Page 1

EDELBROCK/MUSI VICTOR 24° CNC CYLINDER HEAD

For Big Block Chevrolet

Catalog # 61409

INSTALLATION INSTRUCTIONS

PLEASE study these instructions carefully before beginning this installation. Most installations can be accomplished with common tools and

procedures. However, you should be familiar with and comfortable working on your vehicle. If you do not feel comfortable performing this

installation, it is recommended to have the installation completed by a qualified mechanic. If you have any questions, please call our Technical

Hotline at: 1-800-416-8628, 7:00 am - 5:00 pm, Pacific Standard Time, Monday through Friday or e-mail us at edelbrock@edelbrock.com.

IMPORTANT NOTE: Proper installation is the responsibility of the installer.

Improper installation will void warranty and may result in poor performance and engine or vehicle damage.

PLEASEcomplete and mail your warranty card. Be sure to write the model number of this product in the "Part #____" space. THANK YOU.

DESCRIPTION: Edelbrock/Musi Victor 24° CNC-Ported Big Block Chevrolet cylinder heads are designed for high rpm or large displacement big

block Chevrolet applications using rectangular port heads. CNC ported, rectangular intake ports are raised .100” and CNC-ported exhaust ports

are raised .750” for greatly improved flow paths and more power. 118cc open-style, CNC-profiled combustion chambers facilitate high

compression ratios and rocker stud bosses are reinforced for valve train stability. For maximum head gasket retention, these heads include two

auxiliary head bolt holes (Note: These bolt holes must be plugged off if not in use). These heads will accommodate all standard location

rectangular port Victor series intake manifolds. These heads will fit all 1965 and later big block Chevrolet blocks. The valve seats and valve guides

have been machined for recommended valve sizes and will need final clearances to be checked by the engine builder. We recommend Edelbrock

intake #2917 for a matched port intake.

INSTALLATION PROCEDURE

IMPORTANT NOTES : The #61409 heads are designed for a 4.470”

bore or larger. Intake valves should measure 5.600” or longer and

exhaust valves should measure at least 5.500” in length. The unique

valve locations and angles require Edelbrock guideplate #38-6067 for

proper valve train geometry, and also require stud girdle #7796.

ACCESSORIES & INSTALLATION ITEMS: We highly recommend that

premium quality hardware be used with your new heads. See our

catalog for details. To order a catalog, call (800) FUN-TEAM, or visit

our website at: www.Edelbrock.com.

