Page 1

©

2006 Edelbrock Corporation

Catalog #5247, #5248, & #5249

Brochure #63-0469

Rev. 6/06 - DA/mc

Page 1 of 2

Edelbrock Adjustable Trailing Arms

Applications: Catalog #5247 - 1978-1988 A/G Body

Catalog #5248 - 1968-1972 A Body

Catalog #5249 - 1964-1967 A Body &

1967-1978 American Motors Rebel, Matador,

Marlin, and Ambassador

Installation Instructions

Please study these instructions carefully before installing your new Adjustble Trailing Arms. If you have any questions, contact our

Technical Hotline at: 1-800-416-8628, 7 am to 5 pm, Monday-Friday, Pacific Standard Time or

e-mail us at Edelbrock@Edelbrock.com. Please complete and mail your warranty card.

Tools and Supplies Required:

❑ Floorjack and jackstands ❑ Drill motor and 1/2” drill bit or round file

❑ Tire chocks ❑ Torque wrench

❑ Lug wrench ❑ Blue Loctite™

❑ 18mm socket and combination wrench ❑ Grease gun

❑ 3/4” socket and combination wrench

REMOVAL OF STOCK TRAILING ARMS

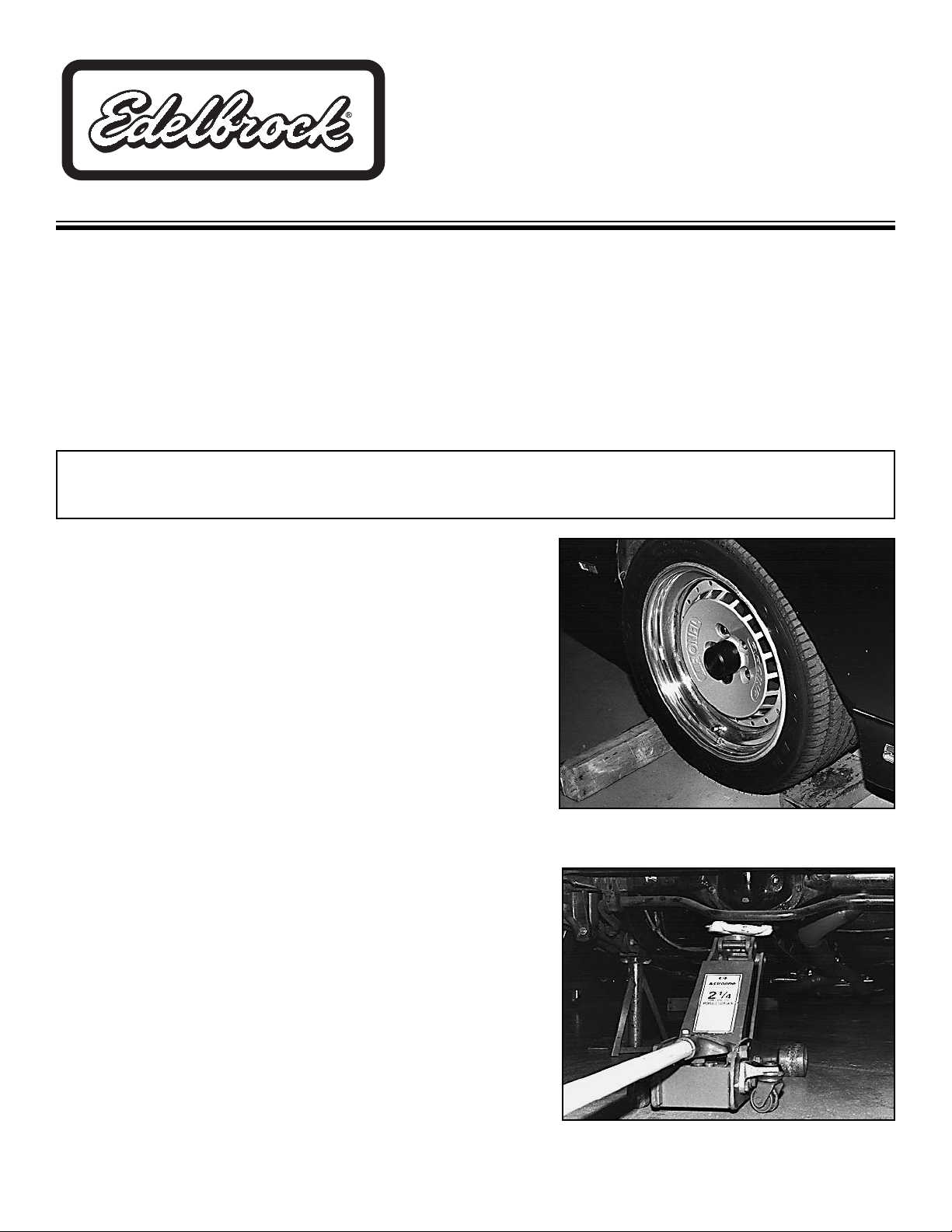

1. Place car on level surface and place tire chocks in front of and behind

front tires

(Figure 1).

