Page 1

HIGH TECH DUAL QUAD

THROTTLE LINKAGE KIT

CATALOG

#7094

INSTALLATION INSTRUCTIONS

PLEASE

contact our

*

DESCRIPTION:

Series carburetors.

study these instructions carefully before installing your new throttle linkage kit. If you have any questions, do not hesitate to

Technical Hotline at: 1-800-416-8628.

This kit fits Edelbrock dual quad manifolds #5420, #5421, #5425, #5435, and #5440 with Edelbrock Performer

KIT CONTENTS

2- 10-32 Male RH Rod Ends with Locknuts 1- Aluminum Collar with Set Screw and Locknut

3- Brass Shoulder Spacers;

3/16" thick

1- Tapered Brass Anti-Rotation Spacer;

5/32" thick 2- Throttle Return Spring Brackets

2- Brass Bearing Blocks with 10-32 Set Screw and Locknut

1-

Stainless Steel Rod, 3" long (10-32 internal thread on one

end)

I- Stainless Steel Rod, 4.5" long (10-32 internal thread on one

end)

INSTALLATION

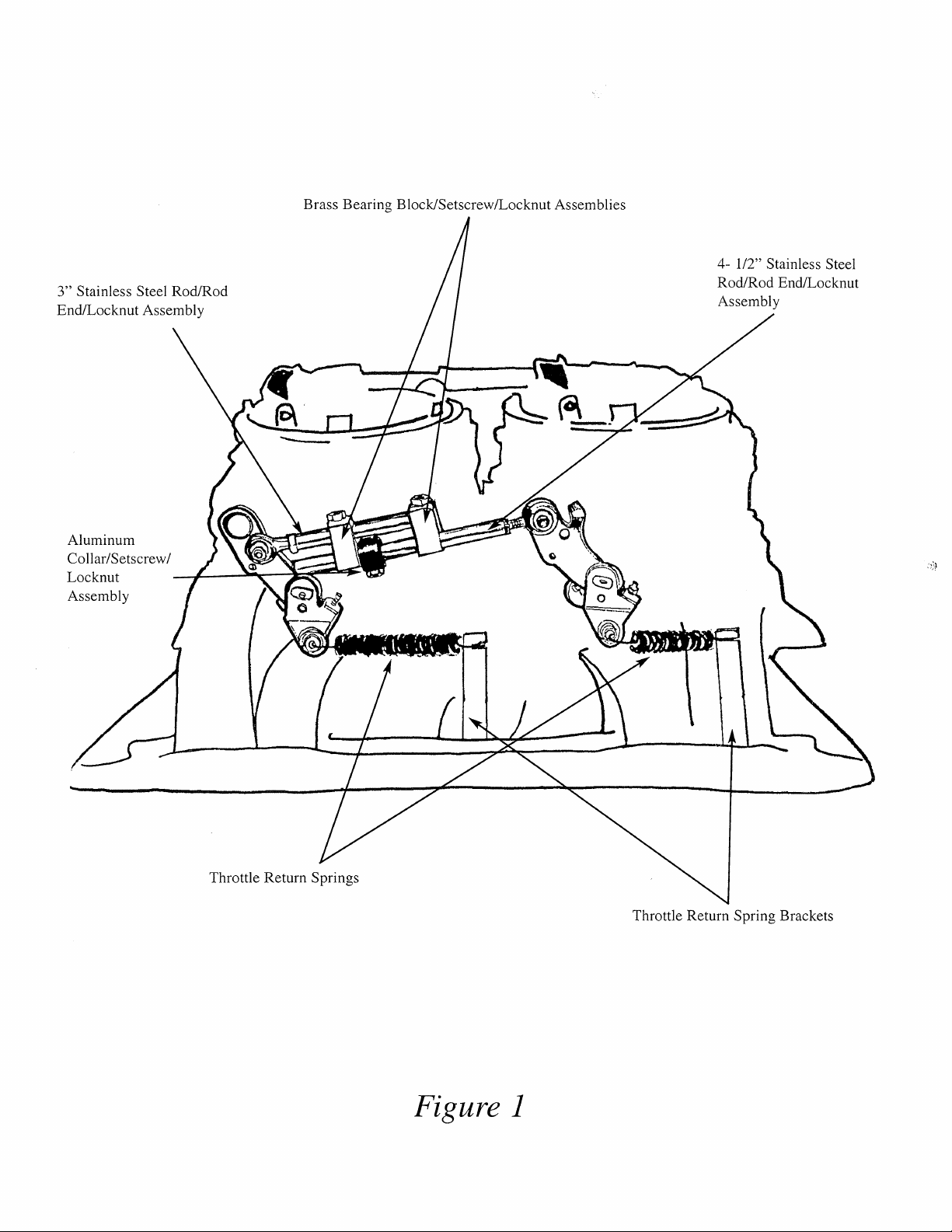

1. This kit contains all the necessary parts to operate Edelbrock

carburetors in a progressive or 1: 1 type operation. Figure

illustrates typical progressive type installation in which the rear

carburetor is the primary carb. This simplifies linkage attachment to the vehicle's existing throttle linkage.