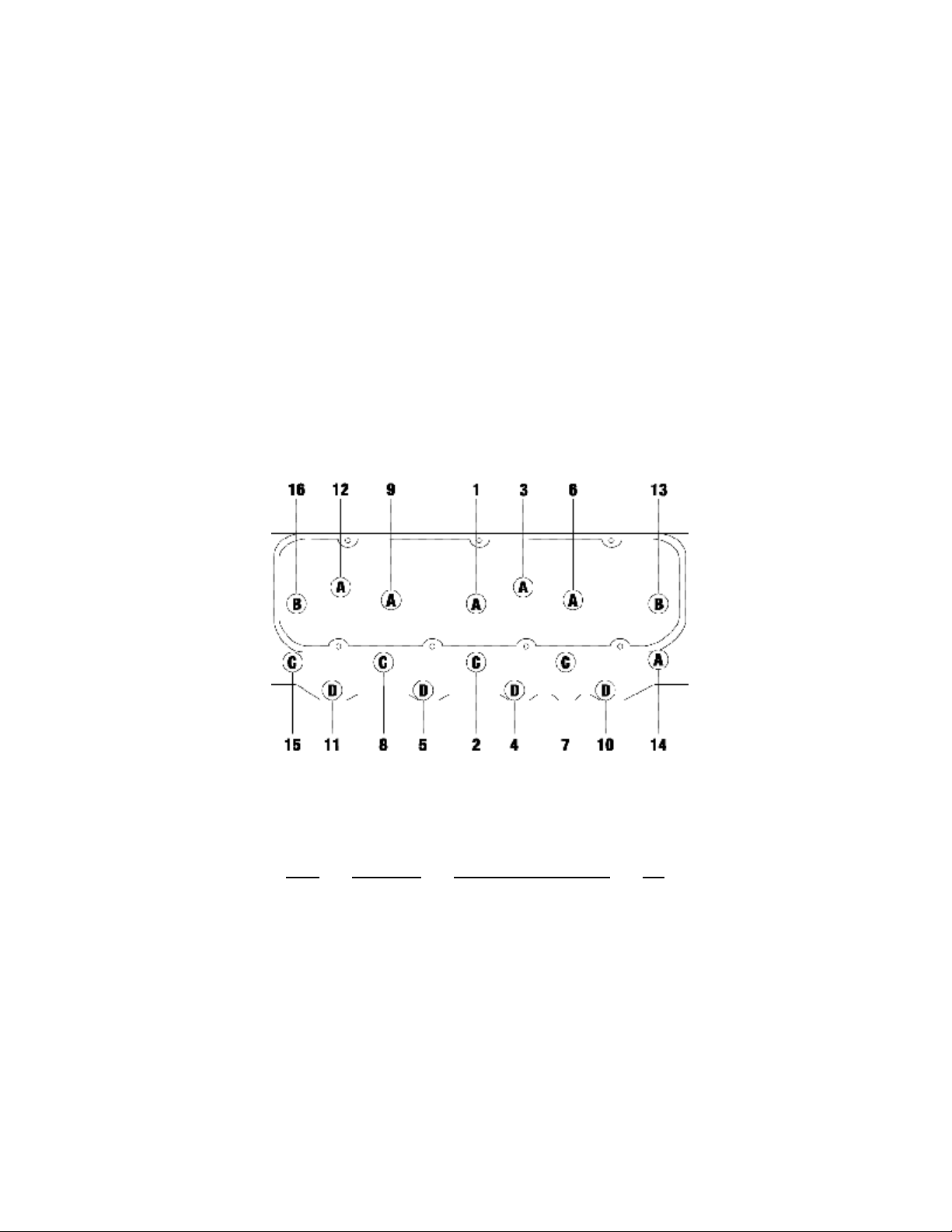

Head Bolts: High quality head bolts or head studs with hardened

washers must be used to prevent galling of the aluminum bolt bosses.

Edelbrock Head Bolt Kit #8554 can be used with all 1965 and later big

block Chevrolet engine blocks. The head bolt boss heights and

required bolt lengths are listed below (See Fig. 1), along with the

head bolt tightening sequence. The bolt bosses adjacent to the

exhaust port exits (position 2, 7, 8, and 15), require a 5.50” long head

bolt. These bosses have been raised to provide more material

thickness between the head bolt boss counterbore and the exhaust

port wall. Many of the other head bolt boss heights have also been

adjusted to prevent head bolt bottoming in Mark IV, Gen V, and Gen VI

engine blocks.

NOTE: Bolt length on positions 13 and 16 must be carefully

checked. It is likely that the bolt will need to be shortened by

one to two threads to prevent bottoming out on blocks with

blind bolt holes.

Shaft Style Rocker Arms: When using shaft style rocker arms,

Edelbrock recommends the use of Jesel or T&D rockers.

Screw-In Stud Rocker Arms: The exhaust rocker stud bosses are

made with extra long thread inserts and hole depth to allow exhaust

rocker studs with extra long installation thread length to improve

rocker stud durability. Select the appropriate rocker arm studs for your

application.

Guideplates: Use ONLY Edelbrock #38-6067 guideplates (included).

Rocker Arms: Aftermarket roller rocker arms must be used for this

cylinder head when using screw-in studs.

