Page 1

PERFORMER RPM 351-C CYLINDER HEAD

For 351 c.i.d. Ford “Cleveland” and 351/400 c.i.d. “M” Engines

Catalog #61609 & #61629

INSTALLATION INSTRUCTIONS

PLEASE study these instructions carefully before beginning this installation. Most installations can be accomplished with common tools and

procedures. However, you should be familiar with and comfortable working on your vehicle. If you do not feel comfortable performing this

installation, it is recommended to have the installation completed by a qualified mechanic. If you have any questions, please call our Technical

Hotline at: 1-800-416-8628, 7:00 am - 5:00 pm, Pacific Standard Time, Monday through Friday or e-mail us at edelbrock@edelbrock.com..

IMPORTANT NOTE: Proper installation is the responsibility of the installer.

Improper installation may result in poor performance and engine or vehicle damage.

PLEASEcomplete and mail your warranty card. Be sure to write the model number of this product in the "Part #____" space. THANK YOU.

DESCRIPTION: Designed for Ford 351-C, 351-M, and 400-M engines,

these street high-performance heads provide great “out-of-the-box”,

performance for your Ford musclecar or streetrod. Performer RPM

351-C heads feature CNC profiled 190cc (intake) and 90cc (exhaust)

port exits for superior flow and efficient 60cc “Compact Charge”

combustion chambers. An optimized spark plug location provides

improved header clearance. Hardened valve seats are compatible with

any fuel. NOTE: These heads may be used in “Hybrid” applications

such as building a “Clevor” or mock Boss 302 engine. See “Hybrid

Applications” section for details.

The complete cylinder heads are assembled with the following:

❑ Stainless steel, one-piece, swirl-polished intake (2.05”) and

exhaust (1.60”) valves with under-cut stems for increased flow

❑ 2-ring positive oil control seals

❑ Edelbrock Sure-Seat valve springs #5792

❑ Retainers #9734

❑ Valve keepers #9612

❑ Valve spring seats #5771

❑ Hardened Guide Plates #9672

NOTE: Complete cylinder heads are assembled and prepared for

installation right out of the box. Bare cylinder heads will have

valve guides and seats installed, but will require final sizing

and a valve job to match the valves you will be using.

IMPORTANT NOTES, READ BEFORE BEGINNING INSTALLATION!:

For a successful installation, the Edelbrock Performer RPM Cylinder

Heads require some components other than original equipment parts.

To complete your installation, you will need the following items:

❑ Head gaskets; Fel-Pro #1013 (see instructions below)

❑ Intake manifold gaskets; Edelbrock #7216.

❑ Exhaust gaskets; Fel-Pro #1430 or equivalent

❑ Cylinder head bolts or studs with hardened steel washers.

(If mounting on 302 block, you must also use Edelbrock head bolt

bushings with integral washers, #9680)

❑ Heads are machined for adjustable rocker arm assembly

❑ Hardened steel pushrods (For 351M/400, use Edelbrock #9633)

