Page 1

©

2006 Edelbrock Corporation

Rev. 9/06 - DA/mc

Catalog #5210, #5211, & #5212

Brochure #63-5210

Page 1 of 2

Edelbrock Tubular Braces

Vehicle Applications: See Below

Catalog #5210, #5211, & #5212

INSTALLATION INSTRUCTIONS

Please study these instructions carefully before installing your new Tubular Braces. If you have any questions, contact our

Technical Hotline at: 1-800-416-8628, 7 am to 5 pm, Monday-Friday, Pacific Standard Time or e-mail us at

Edelbrock@Edelbrock.com.

Vehicle Applications: For GM A-Body and G-Body (includes Chevelle, El Camino, Monte Carlo, Skylark, Cutlass, Tempest,

etc.).

Catalog #5210 - 1978-1988 GM A/G-Body

Catalog #5211 - 1968-1972 GM A-Body

Catalog #5212 - 1964-1967 GM A-Body

Tools and Supplies Required:

❑ Floorjack ❑ 18mm & 19mm or 3/4” sockets and combination wrenches

❑ Jackstands ❑ Torque wrench

❑ Tire chocks ❑ Blue Loctite™

REMOVAL OF STOCK HARDWARE

1. Place car on level surface and place tire chocks in front of and behind front

tires.