Valve Covers: The valve cover flange is designed to work with Gen V

and Gen VI style valve covers with an o-ring seal valve cover gasket,

as well as Mark IV type valve covers. Use Edelbrock Signature Series

chrome valve covers #4680 or Elite Series polished aluminum valve

covers #4280.

Intake Manifolds: Choosing the correct intake manifold will depend

upon your specific engine combination. Please consult with your

engine builder or contact Edelbrock via our Technical Hotline at 1-

800-416-8628, or e-mail us at Edelbrock@Edelbrock.com for

information regarding intake manifold selection.

Exhaust Headers: Any header or manifold designed for original

equipment heads will fit the Edelbrock Race Cylinder Heads. Fel-Pro

exhaust gaskets, #1411, #1412, or equivalent are recommended for

this application. It is recommended to check proper clearance

between the exhaust flange and the head bolt relief.

Spark Plugs: Use 14mm x 3/4” reach, gasketed spark plugs. Heat

range for competition applications will vary. We recommend the use

of anti-seize on the spark plug threads to prevent galling in the

cylinder head, and torque to 10 ft/lbs. DO NOT OVERTIGHTEN.

Catalog # 61409

Rev. 1/06 - RS/mc

©2006 Edelbrock Corporation

Brochure #63-0459Page 1 of 2

Page 2

INSTALLATION:

Note: Prior to assembly, the following should be checked:

1. Valve to Cylinder Wall Clearance

2. Piston to Valve Clearance

3. Piston Dome to Combustion Chamber Clearance

3. Rocker Arm to Valve Cover Clearance

4. Rocker Arm to Valve Cover Rail Clearance (intake only)

Installation is the same as for original equipment cylinder heads.

Consult a service manual for specific procedures, if necessary. For

454 and small Mark IV engines, use Fel-Pro head gasket #1017-1, or

equivalent. For 502 c.i.d. Gen V and Gen VI engines, use Fel-Pro head

gasket #1047 or equivalvent. Be sure that the surface of the block and

the surface of the head are cleaned thoroughly to romove any oily film

before installation. Use alcohol or lacquer thinner on a lint-free rag to

clean. Apply liquid Teflon PST or suitable thread sealer to head bolt

threads that thread into coolant passages. Torque the head bolts to 70

ft/lbs in three steps, following the factory tightening sequence (See

Fig. 1) . A re-torque is recommended after initial start-up and cooldown (Allow 2-3 hours for adequate cooling).

SPECIFICATIONS:

Head Bolt Torque: 70 ft./lbs.

Rocker Stud Torque: 45 ft./lbs.

Combustion Chamber Volume: 118 cc

Deck Thickness: 5/8”

Valve Seats: Hardened, interlocking, compatible

with any fuel

Valve Diameter: Intake - 2.30”, Exhaust - 1.90”

Valve Length: Intake - 5.625”, Exhaust - 5.425”

Valve Stem Diameter: 11/32”

Valve Spring Pocket Diameter: 1.76”

Valve Springs: Manley #221424 (Dual Spring)

Valve Spring Seats: Manley #42121

Valve Spring Retainers: Manley # 23640 (Titanium)

Valve Locks: Manley #13194 (10°)

Catalog # 61409

Rev. 1/06 - RS/mc

Figure 1 - Cylinder Head Bolt Torque Sequence and Bolt Boss Height Chart

Torque Bolts to 70 ft./lbs In The Sequence Shown

Boss Height and Bolt Length

Letter Boss Height Recommended Bolt Length Qty.

A 3.38” 4.19” 6

B 3.38” 4.50” 2

C 4.69” 5.50” 4

D 1.38” 2.19” 4

Edelbrock Corporation • 2700 California St. • Torrance, CA 90503

Tech-Line: 800-416-8628 • E-Mail: Edelbrock@Edelbrock.com

©2006 Edelbrock Corporation

Brochure #63-0459Page 2 of 2

Loading...

Loading...