❑ 14mm x 3/4” reach gasketed spark plugs; Champion RC-12YC or

equivalent

HYBRID APPLICATIONS: Cleveland heads are sometimes used in

hybrid applications such as a “Clevor” (351 Windsor block, 400-M

crankshaft, and Cleveland cylinder heads), or Boss-302 “clone” (302

Block with Cleveland cylinder heads). In these applications, the

cylinder heads must be drilled to provide a coolant crossover passage

for use with certain aftermarket intake manifolds designed specifically

for such hybrid engines. Guide holes are provided for this purpose

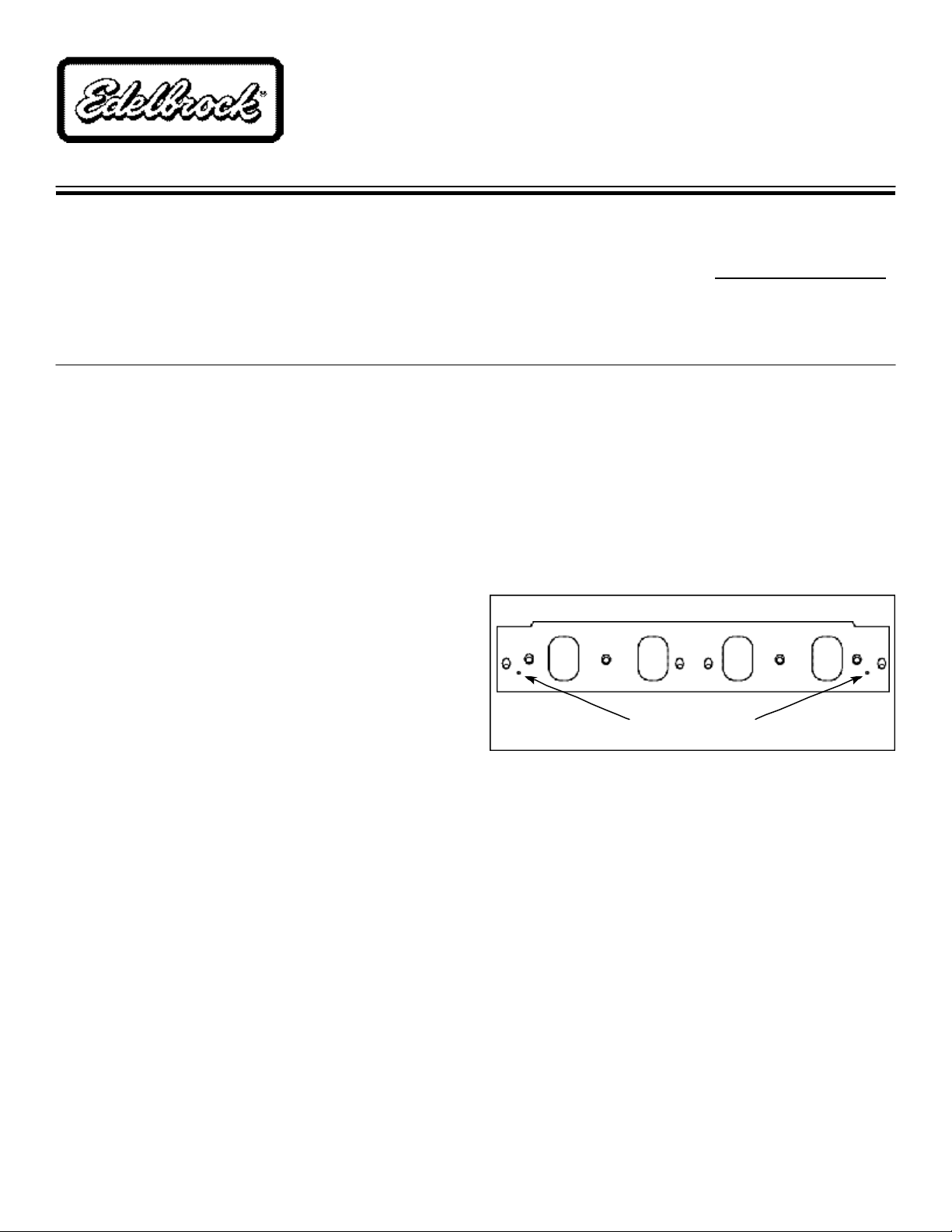

(See Figure 1) . Refer to the manufacturer of your custom intake

manifold for the appropriate location (usually the hole that will be at

the front of the block when the heads are installed) and diameter and

drill accordingly, using the guide holes to align your drill.

Drill Guide Holes

Figure 1 - Intake Flange Water Crossover Drill Locations

for Cleveland/Windsor Hybrid Applications

Additionally, the 3/4” threaded coolant holes in the deck surface of the

block must be plugged for these hybrid applications. Install the

supplied 3/4” aluminum plugs using liquid Teflon thread sealer on the

threads.

NOTE: After installing the plugs, they must be milled flush with the

deck of the cylinder head. This may require milling a small amount off

of the entire deck surface. This operation should ONLY be performed

by a professional engine machine shop.

CHECKING PISTON-TO-VALVE, PISTON-TO-BORE AND PISTON-TOHEAD CLEARANCES: Prior to installation, it is highly recommended

that valve-to-piston clearances are checked and corrected to

minimum specs, if necessary. These cylinder heads have larger-thanstock valve sizes and may not work with the valve pockets in stock

pistons, especially if a high lift cam is used. The use of aftermarket

pistons and/or custom machining of your pistons may be required.