2. Support rear of the car on jack stands

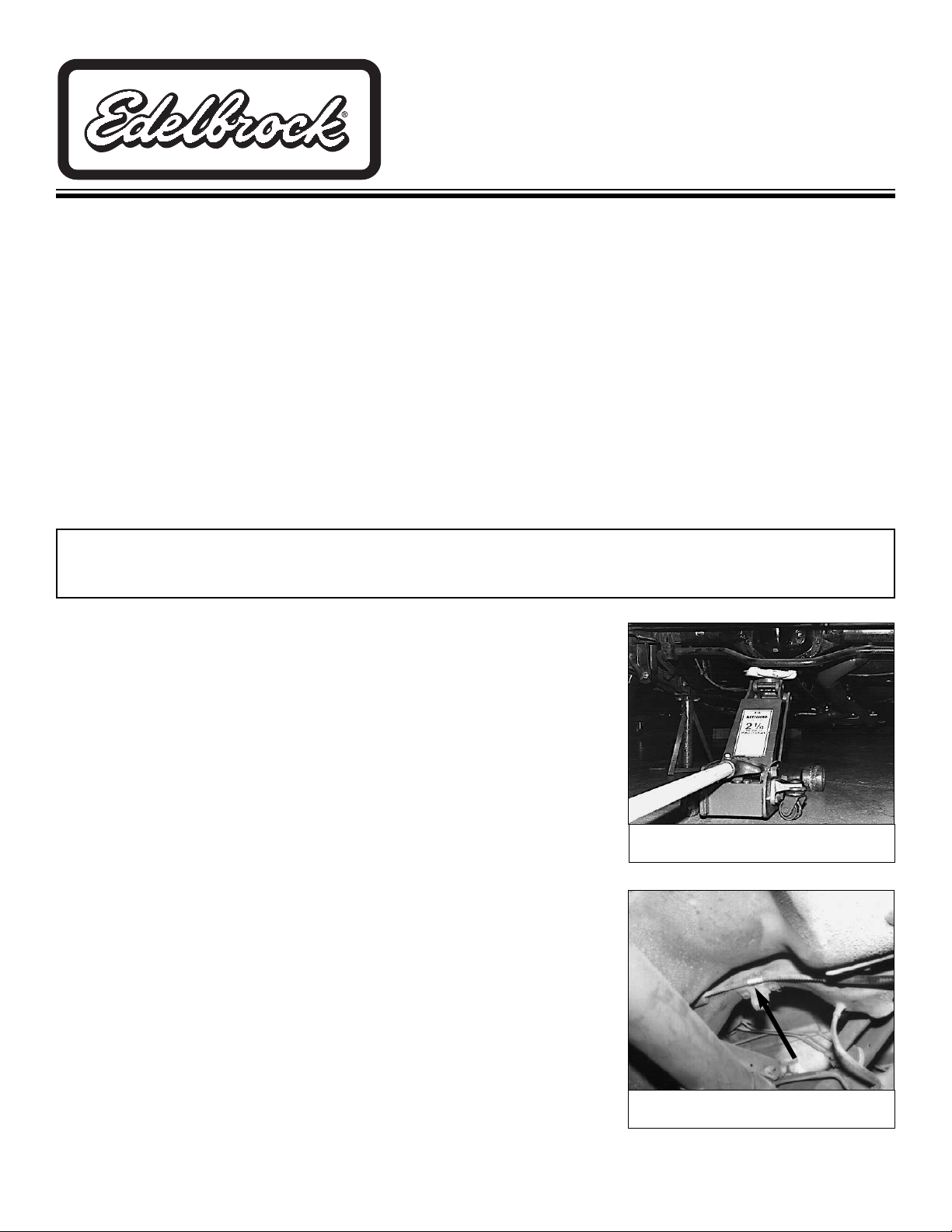

(See Fig. 1)

.

3. Remove shock absorber lower mounting hardware and rear springs to make

it easier to change the bolts.

4. Loosen trailing arm nuts at frame.

5. Place a floor jack under the differential and lift up slightly to remove tension

from the trailing arm bolts - make sure not to lift the car off the jackstands

(See Fig. 1)

. You must remove stock trailing arm bolts and replace with the

hardware included with this kit. Remove and replace only one bolt at a

time! Bolts should be easy to push in or out when correct ride height is

obtained. You may have to raise or lower rear end slightly to find the best

position.

FOR #5210 ONLY

NOTE: Uses metric hardware (18mm & 19mm socket & wrench required).

6. Remove bolt holding emergency brake cable bracket

(See Fig. 2)

and move

brake cable out of the way. Install new bolt with flat washer against bolt

head into left frame rail with threads facing inboard. Slip spacer over bolt,

then install brace with 2 bends on left side of car. With triangular-shaped tab

up, loosely install flat washer and nut, then install bolt/washer/nut in lower

IMPORTANT NOTE:

Proper installation is the responsibility of the installer. Improper installation will void warranty and may

result in poor performance and engine or vehicle damage.

Fig. 1

Fig. 2

S

upport car with two jackstands and use

floorjack to raise and lower rear end

Emergency brake cable bracket (arrow)

must be loosened for clearance (#5210)

Page 2

©

2006 Edelbrock Corporation

Rev. 9/06 - DA/mc

Catalog #5210, #5211, & #5212

Brochure #63-5210

Page 2 of 2

Edelbrock Corporation, 2700 California St., Torrance, CA 90503

Tech Line: 1-800-416-8628

E-Mail: Edelbrock@Edelbrock.com

trailing arm and brace

(See Fig. 3).

Adjust so brace does not hit floor of car

and tighten nuts snug only (do not torque at this time).

7. Note that right side brace has one bend only. Install right side brace following

same procedure as above. Re-install emergency brake cable bracket.

FOR #5211 & #5212 ONLY

NOTE: Uses USS hardware (3/4" socket & wrench required).

6. Both braces have only one bend, but will only fit one way. With triangularshaped tab up, install bolt into left frame rail from outside with lock washer

and flat washer against bolt head. Install flat washer and nut, then install

bolt/washers/nut in lower trailing arm and brace. Adjust so brace does not hit floor of car and tighten nuts snug only

(do not torque at this time).

7. Install right side brace following same procedure as above

(See Fig. 4).

8. Re-install springs and shocks. To achieve ride height, raise rear axle until

car is just off jackstands. Do not remove jackstands! Torque all nuts

to 70 ft./lbs. Use Locktite™ thread locking compound on threads.

9. Remove jackstands and lower vehicle.

Check all nut and bolt tightness after first 10 miles.

Note: To further upgrade your suspension, use other Edelbrock suspension

products such as springs, shocks, torque arm, panhard rod, subframe

connectors, strut tower brace, etc. For more information, go to our website at www.edelbrock.com.

Fig. 3

Left side brace installed (#5210)

Fig. 4

Right side brace installed (#5211)

Loading...

Loading...