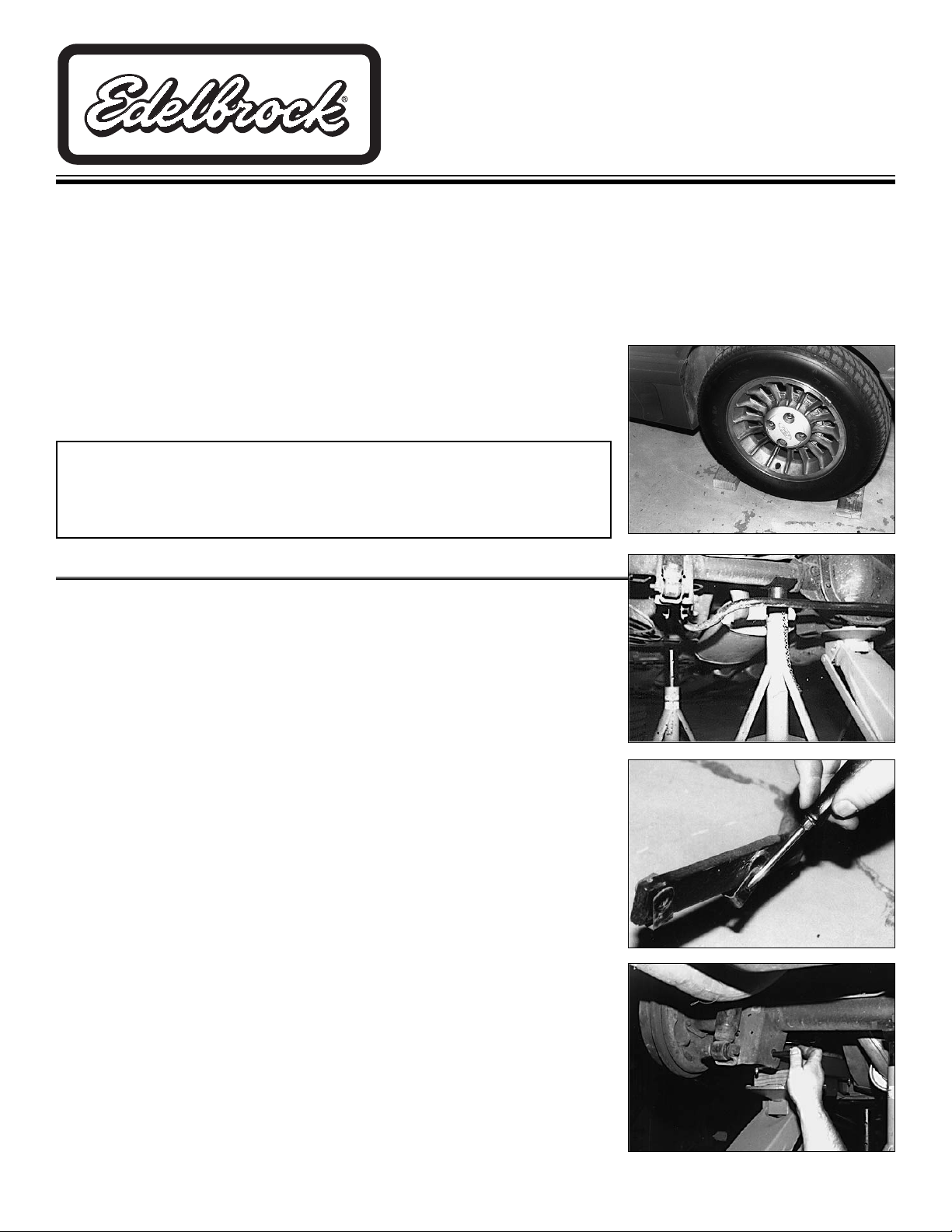

1. Place car on level surface and place tire chocks in front of and behind front tires

(See Fig. 1).

2. Support rear of the car on jackstands and remove the rear wheels.

3. Lift rear axle with floor jack to approximate ride height, then support rear axle with

jack stands

(See Fig. 2).

