Page 1

©

2007 Edelbrock Corporation

Brochure No. 63-641580

Catalog #641580, 541583, 641590, & 641593

Rev. 10/07 - AJ/mc

Page 1 of 4

RUSSELL COMPLETE FUEL SYSTEM KIT

FOR CARBURETED VEHICLES

Catalog #641580 & #641583 for Edelbrock Thunder Series

AVS Carburetors

Catalog #641590 & #641593 for Holley or BG Demon Carburetors

INSTALLATION INSTRUCTIONS

Please study these instructions carefully before installing your new complete fuel system kit. If you have any questions, please call

our Technical Hotline at: 1-800-416-8628, 7:00 am to 5:00 pm, Monday - Friday, Pacific Standard Time or e-mail us at

Edelbrock@Edelbrock.com.

❑ 1 Edelbrock Fuel Pump #1791

❑ 1 Russell 8” 60-micron ProFilter with clamp

❑ 1 Edelbrock Electric Fuel Pump Relay Kit #1795

❑ 1 Russell Fuel Feed Line Kit (641580 / 641583

kits include 3” filter)

❑ 2 Russell Carburetor Adapter Fittings (641590 /

641593 kits only)

❑ 2 Russell adapter fittings for fuel pump (3/8” x -6

AN adapter)

❑ 3 Russell straight hose ends

❑ 1 Russell 90° hose ends

❑ 1 Russell 45° hose end

TOOLS &

SUPPLIES RECOMMENDED

❑ Basic hand tools ❑ AN Wrenches

❑ Miscellaneous hardware for mounting components ❑ Pipe thread sealant

❑ Drill motor & bits ❑ Multimeter or test light

❑ Wire crimpers or soldering equipment ❑ Wire strippers

❑ Extra wire (Red & Black, 12 gauge & 18 gauge) ❑ Wire terminals & connectors

❑ 10A inline fuse

❑ 1 Russell -6 Tube Seal hose clamp with cover

❑ 20 ft. Russell -6 hose

❑ 10 Russell -6 cushion clamps

❑ 12 Cable ties

❑ 1 Edelbrock fuel pump block-off plate with

gaskets & hardware for small-block Chevrolet

❑ 1 Edelbrock fuel pump block-off plate with

gaskets & hardware for big-block Chevrolet &

Ford/Chrysler/AMC engines

❑ 10 ft. Russell 3/16” Wrap-It wire protective sleeve

❑ 10 ft. Russell 5/16” Wrap-It wire protective sleeve

KIT CONTENTS

WARNING!!!

Gasoline and gasoline fumes are extremely flammable. Work in a well-ventilated area away from open flames,

sparks, or other sources of ignition. Try to contain gasoline when connections are loosened, and clean up any

spills immediately. Failure to do so can result in a fire or explosion.

IMPORTANT NOTE:

Proper installation is the responsibility of the installer. Improper installation will void warranty and may result in

poor performance and engine or vehicle damage.

Page 2

©

2007 Edelbrock Corporation

Brochure No. 63-641580

Catalog #641580, 541583, 641590, & 641593

Rev. 10/07 - AJ/mc

Page 2 of 4

1. DISCONNECT BATTERY ground(-) to prevent short that

could damage electrical components or ignite gasoline

or gasoline fumes. Stainless steel braid on hose

included in #641580 and #641590 kit will conduct

electricity.

2. Allow engine to cool. Relieve any residual fuel system

pressure.

3. Remove all fuel system components and plumbing

between fuel tank outlet and carburetor inlet, noting

routing of hoses and lines. Cap off fuel tank outlet.

4. If needed, install appropriate supplied block-off plate

onto fuel pump mounting boss on engine block using

supplied gasket and hardware.