2. Support rear of the car on jackstands and remove the rear wheels.

3. Place a floor jack under the differential and lift up slightly to remove

tension from the trailing arm bolts - make sure not to lift the car off the

jackstands

(Figure 2).

KEEP FLOOR JACK UNDER CAR DURING THE COMPLETE REMOVAL

AND INSTALLATION PROCEDURE.

CAUTION

- DO NOT REMOVE BOTH TRAILING ARMS AT THE SAME

TIME OR THE AXLE WILL ROTATE AND THE TRAILING ARM

INSTALLATION WILL BE MUCH MORE DIFFICULT.

4. Start with either trailing arm and remove the rear bolt.

NOTE: Re-install the bolts in same direction as original.

5. Remove the front trailing arm bolt.

6. Remove the trailing arm.

7. If you are having difficulty removing the trailing arm bolts, then remove

the lower shock bolts and the rear springs to aid bolt removal.

8. Clean frame at trailing arm pivot area with a wire brush.

9. Remove the pressed-in factory rubber bushing from axle housing. Note

direction of bushing in axle housing.

NOTE: Be careful not to damage axle housing.

Fig. 1

Fig. 2

IMPORTANT NOTE:

Proper installation is the responsibility of the installer. Improper installation will void warranty and may result in

poor performance and engine or vehicle damage.

Page 2

©

2006 Edelbrock Corporation

Catalog #5247, #5248, & #5249

Brochure #63-0469

Rev. 6/06 - DA/mc

Page 2 of 2

INSTALLATION OF EDELBROCK ADJUSTABLE TRAILING ARMS

Edelbrock AdjustableTrailing Arms are fully assembled, greased, and ready to install.

1. Install polyurethane bushing into axle housing, facing same direction as stock.

2. Install polyurethane thrust washer on inboard side of bushing. NOTE: Left side only, some thrust washers will require trimming

for clearance to axle housing. If you install thrust washer at the same time as you install bushing, it requires less grinding for

clearance.

3. On 1978-1988 model year vehicles - using metric stock arm pivot bolts, drill or file front locating hole to 1/2” diameter to enable

use of supplied 1/2” diameter bolts.

4. Install new trailing arms with the grease fittings facing down, locating the front bolt first.

5. Place one drop of blue Loctite™ on clean threads and torque the nut to 70 ft./lbs.

6. The trailing arm should then pivot smoothly.

7. Place a thin coat of supplied grease on the sides of the new axle housing bushings.

8. Pivot trailing arm into position over polyurethane bushing and thrust washer. Install rear bolt in same direction as original.

9. Place one drop of blue Loctite™ on clean threads and torque the nut to 70 ft./lbs.

10. Although Edelbrock Trailing Arms are pre-lubed, you may want to finish your installation by lubing the front bushings with a

greasegun. Be sure to replace the dust caps on the Zerk fittings to prevent dirt and corrosion from damaging the fitting.

Check all nut and bolt tightness after first 10 miles.

NOTES:

1. Edelbrock Adjustable Trailing arms come pre-adjusted to stock length. Pinion angle can be adjusted by loosening the jam nuts

on the arms and turning the aluminum adjuster sleeve in the center of the arm. Both arms should be adjusted evenly. A properly

installed and adjusted trailing arm will have the spherical ball straight and parallel with the ball housing. If the ball is twisted in

its housing when installed, the arm could fail during suspension articulation. After adjustment has been made, use a drop of

Loctite™ on threads at jam nuts.

2. Jam nuts should be checked periodically for tightness.

3. To further enhance the handling and performance of your GM vehicle, check our catalog to find out more about Edelbrock

Suspension components such as coil springs, lower trailing arms, tubular braces, anti-hop bars, tie rod sleeves, etc. To order

our catalog, call 1-800-FUN-TEAM.

Edelbrock Corporation, 2700 California St., Torrance, CA 90503

Tech Line: 1-800-416-8628

Tech Fax: (310) 972-2730

E-Mail: Edelbrock@edelbrock.com

Loading...

Loading...