KEEP JACKSTANDS UNDER CAR DURING THE COMPLETE REMOVAL AND

INSTALLATION PROCEDURE.

CAUTION - DO NOT REMOVE BOTH TRAILING ARMS AT THE SAME TIME OR THE

AXLE WILL ROTATE AND TRAILING ARM INSTALLATION WILL BECOME MUCH

MORE DIFFICULT.

4. Remove rear sway bar. Remove clip nuts from sway bar

(See Fig. 3).

Make sure

car is still firmly supported on jackstands.

5. Lift rear of trailing arm with floor jack so bolt can be removed

(See Fig. 4).

Remember, do one side at a time.

6. Carefully remove rear trailing arm bolt. CAUTION: Trailing arm is under tremendous

pressure from the rear spring. Be sure that the floor jack is sturdy and able to

control the release of tension in a smooth, controlled manner.

7. Carefully lower trailing arm, releasing tension on rear spring. Note that the opening

at the bottom coil of the spring is towards the rear of vehicle. It must be re-installed

in the same position or the ride height will be affected. Remove spring. Inspect the

rubber insulators on spring and replace with new Ford parts (#D8BZ-5536-A), if

necessary.

8. Remove front bolt and old trailing arm. A 14"-16" long extension will make it easier

to reach the bolt due to interference from the muffler.

9. Clean frame at trailing arm pivot area with a wire brush.

IMPORTANT NOTE:

Proper installation is the responsibility of the installer. Improper

installation will void warranty and may result in poor performance and

engine or vehicle damage.

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Page 2

©

2007 Edelbrock Corporation

Rev. 6/07 - DA/mc

Catalog #5221

Brochure #63-5221

Page 2 of 2

1. Install bushing sleeve in bushing using supplied grease. Bushing sleeve with small hole is for model years 1979-1998 and sleeve

with large hole is used for 1999–2004 model years.

2. Install new trailing arm with the grease fittings facing down and the sway bar mount toward the front of car. Arm stamped with

P/N 25-4003 is the left and P/N 25-4004 is the right.

3. Install the new trailing arm by locating the front bolt first. If the fit is too tight, grease

the outside edges of the bushing to help the arm slide into place. Install nut and bolt

but do not tighten at this time. The trailing arm should pivot smoothly in the chassis.

4. Re-install spring and all rubber insulation pieces, making sure that opening at

bottom of spring faces the rear of the car

(See Fig. 5)

. Use a block of wood or

similar support between the floor jack and the trailing arm to prevent damage to the

zerk fitting

(See Fig. 6).

5. Place one drop of blue Locktite™ on clean threads and torque the nut to 70 ft./lbs

on both front and rear trailing arm bolts.

6. Repeat for other side.

7. Re-install sway bar with ends to outside of trailing arm sway bar mount. Use factory

bolts with supplied nuts and washers. Re-install E-brake cable clamp on rear most

sway bar bolt if equipped. Bracket may require minor modification.

8. You may want to finish your installation by lubing the front and rear bushings with a

grease gun. Be sure to replace the dust caps on the zerk fittings to prevent dirt and

corrosion from damaging the fitting.

Check all nut and bolt tightness after first 10 miles.

Edelbrock Corporation, 2700 California St., Torrance, CA 90503

Tech Line: 1-800-416-8628

E-Mail: Edelbrock@Edelbrock.com

INSTALLATION INSTRUCTIONS

Fig. 5

Fig. 6

Qty.

Part # Description

❑

1

25-4003 Right Arm Assembly

❑

1

25-4004 Left Arm Assembly

❑

8

-

Polyurethane Bushings (Pre-installed)

❑

4

-

12mm ID Bushing Sleeves

❑

4

-

14mm ID Bushing Sleeves

❑

4

-

Grade C Lock Nuts

❑

4

-

Flat Washers

❑

4

-

Zerk Fittings

❑

4

-

Zerk Caps

KIT CONTENTS

Loading...

Loading...