FUEL PUMP & 8-1/4” PROFILTER

5. Install supplied Russell adapter fittings into inlet and

outlet of Edelbrock electric fuel pump, using pipe thread

sealant

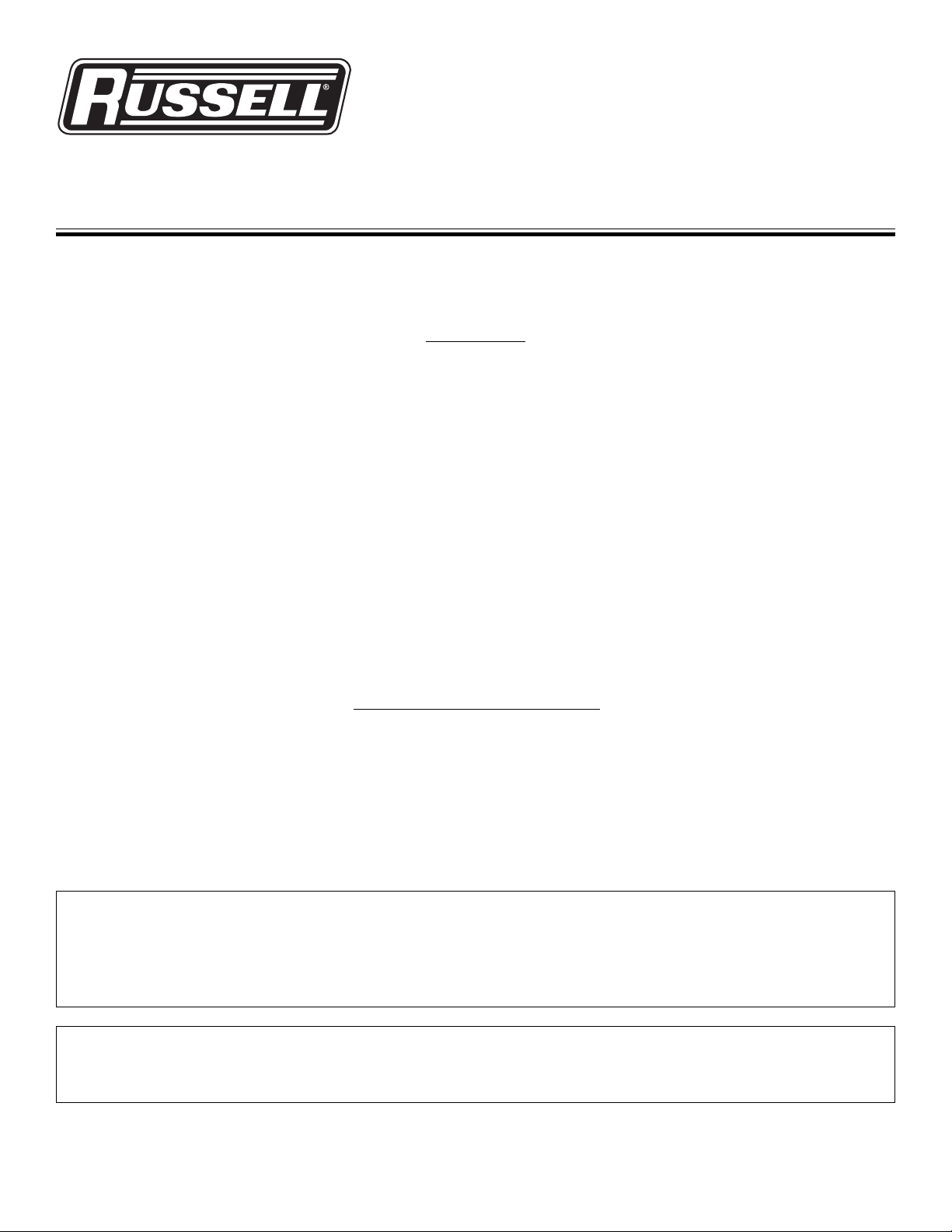

(See Fig. 1)

.

6. Create mounting location for fuel pump and large

Russell filter. Filter goes between tank and pump.

Pump should be as close to fuel tank as possible, and as

low as possible without being exposed to exhaust heat,

suspension or driveline movement, or road hazards.

Use fully-clamped pump mounting bracket as template

for drilling mounting holes. NOTE: fabrication of an

additional mounting bracket may be required

(See Fig. 1)

.

7. Mount fuel pump in desired location. Mount filter with

supplied clamp

(See Fig. 1)

.

