Page 1

©2008 Edelbrock Corporation

Brochure #63-0414

Catalog #61949, 61969, 61979, 61989

Rev. 12/08 - AJ/mc

Page 1 of 2

PERFORMER RPM G.M. GEN III (LS SERIES) CYLINDER HEADS

For Gen III and Gen IV Small-Block Chevrolet V8s

Catalog #61949, 61969, 61979 & 61989

INSTALLATION INSTRUCTIONS

PLEASE study these instructions carefully before beginning this installation. Most installations can be accomplished with common tools and

procedures. However, you should be familiar with and comfortable working on your vehicle. If you do not feel comfortable performing this installation,

it is recommended to have the installation completed by a qualified mechanic. If you have any questions, please call our Technical Hotline at:

1-800-416-8628, 7:00 am - 5:00 pm, Pacific Standard Time, Monday through Friday or e-mail us at edelbrock@edelbrock.com

.

IMPORTANT NOTE: Proper installation is the responsibility of the installer. Improper installation

will void your warranty and may result in poor performance and engine or vehicle damage.

DESCRIPTION: Performer RPM Gen III cylinder heads are designed for

1997 and later 5.7L LS series engines, and other third and fourth

generation small-block Chevrolet V8 engines. These heads provide great

“out-of-the-box” performance and feature CNC-ported, 205cc intake

and 82cc exhaust ports for superior flow, and efficient 65cc CNC profiled

combustion chambers. CNC-ported cylinder heads #61969 & 61979 are

designed for engines with 3.900” or larger bore diameters and will not

fit 4.8L and 5.3L engines with factory 3.780” cylinder bores. Performer

RPM Gen III cylinder heads can also be used on larger displacement Gen

III and Gen IV small block V8 engines including 7.0L (427 c.i.d.) engines

with 4.125” or larger cylinder bores using the C5R block, LS7 block, or

sleeved production blocks.

Partial CNC cylinder heads #61949 provide an economical alternative to

complete CNC ported cylinder heads, featuring as cast, 214cc intake

ports, partial CNC ported 80cc exhaust ports, and fully CNC profiled 65cc

combustion chambers.

As-cast cylinder heads #61989 can be finished to accommodate a

smaller bore size. This would be determined by the professional cylinder

head porting shop performing the finish machine work (See note below).

All heads feature reinforced rocker arm bosses for increased strength.

Complete heads are assembled with the following components:

❑ High quality, stainless steel, one-piece, 2.02” intake and 1.57”

exhaust valves for increased flow

❑ 2-ring positive oil control seals

❑ Valve springs accept camshafts with up to .650” lift

❑ Titanium valve spring retainers

(Steel on 61949)

❑ Hardened valve seats compatible with unleaded fuel

NOTE: Complete cylinder heads are assembled and prepared for

installation right out of the box. Bare cylinder head #61979 will

have valve guides and seats installed, but will require final

sizing and a valve job to match the valves you will be using.

Small-port, bare cylinder head #61989 requires professional

preparation. This is a machined casting from which the

finished heads are made. The small, as-cast ports and

chambers are designed to allow a variety of designs to

completely clean up when CNC-ported. Follow the finisher’s

recommendations regarding maximum valve lift, gaskets,

and additional hardware, as cylinder head setup will vary

depending on the specific cylinder head assembly.

IMPORTANT NOTES, READ BEFORE BEGINNING INSTALLATION!:

For a successful installation, the Edelbrock Performer RPM Cylinder

Heads require some components other than original equipment parts. To

complete your installation, you will need the following items:

❑ Head gaskets (graphite); Right - GM #12558809, Left - GM

#12558810. Or, multi-layer steel shim (MLS) gaskets, GM

#12498544 (both sides) may also be used. NOTE: Stock 4.8L &

5.3L head gaskets are NOT compatible with these cylinder heads.