Catalog #61609, #61629

Rev. 10/05 - RS/mc Page 1 of 2

©2005 Edelbrock Corporation

Brochure #63-0352

Page 2

Actual valve-to-piston clearance should be specified by your camshaft

manufacturer. Valve-to-bore clearance should also be checked, and

the top of the bore notched for clearance, if necessary.

ACCESSORIES: Although Edelbrock Cylinder Heads will accept most

OEM components (valve covers, intake manifold, etc.), we highly

recommend that premium quality hardware be used with your new

heads.

HEAD BOLTS OR STUDS: High quality head studs or head bolts with

hardened washers must be used to prevent galling of the aluminum

bolt bosses. Edelbrock head bolt kit #8560 includes all bolts which

must be used with these cylinder heads (Also use Edelbrock Head Bolt

Bushings #9680 in place of washers on if installing heads on a 302

block). Stock head bolts may be used with hardened washers.

ROCKER ARMS AND VALVE TRAIN: These cylinder heads are

designed to use the preferred Boss 302 7/16” stud mounted rocker

arms. Although stock Boss 302 rocker arms may be used (if new lock

nuts are used), we highly recommend using adjustable aftermarket

roller rocker arms such as Crane Cams, Comp Cams, Crower or any

equivalent. Long slot, roller tip rockers may also be used.

VALVE COVERS: Edelbrock Performer RPM cylinder heads will accept

stock Cleveland valve covers. They also will accept Edelbrock valve

covers #4461.

INTAKE MANIFOLD: Although stock intake manifolds will fit,

Edelbrock Performer RPM Cylinder Heads are matched in size and

operating range with Edelbrock RPM RPM Air-Gap manifold #7564.

Edelbrock intake manifold gasket #7216 is recommended.

NOTE: To ensure maximum performance and a proper seal,

Edelbrock gaskets which are specifically designed and

manufactured for use with Edelbrock parts must be used.

INSTALLATION: Installation is the same as for original equipment

cylinder heads. Consult service manual for specific procedures, if

necessary. Be sure that the surface of the block and the surface of the

head are thoroughly cleaned to remove any oily film before installation.