INSTALLATION PROCEDURE

CARBURETOR FEED LINE

641580/641583 Edelbrock Thunder Series AVS:

8a. Install supplied Russell carburetor fuel feed line using

supplied banjo bolts and washers

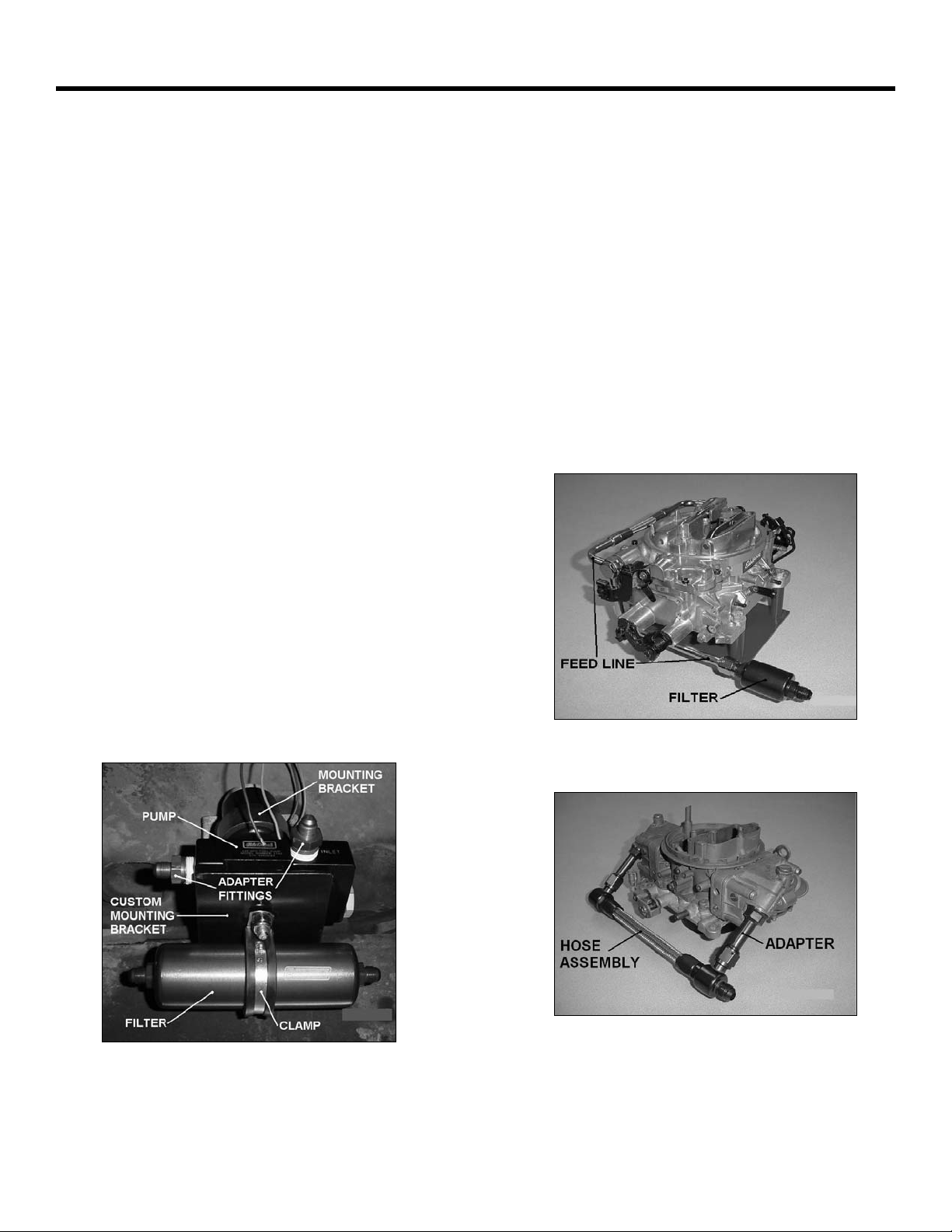

(See Fig. 2)

.

8b. Install small Edelbrock filter onto feed line inlet

(See Fig. 2)

.

NOTE: An additional Russell adapter fitting or hose

assembly may be required to relocate filter if application

has inadequate clearance.

641590/641593 Holley/Demon:

9. Select appropriate carb bowl inlet adapters; lube threads

and install using supplied shim sealing washers. Install

lower flex hose assembly onto adapters

(See Fig. 3)

.