❑ Stock type intake manifold o-ring seals; GM #12533587 for LS1/LS6

intake manifolds, GM #17113557 for later CK truck intakes, or GM

#89017585 for LS2 intake manifolds.

❑ Exhaust gaskets; Edelbrock #6962

❑ New cylinder head bolts or studs, with hardened steel washers

❑ Heads are machined to accept stock rocker arms, aftermarket

rocker arm assemblies for Gen III and Gen IV engines may also be

used

❑ Correct length pushrods (The required pushrod length is dependent

upon camshaft base-circle diameter and the amount that has been

surfaced from the heads or machined from your block. You will need

to check for correct pushrod length.)

❑ 14mm x 17.5mm (.708”) reach, tapered seat, resistor-type spark

plugs

CHECKING PISTON-TO-VALVE, VALVE-TO-BORE AND PISTON-TOHEAD CLEARANCES: Prior to installation, it is highly recommended that

valve-to-piston clearances are checked and corrected to minimum

specs, if necessary. These cylinder heads have larger-than-stock valve

sizes and although they are designed to accept factory pistons in most

cases, it’s possible the use of aftermarket pistons and/or custom

machining of your pistons may be required. Actual valve-to-piston

clearance should be specified by your camshaft manufacturer. Valve-tobore clearance should also be checked, and the top of the bore notched

for clearance, if necessary.

ACCESSORIES: Although Edelbrock Cylinder Heads will accept most

OEM components (valve covers, intake manifold, etc.), we highly

recommend that premium quality hardware be used with your new

heads.

HEAD BOLTS OR STUDS: High quality head studs or head bolts with

hardened washers must be used to prevent galling of the aluminum bolt

bosses. Edelbrock head bolt kits #8596 (pre-2003) and #8595 (post-

2003) include all head bolts needed for use with these cylinder heads.

New production head bolts may also be used. New style blocks use GM

head bolt kit #11519772. Old style blocks use GM #12498545

(See

Note under Figure 1 for year span of old & new style blocks)

.

Because factory bolts are a torque-to-yield type fastener, the stock head

bolts CANNOT be re-used. The tightening procedure listed below Figure

1 is for OEM torque to yield bolts only. Edelbrock bolt kit #8596 should

use the torque values listed in the Installation subsection.

®

Page 2

©2008 Edelbrock Corporation

Brochure #63-0414

Catalog #61949, 61969, 61979, 61989

Rev. 12/08 - AJ/mc

Page 2 of 2

ROCKER ARMS AND VALVE TRAIN: These cylinder heads are designed

to use the stock rocker arms or aftermarket replacement rocker arms

designed for the Gen III and Gen IV engines. Aftermarket stud &

guideplate rocker arm conversions require machine work to the

rocker stud pad for proper guideplate placement. Due to the larger

intake port design on these CNC-ported heads, the factory rocker bolts

will need to be shortened, or you may use aftermarket rocker bolts.

VALVE COVERS: Edelbrock Performer RPM cylinder heads will accept

stock center-bolt design valve covers. Engines originally equipped with

perimeter bolt valve covers will need to convert to center bolt valve

covers. Perimeter bolt cylinder heads are found on 1997, 1998, and

some 1999 vehicles.

INTAKE MANIFOLD: Cylinder Heads will accept stock intake manifolds,

as well as our Performer RPM LS-1 Carbureted intake manifold #7118,

Victor JR. LS-1 Carbureted intake manifold #2908, or Victor Jr. LS-1 EFI

intake manifold #29085 (requires fuel rail kit #3638 or equivalent). Use

stock type LS1/LS6 individual port o-ring seals.

EXHAUST HEADERS: For optimum performance, exhaust headers and a

low restriction exhaust system are highly recommended for use with

Edelbrock Cylinder Heads. Exhaust ports are CNC-profiled to match

stock or Edelbrock #6962 exhaust gaskets which are recommended for

this application.