Use alcohol or lacquer thinner on a lint-free rag to clean. Apply oil or

suitable thread lubricant to head bolt threads and the underside of bolt

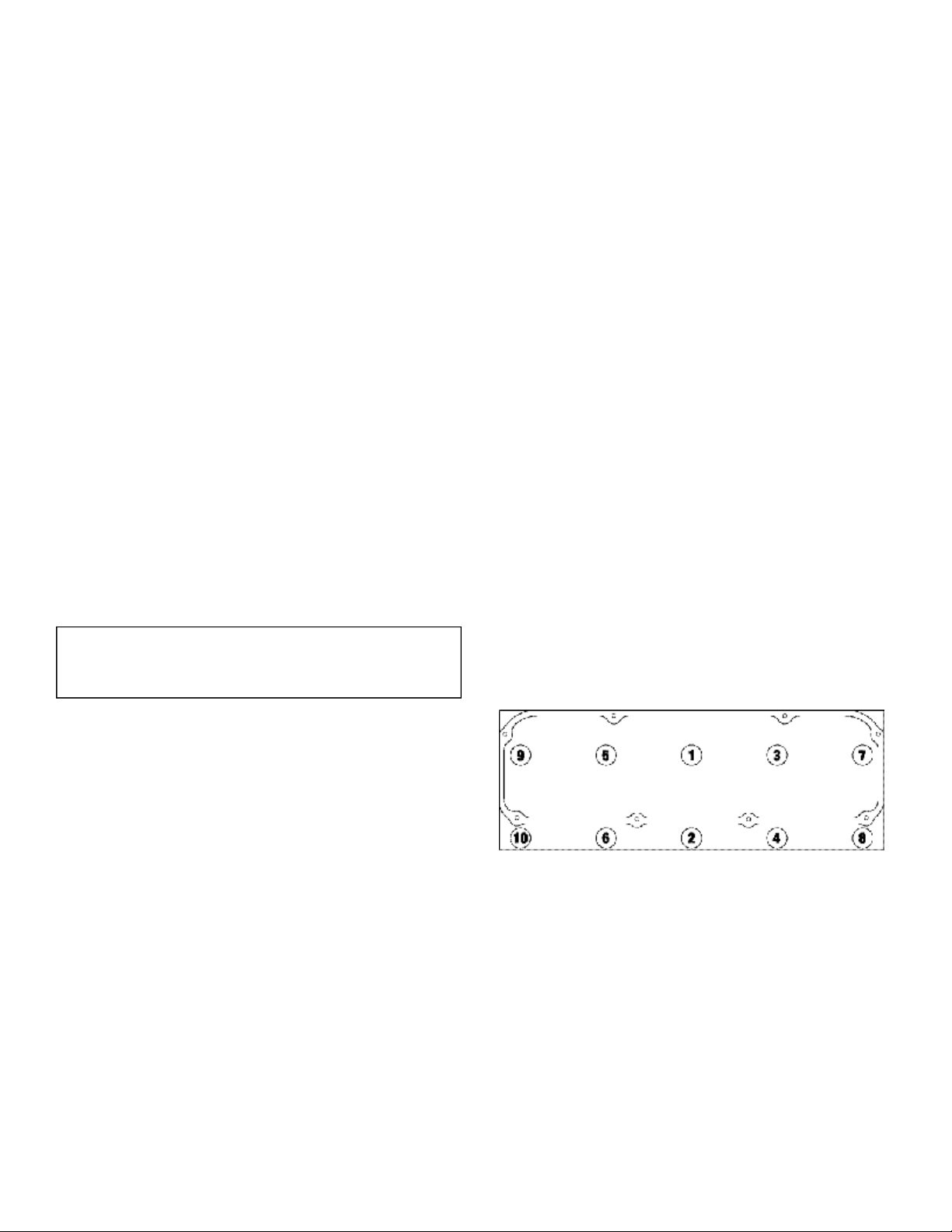

heads and washers. Torque 1/2” bolts to 100-110 ft./lbs (1/2” bolts)

in four steps (30, 60, 90, 100-110) following the factory tightening

sequence (See Figure 2). See intake manifold instructions for

installation of the intake manifold.

NOTES:

BOSS 302 CLONE ENGINES - Use Edelbrock Head Bolt Bushings with

Integral Washers #9680 in place of washers supplied with your head

bolt kit. Torque 7/16” bolts to 65-70 ft./lbs. in four steps (30, 40, 50,

65-70) following the factory tightening sequence (See Figure 2).

ALL ENGINES - A re-torque is recommended after initial start-up and

cool-down (allow 2-3 hours for adequate cooling).

SPECIFICATIONS:

Head Bolt Torque: 7/16” Bolts: 65-70 ft./lbs.

1/2” Bolts: 100-110 ft./lbs.

(Applied gradually in 4 steps)

Rocker Stud Torque: 50 ft./lbs.

Combustion Chamber Volume: 60 cc

Deck Thickness: 5/8”

Valve Seats: Hardened ductile iron, non-

interlocking, compatible with

any fuel

Valve Size: Intake - 2.05”, Exhaust - 1.60”

Valve Spring Diameter: 1.55”

Valve Spring Installed Height: 1.900”

Valve Spring Seat Pressure: 115 lbs.

Max. Valve Lift: .600”

EXHAUST HEADERS: For optimum performance, exhaust headers

and a low restriction exhaust system are highly recommended for use

with Edelbrock Performer RPM Cylinder Heads. Exhaust ports are

CNC-profiled to match Fel-Pro #1430 exhaust gaskets which are

recommended for this application.

SPARK PLUGS: Use 14mm x 3/4” reach gasketed spark plugs. Heat

range may vary by application, but we recommend Champion RC12YC (or equivalent) for most applications. Use anti-seize on the

plug threads to prevent galling in the cylinder head, and torque

to 10 ft./lbs. Do not over-tighten sparkplugs! If short reach

plug is used, poor performance and possible engine damage

may occur.

Edelbrock Corporation • 2700 California St. • Torrance, CA 90503

Tech Line: 800-416-8628 • E-Mail: Edelbrock@Edelbrock.com

Catalog #61609, #61629

Rev. 10/05 - RS/mc Page 2 of 2

(EXHAUST PORT SIDE)

Figure 2 - Cylinder Head Bolt Torque Sequence

Torque Bolts in 4 Steps Following Sequence Above

©2005 Edelbrock Corporation

Brochure #63-0352

Loading...

Loading...