2.

Before attaching anything to the carburetors, loosely assemble

the major

guideline. Note that the longer rod will go to the rear carb with

the flat facing down, and the short rod goes to the front carb

with the flat facing up. The brass bearing blocks should be

positioned so that the set screws will tighten against the flat of

the short rod,

Attach the aluminum collar to the long rod between the bearing

blocks with the set screw against the flat.

3. Attach the linkage assembly to the carbs with the 10-24

head screws and locknuts. Attach to the rear carb using one of

the brass

tapered brass anti-rotation shoulder spacer in the top hole of the

throttle arm

on the inside and the anti-rotation spacer goes on the outside of

the throttle arm. Attach to the front carb using the 3/16" hole

just below the large hole in the throttle arm.

components of the linkage kit using Figure 1 as a

i.e., both bearing block set screws will be up.

518" O.D. x 3/16" I.D. shoulder spacers and the

(112" diameter). Note that the shoulder spacer goes

518" O.D., 3/16" I.D., 112" Shoulder, 2- 10-24 x 1" Socket Head Cap Screw

1-112" Socket Head Cap Screw

.020"-.030" clearance to allow for independent

Attach a return spring to both carburetors as

518" O.D., 3/16" I.D.,

1

allen

1- 10-24 x

2- 10-24 Locknuts

I- Throttle Return Spring, 4- 118" x 318"

1- Throttle Return Spring, 2-318" x 318"

3. Let both throttle arms return to idle position, then adjust the

front brass bearing block to almost touch the aluminum collar.

Leave about

idle speed adjustment of each carburetor. Tighten all set screws,

locknuts, and bolts at this time.

4. Check for smooth operation of linkage from idle to

note that the rear carb will open about

open the front carb. Both carbs should reach WOT at the

time.

5.

IMPORTANT:

shown in Figure 1. Use the return spring brackets supplied,

bending as necessary for attachment to your engine. Generally

the brackets can be attached to the intake manifold using the

existing bolts. Use the longer or shorter spring

front or rear carburetor as required for your particular application. Check for smooth operation and positive return to idle.

6. Attach existing throttle linkage to rear carburetor using the

3/16" hole below the large hole in the throttle arm. It may be

necessary to shorten your existing linkage rod or cable, or to

use an aftermarket cable mounting plate.

BEFORE STARTING ENGINE, DOUBLE-CHECK FOR

SMOOTH OPERATION OF LINKAGE FROM IDLE TO

20" before starting to

WIDE OPEN THROTTLE AND FOR POSITIVE

ADJUSTMENT - NOTE:

rags in the carb throats to absorb the fuel discharged when

working the throttle linkage. This will prevent flooding and

possible damage to the piston rings upon start-up. Be sure to

remove the rags before starting engine.

1.

Tighten the set screw and locknut on the rear bearing block,

making sure that the bearing block is close to the end of the

shaft from the front carburetor.

2. Push the throttle arms of both carbs to WOT (Wide Open

Throttle), then adjust the aluminum collar to touch the rear

brass bearing block. Securely tighten the set screw and locknut

on the

aluminum collar.

If carburetors are full of fuel, place

RETURN TO IDLE.

1:l

OPTIONAL

If 1:l linkage is desired, assemble and attach linkage kit as

above, except that the attachment point to the front carburetor's

throttle arm will be

O.D. x 3/16" I.D. shoulder spacers (similar to the rear carburetor). Adjust the bearing blocks to eliminate all freeplay, so that

all motion to the rear carburetor's throttle arm is transmitted

directly to the front

INSTALLATION

the large 112" hole using the other two 518"

carb's throttle arm.

WOT and

same

on either the

0

1990 Edelbrock Corp.

Rev. 4/92

Page 2

Brass Bearing BlocMSetscrew/Locknut Assemblies

Figure

1

Loading...

Loading...