SPARK PLUGS: Use 14mm x 17.5mm (.708”) reach tapered seat

resistor type spark plugs. Heat range requirements will vary by

application. For many applications, GM factory spark plugs or equivalent

spark plus such as Champion RS14YC6, NGK TR55, or Denso IT16 spark

plugs may be used. Use anti-seize on the plug threads to prevent

galling in the cylinder head, and torque to 10 ft./lbs. Do not over

tighten sparkplugs! If a short reach plug is used, poor

performance and possible engine damage may occur.

INSTALLATION: Installation is the same as for original equipment

cylinder heads. Consult a factory service manual for specific procedures,

if necessary. Factory manuals can be purchased direct from Helm® at:

www

.helminc.com. Be sure that the surface of the block and the surface

of the head are thoroughly cleaned to remove any oily film before

installation. Use alcohol or lacquer thinner on a lint-free rag to clean.

NOTE: Be VERY careful to remove any coolant or other fluids that

may be in the cylinder head bolt holes in the block. These bolt holes

are sealed at the bottom, and any fluid trapped in the holes will

cause the block to crack when you torque the bolts.

When using the GM factory head bolts, be sure to replace all of the bolts

with new bolts, and to follow the factory recommended installation

procedures. The factory bolts and installation procedures do not call for

the use of oil or any lubricant on the threads. When using aftermarket

bolts or studs, follow the manufacturer’s recommended torque

specifications

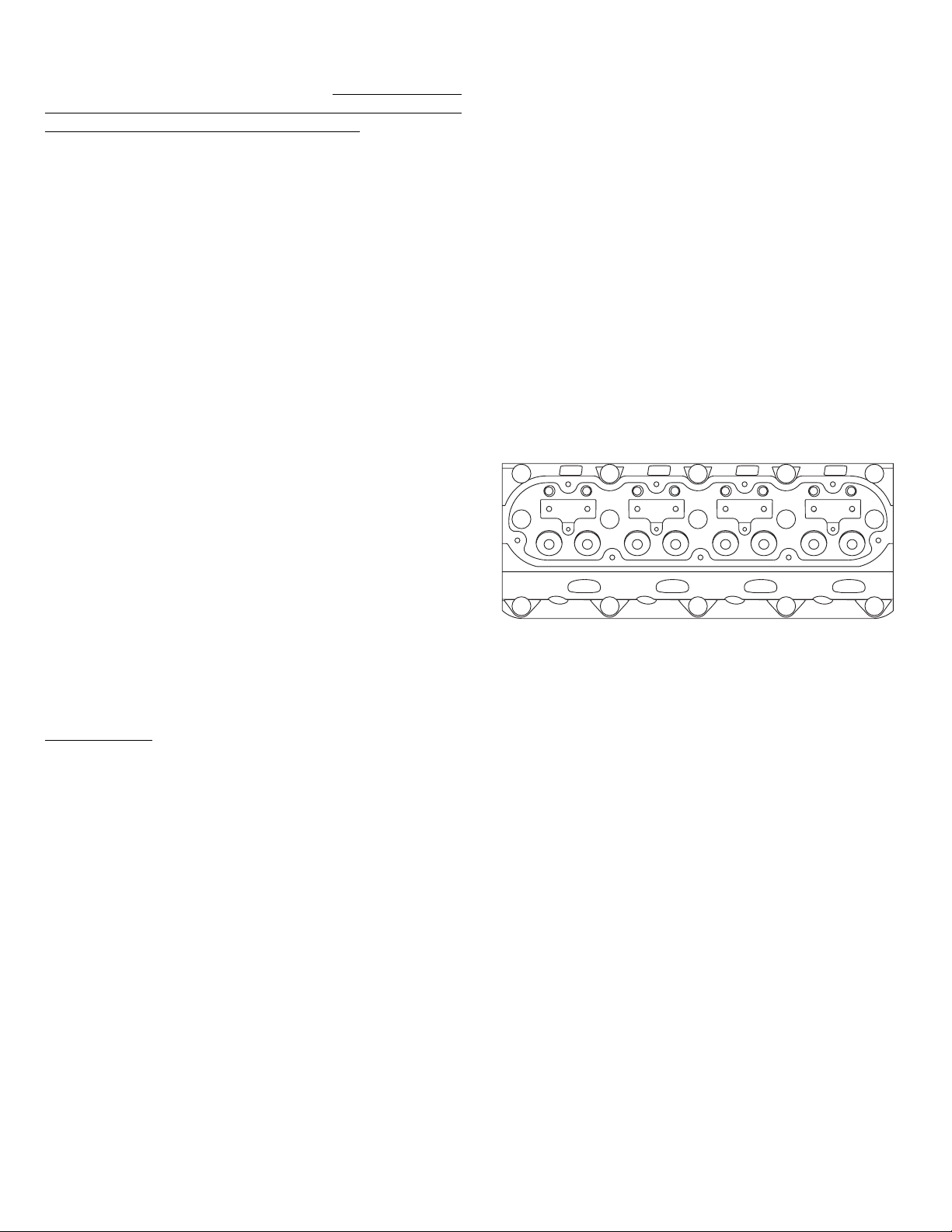

(See Figure 1 for factory tightening sequence)

.

NOTE: A Torque Angle Gauge is required for proper installation.

Torque to yield fasteners are not designed to be re-torqued after

installation.

When using Edelbrock bolt kit #8596 or #8595, lightly coat all head

bolts with 30wt motor oil or ARP moly lube, then substitute a final