Fig. 1

Fig. 2

Fig. 3

Page 3

©

2007 Edelbrock Corporation

Brochure No. 63-641580

Catalog #641580, 541583, 641590, & 641593

Rev. 10/07 - AJ/mc

Page 3 of 4

HOSE ASSEMBLY

10. Select appropriate Russell hose ends for each section

and temporarily screw them onto their respective

adapter fittings to determine hose length. Use supplied

Russell hose clamp with cosmetic socket cover to

attach hose to barbed hard line coming off fuel tank.

NOTE: Route hoses away from exhaust system and

hazards such as driveshaft, exposed electrical

connections (641580/641590 kit), and suspension

pinch points. Do not expose hose to road hazards by

routing below framerails. Also, some motorsports

sanctioning bodies have regulations on fuel hose

routing. Consult appropriate rulebook if vehicle will be

used in competition.

11. Mark supplied Russell hose at point to cut and wrap

hose over cut point with masking or strapping tape to

minimize fraying. Allow enough slack in length for hose

expansion, movement of components, and smooth

bends. Hold hose in vise and cut with a pneumatic

cutoff wheel, heavy-duty shears, or hacksaw. Cut hose

as straight and square as possible

(See Fig. 4)

.

Remove tape after cutting hose.

12. Unscrew red socket from hose end and hold in vise.

Push hose into socket, turning counter-clockwise, until

hose is seated on step in socket

(See Fig. 5)

. Make a

mark on hose at end of socket.

13. Apply assembly lube (motor oil, etc.) to threads on hose

end and in socket. Insert hose end nipple into

socket/hose and start threads by hand (clockwise). Turn

hose end with wrench until there is less than 1/16”

between nipple hex and socket

(See Fig. 6)

. Make

sure socket did not move on hose by observing mark

made in Step 16.

14. Repeat Steps 15, 16, & 17 for other end of hose.

15. Flush hose with solvent or hot soapy water and blow out

with compressed air or let air dry

(See Fig. 7)

. Install

hose. Use supplied cushion clamps and/or cable ties to

secure hose

(See Fig. 8)

.

FUEL PUMP RELAY

16. Mount Edelbrock fuel pump relay at suitable location

under hood (e.g. radiator support, inner fender, firewall)

away from extreme heat

(See Fig. 9)

.

17. Run one large (12 gauge) red relay wire back to red lead

wire on fuel pump. Wire can be routed underneath

along with other wires, hardlines, etc., or through

interior. A 10A inline fuse is recommended on this

circuit (not supplied). NOTE: Route wires so that any

possible cutting, chafing, snagging, pinching, or burning

from suspension, driveline, or exhaust components will

be avoided. Cover wires with supplied Russell Wrap-It

protective sleeve, and use supplied cable ties to secure

wires.

Fig. 4

Fig. 5

Fig. 6

Fig. 7

Page 4

©

2007 Edelbrock Corporation

Brochure No. 63-641580

Catalog #641580, 541583, 641590, & 641593

Rev. 10/07 - AJ/mc

Page 4 of 4

Edelbrock Corporation, 2700 California St., Torrance, CA 90503

Tech Line: 800-416-8628

E-Mail: Edelbrock@Edelbrock.com

Fig. 8

Fig. 9

18. Connect other large (12 gauge) red relay wire to

positive(+) battery terminal.

19. Connect small pink relay wire to 12V switched (key-on)

power supply (e.g. terminal in fuse box or splice on

ignition switch).

20. Connect black relay wire and black fuel pump lead wire

to good chassis, engine, or battery ground.

SET-UP & OPERATION

21. Turn ignition on, but DO NOT START ENGINE. Check

system thoroughly for leaks. Turn ignition off

immediately if a leak is present and repair leak. Factory

preset fuel system pressure for edelbrock fuel pump

(1791) is 6.5 psi. The fuel system pressure can be

externally adjusted from 5 psi to 10 psi. refer to

Edelbrock fuel pump 1791 instructions for further

details.

22. Start engine and evaluate system operation. Re-adjust

fuel pressure if needed.

23. After a few driving cycles, re-check for and repair any

leaks present. Check fuel system pressure and adjust

the fuel pump, if necessary.

Loading...

Loading...