torque value of 85 ft/lbs (or 70 ft/lbs w/ ARP moly lube) for the M11

bolts, and 29 ft/lbs (or 23 ft/lbs w/ ARP moly lube) for the M8 bolts.

SPECIFICATIONS:

Head Bolt Torque: See Figure 1, or use head bolt

manufacturer’s specifications

Deck Thickness: 5/8”

Combustion Chamber Volume: 65 cc

Valve Size: Intake - 2.02”

Exhaust - 1.57”

Valve Seats: Hardened ductile iron, non-

interlocking, compatible with

unleaded fuel

Valve Spring Diameter: Beehive type spring,1.300”

at base of spring

Valve Spring Installed Height: 1.800”

Valve Spring Seat Pressure: 130 lbs. @ 1.800”

Valve Spring Open Pressure 318 lbs. @ 1.200”

Max. Valve Lift: .650”

Coil Bind 1.085”

Figure 1 - Factory Cylinder Head Bolt Torque Sequence

First Design Blocks

(8 long, 2 medium length M11 bolts per cylinder head)

First Pass: Torque all M11 bolts (1-10) in sequence, to 22 ft./lbs.

Second Pass: Turn all M11 bolts (1-10) in sequence, an additional

90 degrees.

Final Pass: Turn all long M11 bolts (1-8) in sequence, an

additional 90 degrees. Turn medium M11 bolts

(9-10) an additional 50 degrees. Tighten M8 bolts

(11-15) in sequence shown to 22 ft./lbs.

Second Design Blocks

(10 long, M11 bolts per cylinder head)

First Pass: Torque all M11 bolts (1-10) in sequence, to 22 ft./lbs.

Second Pass: Turn all M11 bolts (1-10) in sequence, an additional

90 degrees.

Final Pass: Turn all M11 bolts (1-10) in sequence, an additional

70 degrees. Tighten M8 bolts (11-15) in sequence

shown to 22 ft./lbs.

NOTE: First to Second design change-over date is roughly mid

December 2003 for block manufacturing date. Always refer to your

vehicles service manual for specific torque procedures.

(EXHAUST PORT SIDE)

Edelbrock Corporation • 2700 California St. • Torrance • CA 90503

Tech Line: 800-416-8628 • Office: 310-781-2222

E-Mail: Edelbrock@Edelbrock.com

15 13 11 12 14

10 3 1 5 9

7 6 2 4 8

Loading...

Loading...